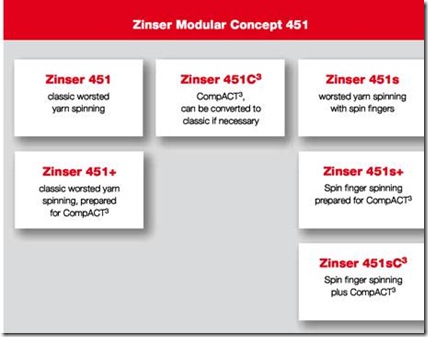

Zinser Modular Concept 451

The most successful ring

spinning technology for

worsted yarns –

CompACT3 and classic

The freedom to develop new opportunities

and markets

Zinser Modular Concept 451 – the most successful

technology in the demanding worsted yarn market

Profit from market-leading Zinser technology Zinser worsted yarn spinning systems by Oerlikon Schlaf-

horst are globally acknowledged as top-quality technological products. This market position is, thanks to our innovative leadership, developed over many years, which enables us

to supply ring spinning solutions for every application. The Modular Concept 451 combines top Zinser technology for premium worsted yarns in a flexible system.

Perfectly suited to today and tomorrow

With the Modular Concept 451, you can exploit the full potential of state-of-the-art worsted yarn ring spinning technology today and in the future. Regardless of whether you produce the finest CompACT3 cashmere yarns for high quality suiting fabrics or coarse acrylic yarns for knitting applications. And the best thing is that you remain as flexible as the textile market itself.

Select the Zinser 451 that meets your requirements

For the ever-changing worsted yarn market, the fact that the machines can be used universally for various qualities and yarn counts is crucially important.

The Zinser Modular Concept 451 offers you a flexible system, customised to your needs.

Option 1: Zinser 451

Top technology for classic worsted

yarn ring spinning

Zinser 451 for classic worsted yarn ring spinning

> The technology for excellent yarn quality and constantly low yarn break rates

> Intelligent design, precise spinning geometry and conscientious processing ensure high productivity and reliability

> Zinser supplies ring spinning systems and auxiliary units as an overall concept from one source – individually customised

> Universal application from fine to coarse

Superior technology for demanding markets Worsted yarns of the highest quality are in great demand among the manufacturers of fine fabrics because they are the key prerequisite for high-quality branded textiles. With the Zinser 451 classic worsted yarn ring spinning machine, you meet the high demands of your customers every time - because the Zinser Modular Concept 451 is based on a

drive concept which guarantees absolute precision and thus a distinctive yarn quality without compromises.

The proven drafting system of the Zinser 451 leads the market. An optimal spinning geometry guarantees excellent yarn quality, low yarn break rates and high productivity, while providing absolute flexibility: for the Zinser 451 ensures impressive results for finest, fine and coarse yarns.

Option 2: Zinser 451+

Future-proof with the

conversion option for CompACT3

Zinser 451+ with the option of retrofitting to CompACT3 worsted yarn spinning

> Maximum flexibility in worsted yarn spinning > Attractive solution with low investment costs

> Retrofitting to compact spinning is quick and easy

> The creel is already prepared for compact spinning

> High economic efficiency and reliability

> High productivity, low yarn break rates and excellent yarn quality

Flexibility and efficiency

Classic production is possible with the ring spinning machine Zinser 451 +, yet every option is kept open for the future.

It is based on the Zinser 451 for classic worsted yarn spinning with the unique Zinser drive and control technology, but can be retrofitted for compact spinning at any time, without difficulty and with little expense. The creel is already prepared for CompACT3.

Spinning mills that produce different yarn qualities and need frequent changes to meet current fashion trends should select the Zinser 451 + when making their investment decisions so that they can remain flexible for future requirements.

Option 3: Zinser 451 C3

Top worsted yarn compact quality for

every metre of yarn –

on the safe side with CompACT3

Zinser 451 C3 for the best compact quality all the way

> Greatest application range - worsted yarn compact spinning for almost all fibre types and blends

> For fine and finest count ranges

> Reliable compacting with the self-cleaning compact unit

> Impressive compact quality with high strength and low hairiness

> Development of new textile products with yarn engineering

> Advantages and cost savings in the downstream process stages

Intelligent, low-maintenance technology

The Zinser CompACT3 system shows its strength in the demanding worsted yarn spinning process in particular. The processing of wool poses special demands which are easily met by the system.

The entire system is self-cleaning. It is immune to wool grease, textile lubricants and finishing agents, thus always ensuring a consistently high level of machine performance with low maintenance times and low costs. It comes as no surprise, therefore, that the Zinser CompACT3 system proves itself every day around the globe.

Top results constantly

The system is also synonymous with outstanding process reliability and a uniformly high yarn quality. With the Zinser CompACT3, you produce compacted and even top-dyed yarns without any problems. A separate negative pressure for the compact unit ensures that this is made possible while maintaining a constantly uniform yarn quality.

The flexibly adjustable tension draft is ideal as well for processing wool fibres. With its help, each wool grade can be adjusted perfectly. You simply adjust the transfer to the different wool finenesses and the wool crimping.

Higher productivity

Naturally, in addition to the excellent yarn quality, the productivity of a system is the most important thing in compact spinning. The Zinser CompACT3 system scores here too. Compared with classic ring spinning systems, an approx. 50 % reduction in yarn breaks can be recorded. As well as this, the twist factor can be reduced by 10 to 15 % with the same strength and elongation. The bottom line is a significant increase in productivity for you.

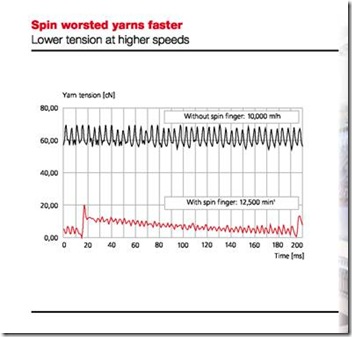

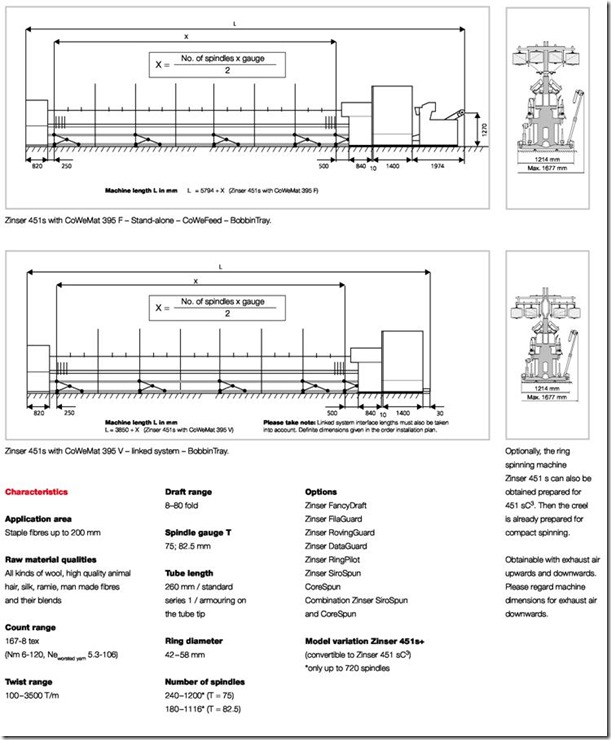

Option 4: Zinser 451s

The speed turbo: spin premium worsted yarns up to

33 % more productively with spin finger technology

Zinser 451s – Spin finger technology for highly productive worsted yarn ring spinning

> Productivity increases of up to 33 % are possible > Reduced balloon, reduced spinning tension

> The spindle speed can be increased significantly

> Alternatively, the number of yarn breaks is reduced at a constant speed

> Model variant Zinser 451 s+ can be optionally converted to CompACT3

Reduced balloon, increased productivity

In spin finger spinning, the yarn balloon is reduced by repeated yarn wrapping around the spin finger. At the same time, the spinning tension is reduced.

The result is more productivity. Compared with classic worsted yarn spinning, the yarn break rate in spin finger spinning is considerably lower in relation to the speed. You either profit from a more favourable yarn break rate - or you can spin much faster at the same yarn break rate.

Outstanding yarn values

With or without spin finger – each Zinser Modular Concept 451 supplies premium worsted yarn all the way. Spin finger technology offers you a significant increase in productivity at the same time as maximum, constant yarn quality.

Option 5: Zinser 451 sC3

The compact turbo: the most productive and

flexible CompACT3 worsted yarn spinning

technology

Zinser 451 sC3 – CompACT3 plus highly productive spin finger technology

> Combines the advantages of both processes

> Spin CompACT3 worsted yarns 10 to 30 % more productively

> More efficient, cost-saving spinning process –

compact advantages even during spinning

> Innovative textile products with yarn engineering

> Built-in flexibility: can be converted to classic spin finger spinning at any time

Benefit twice over: compact spinning and spin finger spinning as the perfect team

In this machine type, the Zinser CompACT3 compact spinning technology is combined with spin finger technology and thus combines the advantages of both processes. Spinning without spinning triangle and spinning with a reduced balloon facilitate significant increases in productivity.

With the Zinser 451 sC3, you spin medium and fine compact wool yarns as well as blends of pure wool and manmade fibres 10 to 30 % more productively. The application range is extensive: all important fibre types and their blends can be processed to all major compact yarn qualities and counts with the Zinser 451 sC3.

Develop new yarns with yarn engineering

The Zinser 451 sC3 offers comprehensive opportunities for new textile products. You can thus satisfy even special

customer requirements and secure a unique position in your market.

Profit from innovation,

set the standards

Rely on full power and maximum

precision with SynchroDrive

Powerful drive technology for peak productivity

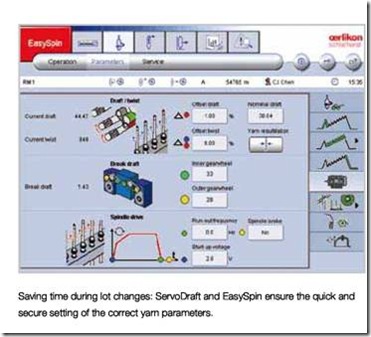

> Yarn count and twist set precisely and easily at the EasySpin touchscreen

> Very short yarn lot changing times, high flexibility > Precise, synchronous running of all spindles

> Higher speeds thanks to high-performance

spindles with the best running properties

> Only at Zinser: SynchroDraft, the double drive for extra-long machines

> Economic technology for lower energy consumption and less wear

Fast lot changing with EasySpin

The controlled drafting system drive ServoDraft permits fast lot changing times and therefore maximum flexibility. Changing the yarn count and twist is carried out easily and quickly at the EasySpin touchscreen of the machine. Twist and draft are infinitely variable.

ServoDraft thinks with you and safeguards your quality

The closed control circuit ensures that the pre-set draft is precisely maintained. ServoDraft checks the set values for plausibility and consistency before they are used by the machine control system. This prevents yarn breaks and faults. Production data can be stored and called up at any time.

Longer service life with OptiMove

Another technological highlight is the separate electric roving guide drive OptiMove. Aprons and top rollers are subject to uniform strain across the entire traversing width with OptiMove. Wear is reduced and service life is increased significantly. The roving guide drive is easily set using inductive proximity switches.

High speeds with Zinser high-performance spindles You can take full advantage of the productivity potential in your machine with Zinser spindles. The precise and highly stable bearing technology in particular ensures absolute running smoothness at top speeds. The spindles are economic thanks to their low energy consumption, require little maintenance and have a long service life.

Double power in the draft system for extra-long ring spinning machines

SynchroDraft is the name of the powerhouse for extra-long ring spinning machines with up to 1200 spindles. The middle bottom rollers are driven from both sides. The drafting system drive is optimally synchronised.

SynchroDrive – synchronous operation of all spindles, uniform twist in yarn

SynchroDrive ensures precise, synchronous running of the spindles, the prerequisite for the lowest possible twist variations in the spun yarn. The unique Zinser multi-motor drive system is performance-optimised for low energy consumption.

Automatically more productive

Doffing with Zinser CoWeMat – gentle

on the yarn, secure, reliable

The most productive doffing technology on the market

> Optimal doffing automation solutions for standalone and linked machines

> Peak efficiency thanks to maximised operating security

> Reduced personnel requirements with CoWeFeed - unsorted tube feeding – only from Zinser

> Fully automated doffing with monitoring - well under 2 minutes

> Top yarn quality thanks to yarn-protecting

transport with pneumatic outer grippers.

> Optimised transport times in combination with the BobbinTray, reserves even for long machines

Secure automation for more productivity

The Zinser CoWeMat has proved itself around the world as the most reliable and economic doffing technology. The doffing speed is clearly set up for operational reliability. Because the most important thing in your spinning mill is how many kilos of yarn are actually produced at the end of the shift: day by day, machine by machine, lot by lot.

Precision from the centre

The frequency-controlled centre drive ensures absolutely synchronous operation of the two doffing bars - for peak, proven operational reliability. Efficiency is significantly increased.

Seamless monitoring, reliable doffing

A light barrier monitors the smooth doffing processes. In the case of a malfunction, the machine stops automatically and signals the interruption.

Yarn-protecting bobbin transport

Pneumatic outer grippers with a wide catching radius grasp the bobbins and tubes securely and precisely at the tube tip. The three-point grip at the tip prevents damage to the yarn body. The outer grippers are also highly suitable for yarns with high tensile strengths in combination with the Zinser spindle cutting technology.

Even faster with CoWeMat 395 F and unsorted tube feeding

The Zinser CoWeMat 395 F relieves you of even more work on stand-alone machines. CoWeFeed can take the unsorted empty tubes and discharge them into the feed container of the ring spinning machine.

CoWeFeed significantly reduces machine operating outlay and eliminates manual tube sorting into boxes.

CoWeFeed is particularly attractive for extra-long machines with 1200 spindles. Here too bobbin removal and the feeding of empty tubes are easily implemented between two doffing operations, as the cycle times are very fast.

A doffing operation can be processed even for 1200 spindles with one tube filling on the CoWeFeed. There are no interruptions due to a lack of tubes.

Zinser CoWeMat 395 V – the combined solution for more economic efficiency

The CoWeMat 395 V is a complete doffing and transport system, suitable for linked systems with all commercial winding machines. The Zinser BobbinTray system transports bobbins and empty tubes without contact, thus ensuring high Zinser yarn quality.

The individually guided, round BobbinTrays and the conveyor belt ensure precise positioning during doffing and a quick, reliable material flow.

Customised: steaming in linked systems

Of course, the Modular Concept 451 ring spinning machines offer the optimal interface in each case for all commercial linked steaming systems. The continuous steaming process between the ring spinning and the winding machine additionally reduces production throughput times.

Premium ring yarn at the touch of a button

Why make spinning complicated when it can

be so simple – with EasySpin

Intuitive operation for constant high yarn quality

> Easy operation through a uniform, transparent and self-explanatory menu structure

> Language-independent menu structure with images and symbols

> Article data archive for easy machine setting > Higher productivity with OptiStep

> Increased traveller service life with OptiStep

> Increased traveller service life and reduced operator input with OptiStart

The right settings – quickly and precisely for optimal spinning results

The Zinser Modular Concept 451 ring spinning machines are so safe and easy to operate that you can rely at all times on the best spinning results. The operator is guided step by step through the setting process on the easy to use EasySpin touchscreen. The clearly structured interface is easy to understand.

The menu structure is uniform and designed to be language-independent with images and symbols – operation is self-explanatory. Your personnel will intuitively understand the system after a rapid learning phase.

Rapid return to production with easy troubleshooting

EasySpin also provides your personnel with intelligent assistance in troubleshooting so that the malfunction is rapidly resolved and production can continue.

Article data archive for rapid access

You gain in flexibility with the EasySpin article data archive – you can store up to 10 different yarn lots per machine and call them up at any time. This reduces set-up times to

a minimum. You can, therefore, produce any yarn lot at any time with identical quality.

Even more flexible with the Zinser Memory Card In addition, any number of lots can be stored on Zinser

Memory Cards and transferred from one Zinser ring spinning machine to another.

Convenient and cost-saving: OptiStart, the automatic ring traveller running-in program

The automatic ring traveller running-in program OptiStart (optional) reliably and precisely executes the individual running-in phases of the ring travellers up to production speed. This significantly increases the traveller service life and relieves your personnel.

Higher speeds with OptiStep

Ensure maximum productivity with OptiStep. The start-up, tip and main spinning speeds can be defined with a 10 point speed curve. This means you can operate far closer to the technological spinning limit across the entire bobbin build and achieve peak production. The traveller service life is also extended. Layer control is also available as an option.

Expand your product range

Unlimited freedom – with high quality

twofold ply yarn, elastic core yarns and

fashionable fancy yarns

Three modules, countless possibilities

> Efficient and versatile yarn production directly on the ring spinning machine

> Top-quality twofold ply yarns – without requiring an additional twisting process

> Core yarns with elastic cores, for comfortable fabrics

> Fancy yarns in all variations by control of draft and twist, mass and twist variations

> All effect parameters can be stored in the article data archive

Spinning and twisting in one operation:

with Zinser SiroSpun

Spin twisted yarn directly at the ring spinning machine - with the ring spinning machine Modular Concept 451 and the SiroSpun option. Technology which is only made possible thanks to outstanding machine precision

In the economic SiroSpun process, two rovings are led in parallel through the drafting system and are only combined after the nip point of the front top and front bottom rollers. A Siro yarn is produced from the twisted single yarns – a twofold ply yarn with twist.

The Zinser Siro yarn is as convincing in further processing as in the finished product – thanks to a round yarn cross-section, outstanding high yarn strength and a smooth yarn surface with a low level of hairiness.

Spin hard and soft core yarns easily with Zinser CoreSpun

Expand your product range with core yarns and thus a wide range of applications – for example fine and at the same time comfortable suiting fabrics. In CoreSpun soft, an elastic core made of continuous filament is covered with the fibre material and provides it with favourable properties: more elasticity and wear comfort. You can also select CoreSpun hard, with a non-elastic core, for more strength in the yarn or you can combine both processes.

Finest, elastic suiting fabrics

By the way: SiroSpun without yarn monitor and CoreSpun soft can be combined. For example for the finest special worsted yarns with an elastic content, for high-quality suiting fabrics.

Yarn effects as required with FancyDraft

Structured materials are a global fashion theme. Each season, new effects are in demand – for example for fine knitware

and in fine outerwear fabrics for men and women. With FancyDraft, Zinser ring spinning machines Modular Concept 451 offer you a convenient and flexible fancy yarn technology with which you can fulfil every customer requirement.

Convenient, precise, versatile

Yarn engineering with FancyDraft uses the unique drive technology of your Zinser 451 for your individual fancy yarn production:

– the electronic drafting system drive ServoDraft – the spindle drive SynchroDrive

– and the EasySpin operator interface.

Combine two set-up options for a thousand and one effects.

You can generate the required effects quickly and easily with FancyDraft.

Option 1: MultiCount – this varies the yarn count by means of specific modification of the main draft.

Option 2: MultiTwist – this varies the twist by specifically changing the delivery speed.

MultiCount and MultiTwist each provide different effects on their own. Infinite effect variations are open to you if you combine MultiCount and MultiTwist.

Save resources, increase productivity

OptiSuction – the intelligent negative pressure

system saves energy wherever possible

Save energy with OptiSuction

> Intelligent control circuit – only produces the

exact amount of negative pressure required

> Optimal adjustment of negative pressure to the article

> Increased efficiency

> Easy set-up of negative pressure value

centrally at the EasySpin touchscreen

> Negative pressure unit for CompACT3, also with energy-optimised OptiSuction technology

Intelligent control circuit saves resources

The controlled single tube suction system of the ring spinning machines Modular Concept 451 always produces the precise negative pressure that is required, saving valuable energy. A control circuit with negative pressure sensor and frequency-controlled motor continuously adapts the negative pressure to the pre-set value for the article.

The energy savings are highest with an empty filter box as the fan speed and negative pressure are the lowest at this time.

Precise setting with EasySpin

Settings can be implemented easily and comfortably at the EasySpin touchscreen. Production is not only more economic, it is also safer as the negative pressure is always optimally adjusted for the respective yarn properties. Constant negative pressure across the entire bobbin build is ensured with this closed control circuit.

OptiSuction also with Zinser CompACT3

The Zinser 451 C3 and Zinser 451 sC3 machines also have a second negative pressure unit for compacting, also with the energy-optimised and controlled OptiSuction system.

Trust is good, control is

better: the Zinser Guard

System

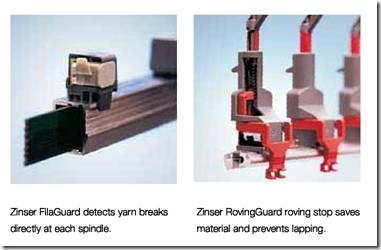

Monitor production online, increase productivity

> Detect and rectify yarn breaks faster > Material savings with roving stop

> Avoidance of machine damage by preventing lapping

> Lower personnel costs thanks to higher spindle assignments

> Optimised productivity across the entire spinning mill

Detect and rectify yarn breaks faster

Increase the productivity of your spinning mill with an optional automated production monitoring system. So that yarn breaks cause the least possible damage.

The electronic eye: FilaGuard

The individual yarn monitor FilaGuard monitors the rotation of the steel ring traveller on each individual spindle and detects each yarn break immediately. Optical signals indicate the specific yarn break, effectively relieving the workload of operating personnel. The problem can be rapidly rectified.

Roving stop RovingGuard prevents material losses and lapping

The automatic roving stop RovingGuard interrupts the roving feed in the area of the drafting system if there is a yarn break. The reaction occurs within milliseconds. Material loss is minimised and dangerous lapping is prevented.

Increase the productivity of your entire spinning mill - with DataGuard and RingPilot

The actual production situation of the ring spinning machine is constantly changing. Numerous influences determine the future quality of the yarn. The yarn break frequency is an indication of the actual production situation. Zinser offers the DataGuard system as an extended process data acquisition system for permanent monitoring of the production process.

DataGuard collects and summarises the information which is then visualised in EasySpin. The data from all the production machines in the spinning mill can be summarised and visualised with the Zinser RingPilot.

The right construction counts

Zinser Modular Concept 451 – developed

for the best worsted yarns in the world

Design advantage for the best spinning results on a continuous basis

> All components produced with maximum precision

> Technologically important components from in-house production in Germany

> Stable construction of machine frame with intermediate stands made of cast iron

> Doffer forces do not affect the machine

> Creel forces do not affect the drafting system

> Precisely centred running of yarn guiding elements with separate guides

High-tech from Germany

You obtain innovative Oerlikon Schlafhorst state-of-the-art technology with the Modular Concept 451 worsted yarn spinning machines. All components are manufactured with the highest possible precision. Technologically important components such as spindles and drafting system components are from our own production in Germany.

Decoupled construction ensures the best running conditions

Doffer forces do not affect the machine. The intermediate stands absorb the creel forces without negatively affecting the drafting system.

Precise manufacturing, precise yarn

The intermediate stands are made from cast iron and therefore form a stable foundation for the machine frame. The cast iron intermediate stands are produced at the same time as the mountings for the yarn guiding element guide units. These parts are therefore produced with excellent fit accuracy, also ensuring that the machine frames are perfectly aligned. This achieves utmost precision for the movement of the yarn guiding elements.

The spindle rails are also manufactured from solid cast iron like the intermediate stands. The vibration-damping properties of cast iron have a positive effect on the running behaviour of the ring spinning machines and therefore on the yarn quality.

Precise spinning geometry for top yarn quality due to separate guidance of the yarn guide elements The yarn guiding element drive is provided by a programme-controlled motor. The bobbin build with winding length, traverse length and displacement can be centrally and precisely specified at the EasySpin touchscreen and can be quickly and easily optimised.

The precise guidance of the yarn guiding elements is supported by precision guides on all intermediate stands. These guide elements are low-maintenance and are characterised by a long service life. The precise position of each individual yarn guiding element is therefore ensured. The spinning tension is kept constant by precisely matched movements, which in turn has a positive effect on the running behaviour of the ring spinning machines.

Profit from the global Oerlikon Schlafhorst

know-how network

We ensure that your investment pays off

Perfect on-site service for profitable machine service life

> Oerlikon Schlafhorst bundles technological know-how along the entire textile process chain - to your advantage

> Worldwide Oerlikon Schlafhorst know-how and service network

> Customised, economic service offers

> Personal consultancy, training and service on request in your mill

> Our engineers speak your language and are familiar with the regional production conditions around the world.

Success through know-how

To enjoy success, you need to keep the entire process in view. Oerlikon Schlafhorst is your strong partner with a process chain competence second to none. Here you can find the right contact for your requirements, whether technical, technological or process-wide, from the fibre via the yarn to the quality package.

Precision technology that provides many years of excellent performance

Take advantage of our customised service offers – our experts are happy to assist you with individual tips on maintenance and care right up to a service contract, because acting with foresight avoids unnecessary machine stoppages and therefore quickly pays for itself.

Technical Data

Zinser 451

Technical Data

Zinser 451 +

Technical Data

Zinser 451 C3

Technical Data

Zinser 451 s und 451 s+

Technical Data

Zinser 451 sC3

Oerlikon Schlafhorst Zweigniederlassung der Oerlikon Textile GmbH & Co. KG Blumenberger Strasse 143–145

41061 Mönchengladbach Germany

Phone: +49 2161 28 0 Fax: +49 2161 28 2645

Internet: http://www.schlafhorst.oerlikontextile.com/ mailto:info.schlafhorst@oerlikon.com