Technical approach.

Airjet weaving and airjet spinning use compressed air for pick insertion and yarn consolidation. Most textile companies rely on compressed air in their production, and improving the usage of compressed air will have significant economic benefit to the textile industry. This thesis research is aimed at improving the energy efficiency of compressed air system in the textile industry. Several approaches were considered for reducing energy consumption by the compressed air system, which include compressors, filtration device, distribution network, and end usage. It was found that eliminating leakage and reducing the operating pressure are two of the most cost-effective steps in energy conservation. An ultrasound probe was used for leakage detection and leakage rate estimation in a production environment. A portable instrument has been constructed and a procedure has been developed to determine the lowest pressure level necessary for reliable machine operation in airjet weaving. In contrast to a trial-and-error approach often employed by the industry, this procedure is easy to follow and would not have a broad impact on the productivity and product quality of the plant. The usefulness of the instrument and procedure have been tested and demonstrated in a series of tests conducted in a weaving plant. An analysis on potential savings has also been conducted and simplified calculation procedures are presented.

Cost Reduction Opportunities

Cost reduction opportunities that were explored include re-use of plant air, compressor motor selection, optimizing compressor control schemes, recovering the heat of compression, ensuring that the distribution lines are properly configured and free of leaks, and determining the minimum pressure and flow requirements at the end use equipment. This research shows techniques that can be used to monitor compressor systems, as well as production equipment parameters.

Air Intake Typically, the air being compressed is taken from outside the plant, from air at

ambient temperature and relative humidity. This creates wide varieties of conditions that the compressor has to be adjusted to meet. During the summer months, the compressor is under the greatest load. Air at 100° F with high relative humidity contains a large amount of water that must be taken out. The volumetric flow rate of the inlet must be higher (around 10%) to provide the same SCFM (standard cubic feet per minute) during the summer months as in the winter.

After air is used at its point of operation, it is added to the air already in the plant. This additional volume of air must leave the plant somehow, i.e. open doors, cracks in door and window frames, etc. This air that is being leaked from the plant would have much lower moisture content than the outside air. The air inside the plant will also have a higher density in the summer months due to a lower temperature. The implementation of a system that recovers the conditioned plant air may prove to be useful in reducing air compression costs. The potential energy savings from reusing this already dry air could be significant when the conditions outside the plant are extremely hot and humid. Certain geographic locations would benefit more than others from this reuse, primarily the southeastern US, which has extremely hot and humid summer months.

The installation cost of such a system can be very high for an existing plant, but this option should be considered when a new plant is designed.

Compressor Motor Efficiency Improvements in motor design have led to increased energy efficiency in motor operation. New motors that are suitable for textile manufacturing plants operate at an efficiency of 95%, comparing to motors designed 15 years ago at 90% or less. Over time, the efficiency of the motors may be reduced. It is not uncommon for the efficiency to drop several percentage points after 10 years of operation. High efficiency new motors should be considered when a replacement or major maintenance is needed on the motors.

A case study was performed using a compressor system analysis software program (Compressed Air Efficiency Survey Version 1. 1, by Bay Controls, Inc.). For a typical manufacturing plant consisting of 6000-HP of total compressor capacity, the annual plant savings would be approximately $105,000 for an improvement in motor efficiency from 90% to 95%. The savings can also be estimated for the change in motor efficiency using the following equation:

A return on investment analysis would determine if this would be a cost effective measure. For a plant that operates six 1000-HP compressors, the cost of replacing the old motors with new 95% efficiency motors would be $40,000 each, or $240,000 total. The simple payback period for the initial investment in the motors would be 28 months, from

Compressor Controls

Compressor Controls Centrifugal compressors typically use inlet guide vanes to control the airflow through the compressor. This throttling is beneficial in that the efficiency is not reduced significantly with this method of control. The typical throttle range is down to around 80% of maximum airflow capacity. The highest efficiency is reached when the compressor is operating at 100% capacity. If air is not being used on the demand side as fast as it is being produced, the pressure will rise in the air receiver. A compressor (or multiple compressors) must be throttled to prevent this. All of the compressors should be operating at full capacity except for the one(s) being throttled. If the total compressor output is still greater than the demand after the compressor(s) has been throttled to their limit, air must be exhausted from the system through the blow-off valve. An appropriate control scheme can reduce or eliminate this wasteful blow-off.

A precise compressor control scheme with little pressure variation is desired. The compressor does not need to produce air at a higher pressure than the minimum pressure required for proper plant operation. The typical pressure output by a compressor tends to fluctuate somewhat throughout the day. A good control scheme would minimize these fluctuations.

Heat Recovery During the process of compressing air, a large percentage of the moisture in the air is condensed into water. There is a latent heat associated with this condensation that must be removed by cooling. A sample calculation was used to determine the significance of the latent heat. For a 600-HP compressor with 2000 SCFM output, and given inlet air conditions of 85°F and 90% RH, the total latent heat dissipated is approximately 2 therms/hour. This would indicate that there is little need to attempt to recover the heat.

Distribution Lines The distribution system represents a great source for possible energy

savings. There are pressure drops associated with the flow through all equipment in the line, even in the piping itself. The pressure drop from the point of use and from the output of the compressor should be as low as possible. Equipment should be properly sized to give a minimum pressure drop. End use equipment should be evaluated so that it is using the lowest possible pressure and flow.

The research team followed a procedure for leak detection in textile mills. An ultrasonic detector was acquired and used (UE Systems, model UP9000) that can find leaks in distribution lines and equipment that go unnoticed to the human ear. The ultrasonic detector is able to focus the sensor at a specific point, making it suitable for detecting leaks while machinery is in operation. Escaping air produces the highest noise levels at a frequency around 40 kHz, well beyond the human audible frequency range. The device measures the loudness level at this frequency. Estimates of the amount of air can be obtained from the dB reading.

End Use Compressed air savings at the end use leads to a direct reduction in the amount of compressed air needed for operation. A general rule of thumb is that 1 SCFM of air costs approximately $65 per year in a large manufacturing plant. Savings at end use can be achieved by either reducing the airflow through the equipment, or by lowering the pressure at the point of use. Lowering the pressure at end use will also have a natural flow reduction effect. The flow and pressure reduction must occur without impacting performance. Manufacturing plants should continually monitor production equipment to make sure the minimum pressure and airflow are being used. The effect of optimizing the end use pressure and flow figures can be substantial.

Cost Savings Estimates For Pressure And Flow Reductions

The ability to quantify savings due to changing system parameters is useful for determining the economic feasibility associated with the implementation costs of these system changes. A software program (AirMaster) was used in quantifying system changes. The program allows a plant to quantify the effect of changing system demand profiles, various system parameters, and leakage percentages before they are actually done. The program is designed to justify energy savings due to system changes such as reducing leaks, altering unloading controls, reducing pressure, reducing run time and adjusting/sequencing controls. These energy saving measures can be analyzed individually, or in combinations. A 600-HP centrifugal compressor was profiled which drew 2717 ACFM at full capacity at a pressure of 105 PSI. This analysis includes both a reduction in pressure of 5 PSI (from 110 PSI to 105 PSI) and a leak reduction of 60% of current leaks. Annual savings of over $23,000 in energy costs could be expected by these system changes. This represents a reduction of 12.7% of the original costs.

Simplified equations based on flow and pressure equations were formulated to approximate the economic impact. The total power reduction for both pressure and flow reductions is given by

For the above example, this simple equation shows a saving of 10.9%. It slightly underestimates the plant savings because they do not take into consideration the non-linearity in the relationship between system pressure and power consumption. But its simplicity makes it a useful tool.

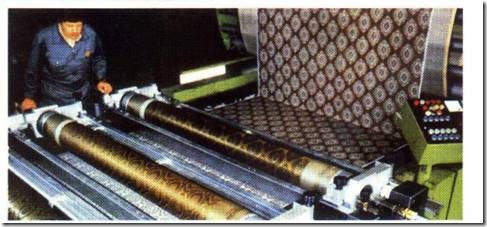

Instrumented Monitoring of Loom Performance Versus Pressure

A portable airflow meter was constructed and used to perform a pressure versus performance analysis on an experimental loom. The research group enlisted the help of a textile manufacturing plant to conduct an experiment on a loom in an environment where production efficiency and quality were of great importance. A pressure regulator was installed in the line to regulate the pressure entering the loom. Figure 1 shows the experimental setup. An experiment was conducted that systematically lowered the pressure of the air entering the loom while weaving quality and efficiency were being closely monitored. Figure 2 shows the relationship between loom filling stops per hour and line pressure at the flowmeter. The acceptable level of filling stops depends on plant, fabric, loom conditions, among others. For our analysis, a typical rate of 1.0 filling stop per hour over a 12-hour shift was used as the threshold for acceptable performance. It is noticed that the loom performance is not significantly affected by air pressure until the pressure drops below a certain level, beyond which a drastic increase in filling stops is observed. In our experiment, unacceptable weaving performance only occurs when the pressure in the flowmeter is lower than 64 PSI, and this represents the minimum pressure required at the experimental loom, a level considerably lower than the manufacturer’s suggested pressure of 80 PSI. In a large manufacturing facility, the total savings resulting from such a pressure and flow reduction could be as much as $440,000 per year for a system operating 500 looms.

By conducting this experiment on selected looms with the most demanding requirement for air pressure (This may require some trial runs), an optimal pressure level can be determined for the entire plant. In contrast to the traditional approach of lowering the system pressure for the entire plant gradually which can compromise the productivity on a broad scale, the approach used by our team would have very limited impact to the productivity of the plant. By minimizing the uncertainty cause by various factors, a lower pressure level can be found by following this procedure. In a traditional plant-wide trial, however, the pressure lowering process is often ended prematurely when some disturbing factors unrelated to the pressure cause some looms to behave abnormally.

IV. Potential application for industry.

IV. Potential application for industry.

Because the wide use of air jet technologies in textile manufacturing, compressed air usage represents a significant part of the overall production cost. This project is relevant to most Georgia textile companies. We are developing easy-to-follow procedures for energy saving in compressed air usage, and increase the awareness of the opportunities of such energy save measures. For example, by reducing air leakage from 12% to 6% (based on plant usage) and lowering system pressure by 16 psi, a saving of about $440,000 annually is expected for a 500 loom plant.

V. Next Steps in Research.

Our research has indicated that there is a great potential for cost savings in the textile industry by effectively manage the compressed air systems. Many companies, including our industry partners, have aggressively pursued various measures to lower the energy consumption, and demonstrated significant savings. This opportunity, however, has often been overlooked by some other companies. We will publicize the economic benefits of proper management of compressed air system through technical presentations and direct interaction with textile companies.

VI. Other Funding Sources/Cost-Share Budget.

Our industry partners have contributed to this project through conducting on-site experiments, meetings with their management and technical personnel, plant tours, and data analysis. The value of this in-kind contribution, mostly in terms of staff time and productivity impact, is approximately $40,000.