by Dr. H. R. Sheikh

Transactions for the sale of yarn between the spinners, weavers and knitters take place subject to the guarantee provided by the spinners that "Barre or Patta" will not appear in the fabric woven or knitted from the yarn.

Isabel B. Wingate [1] defines 'Barre' as a "flaw in fabric consisting of textural or colour bars in the direction of warp or filling which can be caused by imperfections in the yarn or in the construction or finishing of the fabric".

Herbert T. Pratt considers fabric barre as a "continuous visual barred pattern or strippiness parallel to the yarn direction that is caused by physical, optical or dye differences in the yarns or geometric differences in the fabric structure acting either singly or in combination to produce the barred pattern".

According to The Textile Institute [3] "fabric barre comprises of unwanted stripes in the woven fabrics in the direction of the weft. This fault also appears in weft knitted fabrics usually on a multifeeder machine and consists of light or dark course-wise stripes arising from differences in lustre, dye-affinity (unlevel dyeing) in the yarn, yarn spacing or loop length, yarn linear density or defecting plating”.

It is obvious from the foregoing that 'Barre' is a visually conspicuous defect in woven and knitted fabrics, which appears as a result of defects in yarns and in the structure of the fabrics. Such fabrics are unsuitable for subsequent processes of dyeing, printing and finishing and, therefore, unacceptable to wet processors.

The purchase of yarn by weavers and knitters subject to `patta' free guarantee provided by the spinners is therefore a logical demand.

During the conversion of fibres into yarns and yarns into fabrics action and interaction of many causes may give rise to the appearance of 'Barre' some of which are discussed

as follows:

1. Fibres

Approximately 70% of the shading problems in dyed fabrics originate from the presence of immature cotton fibres in yarns spun from pure cotton or blends of cotton with manmade fibres [4]. The maturity of cotton fibre is determined by the degree of cell wall development in relation to the perimeter of the fibre.

During the first half of the growing period the growth of cotton fibre is confined to increase in length only, afterwards thickening of the cell wall takes place.

Successive layers of cellulose are deposited inside the primary wall, giving strength and resilience to the fibre.

This is followed by secondary thickening in which each layer is built up of innumerable minute fibrils of cellulose oriented spirally around the wall. The spirals are inclined with respect to the fibre axis with the direction of inclination reversing at short and irregular intervals. On reaching maturity the bolls burst open, the contents dry up and fibres assume convoluted form. The cross-section of the fibre appears somewhat bean-shaped. Under adverse climatic conditions attack by pests, insects etc. the cell wall development of the fibres is arrested. Such fibres are `immature'. In extreme cases the

degree of thickening of the cell wall may be practically nil in which case the fibres are referred to as `dead'.

In order to prevent the presence of immature or dead fibre in the yarns, tests for the maturity are included in the testing schedule for determination of quality characteristics of cotton in the bales delivered to the spinning mills. The immature fibre content of cotton bales drawn daily for the preparation of cotton mixing should be kept as low as possible - variations in fibre fineness (Micronaire) value between bales should not be more than 0.20.

1.1 Measurement of Maturity of cotton fibres

Since presence of immature fibres in cotton yarn is a major cause of appearance of 'Barre' in fabrics, its measurement is most important. By definition fibre maturity is the degree of cell wall thickening in relation to perimeter which may be expressed as the ratio of the actual cross-sectional area of the wall to the area of the circle with the same perimeter (Fig.No.1).

Fig. 1 Fig. 2

Source: Principles of Textile Testing by J.R. Booth

Director measurement of this ratio is not practically possible because of the microscopical magnitude of the quantities involved. Indirect methods have been developed for routine tests of fibre maturity which are reported below.

1.11 Irrigation with 18% caustic soda

A tuft of parallel and separated fibres is laid on a microscopic slide, covered with another slide and then irrigated with a small quantity of 18% caustic soda solution. Mature fibres become rod-like due to the swelling effect of caustic soda. The condition of the fibres is observed by means of a projection microscope. Dead fibres appear ribbon like even after swelling. Thin-walled fibres lie in between. Method of counting and classification of the fibres as given by Booth [5] is as under:

·All the fibres appearing on the screen are counted.

·The rod-like fibres are counted and classified as normal fibres, N ·The dead fibres are counted and classified, D. maturity ratio is then calculated by using the following formula.

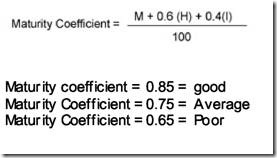

A maturity ratio (M) equal to 0.85 or higher is considered as very good. A modified version of the above method involves counting and classification of 100 fibres into mature (M), half mature (H) and immature (I) categories. Maturity coefficient is then calculated by the following formulae.

1.12 AFIS length & maturity module

Gabriela Peters [6] reports that with AFIS length and maturity module it is for the first time possible to determine not only the length but also the maturity of single fibres and the variation thereof. At the same time the immature fibre content (IFC) and the fibre fineness in mtex and its variations are determined. The light sources and optical sensors of the Uster AFIS create a shadow and scatter image of the fibre. The new technology enables measurement of the circumference and area of the individual fibre. The immature fibre content (IFC) is measured by the apparatus which indicates the percentage of immature fibres in the sample. Lower the immature fibre content, better is the dyeability of fibres.

Experiments conducted by Gabriele Peters [6] have shown that immature fibre content (IFC) is one of the most decisive criterion, affecting the dyeability and the appearance of the fabrics. The spinners should, therefore, consider not only the average micronaire, maturity ratio but also the immature fibre content [IFC] for deciding the composition of the bales in the daily withdrawal programme i.e. lay down of bale sin the blow room.

2. Spinning Process

During the spinning process ineffective or inadequate quality control results in the production of yarn with excessive count, twist variations and hairiness, consequently, 'Barre' appears in the fabrics woven or knitted from such yarns. Yankey [4] estimates that each of these factors contributes about 10% to the problem of 'Barre'. The procedure adopted by the spinners to minimise count and twist variations and hairiness is as follows:

2.1 Excessive Count Variations

Both on-line and off-line techniques are used for control of count variations within permissible limits. On-line devices include Auto-levellers, sliver data and ring data. Auto-levellers are installed on the carding machines and drawing frames. Both short term and long term autolevellers are used on the carding machines. Short term autolevellers are used on the drawing frames. Autolevellers are computer-controlled. The control is fed with required sliver count, nominal draft, delivery speed and levelling signal. If the variations in linear density of the sliver fed exceed permissible limit draft is increased or decreased as required automatically.

Sliver Data monitors and detects quality disturbances round the clock. Limit values can be set for the following quality characteristics:

·Sliver count

· Evenness

· Periodic faults (spectrogram)

· Drafting wave faults ( spectrogram)

· Thick places ( number per 100 m sliver)

If the pre-set values of any of the above listed quality characteristics are exceeded, the sliver data immediately stops the machine and actuates an alarm. The machine producing defective sliver is adjusted and restarted.

Like the sliver data, Ring Data also monitors continuously the production performance of the ring spinning frames as well as the quality of the yarn being produced. Ring data provides a continuous record of end-break frequency enabling detection of spinning positions with high-end-break frequency which can be quickly adjusted or repaired, consequently production of sub-standard quality yarn and appearance of 'Barre' in fabrics in prevented.

2.2 Excessive twist variations

Ring data production reports provide a record of turns per meter facilitating detection of variations in twist at any spinning position and timely remedial action if the variations in twist are excessive.

Similarly Ring Data reports specify number of faulty spindles i.e. spindles with traveller rotational speed variations in excess of -3% or -5% facilitating detection of spindles with slipping tapes or worn out ring flanges. Thus, defective tapes and rings can be replaced, excessive twist variations and appearance of 'Barre' in fabrics, knitted or woven from yarns, prevented.

2.3 Excessive hairiness

Influence of excessive hairiness of yarn is of lesser importance with respect to fabric 'barre' as compared to excessive twist variations [7] . Nevertheless, yarns with high degree of hairiness are not acceptable to the knitters. The spinner should, therefore, control causes of yarn hairiness during the spinning process. Some of the important factors which lead to yarn hairiness are listed as under.

· Failure of the marginal fibres to be fully twisted into the yarn in the balloon.

· Excessive R.H. in the ring shed promoting fibre licking on the delivery rollers of the

ring frame drafting system.

· Worn out or eccentric rings or out of centre spindles causing erratic travellers

rotation. Trapping of fibre fly around the traveller due to failure of the traveller c leaner.

· Yarn balloon lashing on separator plates.

· Trapping of the yarn between the traveller and top of the ring flange.

· Scrapping of the yarn by the traveller.

2.4 Off-Line Techniques

The machines in majority of the spinning mills are not equipped with on-line devices. Consequently, off-line techniques are employed for the control of product quality. The linear density of the blow room laps, slivers, rovings and yarns is tested. Frequency of testing should be adequate and a strict time schedule should be followed to prevent a sub-standard product reaching the client before it is detected by the quality control department. The usual procedure is as follows:

· Take samples

· Test samples

· Interpret results

· Adjust machines [ if the permissible limits in respect of count are exceeded]. · Test samples again.

Similarly yarn is tested for twist per metre to prevent excessive variations of twist. The end-breakage tests per 1000 spindles hours involves observation for a full doff for each count being produced machine-wise. During this test causes of breakage are also noted, rogue spindles, worn out rings and spindles with erratic traveller rotation are detected, slipping tapes are identified and remedial action is taken.

3. Weaving process

Defects of the weaving process may also produce 'Barre' in woven fabrics. Some of these defects are briefly described as under:

3.1 Thick and thin uneven weft

Weft which differs from the normal in some characteristics such as count, colour, lustre, blend or type of mateiral will produce a bar across the full width of the cloth. Mixing of weft pirns should, therefore, be avoided.

3.2 Over or under-picking

Displacement of the cloth fell during weaving resulting from changes in the rate of cloth take-up or from changes in warp tension will produce full width bars due to variable pick spacing repeating at regular intervals throughout the cloth. This defect can be avoided by repairing or replacing faulty components of the loom.

4. Wet processing

'Barre' free grey fabrics received from the knitted and weavers are dyed, printed and finished by pretreatment processes of singeing, desizing, scouring, bleaching, mercerising, application of correct wet processing and colour technology so that beautiful fabrics possessing qualities of handle, drape, print, colour, design and attractive visual appeal are produced as final products. It is customary to develop sample of colour design in the laboratory using datacolor technology, representing the final product. Sample of colour design is ready within 24 hours for approval and transfer to the production department of the textile mill.

In conclusion, it may be stated that a 'barre' - free finished product is always the result of joint efforts by the ginning spinners, knitters, weavers, wet processors and finishers.

Fabric knitted with a combination of yarn samples.

Fabric knitted with a combination of yarn samples.