Woollen Spinning

Houget Duesberg Bosson

HDB is the result of the association, back in 1962, of two very old companies dedicated to the construction of textile machinery: the Ateliers Houget, established in 1823, and Duesberg Bosson who started their activities a few years later.

Situated on the banks of the river Vesdre, in Verviers a town in Belgium, which was in the past very famous for its wool industry, Houget Duesberg Bosson, better known under their initials HDB, is located at the cross road of Europe, right in the middle of an important network of motorways. Exclusively devoted to the manufacturing of machinery for the textile industry, namely the wool and wool-like spinning, HDB makes reference in matters of fibre preparation, carding and spinning operations. These processes are particularly for the production of carpet yarns both by the woollen and the semi worsted process.

From 1996, HDB pursued their activities, adding to their manufacturing program machines for the production of dry-laid nonwoven web. In association with world-renowned partners, HDB presented complete nonwoven units for geo-textiles and artificial leather.

Today, HDB is able to compete on the global textile machinery market and to serve its customers with high quality machines. While providing their customers with the best in service, HDB also offers a wide range of spare parts for all kinds of textile machinery. With a network of more than 30 agents located in all continents, HDBs customers are served with the best care in every part of the world.

HDBs long-time experience allows them to build machines that are innovative and at the same time reliable, robuts and durable. These quality features can be traced back to traditional construction mixed with newest knowledge of a versed HDB team. All machines are built individually and are tailored to customers’ needs.

Opening and Blending

The fibre preparation process describes the operations carried out to allow an efficient feeding to the carding. Hereby, it is important that a sound opening and blending of the fibres is guaranteed. These fibres could be wool or chemical fibres.

HDBs opening and blending machines are designed in order to meet all these important requirements of the fibre preparation. The material is opened, cleaned, mixed and transported through robust and reliable lines of HDB machines which are manufactured to the strictest tolerances.

The feeding and pre-opening of the fibres is carried

out by bale openers or by volumetric or weigh-type hoppers, while the opening, cleaning and mixing is ensured by mixers beaters, picker openers or fearnought pickers.

Fixed or self-emptying bins are designed to cope with the various processed volumes.

The material is transported between the different steps of the process through the piping network due to powerful fans. Through the utilisation of remote controlled pipe switches, flexibility in the fibre paths is guaranteed.

Carding

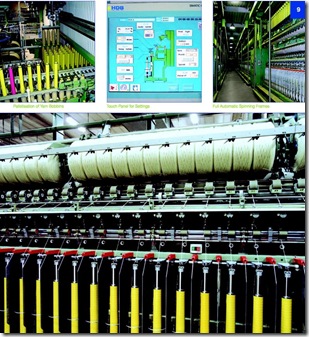

HDBs Galaxy card sets guarantee exceptional production performance and efficiency.

The carefully distribution of the working elements ensures a real progressive carding and production of highest quality slubbing. These results are achieved for each product that is wished to be obtained.

HDB offers carding sets for the processing of all fibre types for the manufacture of yarns in the count range from the coarsest of 0.2 Nm (5,000 tex) to the very fine of 30 Nm (33 tex). Woollen cards from HDB are fitted with an extra robust high speed triple rub condenser and are completed with an automatic doffing device of full condenser bobbins.

Card regulator Servolap®

The density of the material supplied by the volumetric feeder is measured continuously by the scintilla-tor. This device receives the residues of the isotopic ray sent across the lap by the energy source and converts the residual radiation into electric pulses that are conveyed to the Servolap® microprocessor.

Density variations are supplied into a microprocessor which accordingly controls the feed roller motor.

Dialogue with the machine is possible from a control panel that displays all operating and production data.

Web Division with:

Endless tape

One tape for two ends (figure-8 tapes) One tape for one end (series tapes)

in combination with :

Single rubbing Traversing creel

Double rubbing Tandem creel

Triple rubbing Automatic spooldoffer

Woollen Spinning

HDBs extended woollen ring frames programme offers spinning machines covering the range from 0.2 Nm (5,000 tex) to 30 Nm (33 tex). They have a strong design, providing high efficiency and consistent working safety.

Twisting Frames

HDB also supplies ring twisting frames with large ring diameters and tubes for a high bobbin capacity. These machines are manufactured according to the same principles as the spinning frames and form a homogeneous aggregate.

Special characteristics are:

Loose and very high twists.

Twisting capacity up to 6 ends.

In case of breakage of one of the individual ends or of the twisted yarn, the spindle is individually stop- ped and the single yarn feeding is interrupted. External creel designed accordingly to the individual yarn bobbins.

Project Mastery

HDB has a long time experience not only in the construction and design of textile machinery, but also in the realisation of projects.

Knowledge within the different steps of the processing has brought HDB to a position able to master the manufacture of textile machinery while guaranteeing optimal solutions from homogenous and perfectly balanced units.

HDB is constantly committed to meet customers’ expectations, with both high quality machines and excellent service. This service also includes customers’ support by a partner taking full responsibility of the operations.

Projects are studied by a qualified HDB team together with the customer. This close collaboration makes it possible to present best equipment configuration focused on the product that customers wish to realise.

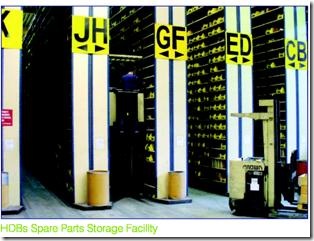

Spare Parts

HDB possess of a large inventory of spare parts. A large range of spare parts are manufactured by HDB machinery. Should a specific part not be immediately available, HDBs spare part division will make every effort to provide the required part within shortest time and best prices.

Erection and Commissioning Division

HDBs erectors are not only very skilled mechanics; they are technical people with experience in the different aspects of the industrial textile processing. Together with workforce provided at the customers’ plant, HDBs assembly team proceeds with the startup of the equipment. Hereby, the customers’ staff is instructed in aspects of operation and maintenance of the new equipment.