1.1. dimensioning methods

When ordering aprons and cots, it is very important to give correct dimensions. Different dimensionings between manufacturer and customer cause to conflicts in many cases. It is from time to time practiced, that the dimensions are not the same as required.

Today many mills prefer to keep zero stock. In this case, dimensioning problems bring the mill manager in difficult position. The dimensioning methods presented here are being used by apron and cot manufacturers all over the world.

1.1.1. Dimensioning methods for aprons

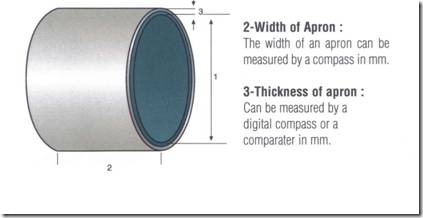

1-Diameter of Apron :

It is the inside diameter of an apron in mm. It can be determined by using a special diameter compass. If this is not available, the apron can be cut open and the length will be measured and the diameter can be calculated by dividing the measured value (mm) to 3,1416.

1.1.2. Dimensioning methods for open aprons

1-Length of apron :

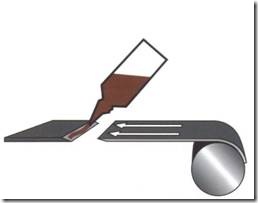

Length of apron: Open aprons will be measured from one end to the other. Care should be taken here, that the skived part of the apron will not be measured. Only the surface which constitutes the glued apron will be measured.

2-3-Apron width and thickness: :

Same system as by the dimensioning will be used.

1.2. information about the usage of aprons

· Before changing aprons, the new aprons should be brought into spinning hall at least 24 hours before mounting, should be taken out from the bundle and the correctness of the dimensions should be controlled. By that way the aprons will be conditioned to the spinning hall and the aprons will relax to their running position. Through that also the correctness of the dimensions can be better controlled.

· Top and bottom aprons should not be changed on the same machine at the same time. The apron manufacturers give a sliding finish to the aprons in order to provide smooth running at the first running stage. Through this treatment, aprons win by the first running period features like not to lap up and easy rotating. But in case when the top and bottom aprons will be changed at the same time, sometimes the perfect drafting of the roving will be hindered.

· Top aprons should be changed according to a plan, but completely all aprons at a time. Top aprons are to be changed all at a time. Single changes on the running machine, since they are not under control, can cause problems.

· When old aprons will be used again, first the good one's must be selected and must be washed out with lukewarm water including detergent. These aprons have to be put on a separate machine. Never use old and new aprons on the same machine! Before changing the aprons completely, the unused spare aprons on the machine should be taken away, because they are affected by the climatic conditions of the spinning hall and therefore will become aged.

· The economical life of an apron is approximately 18 months. Using the aprons more than that period is critical due to quality aspects. If the aprons will be used longer then the economic life, yarn quality parameters such as the Uster thick and thin place values, number of breakages and lap ups will get worse. Same will happen by mechanical components of the drafting system.

· Apron should be taken out from the warehouse according to the principle "first in first out The aprons should be kept in closed places and be protected from light. Under normal conditions, the air contains (03) ozone. Besides that the electrical motors transform (02) to ozone. This concentrated amount of ozone in the air of spinning hall will continously be circulated and affect the aprons negatively. The ozone leads rubber to become aged. For that reason, storing the aprons for a long period of time should be avoided. They should be stored in their original package under low humidity conditions.

1.3. the relation of "X theory" with the aprons

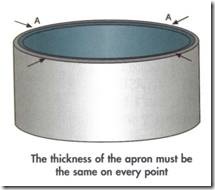

It is well kown that, the "X" distance in the drafting system affects yarn irregularity values. In this "X" distance also the thickness of the apron is included. The variation of apron thickness will therefore influence the yarn irregularity values negatively.

1.4. the influence of the apron thickness variation to the yarn quality (uster) values

The researches have determined that, the aprons have a close relation with yarn breakages and yarn irregularity. In ring spinning, it is very important to keep each individual spinning unit under control. It is impossible to spin a yarn without getting in touch with the apron. Under this point of view, the selection of aprons is extremely important. With the apron type NT-86/S which is developed by ASTEKS with a new

production system,

apron thickness variation is kept under +/-

0,02 mm. What advantages might this devel-

opement bring to our customers? Does it

really have benefits? You will find an answer

to this question in the following topics.

1.4.1. What is the standard for apron thickness variation?

The thickness differences between the outer and inner surface of an apron determines the thickness variation standard. The new concept of Asteks is based on to keep this variation standard by zero. Through a precise apparatus

developed by Asteks, apron thickness and its

variation can be measured with an accuracy of

0,01 mm.

1.6. storage and maintenance of aprons

The aprons should be kept in closed places and be protected from

light. Under normal conditions the air contains (03) ozone. Besides that, the electrical motors transform (02) to ozone. This concentrated amount of ozone in the air of spinning hall will continously be circulated and affect the aprons negatively. The ozone leads rubber to become aged. For that reason, to store the aprons in long period of time should be avoided. They should be stored in their original package under low humidity conditions.

The aprons should never

be put out of their original package onto a shelf. Otherwise, the surface of the aprons will be damaged through light.