TIMOTHY LEUNIG

This paper returns to the long-running debate concerning the slow adoption of ring spinning in Lancashire. It uses new data on the location of firms within Lancashire to more accurately analyse the causes of Lancashire’s continuing preference for the mule. It shows that the primary determinants of spindle type were not the supply side factors of transport costs and technical inter-relatedness, but instead were demand side factors, notably the high level of demand for fine yarn, and the sizeable yarn export trade. The paper also resolves two smaller puzzles, the atypicality of Oldham’s investment patterns, and Lancashire’s lack of interest in paper tube rings.

The paper proceeds as follows. The first section contains a brief summary of the industry’s rise and fall, along with a survey of the literature on the slow adoption of ring spinning. The next section shows analytically that the standard divide into vertically integrated and vertically specialised firms is insufficient, and instead proposes a three way division into vertically integrated firms, vertically specialised spinners located near to weaving firms, and vertically specialised firms with no weavers close by. Section three confirms empirically that all three types of firm existed in substantial numbers. The fourth section shows that vertically specialised spinners located close to weavers adopted rings as often as vertically integrated firms, and these

groups adopted rings four times as often as vertically specialised firms without weavers close by. This allows us to compare the relative merits of the two supply side factors, transport costs and technical inter-relatedness. The final substantive section demonstrates that the division of the industry proposed in the paper, the size of the sectors, and their propensity to adopt rings are in line with both observed investment behaviour and the total stock of spindles in Lancashire. It shows that although the supply side factors mattered, they were less important than the demand side issues in determining the number of rings and mules in Lancashire.

THE INDUSTRY AND THE LITERATURE

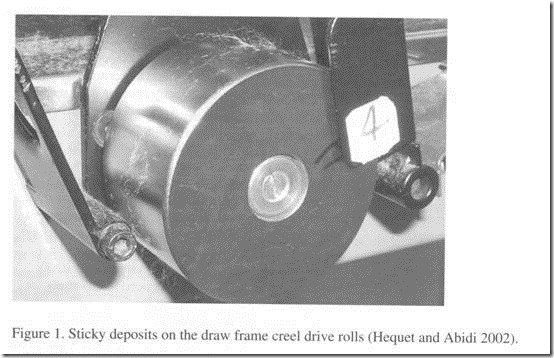

Although Britain grows no cotton, the spinning and weaving of imported raw cotton proved central to Britain’s development as an industrial nation. The rise and decline of the industry is well known, and is summarised in figure 1.

Cotton’s centrality to British industrialisation is reflected in the literature, with all writers from W.W. Rostow to N.F.R. Crafts and C. Knick Harley perceiving cotton to be the most important element in the British industrialisation process.1 But the decline of cotton has not prompted such unity. In particular there remains a dispute as to whether the Lancashire cotton industry should have behaved differently in the ‘glory years’ prior to 1914. A number of issues have been raised, including the question of technology. Why was Britain so much slower at adopting new technology, such as the ring spindle and automatic (Draper) looms? Was the atomised structure of the industry, with a large number of relatively small, vertically specialised firms, part of the problem?

Before we survey the literature looking at the Lancashire’s slow adoption of ring spinning, it may be helpful to offer a short explanation of cotton processing. The industry has two main sectors, spinning and weaving. The spinning sector transforms raw cotton into yarn or thread, which can then be woven or knitted into cloth, or used for sewing or lace. Yarn is divided into ‘warp’ and ‘weft’ yarns; warp yarns are held in position during weaving, while weft yarns are interlaced between the warp yarns to make cloth. Warp yarns have to be stronger than weft, and are sometimes called twist yarns, reflecting the extra twist inserted during spinning to increase strength .2 Once spun, warp yarns are ‘warped’, that is, rewound onto warping beams, each of which contains many parallel warp yarns. The weaving sector transforms yarn into cloth. A single package of weft yarn is placed in a weaving shuttle; that shuttle is then shot back and forth between the warp threads in order to make cloth. In so doing the weft fills the gaps between the warp yarns, and for that reason is sometimes called filling yarn. When the weaving shuttle runs out of yarn, the loom is stopped and the weaver places a new weft package in the shuttle. This process is manual on a power loom, and automatic on an automatic (Draper) loom. The ratio of warp to weft yarns varies according to the type of cloth: on average coarse cloth had 33 percent

more warp than weft.3 All yarns, warp and weft, are classified by count, which measures the fineness of the yarn. A high number indicates a finer yarn; a yarn of count n has n lengths of 840 yards per pound weight. In Britain counts of up to 40 were classified as coarse, counts of 40-80 as medium, and counts of over 80 as fine.4

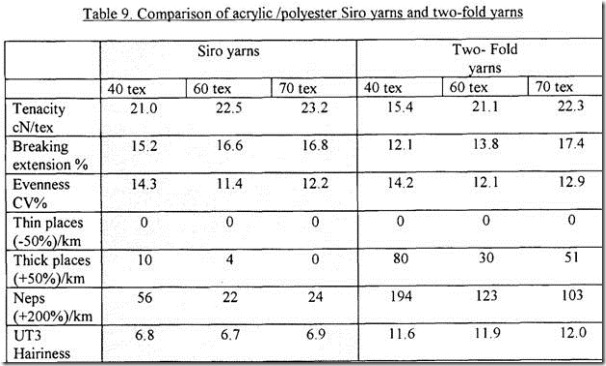

Prior to the first world war there were two competing spinning technologies, mule spinning and ring spinning. In Britain mules were used for spinning all counts of yarn, but rings were rarely used for counts of over 40.5 At a technical level the two methods are fundamentally different. The mule spins intermittently, that is to say, it spins approximately five feet of yarn, and then winds that section of yarn onto the spindle before spinning the next five feet of yarn. The ring, in contrast, spins and winds in one action, and is thus able to spin continuously. The ring spindle produces more yarn per hour than the mule,6 but at a cost of treating the raw cotton more harshly, necessitating the use of a better grade of raw material for any given type of yarn. In Lancashire, and elsewhere, mule spindles were operated by relatively highly paid men, and ring spindles by relatively lowly paid women. Both methods produce yarn in relatively small packages, generally around six to eight inches tall, and no more than two inches across. Mule spun yarn can be lifted off of the machine as a package made up of nothing but yarn, whereas ring spun yarn is attached to a wooden bobbin, from which it cannot easily be removed. Mule spun weft yarn could be taken from the spindle and placed directly into a power loom shuttle, whereas ring spun weft yarn had to be rewound prior to weaving. Ring spun yarn was stronger than mule spun yarn, and was a prerequisite for using automatic looms. For these reasons we say that there are technical complementarities between weft mules and power looms, and between rings and automatic looms.7

Many early writers were in no doubt that Lancashire’s failure to adopt rings was a manifestation of ‘the conservatism of our captains of industry who have idolised the obsolescent techniques which have made the fortunes of their grandfathers.’8 Since the publication of Lars Sandberg’s pioneering work in 1969, no one believes that those firms who purchased mules were doing anything other than responding accurately to the costs that they faced. The question becomes whether the cost structure could have been altered so that rings were preferred more often.9

Sandberg argued that the industry was making a smooth transition towards ring spindles for all counts up to around 40, a little higher for warp, a little lower for weft, but that mules continued to be preferred for counts finer than 40s. In this story the continuation of a large mule sector had two causes, demand patterns and factor costs. The demand for supra-40 counts was high by international standards, and British costs were such that mules remained advantageous for those counts. In particular the relative cost of skilled mule labour to that of unskilled ring labour was low in Britain, so Lancashire employed mules for counts spun on rings in New England.

Sandberg also noted a further potential cost of adopting rings: a ring spinner may face higher transport costs. As mentioned, the mule produces packages consisting entirely of yarn, whereas the ring spins its yarn onto a heavy wooden bobbin from which it cannot be removed easily. The

spinner has two options when transporting the yarn. The first is for the bobbin to be transported with the yarn, and later returned for re-use. As the bobbin weighed twice the yarn spun onto it, this would imply a fivefold increase in transport costs.10 The alternative is to rewind the yarn into packages made up entirely of yarn, prior to shipping, but the cost of so doing was as high as the additional transport cost.11 Lancashire’s industrial organisation system, with individual firms either spinning or weaving, made this potentially important. In contrast it did not matter in the U.S. where spinning and weaving were carried out by a single firm, on a single site. Within Lancashire the additional cost was lower for warp yarns, because they had to be rewound onto (relatively light) warping beams between spinning and weaving in any case. Ring spinners could warp their yarns prior to sending, rather than allowing the weaver to do the warping.

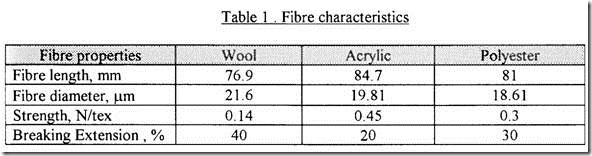

As well as the cost differences in labour, raw cotton and transport; Sandberg noted other potential factors influencing technological choice. The difference in capital cost in purchasing rings and mules, and the cost of fuel and lubricants proved small in both Lancashire and New England. 12 Unions were unimportant in Lancashire, and marginal in New England. In both cases male mule spinners were more likely to be unionised than were female ring spinners, but the Lancashire mule spinners’ union was less likely to be obstructive. Finally Sandberg noted the technical complementarity between ring spindles and automatic looms. Since the latter were rare in Britain, Sandberg argued that technological inter-dependence could be ignored. The advantages and disadvantages of rings and mules are summarised in table one.

Following several empirical corrections to Sandberg’s work, William Lazonick agrees that British managers were responding accurately to the costs that they faced.13 He shows, however, that Sandberg overestimated the labour cost advantage and underestimated the transport cost premium. According to Sandberg the labour cost advantage outweighed the transport cost premium by a factor of five, making transport costs a secondary factor in his analysis.14 In contrast, Lazonick finds that the labour cost saving on rings was less than 25 percent greater than the transport cost premium.15 Given that there was a reasonable chance that the bobbin – an expensive item – would not be returned, Lazonick argues that the savings from using rings were insufficient to lead firms to install them unless the spinner was vertically integrated with the weaver.16 These cost estimates, along with the extensive size of the vertically specialised sector leads him to conclude that ‘The primary constraint on the introduction of ring spinning in Lancashire was the cost of shipping ring yarn.’ 17

Lazonick buttressed his finding that Lancashire’s industrial structure slowed the rate of ring adoption in two ways. First, he argued that not only would vertical integration overcome the transport cost constraint, but was also essential if corporate capitalist firms were to introduce ring spinning and automatic looms in a co-ordinated fashion.18 In this story it is incorrect to dismiss the idea of technological inter-relatedness between ring and automatic loom simply because so few British firms adopted automatic looms prior to the first world war. On the contrary, this fact serves to emphasise the need for co-ordinated technological change in the industry. Lazonick showed that those ring spindles that existed in Britain were concentrated in the vertically integrated sector of the industry,19 especially for weft yarn.20 Observed investment behaviour thus implies that specialised firms faced a constraint not faced by their integrated rivals. Finally,

Lazonick also made use of a detailed case study of one of the Lancashire cotton towns, Oldham. ‘With its standard count of 32, large limited liability companies, and a high growth rate, the Oldham district was very favourable terrain for investment in ring spinning. Yet in the decade prior to World War 1, 75 percent of Oldham’s added capacity took the form of mules.’21 Lazonick argues that Oldham ‘puts the burden of proof on those who reject a “bias in favor of mules” on the part of Lancashire’s cotton mill managers’, 22 although Sandberg held that ‘Oldham was atypical in its response to ring spinning ... its relevance to an industry-wide study is limited.’23

Gary R. Saxonhouse and Gavin Wright use the records that survive for six of the eight textile machinery makers to cast doubt on the link between rings and vertical integration. They note that Japan’s vertically specialised industry used rings, whilst the integrated industries of Russia and Canada continued to make sizeable mule purchases.24 They also note that had Lancashire’s vertically specialised spinners been constrained from adopting rings by the transport costs of moving wooden bobbins, they could have used paper-tube ring machines.25 These machines were manufactured in Lancashire, and enabled the yarn to be spun onto paper tubes instead of wooden bobbins. The very low rate of paper tube adoption leads them to conclude that transport costs cannot have been a constraint for Lancashire cotton spinners. Lazonick notes that Saxonhouse and Wright’s claims for paper tubes do not address the second part of his critique of the industry, that the inter-relatedness between ring and automatic loom implies that these machines will be taken up more readily when investment decisions are co-ordinated.26

Saxonhouse and Wright show that the Indian and Russian industries, which ordered both rings and mules, did not use mules for higher counts than rings. This leads them to argue that ‘the rationalisation of the British preference for mule-spinning in terms of the composition of demand

for British goods is similarly unsustainable.’27 They conclude instead that the main determinant of technological choice at the country level stems from the mules’ more gentle treatment of the raw cotton. Those industries that needed to or chose to economise on cotton, including India, Russia and Lancashire opted for the mule, ‘a machine whose forte was getting the most out of low-quality cotton’,28 while others with plentiful supplies of reasonable cotton, such as Brazil and the US, relied on the ring.

CO-LOCATION: AN ALTERNATIVE WAY TO ELIMINATE

TRANSPORT COSTS

Our re-interpretation of the determinants of technological choice starts from the observation that, excluding paper tubes, to which we return later, there are theoretically three, rather than two, ways in which ring-spinning firms can eliminate the transport cost premium on moving their yarn to the weaver. The first is to rewind the yarn from the bobbin into packages made up entirely of yarn. The literature is unanimous that such rewinding was prohibitively costly. The second, as Lazonick has argued, is for spinning firms to be vertically integrated with weaving firms, so that spinning and weaving are carried out on the same site. The third way, advanced here, is for independent spinners and weavers to be located close together. Avoiding transport costs does not require that the spinner and weaver are co-owned, merely that they are co-located.

It follows that the division of the industry into the vertically integrated and vertically specialised sectors is insufficient. Instead we should sub-divide the vertically specialised sector into two parts: vertically co-located firms, and vertically isolated firms. A vertically co-located spinning firm is defined as one with enough weaving capacity nearby to allow them to be sure that they could sell their yarn to local weavers. Further, that market must be thick enough to avoid hold-up problems: local weavers must not be able to exploit the spinner’s dependence on the local market. In other words the spinner must have both sufficient looms and, independently, those looms must be owned by a sufficient number of weaving firms. In contrast, a vertically isolated firm is defined as one that does not have substantial weaving capacity close by. Note that this

does not imply that the firm is geographically isolated in any absolute sense, simply that it is isolated from firms at next stage in the production process. Indeed, as we shall see, many vertically isolated firms were located in Oldham, a town of many spinners, but few weavers.

Since all firms were located in south-east Lancashire, an area about twenty miles square, we take as given that all three groups of firms faced broadly the same raw materials and labour costs, had the same access to information and were able to purchase new machinery on the same terms. Further, the technical complementarity between weft mules and power looms applied to all

firms. There are, however, two important potential constraints that vary by group. Vertically integrated firms face neither a transport cost constraint nor a problem of introducing rings and automatic looms in a co-ordinated manner. Vertically specialised but co-located firms also escape the problem of transport costs, but do face the co-ordination constraint, while vertically isolated firms face both transport cost and co-ordination constraints. In effect we have three equations and two unknowns. By contrasting the behaviour of integrated and co-located firms we can discover whether co-located firms’ inability simultaneously to introduce rings and automatic looms was a constraint on ring adoption. Similarly, by comparing the rate of ring adoption between vertically co-located and vertically isolated firms, we can test whether transport costs were a constraint. We use constraint to mean a factor that affected ring adoption rates, as opposed to simply being an additional cost that was more than covered by other offsetting cost reductions.

THE EXISTENCE OF CO-LOCATED FIRMS

We begin by demonstrating the existence of the vertically co-located sector. In his original analysis Sandberg assumed that all firms in the Lancashire cotton industry were vertically specialised and vertically isolated, with spinners located 30 miles from weavers. 29 Broadly speaking spinners were to be found in the south, and weavers in the north. Lazonick noted that some Lancashire firms were vertically integrated, but, using the same source, retained the assumption that all vertically specialised spinners were vertically isolated, and located 30 miles

from weavers.30 We use a new source, the British Government’s 1906 Enquiry into Earnings and Hours, to show that of the coarse yarn that was spun and woven into cloth in Lancashire, 33 percent was produced by vertically specialised, co-located spinners. A further 36 percent of yarn came from vertically integrated firms, while only 31 percent had to be drawn from firms that were vertically specialised and geographically isolated.

In 1906 the Board of Trade sent out 2329 detailed earnings and hours schedules to firms in the cotton industry, of which 967,or 41.5 percent, were returned .31 The Board found the sample representative, citing compatibility with the earlier 1904 Factory and Workshop Returns, and concluding that ‘the returns for each of the different industries included may be regarded as covering a sufficiently large proportion of the work people employed to yield sound statistical results.’32 Their report on cotton runs to 324 pages of statistics. For our purposes what is most important is that the regional breakdown of spinners and weavers within Lancashire is accurate. Three pieces of evidence suggest that this criterion is met. First, working from Worrall’s Directory, Mike Williams and D.A. Farnie calculate that the southern (spinning) towns contained 78.5 percent of the industry’s spindles in 1903. Using the 1906 Enquiry, we calculate that these towns contained 81.0 percent of all spindles.33 Again using Worrall’s Directory, Farnie also finds that the weaving district contained 66.4 percent of all looms, while the 1906 Enquiry gives a figure of 64.9 percent.34 In both cases the figures are very close indeed, making it clear that the overall distribution of spindles and looms between spinning and weaving areas is broadly accurate in the 1906 Enquiry. Comparing the 1906 Enquiry figures for Oldham to those provided by Lazonick reinforces this impression of accuracy. Lazonick states that, in 1907, Oldham

accounted for 25 to 30 percent of spinning capacity, contained about 40 percent of Lancashire’s sub-40 mule spindles, well over one-third of Lancashire’s total sub-40 capacity, and that, in the decade prior to 1914, 75 percent of Oldham’s new spindles were mules. According to the 1906 Enquiry the equivalent four figures are 31 percent, 41 percent, 34 percent and 82 percent. 35

Again, in each case the 1906 Enquiry figures are close to those from an independent source. Finally, our confidence is enhanced by the clarity of the results. Those areas found to have sufficient weavers to allow us to define their spinners as co-located do so by a considerable margin. The 1906 Enquiry would need to contain errors of considerable magnitude to reverse the findings. As well as offering a reliable regional breakdown, the 1906 Enquiry has one important advantage over other sources: it distinguishes between coarse, medium and fine spinning. As noted above, rings were only used for coarse yarn in Britain, so we are able to limit our analysis to those spinners who would have been deciding between rings and mules.

The 1906 Enquiry gives job and district specific information on 10,010 mule spinners, 4,001 ring spinners and 72,134 weavers. 36 By converting employment data into output data, we can assess how much yarn was spun and woven in each of twelve districts. The 1906 Enquiry sub-divides weavers in each district by the number of looms tended. This makes it trivially easy to calculate the number of looms of any one area: this measure of weaving capacity is given in table two. 37

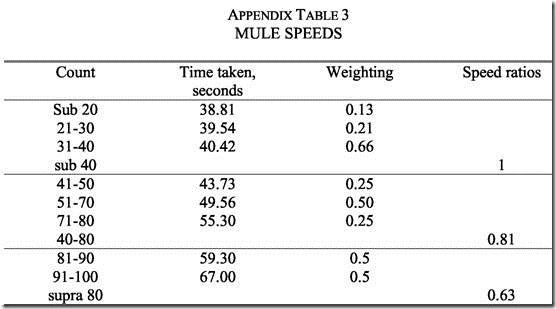

The 1906 Enquiry sub-divides spinners in each district into ring spinners, coarse mule spinners, medium mule spinners and fine mule spinners. Ring and mule spinners tended different numbers of spindles, and each category of spindle had different levels of productivity. We therefore convert first from employment to actual spindle numbers, and then from actual spindle numbers to ‘effective’ spindle numbers, which are corrected for the different level of productivity per spindle. The full details are given in the appendix. Effective spindles are taken as a proxy for output, and reported in table three.

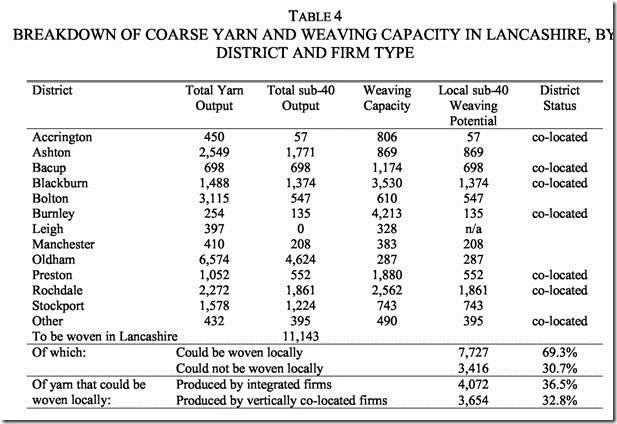

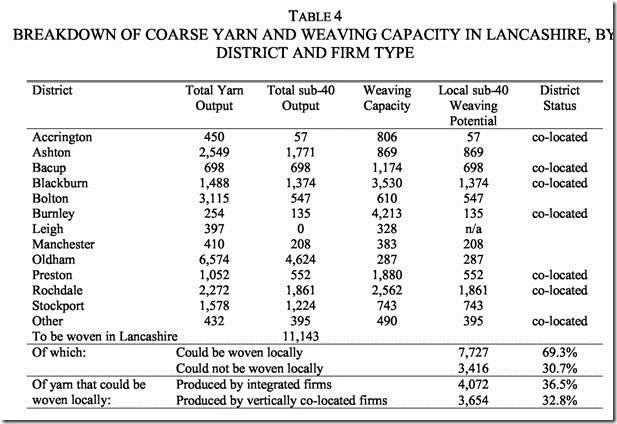

We now have, by district, the number of effective spindles – a close proxy for yarn output; and the number of looms – a close proxy for weaving capacity. We know that, for Lancashire as a whole, yarn output and weaving capacity must be equal, taking into account that some yarn was exported, and some was not woven but used instead for hosiery, lace and elastic webbing. 38 To allow ready comparison of yarn output and weaving capacity in each area, we multiply the number of looms by the spindle to loom ratio, 72:1. This allows us to express both yarn output and weaving capacity in effective spindle terms. The results are given in table four.

Notes: Coarse is defined as sub-40 yarns. All figures are in thousand effective spindles,

figures do not sum owing to rounding. For division between integrated and co-located firms, see text.

Sources: Cols 2 & 3: table 2; col. 4: table 1; col. 5 is the minimum of col. 2 and col. 3.

Those districts where weaving capacity exceeded total spinning output are termed ‘co-located’ districts: all coarse spinners in these areas could have sold all of their yarn to weavers in their districts. Given that weaving firms were on average 30 percent smaller than spinning firms, there would also have been sufficient weaving firms to prevent spinners being faced with hold-up problems.39 Although it is straightforward to classify all spinners in these districts as co-located, it does not follow that all spinners in all other areas were vertically isolated. Some areas, such as Ashton and Stockport had sizeable weaving sectors in absolute terms, while others, such as Manchester, were close to being self sufficient in weaving. In these areas many coarse spinners could have been confident that they could have their yarn woven locally. The one exception that stands out is Oldham, where spinning output exceeded weaving capacity by a factor of 23:1. Oldham spinners were indeed vertically isolated.

Of course, the overall figure for yarn that could be woven locally includes yarn that was spun and woven by integrated firms. We know that integrated firms accounted for 23.6 percent of industry output in 1907, and that they were concentrated in the coarse goods sector. 40 We therefore assume that 80 percent of their output – rather than the 60 percent figure for the industry as a whole – was coarse. This implies that the yarn that could be woven locally was made up of 4.1m spindles-worth of yarn from vertically integrated firms, with the remainder, 3.7m spindles-worth of yarn, being produced by vertically specialised, co-located firms. This gives three sectors broadly equal in size, with integrated firms accounting for 36 percent, co-located firms for 33 percent and isolated firms for 31 percent of coarse yarn production.

Since we define a vertically co-located district as one in which spinners did not face a transport cost constraint, we need to show that weaving firms in such districts were located in the immediate vicinity of spinners, rather than simply in the same district. An unpublished thesis by James Cotton on the town of Blackburn allows us to do this. Cotton lists 132 mills in operation in Blackburn in 1919, stating whether they were vertically specialised spinners, weavers or integrated spinner-weavers at that date. Of these, he is able to exactly locate 118 of these mills: 8 spinners, 104 weavers and 6 integrated firms. He plots these on a large-scale map (six inches to one mile), from which we can measure precisely the distance between spinning and weaving mills.

As table five shows, every vertically specialised spinning firm in Blackburn had more than 20 weaving mills within half a mile. We are correspondingly confident that these spinners are correctly characterised as co-located.41 Although we do not have evidence of this calibre for other towns, Cotton demonstrates that proximity to canals, rivers and major roads explains three quarters of mill locations in Blackburn.42 This strongly suggests that that clustering pattern of mills in Blackburn will be replicated in other cotton towns.

INVESTMENT BEHAVIOUR BY FIRM TYPE: WHAT CONSTRAINED

RING ADOPTION?

Having established the existence of three sectors, we now test whether the sectors differed in their rates of ring adoption. We do this by comparing how frequently firms in each group chose rings over mules between 1880 and 1906/7. 1880 is the year in which the ring first became available, 1906/7 are chosen for data availability. Since all rings in place in 1906/7 were installed

after 1880, comparing the stock of rings in 1906/7 with total spindle purchases between 1880 and 1906/7 tells us how often manufacturers picked rings over mules. Spindle purchases can be divided into two types: additional spindles for new mills and extensions, and replacement spindles. The number of additional spindles is the change in sector size between 1880 and 1906. The number of replacement spindles is a little harder to assess. We know that ‘English mules were built to last’ ,43 and needed replacing only after fifty years.44 This means that mules installed between 1830 and 1856 would have needed replacing between 1880 and 1906. Since the automatic mule was introduced in 1830 all mules in place in 1856 must have been installed between 1830 and 1856, and would have needed replacing between 1880 and 1906. We therefore use the stock of spindles in 1856 as our estimate of the number of spindles replaced between 1880 and 1906.

The behaviour of integrated firms has been extensively studied, and the necessary data is readily available. Farnie uses the Returns of the Factory Inspectors to calculate the number of spindles in integrated firms in both 1856 and 1880.45 Work by Sandberg on the Census of Production and by Lazonick on Worrall’s Directory give the number of rings and mules in integrated firms in 1907.46 This gives us sufficient information to assess the frequency with which integrated firms picked rings over mules.

Although data that explicitly distinguishes between firms that are vertically specialised but co-located and those that are both vertically specialised and isolated is not generally available, town specific data is reasonably available, at least for the post 1880 period. We now know that spinners in Oldham can be characterised as vertically isolated – only 4 percent of their yarn could have been woven locally – so we use the behaviour of Oldham spinners to assess the behaviour of vertically isolated firms. Similarly, we know that all spinners in the northern towns of Accrington, Blackburn, Burnley, Preston and Rochdale were all able to have their yarn woven

locally, so we use data for these towns to measure the behaviour of vertically co-located firms.47 Data on the number of spindles in 1880 and 1906 are taken from Farnie’s work; the proportion that were rings in 1906 is given by the 1906 Enquiry.48 We do not have town specific data prior to 1880, so we assume Farnie’s Lancashire wide figure for the proportion of spindles in all specialised firms in 1880 that were installed prior to 1856 holds for firms in both areas.49

Notes: Co-located districts comprise the Accrington, Blackburn, Burnley, Rochdale and

Preston 1906 Enquiry districts. Figures do not sum owing to rounding.

Sources:

Rows 2 & 3: Integrated firms: 1906: Sandberg, “American Rings,” p. 29, Lazonick “Rings and Mules,” p. 394; 1880: Farnie, English Cotton Industry, p. 317; Co-located districts: Williams and Farnie, Cotton Mills, p. 46; Oldham: Farnie “Emergence,” p. 42. Aggregate spindle numbers are converted to m.e.s. using the ring to mule ratios in table 2.

Row 4: Row 2 minus row 3

Row 5: Farnie, English Cotton Industry, p. 317.

Row 6: Row 4 plus row 5

Row 7: Integrated firms: In the absence of data, we note the standard view that integrated

firms were more heavily concentrated in the coarser section, and assume that 80 percent of m.e.s. were devoted to sub-40 production. Co-located districts and Oldham: table 2.

Row 8: Integrated firms: Sandberg, “American Rings,” p. 29, Lazonick “Rings and

Mules,” p. 394; Co-located districts and Oldham firms, table 2.

Row 9: Row 7 minus row 8

The result from table six is unambiguous: rings were the clear majority choice for both vertically integrated and co-located firms, whereas mules were the clear majority choice for vertically isolated firms. We must note one reservation. The data for ‘firms in co-located districts’ and ‘Oldham’ cover all firms, that is, vertically integrated as well as vertically specialised firms. Since there was little weaving capacity in Oldham the data cannot contain many integrated firms, so the figure is a reliable indicator of the choices of vertically specialised firms in Oldham. In contrast we estimated earlier that just over half of the effective spindles in co-located areas were in fact in integrated firms, adding a strong converging bias to our result. That said, as the results for integrated firms and co-located district firms are close, it follows that vertically specialised co-located firms were choosing rings over mules about as often as were vertically integrated firms.50 Notwithstanding the limitations of the data, the overall result that the choices of co-located firms were similar to those of integrated firms, and substantially different to those of isolated firms seems to be established by a sufficient margin to be considered sound.

We now know which constraints were binding. We noted that vertically isolated firms faced transport costs that was not faced by vertically co-located firms. As vertically isolated firms were only one quarter as likely to pick rings as were vertically co-located firms, we can conclude that Lazonick is right that transport costs did act as a constraint on the adoption of ring spinning. It is worth noting, however, that this constraint, far from affecting all vertically specialised firms, only affected those specialised firms located in areas with few weavers close by. Proving both the existence and limited nature of this constraint allows us to resolve Sandberg and Lazonick’s disagreement over Oldham. Lazonick is right to argue that transport costs did constrain the

adoption of ring spinning in Oldham. But as this paper shows, Oldham was almost unique within Lancashire in having such a high ratio of yarn output to weaving capacity. Lazonick is not right, therefore, to think that ‘the Oldham district was very favorable terrain for investment in ring spinning’51, instead Sandberg was correct to argue that ‘Oldham was atypical in its response to ring spinning ... its relevance to an industry-wide study is limited.’52

We also noted that the difference between integrated and vertically co-located firms was that the former were able to introduce rings and automatic looms in a co-ordinated manner whereas the latter were not. We found the investment behaviour of the two groups to be similar, so we know that vertical specialisation was not per se an obstacle to ring adoption. Vertically specialised firms’ inability to co-ordinate the introduction of these two machines did not retard the adoption of ring spinning. This result should be unsurprising: automatic looms were the exception even in integrated firms.53

The finding that integrated and co-located firms had similar ring adoption rates throws doubt on Lazonick’s claim that rings were used for weft in integrated but not specialised mills. 54 If both groups had the same rate of ring adoption, it seems likely that either both or neither group used rings for weft. In fact the technical complementarity between mules and power looms seems to have been such that neither group used rings for weft to any extent. Instead, firms in both groups shifted well-functioning warp mules over to the production of weft yarn, and used new ring spindles to produce warp yarn. Three pieces of evidence support this claim. First, both integrated and co-located firms had more mules than rings in total, making it possible that rings were limited to one side of the production process. Second, and more importantly, both groups continued to purchase new mule spindles. Nor were their purchases trivial: table six shows that the two groups purchased 1.8 and 1.1 million coarse mule spindles in the quarter century after

the ring’s introduction. This indicates that they perceived mule spindles to have a clear continuing role in the production process.

Third, Worrall’s Directory provides direct evidence that integrated firms rarely used rings to produce weft prior to the invention of the automatic loom.55 Worrall lists 272 integrated firms, with 188 firms specifying spindle type. Of these 188, 13 used only rings, 86 used only mules and 89 used both types. This does not mean that 13 firms used rings for weft, because many integrated firms produced only part of their yarn, purchasing the remainder in the market.56 Of the 13 ring only firms, four state explicitly that they produced only warp yarn, presumably purchasing weft from outside suppliers, while four state that their rings were used for warp and weft, and five give no details. Of these five, three have low spindle to loom ratios similar to those firms known to purchase weft yarn, while two have high spindle to loom ratios, suggesting that they were producing their own weft yarn.57 Our best guess, therefore, is that six of the 188 integrated firms used only rings for weft.

In addition, some firms using both rings and mules may have used rings for weft as well as warp. Without knowing the warp to weft ratio of each firm’s cloth, we cannot be certain. We can say, however, that if British cloth output had the same distribution of warp to weft ratios as the 677 coarse cloths sampled by the US Tariff Board, then the distribution of rings to mules in the Worrall sample would imply that ten integrated firms used both rings and mules to produce

weft.58

It appears, therefore, that rings were used for weft by no more than 10 percent of the 188 integrated firms whose machinery choices are recorded. This figure overstates the percentage of weft that was spun on rings, as the majority of these firms were using both mules and rings for weft production. Since integrated firms account for under a quarter of the total industry,59 and that we know that rings for weft were very much the exception in vertically specialised firms, it seems unlikely that more than 2 percent of Lancashire’s total weft was spun on rings. The cost of rewinding ring weft yarn into shuttle ready packages – a stage not necessary when using mules – appears to have been sufficiently high that the use of weft rings and power looms was exceptional, whether or not the firm was integrated. Since even integrated firms adopted automatic looms only very slowly, the use of rings for weft was, if not unheard of, at least unusual in this period.

This finding would explain the relatively sparse references to ring weft in standard contemporary texts. Sandberg laments that James Winterbottom, writing in 1907, ‘neglected to include ring weft’, in his discussion of the suitable raw cotton lengths for differing counts of yarn. 60 Winterbottom’s ‘neglect’ is much easier to comprehend if rings for weft were an unusual choice. Similarly J.E. Holme, writing in 1887, states that ‘the ring has made great progress in the cotton industry for warp yarns; but it has not yet brought any great advantage for weft yarns.’61 Even as late as 1921 William Taggart argued that ‘Weft yarns are not so easily produced on the ring system as on the mule.’62 Like Winterbottom, he gives details of suitable twist factors for mule warp, mule weft and ring warp, but not for ring weft .63

The finding that rings for weft were exceptional even for integrated firms allows us to better understand the sense in which transport costs acted as a constraint on vertically isolated firms in Oldham. It is clear that the issue is not, after all, the transport of ring weft on heavy wooden bobbins: even integrated firms did not use rings for weft. The difference between ring usage in

integrated and co-located firms on the one hand, and vertically isolated firms on the other, relates to the spinning of warp yarns, not weft yarns. Ring warp yarns did not, of course, have to be shipped on heavy wooden bobbins, as the spinner could warp the yarn prior to sending it to the weaver. Warping beams were not, however, weightless. A standard 36-inch warping beam weighed in the region of 30 to 521/2 pounds in 1900.64 That beam would have held between 91 and 248 pounds of yarn, depending on the type of cloth to be made.65 Given that the beam had to be returned, the transport cost of shipping ring warp on a beam would exceed that of shipping mule warp in yarn packages by between 24 and 115 percent, depending on the exact weight of the beam and the fineness of the yarn. These figures are dramatically smaller than the five-fold increase in transport costs for ring weft. That a smaller increase in transport costs should act as a constraint on ring adoption fits well with the conclusions from Saxonhouse and Wright’s machinery data, namely that the choice between rings and mules was much more finely balanced than had previously been realised.66 In that context a much smaller transport cost increment would be sufficient to reduce the take-up of ring spinning. The finding that ring warp but not ring weft was moved from spinner to weaver would explain why contemporaries noted spinners complaining that warping beams and skips were not returned from the weavers, but did not hear them make the same complaint about bobbins.67

The relatively small size of the transport cost premium on warp yarn explains Oldham’s lack of interest in paper tube rings. Notwithstanding that transport costs acted as a constraint, the absolute reduction in transport costs that could be gained by using paper tubes for warp yarn was small. This means that paper tubes would only have needed a small drawback to outweigh the benefits they offered in terms of lower transport costs. It appears, in fact, that paper tubes had a number of disadvantages. One of the few contemporary authors to mention paper tube rings, Melvin Copeland, noted that ‘paper tubes are used instead of wooden bobbins in some ring

spinning mills, but the bobbins yield better results’. 68 Mule spun warp also retained an advantage over paper tube ring warp because mule warp packages contained more yarn than ring warp packages, in that both have approximately the same total volume, but the latter contains a hollow paper tube at its core. 69 This means that mule cops would not have to be changed as frequently when being wound onto warping beams, lowering costs to the warper. It is also worth noting that Lancashire was not alone in ignoring paper tubes. Japan, the other internationally successful industry with vertically specialised spinners, did not adopt paper tubes even though they were large users of ring spindles .70 That neither Lancashire nor Japan adopted paper tubes suggests that they were not a good solution to the problem of transport costs.

ACCOUNTING FOR RINGS

It has long been clear that the lower transport costs associated with mule spun yarn ensured that yarn spun for export was effectively reserved for mule spinning. Similarly we already knew that the mule was much the better machine for all counts above the low 40s. This paper has shown that the technical complementarity between mule and power loom ensured that almost all weft yarn was spun by mules. Further, we have shown that transport costs affected specialised firms in Oldham, and, to a lesser extent, the neighbouring districts of southern Lancashire, obliging them to use mules for coarse warp. In contrast firms with weaving capacity nearby (whether integrated or co-located) were able to use rings to produce sub-40 warp yarn. We will now show that this analysis is compatible with both the overall gross investment pattern of the industry between the invention of the ring in 1880 and 1907, and with the total stock of spindles in that year.

Gross investment figures can be drawn from the 1907 Census and from Saxonhouse and Wright.71 Table seven compares these investment figures with those predicted by our sectoral breakdown and sector specific estimates of ring adoption rates. As can be seen, the predicted and actual investment figures are very similar, with the model overpredicting the adoption of rings by less than 2 percent of total investment.

Notes: Co-located firms includes integrated firms. Figures do not sum owing to

rounding.

Sources: Row 2: Saxonhouse and Wright, “New Evidence,” p. 511; Row 3 & 4: col. 2,

Sector sizes from table 4 row 16 and 17 respectively, multiplied by investment rates from table 6; cols. 3 & 4 from table 6. Row 6: Saxonhouse and Wright, “New Evidence,” and 1907 Census, see text.

As well as assessing our results by dividing the industry by firm type, we can also divide the industry by product type. We noted that rings would have been used only occasionally when producing yarn to be exported, weft yarn, warp yarn produced by isolated firms, as well as supra40 warp yarn produced by integrated and co-located firms. In contrast, without any constraints to their take-up, and given the possibility of shifting well functioning mules from warp to weft

production, we would expect all sub-40 warp yarns produced by non-isolated firms to be spun on rings. Since we know the relative size of these sectors in 1906, we can allocate rings and mules to these sectors as predicted above; table eight compares the results with the observed stock of spindles in 1907.

Notes: Co-located firms includes integrated firms. Figures do not sum owing to

rounding.

Sources:

Row 2: col. 3: 1907 Census, includes yarn for lace, hosiery and elastic webbing, see text.

Row 3: col. 3, table 3; col. 4 & 5, Saxonhouse and Wright, “New Evidence,” p. 511.

Row 4: col. 3, 1912 Tariff Board Report, see text; col. 4, Worrall Directory, see text.

Row 5: col. 2, 1912 Tariff Board Report, see text.

Row 6: col. 3, table 4, row 17, col. 4 & 5, table 6, col. 4.

Row 7: col. 3, table 4, row 16.

Row 8: sum rows 2 to 7

Row 9: UK Census of Production 1907, p. 293

It is clear that our predicted patterns of behaviour are a good explanator of the stock of rings and mules in Britain. This gives us confidence that the overall breakdown of the industry presented here, and our assessment of the incentives and constraints faced by each sector, are correctly characterised.

CONCLUSIONS

This paper has shown that many of the previous ideas used to explain the slow take-up of rings in Lancashire are incomplete. We are now, however, in a position to be clear about the reasons for Lancashire’s continued and positive preference for the mule. The principal reason was Lancashire’s greater emphasis on fine cottons. Lazonick records that 42 percent of Lancashire’s yarn was of counts finer than 40, the 1906 Enquiry data gives a figure of 44 percent, while Saxonhouse and Wright’s data suggests that 53 percent of new machinery were for counts of over 40.72 In contrast only 8 percent of yarn in the United States was of such counts.73 Although it was technically possible to spin these higher counts on rings, contemporary literature is unanimous that the mule was the better machine. There is a second demand side factor that favoured mule spinning: the large demand for yarn exports, both to be woven abroad, and to be made into lace and knit goods elsewhere in Britain. The mule’s ability to produce lightweight packages consisting entirely of yarn made it well suited to this sizeable market niche. As table eight shows, these two demand side factors together ensured that a little over half of Lancashire’s yarn would be spun on mules.

Supply side factors, as well as demand side factors, mattered too. That rings were adopted at all shows that the unit labour cost saving gained by replacing male mule spinners with female ring spinners outweighed the extra cost of buying the slightly better raw cotton needed for ring spindles. But very few firms, integrated or otherwise, used rings for weft. Ring weft, unlike mule weft, had to be rewound to make it shuttle ready. In this case the labour cost saving was insufficient to outweigh the combination of the raw cotton and rewinding premiums. There is a sense, then, in which wage moderation on the part of mule spinners was sufficient to keep mule spinning as the method of choice for weft production, but insufficient to prevent ring spinning becoming important in warp production. Second, the additional transport cost of moving ring warp was sufficient to make the decision between ring and mule at best marginal for those firms

that needed to move their yarn any distance to the weaver. This factor was, however, relatively unimportant: even had the transport cost premium been eliminated altogether, the figures in table eight show that Lancashire’s spinners would have used just 3.5 million fewer mule spindles, that is, an eight percent fall in the total stock of mule spindles.

APPENDIX

CONVERTING EMPLOYMENT FIGURES INTO EFFECTIVE SPINDLE FIGURES. CONVERTING EMPLOYMENT FIGURES INTO ACTUAL SPINDLE FIGURES.

RING SPINNING

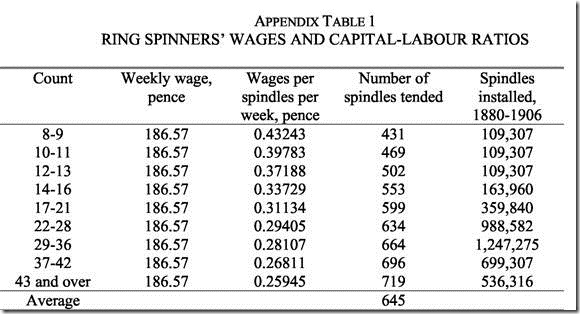

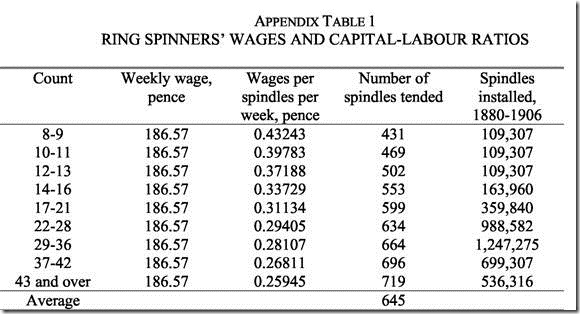

The number of spindles is calculated by multiplying employment data by the number of spindles per operative. The numbers of spindles per operative are derived by dividing data on weekly earnings by the Universal Wage List, which gives the rate paid per spindle tended. We use Saxonhouse and Wright’s data on the count distribution of rings to average the count specific spindleage numbers.

Sources: Col 2: 1906 Enquiry, p. 30.

Col 3: Jewkes and Gray, Wages, p. 121.

Col 5: Saxonhouse and Wright, “New Evidence,” p. 511, sub-divided pro-rata where necessary

Notes: Col 4 equals col. 2 divided by col. 3.

The average is the average of column 4, weighted by column 5.

MULE SPINNING

John Jewkes and E.M. Gray give the number of spindles on typical new mules in Oldham and Bolton at ten yearly intervals.74 We use the figures for new mules installed in 1886-7 as a proxy for all mules in place in 1906. Mules lasted some 50 years,75 and the mule sector was growing relatively slowly in this period,76 so an average age of twenty years seems reasonable. In any case the growth in spindles per mule was only around 1 percent per year,77 so mis-estimating the average machinery age will yield only a small mis-estimation of the capital to labour ratio. We weight the figures for Oldham and Bolton (1044 and 936 respectively) by the ratio of mule spinners in each town as given in the 1906 Enquiry (3165 and 1806),78 remembering that each spinner tended two machines.79 This tells us that each mule spinner and his team tended 2046 mule spindles.

Spindles: rings: Jewkes and Gray, Wages, p. 121, Saxonhouse and Wright, “New Evidence,” p. 511; mules: Jewkes and Gray, Wages, p. 205.

CONVERTING ACTUAL SPINDLE DATA INTO EFFECTIVE SPINDLE DATA

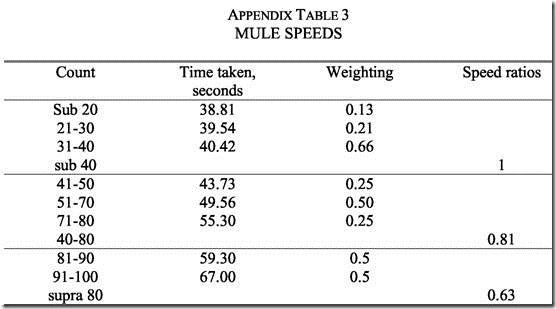

Different types of spindle produced different amounts of yarn per hour. Following the literature, we use one coarse mule spindle as our numeraire spindle, and covert other spindles into coarse mule equivalent spindles, which we term effective spindles. For sub-40 counts ‘effective spindles’ are exactly analogous to ‘mule equivalent spindles’. More generally the definition of an effective spindle is one that produces an equivalent length of yarn per hour, so data for effective spindles is a proxy for yarn output.

For ring spinning, we use the standard assumption that the output of one ring spindle was equal to that of 1.45 coarse mule spindles. 80 For mule spinning Jewkes and Gray give count-specific information on the time taken to complete three cycles of the mule, the traditional way of measuring mule speeds. We use the Saxonhouse and Wright installation data to construct a weighted average for sub-40 counts, and in the absence of further data, we use linear weights for averaging data for finer yarns.