AHMED SAYED SOLIMAN, B.S., M.S.

A DISSERTATION IN

AGRICULTURE

Submitted to the Graduate Faculty of Texas Tech University in Partial Fulfillment of the equirements for the Degree of DOCTOR OF PHILOSOPHY

INTRODUCTION

Commercial rotor spinning began in 1967 in Czechoslovakia. Since that time, many researchers have studied factors that affect rotor spinning of fine yarns. At the present, the break-even point, i.e., the economical count beyond which rotor spinning becomes more expensive than conventional_ ring spinning, is becoming ever finer, and is now approaching Ne 30 (the English system is used for yarn count). The alternative count system, tex or gram/kilometer, is given by tex X Ne = 590.6.

The purpose of this research was to study the interaction between five principal factors known to influence rotor spinning of fine cotton yarns. The factors investigated were raw material, preparation, sliver weight, count, and twist. The study was set up as a factorial design with two replications.

The general effect of varying any one of these factors on rotor spinning is already well understood. By examining their interactions, however, it was deemed possible to acquire information on a number of other troublesome questions which are enumerated as follows:

1. Is combing beneficial generally, or only at fine counts, or only with long-staple cottons?

2. Is a long-staple cotton generally advantageous, or only at low twist?

3. When a low-micronaire cotton is used, under what conditions, if any, does the higher number of fibers in the yarn cross-section offset the tendency to form neps? Is the net effect of a fine cotton a function of yarn count?

4. To what extent is very high draft undesirable, i.e., should finer slivers be used in spinning fine yarns?

5. Are there high-order interactions, e.g., does fine yarn call for a long combed fiber with a low sliver weight?

6. Are the results of spinning performance consistent with those obtained by measuring yarn properties such as evenness, tenacity and appearance?

REVIEW OF THE LITERATURE

2.1. The History of Spinning

Seven thousand years ago spinning was already well established as a domestic craft. At that time and until the early middle ages spinning was an incredibly slow and tedious task. Throughout this period the spinning of one pound of cotton into a yarn suitable for the weaving of what we would now regard as a fairly heavy apparel fabric would keep a spinner busy for several weeks.

The earliest spinners probably twisted the yarn directly between finger and thumb but the spindle-and-whorl (a small clay, stone or hardwood flywheel to facilitate rapid rotation of the spindle) became the universal tool of spinners at an early date. The process was necessarily discontinuous.

With the wheel-driven spindle, as with the simple spindle, spinning remained a discontinuous process, and it was not until 1519 that Leonardo da Vinci invented a continuous spinning device, the spindle-and-flyer mechanism.

The invention of the flyer marked a big step forward in that, for the first time, it allowed twisting and winding-on to proceed simultaneously. An early embodiment of the principle, the Saxony wheel, appeared in 1555 and quickly became established as offering the most efficient way of spinning the relatively coarse woolen yarns which were in great demand in Northern Europe.

In the 1760's, Richard Arkwright succeeded in establishing the first successful commercial mills, based on the use of the automatic continuous spinning machine, later known as the water frame.

The third and final step in this first phase of mechanization of spinning was the mule invented by Samuel Crompton in 1779, so-called because the mule was a hybrid between the roller drafting of the water frame (to achieve fineness) and the inherently stable system of drafting against running twist of the jenny. By this means it was found possible to spin yarns fine enough for the weaving of Indian-type muslins. The mule, too, was commercially successful, particularly for the spinning of fine yarns.

The opening years of the 19th century were years of frenzied activity. By this time the mule had become by far the most popular spinning machine. Eventually a completely automatic mule was devised by Richard Roberts, 1827.

In the same year (1828) that the cap frame appeared, John Thorp patented his ring frame. Only one year later the last important step was taken when Addison and Stevens patented the ring-and-traveler, a concept which became the dominant spinning device in the 20th century.

Jenny, mule, throstle,and ring frames introduced twist into the yarn being spun by rotating the package (or "bobbin") of yarn.

By 1960, there were many contenders for the great prize of introducing a commercially successful "open-end" spinning machine (Catling, 1983). The first development of a mill-scale open-end machine (Czech KS 200 Break Spinner) was demonstrated in 1966 by Vyzkumny Ustav Bavinarsky (V.U.B.), a Textile Research Institute in Czechoslovakia. This machine was soon accepted in industry.

In 1967, the BD 200 rotor spinning machine--a modification of the previously mentioned machine--was also announced by the V.U.B.

Since that time, many workers have been interested in studying, applying, and developing rotor spinning machines.

2.2. Factors Affecting Rotor Spinning

of Fine Cotton Yarns

Many factors are known to affect the process of rotor spinning; a number of these factors are as follows.

2.2.1. Raw Materials and Their Properties

The open-end rotor-spinning system is especially suitable for short-staple fibers (LUnenschloss et al, 1975). Good results were obtained by Vaughn and Rhodes (1977) using fiber of medium length, with intensive gin cleaning. Because trash accumulation in rotors makes this type of spinning especially sensitive to impurities, it was early realized that thorough cleaning is required (Liinenschloss and Hummel, 1968). Their conclusions were based on comparative trials in which American cotton was spun by both ring and rotor (BD 200)

systems. They showed that, despite the need for higher twist, the rotor yarn was better in most respects, such as evenness, abrasion resistance, extensibility and reduced hairiness, but the ring-spun yarn was stronger. A similar comparison using African cottons (Bruggeman, 1979) concluded that the method

of spinning affects fabric properties in the warp and filling directions as much as do the origin and type of cotton.

Cheaper mechanically harvested cottons were rotor-spun on a BD 200 RC, a modified BD 200 machine equipped with a cleaning system (Pospisil, 1976). The yarns obtained had reduced breakage rate, and improved yarn quality, i.e.,

fewer thin and thick places. Using a PR-150-1 rotor spinning machine to make 250-tex cotton yarns,Shcherbakova et al (1983) likewise showed that lower-grade cotton can be processed on this machine, leading to fewer faults and a more regular yarn than those processed on the ring frame. Similar results were obtained by Chemie and Kowalski (1983) in mill trials on low-grade R3 Soviet cotton.

Several cottons of staple length <7/8" were spun in both ring and rotor machines (Pillay, 1975). He found that fabrics from 0-E yarns had significantly lower breaking strength, tearing strength, and bursting strength than fabrics from ring-spun yarns; fabric breaking elongation, air permeability, and abrasion resistance were not substantially altered. Despite the fiber disorientation in rotor yarns, which prevents fibers from making their full potential contribution

to yarn strength, researchers at Texas Tech University (1978) reported that strong open-end spun yarn was produced from Paymaster 266 cotton. A 59-tex (Ne 10) yarn was found to have Uster single yarn strength of approximately 800 g.

The finest yarn count that could be spun in a Rieter M1/1 machine was found to be limited by the quality of the raw material, particularly fiber fineness (Stalder, 1979).

2.2.2. Preparation for Spinning

Despite improvements in trash extraction in rotor frames, it has long been known (e.g., Kluka and Wojciechowski, 1973) that thorough cleaning in preparatory processes is repaid by a reduced rate of end breakage during rotor spinning. Using Texas cotton, Towery (1976) found that 3 cardings and 2 drawings gave the best yarn strength by reducing plant residues and very short fibers before spinning. Simpson (1978) reported that strength of the 0-E yarns from double-carded sliver is greater than from single-carded sliver.

crusher and drawing zone, followed by a single drawing.

Uniform card sliver is necessary to produce strong yarn (e.g., PUtzschler, 1976). Nep formation in carding was found to be lower in Indian Sujata and Hybrid 4 cottons when compared with two imported varieties (Giza 45 and Sudan XG2VS). When the fibers were combed, however, the imported cottons produced stronger and more even yarn.

Several other investigators have examined the effect

of combing on rotor spinning, mostly using long-staple cotton. Artzt and Hehl (1978) made a comparative study of ring- and rotor-spun yarns from combed and carded sliver. The effects of sliver fineness, fiber strength, and combing on the properties of the yarns were all evaluated. Results suggested that quality criteria which necessitate combing for ring-spun yarns do not apply to rotor-spun yarns, and that the quality of rotor-spun yarns is not adversely affected by a certain proportion of short fibers. Knitted fabrics made from carded rotor yarn were comparable in most properties with those made from combed ring yarn, except that the hand of the rotor yarn was subjectively judged as being harsher (Bruno, 1980).

Gupte et al (1981), studying four Indian cottons on a Platt Hartford comber, showed that all the important fiber length parameters such as mean fiber length, short fiber percentage, and dispersion percentage can together explain almost all the variations taking place in yarn strength after combing.

2.2.3. Sliver Weight and Spinning Draft

Open-end methods have the general advantage of allowing very high draft and enabling yarn to be spun direct from sliver. Drafts in the opening zone of about 100 are considered optimal for a BD 200 S machine (Audivert and Castellar, 1981). Drafts exceeding 300 are feasible as long as the delivery speed from the drafting system is high enough (Krause and Soliman, 1970). With a yarn withdrawal speed

of 120 m/min they processed 4 kilotex sliver with a draft of 363. This maximum feasible draft is reduced at shorter staple lengths (Frey, 1974). As an example, Starodubov (1981), studying yarn formation during mass piecing-up on BD 200-M-69 machines, concluded that 18.5 and 50 tex (Ne 32 and 12) cotton yarns could be produced from a 3.7 ktex (52 gr/yd) sliver with a fiber length of 30 to 31 mm.

Very high draft causes uneven yarn and excessive end breaks. Finer sliver is recommended in spinning fine yarns (Landwehrkamp, 1979). For a yarn count of 33 to 100 tex (Ne 6 to 18) a sliver weight of about 4 ktex (56 gr/yd) is

needed; for yarns of 25-33 tex (Ne 18 to 24) a sliver weight of 3.4 ktex (48 gr/yd) and for finer yarns of 20-25 tex (Ne 18 to 30), a sliver weight of 2.5-3 ktex (35 to 42 gr/yd) is recommended in order to avoid excessive drafts. Likewise,

a formula for predicting yarn evenness developed by Seshan et al (1979) shows opening-roll draft as one of the three chief components of yarn irregularity.

2.2.4. Yarn Count Range

Rotor spinning has been more successful in spinning coarse yarns. As yarn becomes finer, ring spinning is generally more economic because spindle speed can be increased and the capital cost/spinning position is much lower. Knitting yarns in the range 12 to 400 tex were rotor-spun at the Textile Research Center, Lubbock, Texas (Towery, 1976). Rohlena (1977) reported that the BD system can produce yarn of fine counts. Tex counts of 15 and 17 were spun from medium-quality cottons. He added that the BD 200 S is a more universal machine able to spin yarns from 15 to 100 tex (Ne 6 to 40) with yarn-withdrawal speeds up to 150 m/min. The superior evenness of rotor yarns was found to extend to yarns as fine as 19 tex (Ne 31) spun on a BD 200 S machine (Lennox-Kerr, 1979). Attempts to spin finer yarns on rotor machines hav3 met with excessive end-breakage rates. For example, workers at Texas Tech University (1980) spun 7 tex (Ne 80) yarn from grade 3 combed Pima cotton on Elitex BD 200 S at

10 rotor positions, but with 19 ends down/1.5 rotor hours. However, Sultan and El-Hawary (1974) found that the BD 200 open-end spinning machine could not be recommended for spinning fine yarns from long-staple Egyptian cotton. Instead, shorter cottons can be used more effectively to produce yarns of coarser count.

As distinct from technological possibility, economic feasibility has generally been limited to coarse and medium

counts (Stalder, 1972). Earlier, S.A.C.M. (1967), in marketing the Integrator which is a turbine spinning machine, advised that the effective range of yarn count is from 36 to 170 tex. Cizek (1968), using the BD 200 break spinning machine under mill conditions in Czechoslovakia, reported that the count range limits tested are from 15 to 62 tex (Ne 10 to 40) on fiber with staple length up to 40 mm. Similar conclusions were reached by Wassef (1972). Frey (1974) and Herold (1976) suggested an economic limit of 25 tex (Ne 24) and Lennox-Kerr (1974), referring to Platt Rotospin 833 and 835 machines, indicated 20 tex (Ne 30). Jain and Marwaha (1975) confirmed that the rate of return on investment in rotor spinning in the initial years is satisfactorily high for counts between 32 and 59 tex (Ne 10 and 18) and that, even for counts as fine as 20 tex, the long-term return is good. In general, it was considered profitable to adopt open-end spinning in India, particularly for mills producing coarse and medium counts. Commercial production by Daiwa was limited to yarns of 32 tex (Ne 18) and coarser (Konishi, 1976). A practical limit of 30 tex (Ne 20) was also found for blends of cotton and man-made fiber having staple lengths up to 40 mm (Tyukov et al, 1981).

Nikolic (1980) reported that the quantitative and economic indices for a 20 to 50 tex (Ne 12 to 30) yarn are significantly better if open-end spinning is used. However, the qualitative index is better and the range of application is

wider if ring spinning is used. Brunk (1982) used combed long-staple cotton to spin fine yarns in a rotor spinner. Starting with fiber counts of 100 mtex, it was possible to spin yarns of 14 to 16 tex (Ne 37 to 42). The study showed that the yarn strength efficiency is related to twist in a similar way for 110 to 170 mtex fiber. Cost analysis showed that rotor spinning of fine fibers into fine yarns is advantageous only in comparison with ring spinning of combed cotton.

Fine (21 tex = Ne 28) rotor yarn was found to be weaker and less rigid than ring-spun yarn. Coarser (49 to 67 tex or Ne 9 to 12) rotor yarns were more rigid than corresponding ring yarns (Tiranov et al, 1977).

Artzt and Schenek (1977) investigated the effect of rotor diameter, yarn count, and rotor speed on the minimum twist level. Rotors having diameters of 45, 55, and 65 mm over a yarn count range of between 25 and 125 tex (Ne 4 and 24) with rotor speeds from 45,000 to 65,000 rev/min, were used.

Results showed that fine yarns should be spun on small rotors, while larger rotors were suitable for coarse yarns.

2.2.5. Yarn Twist

Cotton yarns spun on BD 200 spinning machines need 10- 15% more twist than ring-spun yarns (Barella and Vigo, 1970; Herold, 1976). Audivert (1981) found that the more flattened twist/strength curves of rotor-spun yarns, compared with those of ring-spun yarns, were attributed to the increase in

fiber breakage and reduction of fiber straightening. Barella et al (1982) indicated that the diameter of cotton rotor yarns was influenced to a lesser extent by twist angle than ring yarns. Rotor-spun yarn was found to have a greater diameter than a conventional ring-spun yarn because of the different method of applying twist (Barella et al, 1984).

Higher twist values were found to be one answer to the problems of higher end-breakage rate and reduction of yarn breaking strength that characterize rotor spinning when compared with ring spinning, (Coll-Tortosa and Phoa, 1976). Audivert (1980) indicated that in rotor-spun cotton yarn, elastic recovery varied directly with yarn twist and inversely with percentage elongation. The effect of twist and draft on cotton yarn properties was studied by Polyakova (1980). She confirmed that twist should increase with indirect count by an exponent just above 0.5. Mitova (1981) found that the abrasion resistance increased with twist due to greater cohesion.

The resistance to repeated extensions of cotton rotor-spun yarns tends to increase as the twist increases (Barella and Manich, 1981). Researchers at Texas Tech University (1981) studied the influence of twist miltiplier level on count-strength product. They found that yarns formed by a Platt T 883 spinning machine were superior to those formed by the older type of spinning unit. For combed long-staple fibers in the range 0.11 to 0.17 tex, the fiber-strength

utilization in yarns spun in a BD 200 RS machine increased directly with twist (Brunk, 1982). Barella et al (1983) concluded that twist did not affect yarn regularity, but it did influence very significantly the accumulated trash in the rotor. The most satisfactory twist was found to be 1200 t/m at yarn count of 16.5 tex (Ne 36) and twist multiplier of 4900, (Yurkova et al, 1983). The difference between the theoretical and the measured twist in rotor spun yarns was found to be affected by the type of rotor, the atmospheric pressure in the cleaning system, the rotational speed of the opening roller, and the number of fibers in yarn cross-section (Manich and Barella, 1984).

2.3. Yarn Properties

2.3.1. Yarn Appearance

The yarn produced by the rotor spinning method was characterized by a very even appearance and low breaking strength (Shimizu et al, 1968). Louis (1978), comparing the ASTM method and Uster evenness Tester data, indicated that the Uster data were found to be adequate in indicating grades, provided that a narrow range of yarn count was involved in each evaluation.

2.3.2. End Breakage in Spinning

In order to ensure normal operation of a BD 200 spinning machine, yarn breaks must not exceed 50/1,000 rotor

hours (Feigenberg et al, 1970). It is possible to reduce yarn breakages while at the same time reducing the amount of twist necessary for spinning on BD machines by fitting a guide edge of specified radius in the yarn withdrawal path (Hom, 1974). El-Messiry (1977) indicated that economic effectiveness in spinning Egyptian cotton was found to fall rapidly at a breakage rate exceeding 500 ends/1,000 rotor hours. Yarns with a linear density of 29.4 tex (Ne 20) were spun on PPM rotor spinning machines at rotor speeds of 60,00C r.p.m. with 40 breakages/1,000 rotor hours (Avrorov and Privalov, 1983).

2.3.3. Yarn Evenness

Krause and Soliman (1971), Douglas (1972), and Lord (1974) have stated that evenness of rotor-spun yarn was better than ring-spun yarn, due to the deposition of fibers on the inner wall of the spinning rotor. The effect of cotton fiber maturity on the irregularities of yarns spun on ring frames and rotor spinning machines was studied by Czaplicki (1973). He found that yarns spun on a ring frame from fully mature fibers were more regular than those from immature ones, while quality of rotor yarns was little affected by fiber maturity.

Because of the low number of thick places and knots after cleaning in coarse to medium counts, rotor-spun yarns have been considered ready for further processing without

winding (Rohlena, 1974). Delerm (1976) explained how the quality advantages of rotor-spun yarns (uniformity, absence of knots, good covering power) can be exploited.

2.3.4. Yarn Tenacity

Fibers migrate in spinning differently from those in ring-spun yarn and the fiber-helix wavelengths vary according to yarn radius; fiber tensions are lower. Bridging fibers are converted into hooks, thus reducing the effective fiber length in the yarn (Lord, 1971). These factors contribute to the weakness, bulk and extensibility of rotor yarns. Yarn strength increases as the fiber's staple length increases in the range 31.5 to 37.6 mm and its linear density decreases, but fiber strength utilization in the yarn decreases as staple length increases (Chukaev and Manakova, 1972). They concluded that fibers with shorter staple lengths were used more effectively in spinning on the BD 200 machine. Yarn strength was found to depend less on sliver uniformity than on the blending and cleaning derived from the two drawing processes that gave maximum yarn strength (Texas Tech University, 1978a). The lower yarn strength of rotor yarns from a BD 200 machine was explained by a decrease in modal length of 3 to 5 mm (Kochetkova and Kovacheva, 1976). Part of the low fiber-strength utilization in rotor yarns is explained by surface wrapper fibers, which comprise an increasing proportion of the yarn as yarn count becomes finer (LUnenschloss and Kampen, 1976). The effect of three types of rotor profiles (narrow-, medium-

and wide-grooved) in a Platt Saco-Lowell T 833 machine was examined (Texas Tech University, 1984a). The narrow groove produced the strongest and most uniform yarn.

The relationship between fiber and yarn properties has been described in a series of publications from the Textile Research Center. For a nearly constant micronaire value, 96% of rotor yarn strength variation at both 23 and 59 tex (Ne 10 and 26) can be explained by fiber strength variation (Texas Tech University, 1978b). The Stelometer instrument

was found to be the most sensitive predictor of yarn strength (Texas Tech University, 1984b). Tests on Acala 1517-75 cotton and a hybrid Upland X Pima cotton on a Rieter M1/1 machine and a Saco-Lowell SF3H ring frame showed that the higher length and strength of the hybrid cotton contributed to high yarn strength regardless of yarn count (Texas Tech University, 1980).

2.4. General Comparison of Ring and

Rotor Yarns

Many investigators, such as Locher and Kasparek (1967), Kasparek (1968), Barella and Torn (1969), Pospisil and Kasparek (1969), Burlet et al (1971), Parthasarathy and Govindarajan (1972), Hunter et al (1976), and Santhanam (1977), have shown that rotor yarn is weaker on average than ring yarn but, being more even, has better appearance and is relatively free of weak spots that may cause yarn breaks in later processes.

3.1. Materials

The materials utilized in this study consisted of two long-staple cottons; Pima, (Gossypium barbadense L.), henceforth alluded to as (A), and a California variety, (Gossypium hirsutum L.) alluded to as (B), plus two short-staple G. hirsutum L. varieties, a West Texas fine (C), and a West Texas coarse (D). All of these cottons were sampled and tested for fiber properties at the sliver stage.

3.2. Preparation

Two samples of the long-staple cotton, weighing 110 lb each, were introduced into the Textile Research Center opening/cleaning/carding line, to produce card sliver. Because the waste expected to be removed in combing the short-staple cottons exceeds that of the long-staple types, 120 lb of C and D were fed to the opening hoppers. Total opening and carding waste as a percentage of the weight fed was measured as 6.7% and 9.5% for A and B, respectively, and 10.2% for C and D.

The card sliver of both long-staple and short-staple cottons was divided into two unequal parts, 45% and 55% of the card sliver weight, for carded and combed sliver, respectively.

For the coarse slivers, forty-five percent by weight of the card sliver was passed through two successive drawing processes by using the draw frame. The remaining fifty-five percent of the same card sliver was pre-drawn once, lap-formed, combed and drawn twice again before being rotor-spun.

The fine slivers all required an additional drawing for attenuation to 30 gr/yd. This introduced some short-term irregularity and raised sliver C.V. values (see Appendix). Moreover, Vaughn (1975) reported a yarn strength increase

of two percent due to a third drawing. For these reasons, any comparisons of results between the two sliver weights are to be interpreted cautiously.

For setting counters to determine the length to be taken for different pre-spinning processes, the following equation was applied:

3.2.1. Spinning

In the rotor spinning stage, sixteen cans were used, as follows:

1--Cans of 60-grains/yard sliver

a--four carded lots b--four combed lots 2--Cans of 30-grains/yard sliver

a--four carded lots b--four combed lots

The spinning process was carried out from the sixteen cans by using the rotor spinning machine BD 200-S to convert the slivers into yarns. Eight spinning positions were chosen, with the sliver samples arranged at random in front of each

position.

3.2.2. Spinning Conditions

1--Rotor speed was 46,400 r.p.m.

2--Opening roll speed was 6,200 r.p.m.

3--Opening roll type was OK 40

4--Rotor diameter was 54 mm

5--Navel type used was:

a--smooth for maximum strength at high twist b--grooved for spinnability at low twist

then adjusted if necessary after checking the yarn count of a 120-yd sample in the skein winder. On the basis of the adjusted draft, the exact value of yarn count was evaluated.

In general, twist (tpm) decreases with increasing tex count according to t=k/texn where t is twist in turns/metre, k and n are constants. For present work, an exponent, n, of 0.60 was used.

High and low twists in turns/metre were calculated according to the two following equations, respectively, for

Ne 20, 30 and 45 (29.5, 19.7 and 13.1 tex, respectively): High twist = 6700/tex0.6 , i.e., 879, 1120 and 1429 tpm Low twist = 4900/tex0.6 , i.e., 643, 819 and 1045 tpm

Put another way, the simple twist multiplier, defined as

turns/metre multiplied by tex, was increased in proportion to

tex-0.1

In addition, the spinning time and the number of yarn end-breaks at each spinning position were recorded.

3.2.3. Identification Code

Every cheese of yarn was identified by a six-digit code. Every one of the six digits identifies fiber, processing, sliver weight, yarn count, twist and replications, respectively.

The first digit of the identification code represents four levels of the cotton fibers.

1 = Pima

2 = California

3 = West Texas fine

4 = West Texas coarse

The second digit refers to processing: number 1 for

the carded sliver, and number 2 for the combed sliver.

The sliver weight (60 or 30 grains/yard) was described

by the number 1 or 2 in the third identified digit.

The fourth digit had the number 1, 2, or 3 according to

the yarn count, 45s, 30s or 20s, respectively.

High and low twist were expressed by number 1 or 2 in

the fifth digit.

The last identification digit represents the first or second replication, according to the number (1 or 2).

Example:

identification code = 212111

2 = California cotton

1 = Carded sliver

2 = Fine sliver weight (30 gr/yd)

1 = Fine yarn count (45s) 1 = High twist

1 = First replication

The levels of each factor are summarized in Table 1.

3.2.4. Fiber Tests

The cotton fibers were tested using the Motion Control High Volume Line (HVL), to measure:

1--Micronaire

2--Length

3--Uniformity ratio (UR)

4--Tenacity

3.2.5. Sliver Tests

The above-mentioned properties were investigated for cotton sliver, but a newly available Peyer instrument was used to measure length distribution. Both fiber length

(2.5% span length in inches) and uniformity ratio were tested in accordance with corresponding ASTM standards. The Stelometer was used to re-examine fiber tenacity (g/tex).

In addition, fiber micronaire, hair weight (mtex) and maturity (%) data were measured by the Shirley/I.I.C. Fineness-Maturity Tester (FMT).

3.2.6. Yarn Tests

Yarn appearance was assessed according to ASTM D2255-75, with each result based on the mean of three independent observers.

Each yarn evenness result is a single determination

made on an Uster evenness tester at 100 m/min for 2.5 minutes, and thus represents 250 m of yarn.

Yarn strength was measured automatically in an Uster

Tensorapid instrument, with 25 breaks for each replicate. Thus, for instance, each of the four fibers was tested 1200 times; each sliver weight, 2400 times, making for a sensitive measure of factors affecting strength. Tenacity was calculated by dividing the mean strength by the nominal yarn count. Deviations between nominal and actual count were slight.

3.3. Design of the Experiment

A factorial design was used, primarily because of its capability of detecting both main effects and factor-interactions among studied factors.

Table 1 represents the factors and number of their levels; both control and experimental. With each combination repeated, there were 192 spinning experimental units, with corresponding tests of yarn properties.

Results of yarn end-breakage, evenness, and tenacity were logarithmically transformed for the following reasons:

1--to make the residual variance homogeneous

2--to avoid spurious interactions

The results of yarn appearance were not logarithmically transformed, however, because this property depends on eye response, which varies with the logarithm of the stimulus. This is confirmed by the fact that appearance results are already normally distributed. End-breakage rate/rotor hour (EDRH)

was transformed into In (1 + EDRH).

RESULTS

The present data illustrate the effect of five factors (raw material, preparation, sliver weight, yarn count and twist) on rotor-spun yarns of four different cottons (Pima, California, West Texas fine, and West Texas coarse).

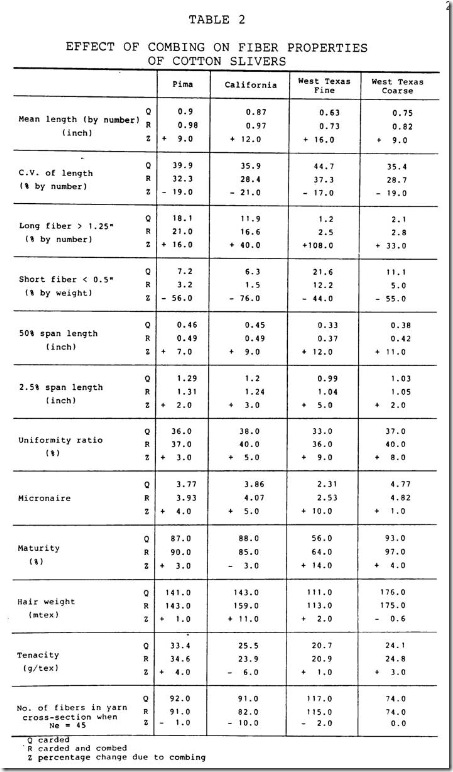

The effect of combing on the fiber properties; mean length, coefficient of variation of length, the percent of long fibers >1.25", the short fibers <0.5", 50% and 2.5% span lengths, uniformity ratio, micronaire, maturity, hair weight, tenacity and the calculated number of fibers in the yarn cross-section, is shown in Table 2. These properties were measured on the sliver as spun, and their effects on spinning were assessed by four sets of measurements: appearance, end breakage rate, evenness and tenacity.

Table 2 represents the effect of carding (Q) and both carding and combing (R) on the properties of the cotton fibers. The percentage change due to combing (Z) is also illustrated. The AL-101 apparatus was used for all length measurements. The uniformity ratio (U.R.) of the sample was calculated according to the following equation:

Micronaire, percent maturity and hair weight (mtex)

were evaluated by using the Shirley/I.I.C. Fineness-Maturity

Tester (FMT). The Stelometer apparatus was utilized to measure the tenacity of the cotton fibers expressed as grams/ tex at 1/8 -inch gauge length. The table also shows the calculated number of fibers in the yarn cross-section according to the following formula:

In the fine yarn, only the fine West Texas cotton reached a standard of 100 fibers in the yarn cross section. The two West Texas cottons differed chiefly in micronaire value, about half of this difference being due to fineness, half to immaturity.

Table 3 illustrates the appearance of the cotton yarns. Measured letter grades were quantified according to the following table:

Intermediate grades were assigned numerical values between the above figures, e.g., B+ became 115, B- was 105.

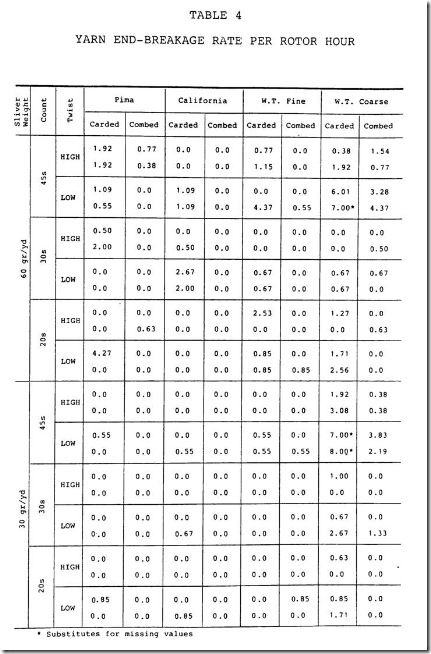

Table 4 shows the effect of combing on the yarn end-

breakage rate per rotor hour under the previously mentioned conditions. The following equation was applied:

Tables 5 and 6 represent the yarn evenness and tenacity of the tested cottons expressed as C.V.%- and g/tex by using the Uster evenness tester and Tensorapid, respectively. The effect of combing after carding on the fibers of different counts (45s, 30s, 20s) at the high and low twists was studied in both the coarse and fine slivers.

Table 7 summarizes the effect of tested factors on cotton yarn properties (appearance, end-breakage rate, evenness and tenacity). Analysis of variance was carried out using the TELEX 178 computer and applying the subprogram SPSS.

The significance of main effects and all interactions was evaluated at three different levels.

Table 8 is a summary of the main factors (cotton fibers, preparation, sliver weight, count and twist) as measured by the properties (appearance, end-breakage, evenness and tenacity) of yarns produced from the four cotton types (Pima, California, West Texas fine, and West Texas coarse). Minimum significant difference between pairs of readings can be determined approximately from

where s is the residual standard deviation of the logarithms

R is the mean reading in original units

k is the number of categories being compared

Pairs having any common superscript are not significantly

different at the 5% level.

Three yarns could not be spun to a count of Ne 45 with low twist from carded material of Lot D, the coarse West Texas cotton, both replicates from the fine sliver and one from the coarse sliver. Such yarns as were made from these broke repeatedly in spinning and contained so much seed yarn that any tests on them would have been invalid.

To complete the analysis of variance, these missing values were calculated in the usual manner except that the result in the same cell was assigned high and low values to give two replicates having the same variance as the average residual variance. These missing values caused the number of laboratory measurements to be reduced from 192 to 189, the residual degrees of freedom from 96 to 94, and the degrees of freedom in the highest-order interaction from 6 to 5. This procedure always causes the analysis to err on the conservative side, possibly overlooking some effects but avoiding the risk of detecting false effects.

DISCUSSION

This chapter describes all significant interactions including any corresponding lower-order interactions and main effects, which are not discussed further, except descriptively in Table 8. M.S.D. is the minimum significant difference based on the logarithms used in the analysis. This is the most exact criterion.

5.1. Yarn Appearance

Because the test uses different photographic standards for the three counts, any differences between counts are to be interpreted cautiously.

Combing significantly improves yarn appearance, but only at fine and medium counts (45s and 30s) with fine sliver. This improvement of yarn appearance by combing is in accordance with Srinathan et al (1976), as shown from Table 9.

In general, the best yarn appearance was observed in W.T. Coarse cotton at all yarn counts, but especially with coarse sliver (60 gr/yd). Improving yarn appearance by using W.T. coarse cotton may be attributed to the coarseness and maturity of the fiber, which tends to decrease the number of neps in the yarn. This cotton gave better appearance than any other with 45s yarn and fine sliver, as shown from

Table 10.

5.1.3. Effect of Twist on Yarn Appearance

As shown from Table 8, high twist with a smooth navel gave significantly better yarn appearance than low twist with a grooved navel. There were no significant interactions involving twist, one of only two instances in the experiment

in which an unqualified main effect was identified. The main effect (Table 8) indicated a quite general improvement in appearance at the higher twist. This consistency confirms that the two twists selected for each of the three quite different counts were appropriate.

5.2. End-Breakage Rate

The results were not normally distributed, because of the number of trials in which no breaks occurred. Therefore, only effects showing a significance level below 3% are discussed.

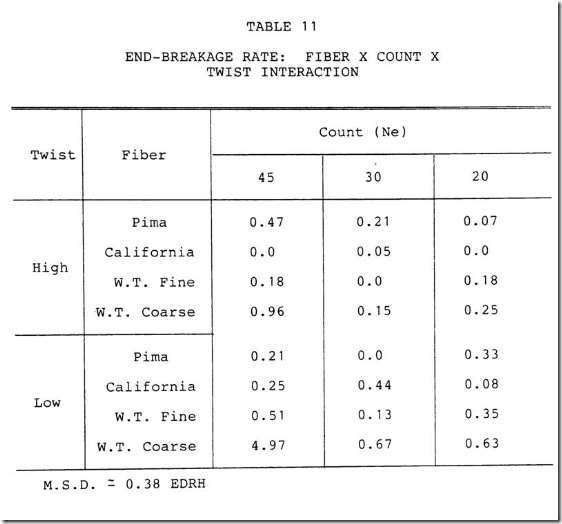

5.2.1. Fiber X Count X Twist Interaction

Apart from the extraordinarily high rate for the coarse W.T. cotton at low twist, all counts show similar rates of end break, with the lower twist consistently causing more breaks, especially in the coarse W.T. cotton. The findings indicate that high twist improved yarn end-breakage rate. This confirms the results of Coll-Tortosa and Phoa (1976), who reported that higher twist values are one answer to the problems of increasing end-breakage rate, but this is not true of the long Pima cotton, as shown from Table 11.

5.2.2. Fiber X Preparation X Sliver

Weight Interaction

Table 12 shows that reducing the sliver weight greatly reduces the rate of end breaks, although with combed W.T. fine and California cottons, the rate is already so low that the effect is negligible. Combing is likewise beneficial, though the effect is not significant in fine W.T. cotton from fine sliver. On average, combing reduced the end-break rate by a factor of 3.5, and halving the sliver weight halved the rate of end breaks. Work loads in rotor spinning can therefore be increased if the sliver is attenuated and the fiber is combed.

5.3. Yarn Evenness

In general, yarn evenness results were poor, near the Uster provisional 75% level (Zellweger Uster, 1982, p. 34). This is, however, typical of tests in which the wrapper fibers are redistributed in the hairiness measurement which comes before the evenness test.

5.3.1. Sliver X Count X

Twist Interaction

Table 13 shows that higher twist impairs evenness, but in conventional rotor spinning, where a heavy sliver is used to make a coarse yarn, this effect is not significant. Consequently, the advent of fine-yarn spinning, and the use of finer sliver to reduce draft, may cause more irregularity than is at present apparent to manufacturers, especially when high twist is applied in an effort to maximize yarn strength in fine yarns. Barella et al (1983), testing Ne 12 and 16 yarn, reported that twist has no influence on yarn irregularity (two machines were used in their study, SUssen and SKF). This result confirms our finding at Ne 20.

5.3.2. Preparation X Twist Interaction

Table 14 shows that the tendency for evenness to improve at low twist is more pronounced in carded than in combed fiber. Combing has a better effect on yarn evenness at high twist. Thus, in general, lower twist gives better yarn C.V.

5.3.3. Preparation X Sliver

Weight Interaction

Table 15 shows that coarse sliver gave better evenness, but only in carded yarn. This implies that spinners could achieve better yarn evenness by choosing coarse slivers to be spun on rotor machines. Attenuating the sliver, despite a substantial reduction in end breakage, did increase yarn irregularity, especially in carded sliver. Because drawing

was done without autoleveling, there is potential for greatly-improving the evenness values quoted in the appendix, hence the yarn evenness, especially from fine sliver.

5.3.4. Fiber X Twist Interaction

Low twist improved yarn evenness only in Pima and West Texas coarse cottons. Evenness of yarns from the ordinary rotor-type cottons could not be improved much by reducing twist. But, in general the long-staple cottons (Pima and

California) gave better yarn evenness than the short-staple cottons (W.T. fine and W.T. coarse) especially at low twist, as shown from Table 16.

5.3.5. Fiber X Count Interaction

Table 17 shows that coarse count (20s) gave the best yarn evenness with Pima, California, and coarse W.T. cottons, but less so in fine W.T. cotton. In general, the best result was obtained at 20s with Pima Cotton; even at 30s and 45s Pima is still superior in yarn evenness when compared with the other three cottons. This result confirms that of Stalder (1979), who stated that the unevenness of rotor-spun yarns reaches a minimum with fiber lengths of approximately 40 mm. On the other hand, the present results contradict that of Liinenschloss and Hummel (1968), who reported that

.tv short-staple cottons give better yarn evenness. The effect

of increasing yarn fineness is to raise the C.V., less so in the W.T. fine fiber.

5.3.6. Fiber X Sliver Weight Interaction

Coarse sliver gave better yarn evenness with fine W.T. and coarse W.T. cottons. For the longer cottons, evenness was independent of sliver weight, as shown from Table 18.

5.4. Yarn Tenacity

Results were generally good, near the Uster provisional 25% level (Zellweger Uster, 1982, p. 37).

5.4.1. Fiber X Preparation X

Sliver Interaction

Table 19 shows that the effect of combing is greater

for fine W.T. cotton in coarse sliver, least for W.T. fine in

fine sliver. In general, the best yarn tenacity was obtained from fine combed sliver of Pima cotton. The improved yarn tenacity in long-staple Pima cotton is in agreement with Chukaev and Manakova (1972), and researchers at Texas Tech University (1980). Reducing the sliver weight, hence the draft in the opening roll, makes a substantial improvement to yarn strength, but the effect is slight in the shorter cottons. The longer cottons respond better to the lower sliver weight, but the beneficial effect of combing is apparent

even in the short-staple fiber.

5.4.2. Fiber X Twist Interaction

Table 20 shows that high twist gave high yarn tenacity in all the four cottons used in the study. The W.T. coarse cotton was the most sensitive to twist.

Morikawa and Hariwuchi (1968) stated that yarn produced from the BD 200 rotor spinning machine showed greatest strength at a twist about 15% above the "high" level of the trials reported here. As expected, increasing the twist improves tenacity of the short coarse cottons the most.

5.4.3. Effect of Count on

Yarn Tenacity

As shown from Table 8, the yarn has a higher tenacity at coarse count (20s), and as the yarn gets finer the tenacity significantly decreases. This explains the higher breakage rate for the yarn at very fine count (45s).

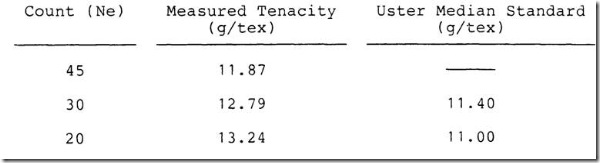

When compared with Uster Tenacity Standards, our tenacity results in Table 8 appeared better in yarn tenacity as follows:

Whereas the same materials and processing were used in the present research, the Uster provisional experience values are based on industrial practice, varying from mill to mill. Plants spinning fine counts can generally be expected to have more modern machinery, higher quality standards and better raw materials than conventional coarse-yarn

rotor-spinning mills. Thus, the strength improvement in fine counts shown in the Uster values does not necessarily imply that a given spinner will find higher tenacity when it makes fine yarns. In the present study, with the above factors held constant, a steady decrease in tenacity was observed as count became finer.

CONCLUSIONS

The results of this study indicate a number of significant two- and three-factor interactions in all four yarn properties.

The results can be summarized as follows:

1. Lowering the twist improved yarn evenness especially in the finer counts, but impaired yarn appearance generally. The end-breakage rate of the coarse short cotton at the finest count was especially sensitive to twist. The higher twist greatly increased the strength of yarns from the two short cottons, but the response to twist in the long-staple types was slight because of their lower twist requirements.

2. Reducing the sliver weight had no effect on the end break rate of W.T. coarse cotton, but the average effect on the other three fibers was a reduction of 60%. Yarn appearance was improved by using a fine sliver, but only if the sliver had been combed. For carded sliver, coarse sliver gave better yarn appearance. Yarn evenness was generally worse especially in the coarse yarn. Tenacity was little affected, though the Pima cotton gave stronger yarn when spun from fine sliver.

3. Combing is beneficial in improving yarn appearance, especially at fine and medium counts (45s and 30s). Generally, combing reduced the end-breakage rate by a factor of 3.5, and can be expected to improve the spinnability of fine rotor yarns. Combing exerted a positive effect on yarn evenness at high twist, and improved yarn tenacity of long-staple Pima cotton. Even the shorter cottons were improved in all respects by combing, because of the removal of short fibers.

4. The finest count showed a high end-breakage rate. Yarn evenness deteriorated steadily as the yarn became finer.

5. Yarn tenacity decreased as the yarn count became finer; this was a main effect that was independent of the other four factors.

6. Using a low-micronaire cotton impaired yarn appearance, but improved yarn end-breakage rate, especially at high twist. It also improved yarn evenness relative to W.T. coarse cotton. Yarn tenacity was improved at low twist in W.T. fine cotton compared with W.T. coarse cotton. However, neps from low-micronaire cotton were so abundant and thick that they could not be concealed in the fine count, which had unsatisfactory appearance.

7. Using long-staple cottons (Pima and California) reduced end-breakage rate, especially in California cotton, at high twist and at all three counts. Long-staple cottons improved yarn evenness, particularly at low twist and coarse count. The yarn tenacity was higher in Pima and California cottons compared with W.T. short-staple cottons, especially at high twist.