| PACK: 1. The complete assembly of filters and spinneret through which polymer flows during extrusion. 2. A unit of weight for wool, 240 pounds. PACKAGE BUILD: A general term that applies to the shape, angles, tension, etc., of a yarn package during winding. Package build affects performance during subsequent processing. PACKAGE DYEING: See DYEING, Yarn Dyeing. |  |

PACK LIFE: The time during which a pack assembly can remain in use and produce good- quality yarn.

PADDING: The application of a liquor or paste to textiles either by passing the material through a bath and subsequently through squeeze rollers, or by passing it between squeeze rollers, the bottom one of which carries the liquor or paste.

PADDLE DYEING MACHINE: A machine used for dyeing garments, hosiery, and other small pieces that are packaged loosely in mesh bags. The unit consists of an open tank and revolving paddles that circulate the bags in the dyebath.

PAD DYEING: See DYEING.

PAISLEY: A drop-shaped pattern that is extremely popular for men’s ties and womenswear.

PANELS (HOSIERY): Knitted panels used for testing purposes.

PANNÉ SATIN: A satin fabric with an unusually high luster because of the application of very heavy roll pressure in finishing. Panné satin is made of silk or one of the manufactured fibers.

PANNÉ VELVET: Velvet of silk or a manufactured fiber, with a finish in which the pile is flattened and laid in one direction. Panné velvet is a lustrous, lightweight fabric.

PAPERMAKER’S FELT: Formerly, a heavy, wide, coarse, worsted or woolen fabric that was threaded between the rolls of the papermaking machine to form an endless conveyer belt for pulp or wet paper in its passage through the machine. These products are now also made of various constructions, woven and nonwoven, of manufactured fibers and monofilaments.

PARA: A chemical prefix, usually abbreviated p, indicating that two substituents on a benzene ring are separated by two carbon atoms.

PARALLELING: The process of aligning fibers to produce a more uniform, smoother, stronger yarn.

PARTIALLY ORIENTED STAPLE: Staple fibers cut from tow that has been drawn less than normal so that only partial longitudinal orientation of the polymer molecules exists.

PARTIALLY ORIENTED YARNS (POY): Filament yarns in which the draw ratio is less than normal resulting in only partial longitudinal orientation of the polymer molecules.

PART RUN: A partially filled bobbin that occurs when an end breaks before the completion of a doff cycle. The total weight of yarn normally wound during a cycle is not obtained on the bobbin at the break position. The number of part runs is used as a measure of spinning performance.

PATTERN: 1. An arrangement of form; a design or decoration such as the design of woven or printed fabrics. 2. A model, guide, or plan used in making things, such as a garment pattern.

PATTERN WHEEL: In a circular-knitting machine, a slotted device for controlling individual needles so that patterns can be knit in the fabric.

PBI: See POLYBENZIMIDAZOLE FIBER. PEARL: See PURL, 2.

PEAU DE SOIE: A heavyweight, soft satin of silk or manufactured fiber with a fine cross rib and a dull luster. The term is French for “skin of silk.”

PEBBLE-WEAVE FABRIC: A fabric with an irregular or rough surface texture formed by either a special weave or by the use of highly twisted yarns that shrink when they are wet.

PECE: Post-chlorinated vinyl chloride polymer. The post-chlorination process increases chlorine content form 57% to 64%. The resulting polymer is soluble in acetone and can be wet spun.

PEEL ADHESION: The force required to delaminate a structure or to separate the surface layer from a substrate. Peel adhesion is the usual measure of the strength of the bond between fiber reinforcements and rubber in tires and other mechanical rubber goods.

PEELER: In beaming, a defect caused by a portion of an end sticking or remaining on the beam, causing the filament to strip back or peel until it is broken. Although they are often associated with ringers, peelers are not necessarily defects that will circle the beams.

PEGGING: A finishing process for velveteen consisting of applying friction with blocks of wood or soapstone to impart a gloss or sheen to the fabric.

PEGGING JETS: A technique for freeing a plugged hole in a spinneret by rubbing the face with a piece of wood. Use of the technique has been discouraged because of damage to the spinneret.

PELERINE: A device for transferring stitches from the cylinder to the dial or vice versa on a circular-knitting machine.

PERCALE: A closely woven, plain-weave, spun fabric used for dress goods and sheeting, generally 80 x 80 threads per inch or better.

PERCHING: Inspection of cloth for defects while it is run over a roller.

PERMANENT DEFORMATION: The change in length of a sample after removal of an applied tensile stress and after the removal of any internal strain (e.g., by boiling off the sample and allowing it to dry without tension). The permanent deformation is expressed as a percentage of the original sample length.

PERMANENT FINISH: A term for various finishing treatments, chemical and/or mechanical, applied to fabric so that it will retain certain properties, such as glaze of chintz, crispness of organdy, smoothness of cotton table damask, and crease, crush, and shrinkage resistance of many apparel fabrics during the normal period of wear and laundering.

PERMANENT GROWTH: See SECONDARY CREEP.

PERMANENT PRESS: See DURABLE PRESS.

PERMANENT SET: See SECONDARY CREEP.

PERMEABILITY: The state or quality of being penetrable by fluids or gases. PERMITTIVITY: See DIELECTRIC CONSTANT.

pH: Value indicating the acidity or alkalinity of a material. It is the negative logarithm of the effective hydrogen ion concentration. A pH of 7.0 is neutral; less than 7.0 is acidic; and more than 7.0 is basic.

PHASES BEAM: A beam on which each of the ends is wound from the same depth of each of the bobbins on the creel. Phased beams are prepared when yarn properties vary from the inside to the outside of the bobbins in order to prevent warp streakiness in the finished fabric.

PHASE-SEPARATION SPINNING: See SPINNING, 2.

PHENOLIC: 1. A resin or plastic made by the condensation of a phenol with an aldehyde and used particularly in coatings and adhesives. 2. Containing or pertaining to phenol.

PHENYL: A chemical radical, (C6H5-), derived from benzene. It is the basis of many aromatic derivatives.

PHOSPHORESCENCE: Emission of light that persists for a noticeable time after the removal of the excitation source.

PHOSPHORIC ACID: An inorganic acid having the formula (H3PO4). PHOTOGRAPHIC PRINTING: See PRINTING.

PHTHALIC ACID: An organic acid obtained by oxidation of various benzene derivatives and having two adjacent (ortho) acid (COOH) groups on the benzene ring.

PICK: A single filling thread carried by one trip of the weft-insertion device across the loom. The picks interlace with the warp ends to form a woven fabric. (Also see FILLING.)

PICK COUNT: The number of filling yarns per inch or per centimeter of fabric.

PICK COUNTER: 1. A mechanical device that counts the picks as they are inserted during weaving. 2. A mechanical device equipped with a magnifying glass used for counting picks (and/or ends) in finished fabrics.

PICKER: 1. A machine that opens staple fiber and forms a lap for the carding process used in the production of spun yarns. 2. That part of the picking mechanism of the loom that actually strikes the shuttle.

PICKER LAP: A continuous, considerably compressed sheet of staple that is delivered by the picker and wound into a cylindrical package. It is used to feed the card.

PICKER STICKS: The two sticks that throw the shuttles from box to box at each end of the raceplate of the loom.

PICKING: 1. A process that continues the opening and cleaning of staple and forms a continuous fiber sheet (or lap), which is delivered to the card. 2. The operation of passing the filling through the warp shed during weaving.

PICK-OUT MARK: A fillingwise band or bar characterized by a chafed or fuzzy appearance due to pulled-out picks.

PICOT: 1. A small loop woven on the edge of ribbon, or a purl on lace. A picot edge may also be produced by a hemstitching machine. 2. A run-resistant loop usually found at the top of hosiery.

PIECE: A standard length of a fabric, such as 40, 60, 80, or 100 yards. PIECE DYEING: See DYEING.

PIECING: The joining of two or more ends of sliver, roving, yarn, etc.

PIGMENT: An insoluble, finely divided substance, such as titanium dioxide, used to deluster or color fibers, yarns, or fabrics.

PIGMENTED YARN: A dull or colored yarn spun from a solution or melt containing a pigment. (Also see DYEING, Mass-Colored.)

PIGMENT PRINTING: See PRINTING.

PILE: 1. A fabric effect formed by introducing tufts, loops, or other erect yarns on all or part of the fabric surface. Types are warp, filling, and knotted pile, or loops produced by weaving an extra set of yarns over wires that are then drawn out of the fabric. Plain wires leave uncut loops; wires with a razor-like blade produce a cut-pile surface. Pile fabric can also be made by producing a double-cloth structure woven face to face, with an extra set of yarn interlacing with each cloth alternately. The two fabrics are cut apart by a traversing knife, producing two fabrics with a cut-pile face. Pile should not be confused with nap. Corduroys are another type of pile fabric, where long filling floats on the surface are slit, causing the pile to stand erect. 2. In carpets, pile refers to the face yarn, as opposed to backing or support yarn. Pile carpets are produced by either tufting or weaving. (Also see CUT PILE and LOOP PILE.)

PILE CRUSH: The bending of upholstery or carpet pile that results from heavy use or the pressure of furniture.

PILE WEAVE: A weave in which an additional set of yarns, either warp or filling, floats on the surface and is cut to form the pile. Turkish toweling is a pile-

weave fabric with uncut loops on one or both sides.

PILE WIRE: A metal rod over which yarn is woven to generate a pile fabric.

PILL: A small accumulation of fibers on the surface of a fabric. Pills, which can develop during wear, are held to the fabric by an

entanglement with surface fibers of the material, and are usually composed of the same fibers from which the fabric is made.

PILLING: The tendency of fibers to work loose from a fabric surface and form balled or matted particles of fiber that remain attached to the surface of the fabric.

| PILOT: A woolen cloth generally made in navy blue and used for seamen’s coats. It is usually a heavily milled 2/2 twill with a raised, brushed finish. PIN DRAFTING: Any system of drafting in which the orientation of the fibers relative to one another in the sliver is controlled by pins. |  |

PINHOLE: A very small hole in hosiery or fabric.

PINION BARRÉ: A fine, fillingwise fabric defect appearing as one or two pick bars in an even repeat. It is caused by a faulty loom pinion.

PIN MARK: See CLIP MARK.

PINNING: See PIN DRAFTING.

PINSONIC® THERMAL JOINING MACHINE: A rapid, efficient quilting machine that uses ultrasonic energy rather than conventional stitching techniques to join layers of thermoplastic materials. The ultrasonic vibrations generate localized heat by causing one piece of material to vibrate against the other at extremely high speed, resulting in a series of welds that fuse the materials together.

PIQUÉ: 1. A medium weight to heavyweight fabric with raised cords in the warp direction. 2. A double-knit fabric construction knit on multifeed circular machines.

PIRN: 1. A wood, paper, or plastic support, cylindrical or slightly tapered, with or without a conical base, on which yarn is wound. 2. The double-tapered take-up yarn package from drawtwisting of nylon, polyester, and other melt spun yarns.

PIRN BARRÉ: A fabric defect consisting of crosswise bars caused by unequal shrinkage of the filling yarn from different points on the original yarn package.

PITCH: In pile floor covering, the average number of pile ends per inch in the fillingwise direction.

PLAIN-KNIT FABRIC: See FLAT-KNIT FABRIC.

PLAIN WEAVE: One of the three fundamental weaves: plain, satin, and twill. Each filling yarn passes successively over and under each warp yarn, alternating each row.

PLAITING: See BRAIDING.

PLASTIC: A high polymer, usually combined with other ingredients such as curatives, plasticizers, and fillers. It can be molded under heat and pressure and then machined accurately in its hardened state. General term for a wide range of substances.

PLASTICIZER: 1. A chemical added to polymers and resins to impart flexibility, workability, or stretchability. 2. A bonding agent that acts by solvent action on fibers.

PLATED: 1. A term to describe a fabric that is produced from two yarns of different colors, characters, or qualities, one of which appears on the face and the other on the back. 2. A term to describe a yarn covered by another yarn.

PLEAT: Three layers of fabric involving two folds or reversals of direction; the back fold may be replaced by a seam.

PLIED YARN: A yarn formed by twisting together two or more singles yarns in one operation. PLIED YARN DUCK: See DUCK.

PLISSÉ: A cotton, rayon, or acetate fabric with a crinkled or pleated effect. The effect is produced by treating the fabric, in a striped or spotted motif, with a caustic-soda solution which shrinks parts of the goods.

PLUCKING: A condition found at the feed roll and lickerin section of the card when larger than normal clusters of fiber are pulled from the lap by the lickerin. This situation is normally caused by uneven laps or the inability of the feed rolls to hold the lap sheet while small clusters of fibers are being pulled from the lap by the lickerin. Plucking inevitably produces flaky webs.

PLUGGING VALUE: In the manufacture of acetate fibers, a measure of filterability. It is the weight of solids in an acetate dope that can be passed through a fixed area of filter before the filter becomes plugged. It is expressed as weight of solids per square unit of filter area, e.g., g/cm2.

PLUSH: A term describing a cut-pile carpet in which the pile yarns are only slightly twisted, dense, and very evenly sheared. A plush carpet has the look of a solid, flat velvet surface. Similar pile constructions are also used in upholstery fabric.

PLY: 1. The number of singles yarns twisted together to form a plied yarn, or the number of plied yarns twisted together to form cord. 2. An individual yarn in a plied yarn or cord. 3. One of a number of layers of fabric (ASTM). 4. The number of layers of fabric, as in a shirt collar, or of cord in a tire.

PLYFIL®: A proprietary system of making two-fold long-and-short staple yarns by using ultrahigh drafting. The slightly twisted ends produced are not useable yarns but are well suited for subsequent processing, i.e., twisting.

PLYING: Twisting together two or more singles yarns or ply yarns to form, respectively, ply yarn or cord.

PLY TWISTING: See PLYING.

POINT BONDING: See BONDING, 2.

POLYAMIDE: A synthetic polymer and the fibers made from it in which the simple chemical compounds used for its production are linked together by amide linkages (-NH-CO-). (Also see NYLON FIBER.)

POLYARYLATE: High-temperature-resistant aromatic polyesters from bisphenols.

POLYBENZIMIDAZOLE FIBER (PBI): A manufactured fiber in which the fiber-forming substance is a long chain aromatic polymer having recurrent imidazole groups as an integral part of the polymer chain. (FTC definition). The polymer is made from tetraaminobiphenyl and diphenyl isophthalate and is dry spun from a dope with dimethylacetamide as a solvent.

CHARACTERISTICS: A high-performance fiber with high chemical resistance that does not burn in air. It has no melting point and does not drip when exposed to flame. The fiber and fabrics from PBI retain their flexibility, dimensional stability, and significant strength without embrittlement even when exposed to flame or extreme heat. The fiber emits little smoke in extreme conditions. It processes well on conventional textile equipment, having processing characteristics similar to polyester. It can be used in 100% form or blended with other fibers. It has a high moisture regain and low modulus with comfort properties similar to cotton. The natural color of PBI is a gold-khaki shade, but it can be dyed to almost any medium to dark shade with conventional basic dyes.

END USES: With excellent thermal, flame, and chemical resistance, combined with good comfort properties, PBI is a good fiber for many critical uses including: firefighter’s protective apparel, aluminized proximity gear, industrial apparel such as pants, shirts and underwear, protective gloves, welder’s apparel, aircraft fire-blocking layers, aircraft wall fabrics, rocket motor insulation, race car driver’s apparel, and braided packings among others.

POLYBLENDS: See BICONSTITUENT FIBER.

POLYCHLAL FIBER: A manufactured, bicomponent fiber of polyvinyl alcohol and polyvinyl chloride. Some vinyl chloride is grafted to the polyvinyl alcohol (Japanese Chemical Fibers Association definition). The fiber is emulsion spun into tow and staple.

CHARACTERISTICS: Polychlal fibers have a soft, lamb’s wool-like hand and moderate moisture regain. The fibers are also characterized by high flame resistance and high abrasion resistance.

END USES: Polychlal fibers are suitable for end uses such as children’s sleepwear, blankets, carpets, curtains, bedding, upholstery, nonwovens, and papermaking.

POLYESTER FIBER: A manufactured fiber in which the fiber-forming substance is any long chain synthetic polymer composed of at least 85% by weight of an ester of dihydric alcohol and terephthalic acid (FTC definition). The polymer is produced by the reaction of ethylene glycol and terephthalic acid or its derivatives. Fiber forms produced are filament, staple, and tow. The process of production resembles that of nylon. Polymerization is accomplished at a high temperature, using a vacuum by one of two methods. (1) The glycol

and a terephthalate ester react to form a polymer chain, releasing methanol; or (2) the glycol and terephthalic acid react directly to form the polymer with water as the by-product. As with nylon, the filaments are spun in a melt-spinning process, then stretched several times their original length, which orients the long chain molecules and gives the fiber strength.

CHARACTERISTICS: Polyester fibers have high strength and are resistant to shrinking and stretching. Fabrics are quick drying and tend to have wrinkle resistance and crease retention, wet and dry. Polyester is used alone and in blends. It has been one of the first fibers to be developed in fabrics with durable-press features.

END USES: Polyester is widely used in many types of apparel fabrics such as textured knits and wovens, durable-press blend fabrics, shirtings, dress goods, rainwear, worsted-blend summer suitings, sleepwear, underwear, bloused, and lingerie. It is also used extensively in floor coverings and for tire cord and other industrial uses such as sewing thread. Polyester fiberfill is used in filled items such as quilted jackets, comforters, pillows, furniture cushions, and sleeping bags.

POLYETHERETHERKETONE FIBER (PEEK): A manufactured fiber from polyetheretherketone polymer with high temperature and chemical resistance used in composites as a matrix material and in other industrial applications.

POLYETHERIMIDE FIBER (PEI): A manufactured fiber spun from polyetherimide polymer having high temperature resistance, excellent processibility, and toughness. Used for matrix materials in composites and in other industrial applications.

POLYETHERSULFONE FIBER (PES): High molecular weight fibers from polymers containing sulfone (-SO2-) groups and aromatic nuclei. They demonstrate high thermal stability and chemical inertness.

POLYETHYLENE FIBER: A manufactured fiber made of polyethylene, often in monofilament form as well as continuous filament yarns and staple. Ethylene is polymerized at high pressures and the resulting polymer is melt spun and cold drawn. It may also be dry-spun from xylene solution.

CHARACTERISTICS: Polyethylene fibers have a low specific gravity, extremely low moisture regain, the same tensile strength wet and dry, and are resistant to attack by mildew and insects. These qualities have made polyethylene fiber suitable for industrial applications, geotextiles, outdoor furniture, and similar applications. Polyethylene fiber does not dye, and in most cases, it is colored by the addition of pigments and dyes to the material prior to spinning. It has a low melting point, a property that has restricted its use in apparel.

POLYIMIDE FIBER: Fully imidized, manufactured fiber formed from the condensation polymer of an aromatic dianhydride and an aromatic diisocyanate. The fiber is produced by dry spinning. It is a high-shrinkage fiber used in the formation of mechanically stable nonwoven fabrics. These fabrics are made without binders or resins; bonding apparently results from the local temperature and pressure that develop during shrinkage.

POLYMER: A high molecular weight, chain-like structure from which manufactured fibers are derived; produced by linking together molecular units called monomers.

POLYMERIZATION: A chemical reaction wherein small molecules combine to form much larger molecules. (Also see ADDITION POLYMERIZATION and CONDENSATION POLYMERIZATION.)

POLYMERIZE: To undergo polymerization. To react molecules resulting in their combining and forming relatively long-chain, large molecules.

POLYNOSIC FIBER: A high-wet-modulus rayon staple having a microfibrillar structure of fibers. The molecular chain length of the cellulose forming the fiber is about twice as long as in conventional rayon.

POLYOLEFIN FIBER: A fiber produced from a polymerized olefin, such as polypropylene or polyethylene.

POLYOXYAMIDE FIBER: Copolymeric fiber with good comfort properties, particularly high moisture absorption and transfer, and intrinsic softness.

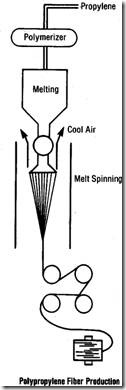

POLYPROPYLENE FIBER: A manufactured, olefin fiber made from polymers or copolymers of propylene. Polypropylene fiber is produced by melt spinning the molten polymer, followed by stretching to orient the fiber molecules.

CHARACTERISTICS: Polypropylene fibers have a number of advantages over polyethylene fibers in the field of textile applications. The degree of crystallinity, 72 to 75%, results in a fiber that is strong and resilient, and does not fibrillate like high-density polyethylene. Polypropylene has a high work of rupture, which indicates a tough fiber, and may be made with tenacities as high as 8.0 to 8.5 grams per denier. The melting point of polypropylene is 165°C, which is low by comparison with nylon or polyester, but is high enough to make it suitable for most textile applications. So light that it actually floats, polypropylene fiber provides greater coverage per pound than any other fiber. It is highly resistant to mechanical abuse and chemical attack.

END USES: Polypropylene fibers are widely used in industrial, carpet, and geotextile applications. They have found important uses in fishing gear, in ropes, and for filter cloths, laundry bags and dye bags. The excellent chemical resistance of polypropylene fiber is of advantage in the filtration and protective clothing fields. Fibrillated polypropylene yarns are widely used in indoor-outdoor carpets. Staple fiber finds application in blankets, pile fabrics, underwear, and industrial fabrics; it

is being developed for carpets, candlewicks, knitted outerwear, hand-knitting yarns, and upholstery.

POLYTETRAFLUOROETHYLENE FIBER (PTFE): Fluorine-containing manufactured fibers characterized by high chemical stability, relative inertness, and high melting point. Made my emulsion spinning, a process that essentially results in fusion of fibrils by passing an emulsion through a capillary, then drawing the resulting fiber. The fiber has a moderate tensile strength and is particularly resistant to the effect of high temperatures and corrosive chemicals. Having very low frictional coefficients, it has a slippery hand. Its principal uses are in packaging and filtration media.

POLYURETHANE FIBER: See SPANDEX FIBER.

POLYVINYL ALCOHOL: A colorless, water-soluble resin made by the hydrolysis of a polyvinyl ester (usually the acetate). Polyvinyl alcohol is used in textile processing as a size, frequently for nylon, and in fiber manufacture as a raw material for the production of polyvinyl alcohol fibers.

POLYVINYL ALCOHOL FIBER: A manufactured textile fiber developed in Japan. It is made by dissolving polyvinyl alcohol in hot water and extruding this solution through a spinneret into a sodium sulfate coagulating bath. In Japan, the fiber is used in apparel, household, and industrial fabrics.

PONGEE: 1. A thin, naturally tan-colored silk fabric with a knotty, rough weave. 2. A cotton fabric made from yarns spun from fine-combed staple and finished with a high luster. This fabric is used for underwear. 3. Fabrics like cotton pongee made from manufactured fibers.

PONTE DI ROMA: A common double-knit fabric construction with a four-feed repeat produced with the dial and cylinder needles in interlock gaiting. The fabric is plain and looks the same on both sides.

POPCORN: 1. A special-effect yarn containing short, thick spots. 2. In polymer manufacture a term used to describe oversize, deformed chip.

POPLIN: A plain-weave fabric of various fibers characterized by a rib effect in the filling

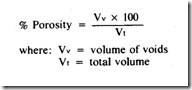

POROSITY: The ratio of the volume of air or void contained within the boundaries of a material to the total volume (solid matter plus air or void) expressed as a percentage.

POTASH: A common name for potassium or potassium compounds. Generally used to mean potassium carbonate.

POT SPINNING: A method formerly used for making viscose rayon. The newly spun yarn was delivered into the center of a rapidly rotating, centrifugal pot, where it received twist and centrifugal force caused it to go to the wall of the pot. The yarn package so formed was called a cake.

POWDER-BONDED NONWOVEN: A manufactured product in which a carded web is produced and treated with a thermoplastic powder that has a melting point less than that of the fiber in the web. The powder is heated to its melting point by through-air and infrared heating or by hot-calendering to effect bonding.

POWER FACTOR: Of an insulating material, the ratio of the power in watts dissipated in a capacitor in which the material is dielectric, to the product of the sinusoidal voltage and current expressed in effective volt-amperes.

POY: See PARTIALLY ORIENTED YARNS.

PRECONDITIONING: Bringing a sample or specimen of textile material to a relatively low moisture content (approximate equilibrium in an atmosphere between 5 and 25% relative humidity) prior to conditioning in a controlled atmosphere of higher humidity for testing. (While preconditioning is frequently translated as predrying, specimens should not be brought to the overdry state.)

PREFORM: 1. Fabrics that have been stacked in multiple layers and bonded with a stitching yarn or by other means. The preform may be cut into a shape for subsequent molding into a composite part. 2. A preshaped nonwoven made by distributing fibers over a screen in the approximate contour of the finished part. 3. A preshaped, three-dimensional reinforcement made via braiding, weaving, or knitting or some combination of these. 4. A formed but not fully consolidated stack of prepreg layers which have the contour of the finished product. 5. The first stage in the production of blow-molded products such as PET bottles.

PREOXIDIZED FIBER: In carbon fiber production, a fiber that results from a relatively low-temperature (200-500°C) heat treatment in the presence of oxygen which converts the precursor fiber, PAN or rayon, to an infusible fiber that is stable to further processing.

PREPREG: Ready-to-mold, reinforcing material, either fiber, fabric, or mat, that is fully impregnated with resin and in some cases, partially cured. Prepregs are then used by fabricators in laying-up and molding composites after which curing is completed.

PRESSLEY INDEX: A measure of the strength of fiber bundles determined under prescribed conditions and expressed in an arbitrary unit, pounds per milligram.

PRESSURE DROP: 1. A decrease in pressure that is caused by friction between a flowing liquid and a constricting container. The pressure drop is increased by a reduction in diameter of the container. 2. The change in pressure across a filter.

PRESSURE DYEING: See DYEING. PRESSURE MARK: See FINGER MARK.

PRETENSION: The relatively low tension applied to remove kinks and crimp when mounting a specimen preparatory to making a test or to a textile processing operation, etc.

PRIMARY BACKING: The material, usually woven or nonwoven polypropylene or jute, into which a carpet is tufted. The primary backing allows the positioning of each tuft and holds the tufts in position during processing, after which a secondary backing (q.v.) is applied to provide dimensional stability.

PRIMARY COLORS: Magenta, yellow, and cyan (red, yellow, blue); these are the subtractive primaries used when mixing dyes, paints, etc., to make all other colors. In the CIE (Commission Internationale de l’Eclairage) system of color measurement, which is the international system most widely used today, the primary color vectors are red, green, and blue-violet. These are additive primaries based on the perception of color of reflected light by the human eye.

PRIMARY CREEP: The recoverable component of creep. (Also see DELAYED DEFORMATION.)

PRINT: A fabric with designs applied by means of dyes or pigments used on engraved rollers, blocks, or screens. (Also see PRINTING.)

PRINT BONDING: See BONDING, 2.

PRINTCLOTH: A mediumweight, plain-weave fabric made of carded yarns, usually cotton or polyester/cotton blends, with counts from 28’s to 42’s. Millions of yards of printcloth are printed annually and other millions are finished as white goods. Large amounts of the goods are also used in the greige for bags, containers, and base fabric for coated materials.

PRINTING: A process for producing a pattern on yarns, warp, fabric, or carpet by any of a large number of printing methods. The color or other treating material, usually in the form of a paste, is deposited onto the fabric which is then usually treated with steam, heat, or chemicals for fixation. Various types of printing are described below: (Also see DYEING.)

1. Methods of Producing Printed Fabrics:

Block Printing: The printing of fabric by hand, using carved wooden or linoleum blocks, as distinguished from printing by screens or roller.

Blotch Printing: A process wherein the background color of a design is printed rather than dyed.

Burn-Out Printing: A method of printing to obtain a raised design on a sheer ground. The design is applied with a special chemical onto a fabric woven of pairs of threads of different fibers. One of the fibers is then destroyed locally by chemical action. Burn-out printing is often used on velvet. The product of this operation is known as a burnt-out print.

Direct Printing: A process wherein the colors for the desired designs are applied directly to the white or dyed cloth, as distinguished from discharge printing and resist printing.

Discharge Printing: In “white” discharge printing, the fabric is piece dyed, then printed with a paste containing a chemical that reduces the dye and hence removes the color where the white designs are desired. In “colored” discharge printing, a color is added to the discharge paste in order to replace the discharged color with another shade.

Duplex Printing: A method of printing a pattern on the face and the back of a fabric with equal clarity.

Etching: See PRINTING, Burn-Out Printing.

Extract Printings: See PRINTING, Discharge Printing.

Heat Transfer Printing: A method of printing fabric of polyester or other thermoplastic fibers with disperse dyes. The design is transferred from preprinted paper onto the fabric by contact heat which causes the dye to sublime. Having no affinity for paper, the dyes are taken up by the fabric. The method is capable of producing well-defined, clear prints.

Ink-Jet Printing: Non-contact printing that uses electrostatic acceleration and deflection of ink particles released by small nozzles to form the pattern.

Photographic Printing: A method of printing from photoengraved rollers. The resultant design looks like a photograph. The designs may also be photographed on a silk screen which is used in screen printing.

Pigment Printing: Printing by the use of pigments instead of dyes. The pigments do not penetrate the fiber but are affixed to the surface of the fabric by means of synthetic resins which are cured after application to make them insoluble. The pigments are insoluble, and application is in the form of water-in-oil or oil-in-water emulsions of pigment pastes and resins. The colors produced are bright and generally fat except to crocking.

Resist Printing: A printing method in which the design can be produced: (1) by applying a resist agent in the desired design, then dyeing the fabric, in which case, the design remains white although the rest of the fabric is dyed; or (2) by including a resist agent and a dye in the paste which is applied for the design, in which case, the color of the design is not affected by subsequent dyeing of the fabric background.

Roller Printing: The application of designs to fabric, using a machine containing a series of engraved metal rollers positioned around a large padded cylinder. Print paste is fed to the rollers and a doctor blade scrapes the paste from the unengraved portion of the roller. Each roller supplies one color to the finished design, and as the fabric passes between the roller and the padded cylinder, each color in the design is applied. Most machines are equipped with eight rollers, although some have sixteen rollers.

Rotary Screen Printing: A combination of roller and screen printing in which a perforated cylindrical screen is used to apply color. Color is forced from the interior of the screen onto the cloth.

Screen Printing: A method of printing similar to using a stencil. The areas of the screen through which the coloring matter is not to pass are filled with a waterproof material. The printing paste which contains the dye is then forced through the untreated portions of the screen onto the fabric below.

Warp Printing: The printing of a design on the sheet of warp yarns before weaving. The filling is either white or a neutral color, and a grayed effect is produced in the areas of the design.

2. Methods of Producing Printed Carpets:

Millitron® Process: A computer-controlled, non-contact spray printing process that allows the production of intricate multicolored designs. Although this process was developed for carpets by Milliken & Co., it can also be used for upholstery, pile fabrics, and other textiles.

Mitter Printing Machine: A rotary carpet printing machine with up to eight stainless-steel mesh screens, and with cylindrical squeegees of moderately large diameter in each rotary screen. The unit has a streaming zone for dye fixation.

Stalwart Printing Machine: A carpet printing machine in which color is applied to the carpet with a neoprene sponge laminated to the pattern. The pattern is cut in a rubber base attached to a wooden roll. It is very

similar to relief printing. Used primarily for overprinting random patterns on dyed carpets. Suitable for shags and plush carpets as well as level loop and needletuft types.

Zimmer Flatbed Printing Machine (Peter Zimmer): A carpet printing machine that uses flat screens and dual, metal-roll squeegees. The squeegees are operated by electromagnets to control the pressure applied. The unit also has a steamer for dye fixation. The Zimmer flatbed machine is normally used for carpets of low to medium pile heights. Very precise designs are possible, but speeds are slower than with rotary screen printers.

Zimmer Rotary Printing Machine (Johannes Zimmer): A three-step,

rotary carpet printing machine consisting of: (1) rotary screens with small

diameter steel-roll squeegees inside, with pressure adjusted

electromagnetically for initial dyestuff application; (2) infrared heating units to fix dyes on the tips of the tufts; and (3) application of low-viscosity print paste, followed by steaming for complete penetration of dyes into tufts.

Zimmer Rotary Printing Machine (Peter Zimmer): A rotary carpet printing machine in which each rotary screen has a slotted squeegee inside to feed print pastes through the screens to the carpet. Pressure of the print paste is adjusted by hydrostatic head adjustments.

PRINT PASTE: The mixture of gum or thickener, dye, and appropriate chemicals used in printing fabrics. Viscosity varies according to the types of printing equipment, the type of cloth, the degree of penetration desired, etc.

PRODUCER-COLORED: See DYEING, Mass-Colored.

PRODUCER-TEXTURED YARNS: Continuous filament yarns that have been bulked during manufacturing by the fiber producer. (Also see TEXTURING.)

PRODUCER TWIST: Small amounts of twist, usually 1/2 turn per inch or less, applied to yarns by the manufacturer to provide cohesion of filaments for further processing.

PROJECTILE LOOM: A shuttleless loom that uses small, bullet-like projectiles to carry the filling yarn through the shed. Fill is inserted from the same side of the loom for each pick. A tucked selvage is formed. (Also see WEFT INSERTION.)

PUCKER: Uneven surface caused by differential shrinkage of the yarns in a fabric or differential shrinkage of the fabric and sewing thread. May be desirable and planned, or undesirable.

PULLED-IN FILLING: An extra thread dragged into the shed with the regular pick and extending only a part of the way across the fabric.

PULP: The end product of cooking wood chips, cotton, or some source of cellulose with water and appropriate chemicals. Used in the manufacture of cellulosic fibers, paper, and other cellulose-based products.

PULTRUSION: The production of continuous lengths of fiber-reinforced advanced composites. Fibers are fed as roving, fabric, or mat, or some combination of these, through a resin impregnation process, to a forming guide, then to a heated die to produce a specific shape, and finally to a puller where the structure is pulled through different forming and cooling stages. Thermoplastic fibers may be substituted for the resin in the pultrusion process

PURL: 1. A knitting stitch that results in horizontal ridges across the fabric. It is made by drawing alternate courses through each side of the fabric. 2. A picot or small loop that edges needlework, lace, or ribbon. Sometimes spelled pearl. (Also see PICOT.) 3. Coiled gold or silver thread used for embroidery.

PYROLYSIS: A chemical change brought about by the action of heat, usually in the absence of a reactive medium. Complex chemical molecules are reduced to simpler chemical units as a result of pyrolysis.