ULTIMATE TENSILE STRENGTH: See TENSIL STRENGTH. ULTRASONIC QUILTING: See PINSONIC® THERMAL JOINING MACHINE.

ULTRAVIOLET DEGRADATION: Weakening or deterioration caused by exposure to ultraviolet rays of sunlight or artificial light.

ULTRAVIOLET RESISTANCE: Ability to retain strength and resist deterioration on exposure to sunlight.

UNCRIMPING ENERGY: See CRIMP ENERGY.

UNDRAWN TOW: See DRAWN TOW.

UNDRAWN YARN: Extruded yarn (filaments), the component molecules of which are substantially unoriented. Undrawn yarn exhibits predominantly plastic flow in the initial stages of stretching and represents an intermediate stage in the production of a manufactured yarn.

UNEVEN DYEING: A fabric dyeing that shows variations in shade resulting from incorrect processing or dyeing methods or from use of faulty materials.

UNEVEN SHRINKAGE: A wavy, warpwise condition in the fabric that prevents it from lying flat on a horizontal surface.

UNEVEN SURFACE: An irregular surface characterized by nonuniformity in the physical configuration of the yarns or fibers making up the surface of the fabric.

UNEVEN YARN: A yarn that varies in diameter to an abnormal degree.

UNFINISHED WORSTED: A worsted fabric with a relatively soft hand and a light nap. UNIDIRECTIONAL FABRIC: A fabric having reinforcing fibers in only one direction.

UNION CLOTH: A term describing a fabric woven from two or more types of yarn. For example, a union cloth may have a cotton warp and a wool filling. (Also see COMBINATION FABRIC.)

UNION DYEING: See DYEING.

UNOPENED STAPLE: Staple fiber in bunches or clusters in the bale in such a condition that it will not process smoothly through carding and subsequent operations in the spun-yarn plant.

UNRELAXED YARN: See RELAXED YARN.

UPDRAFT METIER: A dry spinning machine in which the air flow within the drying cabinet is countercurrent to the yarn path (upward).

UPTWISTER: A machine used for twisting yarns in an upward path from a rotating vertical supply package to a horizontal take-up package. Used for spun yarns and to a small extent for adding twist to some filament yarns.

UPTWISTING: The process of twisting yarn on the uptwister. The yarn to be twisted, which has been wound on a balanced support package, is placed on a revolving spindle. The yarn form the revolving supply package is fed upward through a gathering eye or guide, over a stop motion and a tension bar or bars, through a traversing guide, and onto the revolving collecting package.

URETHANE: The name of a group of organic chemical compounds or resins built from isocyanate, a very reactive material that liberates gas during reaction to produce foams of various types. Two types of compounds that react with isocyanate to form foam are polyesters and polyethers. Polyurethanes are used for foams and in other compounds in fiber form. The polyester variety should not be confused with polyester fibers. (Also see SPANDEX FIBER.)

USTER TESTER: An instrument that provides a continuous measurement of the variation in weight per unit length of sliver, roving, and yarn.

UV ABSORBERS: Polymer additives that absorb light in the UV region or that trap radicals produced in fiber during photooxidation. They provide stabilization against actinic degradation. Some critical applications include geotextiles, recreational surface polymers and fibers, tenting tarpaulins, etc.

V

VARIANT: A manufactured fiber modified in polymer configuration or by additive during manufacture, resulting in a change in the properties of the fiber. Examples are flame-retardant variants, deep-dyeing variants, high-tenacity variants, low-pilling variants, and cotton-blending or wool-blending variants.

VAT DYES: See DYES.

V-BED FLAT-KNITTING MACHINE: A latch-needle weft-knitting machine with two needlebeds at a 90° angle to each other in the form of an inverted V. Each needlebed is at a 45° angle to the horizontal. These machines are used primarily to produce collars, sleeves, sweater strips, and rib trims.

VEGETABLE FIBER: A textile fiber of vegetable origin, such as cotton, kapok, jute, ramie, and flax.

VELOUR: 1. Generally, a soft, closely woven fabric with a short, thick pile, weighting about 10 to 20 ounces per yard and made in a plain or satin weave. Velour is usually made of cotton or wool, or with a cotton warp in wool, silk, or mohair velour. It is also made in blends of spun manufactured fiber and wool. Velours are used for coats, draperies, upholstery, powder puffs, and other pile items. 2. A felt with velvet-like texture used for men’s and women’s hats.

VELVET CARPET: A woven carpet in which the pile ends are lifted over wires that are inserted in the same manner as the filling and that cut the pile as they are withdrawn.

VELVETEEN: A fabric with a low filling pile made by cutting an extra set of filling yarns woven in a float formation and bound to the back of the material at intervals by weaving over and under one or more warp ends.

VELVET FABRIC: A warp-pile woven fabric with short, dense cut pile that produces a rich fabric appearance and soft texture. Two methods are used for weaving velvets. In the double-cloth method, two fabrics are woven face to face with the pile ends interlocking. A reciprocating knife cuts through these pile ends to produce two separate pieces of velvet. In the second method, pile ends are lifted over cutting wires that are inserted with the filling and that are withdrawn to cut the pile. Velvet is produced in a wide range of constructions and types. Originally made of silk, but now also of cotton or manufactured fibers giving fabrics that are sometimes washable. The fabric can be specially finished to make it crush-resistant and water-repellent or it may be embossed or patterned by burn-out printing.

VERTICAL FLAME TEST: See FLAMMABILITY TESTS.

VIBROSCOPE: An instrument for determining the mass per unit length of a fiber.

VINAL FIBER: A manufactured fiber in which the fiber-forming substance is any long chain synthetic polymer composed of at least 50% by weight of vinyl alcohol units and in which the

total of the vinyl alcohol units and any one or more of the various acetal units is at least 85% by weight of the fiber (FTC definition). Vinal fibers show good chemical resistance but soften at comparatively low temperatures. Vinal fibers are used for apparel, industrial goods, and fishnets.

VINYL: A univalent radical, (CH2=CH-), derived from ethylene.

VINYLIDENE CHLORIDE: A chemical material obtained from ethylene, a petroleum product, and from chlorine. It is used for the manufacture of textile monofilaments and film. It is more commonly identified in the U.S. as saran. (Also see SARAN FIBER.)

VINYON FIBER: A manufactured fiber in which the fiber-forming substance is any long chain synthetic polymer composed of at least 85% by weight of vinyl chloride units (FTC definition).

VISCOMETER: A device designed to measure the viscosity (resistance to flow) of the fluid. Many types exist from simple calibrated glass tubes to extensively instrumented, on-line shear viscometers.

VISCOSE PROCESS: 1. One of the methods of producing rayon. (Also see RAYON FIBER). 2. The chemical process used in the manufacture of cellophane. (Also see VISCOSE SOLUTION).

VISCOSE RAYON: One type of rayon. It is produced in far greater quantity than cuprammonium rayon, the other commercial type. (Also see RAYON FIBER.)

VISCOSE SOLUTION: The solution obtained by dissolving cellulose xanthate in caustic soda, from which viscose filaments and cellophane are produced.

VISCOSITY: The internal flow resistance of a fluid. (Also see INTRINSIC VISCOSITY and RELATIVE VISCOSITY.)

VOILE FABRIC: A sheer spun cloth that is lightweight and soft. It is usually made with cylindrical, combed yarn. Voile is used for blouses, children’s wear, draperies, bedspreads, etc.

VOLATILE: Readily vaporized at a relatively low temperature.

VOLATILITY: Property of having a low boiling point or temperature of sublimation at normal pressure. Likewise, having a high vapor pressure at ambient conditions.

VOLUME RESISTIVITY: The ration of the potential gradient parallel to the direction of current flow in a compound to the current density after a specified time of voltage application.

VULCANIZATION: See CURING, 2.

W

WALE: 1. In knit fabrics, a column of loops lying lengthwise in the fabric. The number of wales per inch is a measure of the fineness of the fabric. 2. In woven fabrics, one of a series of ribs, cords, etc., running either warpwise or fillingwise.

WARP: 1. The set of yarn in all woven fabrics, that runs lengthwise and parallel to the selvage and is interwoven with the filling. 2. The sheet of yarns wound together on a beam for the purpose of weaving or warp knitting. (Also see WARP SHEET.)

WARP BEAM: A large spool or flanged cylinder around which the warp threads, or ends, are wound in a uniform and parallel arrangement. (Also see BEAM.)

WARP-DRAWING: See DRAW-WARPING. Warp-drawn fibers may be taken up on packages other than beams.

WARP HOLDING PLACE: See STICKER, 1. WARPING: See BEAMING.

WARP-KNIT FABRIC: A fabric that is knit with the yarns running lengthwise, e.g., tricot, milanese, and Raschel.

WARP KNITTING: See KNITTING, 1.

WARP PILE: The extra set of warp yarns that forms the surface in a double-woven pile fabric, including types such as velvet and velour. Upholstery fabrics such as mohair, plush, and friezé are produced by this method. (Also see PILE and VELVET FABRIC.)

WARP PRINTING: See PRINTING.

WARP SHEET: A sheet comprising up to several thousand ends that are combined to make up the warp during preparation for weaving or warp knitting. (Also see WARP.)

WARP SIZING: See SLASHING.

WARP STREAKS: A fabric fault that shows as bands or streaks running warpwise. Warp streaks should not be confused with reed marks.

WASH-AND-WEAR: A generic term applied to garments that satisfactorily retain their original neat appearance after repeated wear and home laundering with little or no pressing or ironing. A wash-and-wear garment is essentially free from undesirable wrinkles both during wear and after laundering and retains any original pressed-in creases or pleats. The garments should meet normal consumer demands for durability, color, stability, and shrinkage. The performance of a wash-and-wear fabric or garment depends on several factors, including the types and amounts (percentages) of fibers used, the fabric construction, the finishing treatment, the presence of a colored pattern (either woven or printed), and the methods used for washing and drying. These factors determine, in any specific instance, if a fabric or garment’s performance will meet

customer requirements. Variable conditions result in the varying behavior of a specific fabric or garment. Garments are labeled to specify the appropriate care for optimal performance. (Also see EASE-OF-CARE and DURABLE PRESS.)

WASHFASTNESS: The resistance of a dyed fabric to loss of color or change in properties during home or commercial laundering.

WASTE: By-products created in the manufacture of fibers, yarns, and fabrics. WATER IMBIBITION: See IMBIBITION.

WATER-JET LOOM: See JET LOOM.

WATERLESS DYEING: See DYEING, Solvent Dyeing.

WATERPROOF: A term applied to materials that are impermeable to water; waterproof fabrics have had all their pores closed and are also impermeable to air and very uncomfortable.

WATER-REPELLENT: A term applied to fabrics that can shed water but are permeable to air and comfortable to wear. These fabrics are produced by treating the material with a resin, wax, or plastic finish that is not completely permanent.

WAVY CLOTH: See BAGGY CLOTH.

WAVY SELVAGE: See SLACK SELVAGE.

WEAK WEB: A web of fiber that, when being transferred from the card doffer to the calender rolls to form sliver, does not have sufficient strength from fiber cohesion or clinging entanglement to hold itself together while forming a continuous bridge in processing.

WEAK YARN: A yarn that is found to be either below standard breaking specifications or to be weak enough to cause an abnormally high degree of stops in textile processing.

WEAR TEST: A test for fabric wear, abrasion, flexibility, washing, crushing, creasing, etc., in which the fabric is made into a garment, worn for a specific time, then assessed for performance.

WEATHER-OMETER: An instrument used in measuring the weather resistance of textiles. It can simulate various weather conditions such as sunlight, rain, dew, and thermal shock. Weathering is accelerated to the degree that the effects of years of normal use are attained in only a few days.

WEAVE: A system or pattern of intersecting warp and filling yarns. There are three basic two dimensional weaves: plain, twill, and satin. All other weaves are derived from one or more of these types. (Also see PLAIN WEAVE, TWILL WEAVE, and SATIN WEAVE.)

WEAVING: The method or process of interlacing two yarns of similar materials so that they cross each other at right angles to produce woven fabric. The warp yarns, or ends, run lengthwise in the fabric, and the filling threads (weft), or picks, run from side to side. Weaving can be done on a power or handloom or by several hand methods. (Also see LOOM and WOVEN FABRIC.)

WEB: 1. The wide film of fibers that is delivered from the card. 2. A similar product of other web-forming equipment, such as that formed by air deposition and used to make nonwoven fabrics. 3. A term loosely used for lightweight nonwoven fabrics. 4. See WEBBING.

WEBBING: Strong, narrow fabric, closely woven in a variety of weaves and principally used for belts and straps that have to withstand strain (e.g., automobile seat belts, reinforcement of upholstery, suspenders, etc.). Elastic webbing is made with spandex or rubber yarns in part of the warp or filling, or both. (Also see WEB, 2.)

WEFT: See FILLING:

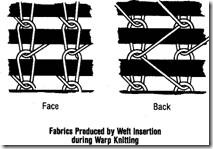

WEFT INSERTION: 1. Any one of the various methods, shuttle, rapier, water jet, etc., for making a pick during weaving. 2. A marriage of warp knitting and weaving brought about by inserting a length of yarn across the width of the knitting elements and fastening the weft yarn between the needle loop and the underlap. (Also see METAP WEAVE-KNIT PROCESS.)

WEFT-KNIT FABRIC: See CIRCULAR-KNIT FABRIC and FLAT-KNIT FABRIC.

WEFT KNITTING: See KNITTING, 2.

WEIGHTED SILK: Silk that has been treated with metallic salts during dyeing and finishing to increase the fabric’s weight and improve its drape. Over-weighting can cause deterioration of the fabric.

WELT: 1. A finished edge on knit goods, especially hosiery. In women’s stockings, it is a wide band knitted from heavier yarn than the leg and folded on itself. 2. A small cord covered with fabric and sewn along a seam or border to add strength. 3. A seam made by folding the fabric double, generally over a cord, and sewing it. 4. A term sometimes used for piqué.

WET FORMING: The production of a nonwoven fabric web from an aqueous suspension of fibers by filtering the short fibers onto a screen belt or perforated drum.

WET-LAID NONWOVEN: Fabric made by the wet-forming process. The short fibers typically have more random orientation in the web and the web has more isotropic properties than carded webs.

WET SPINNING: See SPINNING, 2.

WET STRENGTH: The measurement of the strength of a material when it is saturated with water, normally relative to the dry strength.

| WHIPCORD: A compact woven fabric having a very steep twill on the face of the goods. Whipcord is used in dress woolens, worsteds, or wool blends and in many types of uniforms. WHIPPED CREAM: A type of crepe fabric produced from false-twisttextured polyester yarn. |  |

WHITE GOODS: A broad term describing any goods that have been finished in the white conditions.

WICKING: 1. Cord, loosely woven or braided tape, or tubing to be cut into wicks. 2. Dispersing or spreading of moisture or liquid through a given area, vertically or horizontally; capillary action in material.

WIDTH: A horizontal measurement of a material. In woven fabric, it is the distance from selvage to selvage, and in flat-knit fabric, the distance from edge to edge.

WILLIAMS UNIT: A wet-processing unit for open-width processing of fabric. The fabric passes up and down over rollers in the liquor. The unit is widely used for dyeing, washing, pretreating, and aftertreating.

WILTON CARPET: Woven carpet in which the pile yarns are woven in as an integral part of the carpet, being held in place by the filling, usually made on a loom with a Jacquard head. The pile may be formed by wires and hooks or by weaving between two backings, in which case, the pile ends are cut to form two separate carpets. Wilton carpets are made in two types: (1) cut pile, e.g., tournia, Wilton moquette, plush, and velvet, and (2) loop pile, e.g., Brussels.

WINCH: See BECK.

WINDING: Winding is the process of transferring yarn or thread from one type of package to another to facilitate subsequent processing. The rehandling of yarn is an integral part of the fiber and textile industries. Not only must the package and the yarn itself be suitable for processing on the next machine in the production process, but also other factors such as packing cases, pressure due to winding tension, etc., must be considered. Basically, there are two types of winding machines: precision winders and drum winders. Precision widers, used primarily for filament yarn, have a traverse driven by a cam that is synchronized with the spindle and produce packages with a diamond-patterned wind. Drum winders are used principally for spun yarns; the package is driven by frictional contact between the surface of the package and the drum.

WINDOW PANING: A fabric defect caused by nonuniform yarn. When thin sections of yarn become grouped together, the resultant increase in the transparency of the fabric is called window paning.

WIND RATIO: The number of wraps that an end or ends make in traversing from one side of a wound package to the other side and back to the first side.

WOOD GRAIN: A fabric defect that consists of fillingwise streaks resembling the irregular appearance of wood grain in lumber. Wood grain is usually caused by strained filling in quilling, the tension being more pronounced near the butt of the quill.

WOOD PULP: The cellulosic raw material for viscose rayon and for acetate.

WOOF: See FILLING.

WOOL: The term is usually used for the fleece of sheep, but according to the Textile Fiber Products Identification Act, wool is defined for purposes of labeling as: “The fiber from the fleece of the sheep or lamb or hair of the Angora or Cashmere goat (and may include the so- called specialty fibers from the hair of the camel, alpaca, llama, and vicuna) which has never been reclaimed from any woven or felted wool product.”

Wool is used in a variety of blends in which it is combined with nearly all natural or manufactured fibers. Wool fibers have scales that tend to interlock with each other, binding the fibers together. This process is called felting. In blends, particularly those with manufactured fibers, wool is used to improve the feel or appearance of finished products. Manufactured fibers are sometimes blended with wool to enable the spinning of very fine or loosely twisted yarns with increased tensile strength or to produce ease-of-care properties. Wool can be treated to control shrinkage, to provide resistance to damage by moths, to impart stain-resistance, and to set permanent creases in fabrics.

WOOLEN CARD: A type of roller card used in the woolen spinning system, usually consisting of three cards in tandem: the breaker, intermediate, and finisher sections.

WOOLEN COUNT: The two systems used to determine woolen yarn counts in the U.S. are the run system and the cut system. The run system has a standard of 1600 yards per hand, while the cut system is based on 300 yards per hank.

WOOLEN CUT: A woolen yarn measure. A 1-cut woolen yarn has 300 yards in one pound of yarn.

WOOLEN RUN: A woolen yarn measure. A 1-run woolen yarn has 1,600 yards in one pound of yarn, a 2-run yarn has 3,200 yards, and so on.

WOOLEN SYSTEM: The fundamental system of making yarns for woolen fabrics. In yarns spun on the woolen system, the fibers are not parallel but are crossed in what appears to be a haphazard arrangement. After blending, fibers produced on the woolen system are evenly distributed in carding on two, three, or even four cards. From here, the split web, called roving, goes to the spinning frame. In addition to wool, manufactured fibers, cotton, wastes, and noils can be processed on the woolen system. In general, the fibers used are shorter and more highly crimped than those used on the worsted system and are of the type that can be fulled.

WORKING LOSS: The irrecoverable loss of weight or yardage of a textile material that occurs during a textile process.

WORK RECOVERY: The ratio of recoverable work to the total work required to strain a fiber a specified amount under a given program of strain rate.

WORK-TO-BREAK: See ENERGY-TO-BREAK.

WORSTED: A general term applied to fabrics and yarns from combed wool and wool blends. Worsted yarn is smooth-surfaced, and spun from evenly combed long staple. Worsted fabric is made from worsted yarns and is tightly woven with a smooth, hard surface, Gabardine and serge are examples of worsted fabrics.

WORSTED CARD: A type of roller card user for worsted-system processing. It usually comprises two cards in tandem; the unit has a roller that carries the stock from the first card to the feed-in of the second card.

WORSTED COUNT: A woolen yarn measure. A 1’s worsted yarn has 560 yards in one pound of yarn.

WORSTED SYSTEM: A system of textile processing for manufacturing spun yarns from staple fibers usually over 3 inches in length. The main operations are carding, combing, drafting, and spinning. There are three basic systems of worsted yarn spinning: the Bradford (or English system), the French (Alsatian or Continental system), and the American system.

WOVEN FABRIC: Generally used to refer to fabric composed of two sets of yarns, warp and filling, that is formed weaving, which is the interlacing of these sets of yarns. However, there are woven fabrics in which three sets of yarn are used to give a triaxial weave. In two-dimensional wovens, there may be two or more warps and fillings in a fabric, depending on the complexity of the construction. The manner in which the two sets of yarns are interlaced determines the weave. By using various combinations of the three basic weaves, plain, twill, and satin, it is possible to produce an almost unlimited variety of constructions. Other effects may be obtained by varying the type of yarns, filament or spun, and the fiber types, twist levels, etc.

WRINKLE MARK: See SEAM MARK.

WRINKLE RECOVERY: That property of a fabric that enables it to recover from folding deformations.

WRINKLE RESISTANCE: That property of a fabric that enables it to resist the formation of wrinkles when subjected to a folding deformation. Wrinkle resistance in a fabric is a desirable attribute, but it is not easily measured quantitatively. Wrinkle resistance varies from quite low in many fabrics to very high in resilient fabrics. In order to form a wrinkle, a fabric’s wrinkle resistance must be overcome. The fabric may, however, produce strains and store potential energy that can become evident as wrinkle recovery under suitable conditions.

WRONG COLOR PICK: See MIXED END or FILLING.

WRONG PICK: See MISPICK.