Technical textiles have some characteristics in common with traditional fabrics, but also other specific and different characteristics.

The elements which should be taken into consideration to identify this sector are:

· the raw materials

· the technologies

· the products and the end-uses.

Raw materials

Raw materials for the production of technical textiles are virtually all fibres, with preponderance of man-made fibres.

Technical textiles are still nowadays composed largely by traditional fibres, entirely similar to the raw materials of traditional textiles.

Innovative fibres are going however to be created even more in the future; these fibres have new and special features unobtainable in nature, aimed also at attaining performances which often conflict with each other (e.g. tenacity and softness, durability and degradability after use) which cannot be obtained with traditional fibres.

These high performance fibres (HP fibres) have however a cost considerably higher than traditional fibres.

Their cost is in fact closely related to the exceptional performances imparted by them, consequently their use has to be weighed depending on the real requirements of the single end-use.

Production technologies

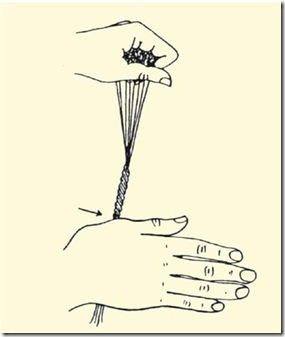

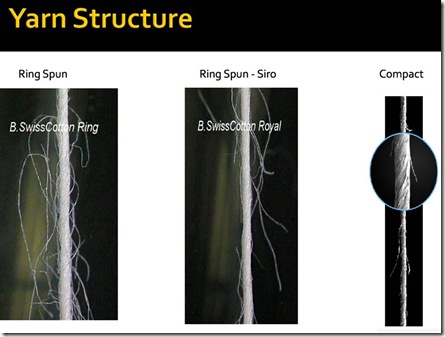

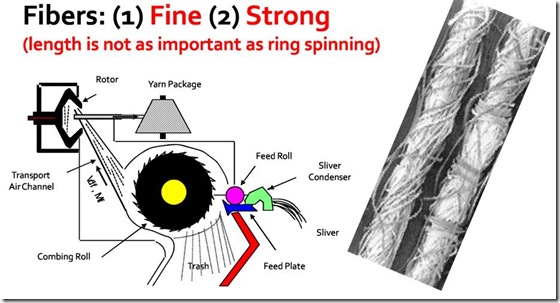

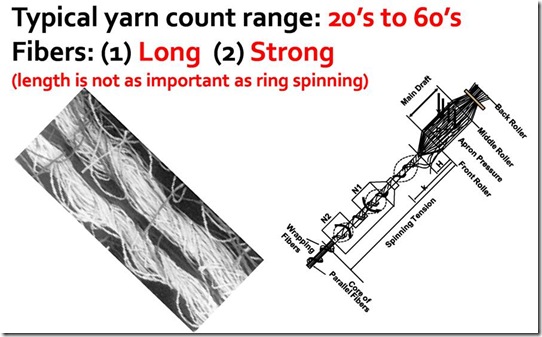

Many of the technologies used for technical textiles are the same as for traditional textiles, from spinning to weaving until making-up, with some adjustments and modifications.

In some cases, however, specific technologies are used, which find exclusively application in technical textiles: f.i. nonwoven production, three-dimensional weaving, braiding, composite formation.

In this regard we point out that nonwovens overlap to a wide extent technical textiles: in fact nonwovens are largely applied in technical textiles, of which they have an important share.

Products and applications

Textiles for technical uses are products which are assessed on the basis of a series of factors which are the same used for assessing traditional textiles, but refer to a different hierarchy of values in terms of importance and of priority.

In reality we are facing two different worlds which however have some overlapping areas and some zones of common interest:

· they use the same kind of raw materials

· they use the same processes, and often the same machines

· they involve the same kind of operators

· in many cases the producers of technical textiles come, more or less directly, from traditional textile enterprises

· many enterprises have in their production both technical and traditional items technical products too have to comply with high aesthetical requirements, while traditional products must have well defined technical performances.

As for traditional textiles, also in the case of technical textiles there is a close link between the economical situation and the consumption volumes, but it differs according to the sector.

For instance, the trend of the transport sector conditions considerably the consumption of textiles for automotive applications (air bags, safety belts, panels and seat covers), just as the trend of avionics conditions the consumption of composites.

In other cases, on the contrary, technical textiles are anyway expanding, e.g. in the sectors related to ecology, health and wellbeing. Here trends remain even under difficult economic situations: in fact some values have become for certain reasons irremissible. The following tables show the fibre consumption for technical textiles in the major countries, the percentages of used fibers, the processes employed, the products and the market shares of each type of technical textile.

Air conditioning, waste recovery, dusty air control, noise abatement, are all essential conditions to optimize product quality and working environment.

Air conditioning, waste recovery, dusty air control, noise abatement, are all essential conditions to optimize product quality and working environment.