NAINSOOK: A fine, lightweight, plain-weave fabric, usually of combed cotton. The fabric is often mercerized to produce luster and is finished soft. Nainsook is chiefly used for infants’ wear, lingerie, and blouses.

NAP: A downy surface given to a cloth when part of the fiber is raised from the basic structure.

NAPHTHALENE: A solid aromatic hydrocarbon (C10H8) derived from coal tar. Naphthalene is used as moth flakes and as the basis of certain dye components.

NAPHTHOL DYES: See DYES.

NAPPING: A finishing process that raises the surface fibers of a fabric by means of passage over rapidly revolving cylinders covered with metal points or teasel burrs. Outing, flannel, and wool broadcloth derive their downy appearance from this finishing process. Napping is also used for certain knit goods, blankets, and other fabrics with a raised surface.

NARROW FABRIC: Any nonelastic woven fabric, 12 inches or less in width, having a selvage on either side, except ribbon and seam binding.

NATURAL FIBER: A class name for various genera of fibers (including filaments) of: (1) animal (i.e., silk and wool); (2) mineral (i.e., asbestos); or (3) vegetable origin (i.e., cotton, flax, jute, and ramie).

NECKING: 1. The sudden reduction in the diameter of an undrawn manufactured filament when it is stretched. 2. Narrowing in width of a fabric or film when it is stretched.

NEEDLE: 1. A thin, metal device, usually with an eye at one end for inserting the thread, used in sewing to transport the thread. 2. The portion of a knitting machine used for intermeshing the loops. Several types of knitting needles are available. (Also see SPRING NEEDLE and LATCH NEEDLE.) 3. In nonwovens manufacture, a barbed metal device used for punching the web’s own fibers vertically through the web.

NEEDLE BED: Flat metal plate with slots at regular intervals in which the knitting needles slide on the knitting machine.

NEEDLED FABRICS: The product of the needle loom (q.v.). Needled fabrics are used for rug pads, papermaker’s felts, padding, linings, etc.

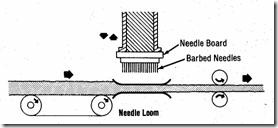

NEEDLE LOOM: A machine for bonding a nonwoven web by mechanically orienting fibers through the web. The process is called needling, or needlepunching. Barbed needles set into a board punch fiber into the batt and withdraw, leaving the fibers entangled. The needles are spaced in a nonaligned

arrangement. By varying the strokes per minute, the advance rate of the batt, the degree of penetration of the needles, and the weight of the batt, a wide range of fabric densities can be made. For additional strength, the fiber web can be needled to a woven, knit, or bonded fabric. Bonding agents may also be used.

NEEDLE LOOP: A loop of yarn drawn through a loop made previously.

NEEDLEPUNCHING: The process of converting batts or webs of loose fibers into a coherent nonwoven fabric on a needle loom (q.v.).

NEEDLE SET-OUT: A term that refers to long periods of time when certain needles are removed from the knitting cycle. The process is used to make sweater cuffs.

NEEDLE SLOT: A groove that houses a needle in the cylinder or dial of a circular-knitting machine or the needle bed of a flat-bed machine.

NEP: A small knot of entangled fibers that usually will not straighten to a parallel position during carding or drafting.

| NET: An open fabric made by knotting the intersections of thread, cord, or wires to form meshes. Net can be made by hand or machine in a variety of mesh sizes and weights matched to varying end uses, i.e., veils, curtains, fish nets, and heavy cargo nets. NET RATE: In a fiber production process the total throughput less waste and inferior or off-grade material. NETTING: The process of knotting threads into meshes that will not ravel. NEUTRON-ABSORBING FIBER: Polyethylene fiber modified with boron used in the nuclear industry for reducing neutron transmission. NINON: A lightweight fabric of silk or manufactured fibers made in a plain weave with an open mesh. Used for curtains and evening wear. NIP: 1. The line or area of contact between two contiguous rollers. 2. A defect in yarn consisting of a thin place. |  |

NOIL: A short fiber that is rejected in the combing process of yarn manufacture.

NONELASTIC WOVEN TAPE: A woven narrow fabric, weighing less than 15 ounces per square yard, made principally of natural and/or manufactured fibers, including monofilaments, but not containing rubber or other similar elastic stands.

NONTORQUE YARN: See TEXTURED YARNS.

NONWOVEN FABRIC: An assembly of textile fibers held together by mechanical interlocking in a random web or mat, by fusing of the fibers (in the case of thermoplastic fibers), or by bonding with a cementing medium such as starch, glue, casein, rubber, latex, or one of the cellulose derivatives or synthetic resins. Initially, the fibers may be oriented in one direction or may be deposited in a random manner. This web or sheet of fibers is bonded together by one of the methods described above. Normally, crimped fibers that range in length from 0.75 to 4.5 inches are used.

Nonwoven fabrics are used for expendable items such as hospitable sheets, napkins, diapers, wiping cloths, as the base material for coated fabrics, and in a variety of other applications. They can also be used for semi-disposable items and for permanent items such as interlinings.

NOVELTY YARN: A yarn produced for a special effect. Novelty yarns are usually uneven in size, varied in color, or modified in appearance by the presence of irregularities deliberately produced during their formation. In singles yarns, the irregularities may be caused by inclusion of knots, loops, curls, slubs, and the like. In plied yarns, the irregularities may be effected by variable delivery of one or more yarn components or by twisting together dissimilar singles yarns. Nub and slub are examples of novelty yarns.

NOVOLOID FIBER: A manufactured fiber containing at least 85% by weight of a cross-linked novolac (FTC definition). Novoloid is flame resistant and nonmelting. Its primary use is in flame-protective garments and products.

NOZZLE: 1. The spout through which something is discharged, i.e., oil in finish application or fibers in web laying. 2. A term sometimes used to refer to spinnerets.

NUB YARN: A novelty yarn containing slubs, beads, or lumps introduced intentionally.

NUCLEATION: A process by which crystals are formed. Crystals form initially on minute traces of foreign substances that act as the nucleus, then grow by external addition.

NUN’S VEILING: A soft, lightweight, plain-weave fabric that usually comes in black and white, nun’s veiling is a rather flimsy, open fabric but always of high quality. It may be made from fine woolen yarn or yarns spun from manufactured fibers such as nylon, acrylic, or polyester.

NYLON FIBER: A manufactured fiber in which the fiber forming substance is any long chain synthetic polyamide having recurring amide groups (-NH-CO-) as an integral part of the polymer chain (FTC definition). The two principal nylons are nylon 66, which is polyhexamethylenedianime adipamide, and nylon 6, which is polycaprolactam. Nylon 66 is so designated because each of the raw materials, hexamethylenediamine and adipic acid, contains six carbon atoms. In the manufacture of nylon 66 fiber, these materials are combined, and the resultant monomer is then polymerized. After polymerization, the material is hardened into a translucent ivory-white solid that is cut or broken into fine chips, flakes, or pellets. This material is melted and extruded through a spinneret while in the molten state to form filaments that solidify quickly as they reach the cooler air. The

filaments are then drawn, or stretched, to orient the long molecules from a random arrangement to an orderly one in the direction of the fiber axis. This drawing process gives elasticity and strength to the filaments.

Nylon 6 was developed in Germany where the raw material, caprolactam, had been known for some time. It was not until nylon 66 was developed in the United States that work was initiated to convert caprolactam into a fiber. The process for nylon 6 is simpler in some respects than that for nylon 66. Although nylon 6 has a much lower melting point than nylon 66 (a disadvantage for a few applications), it has superior resistance to light degradation and better dyeability, elastic recovery, fatigue resistance, and thermal stability.

Two other nylons are: (1) nylon 11, a polyamide made from 11-amino-undecanoic acid; and (2) nylon 610, made from the condensation product of hexamethylenediamine and sebacic acid. Nylon 610 has a lower melting point than nylon 66 and the materials for its manufacture are not as readily available as those for nylon 66. Experimental work has been conducted on other nylons.

CHARACTERISTICS: Although the properties of the nylons described above vary in some respects, they all exhibit excellent strength, flexibility, toughness, elasticity, abrasion resistance, washability, ease of drying, and resistance to attack by insects and microorganisms.

END USES: Nylon is used for apparel such as stockings, lingerie, dresses, bathing suits, foundation garments, and wash-and-wear linings; for floor coverings; for tire cord and industrial fabrics; and in-home furnishings such as upholstery fabrics.

NYTRIL FIBER: A manufactured fiber containing at least 85% by weight of a long chain polymer of vinylidene dinitrile [-CH2-C(CN)2-] and having the vinylidene dinitrile group in no less than every other unit in the polymer chain (FTC definition). Nytril fibers have a low softening point so they are most commonly used in articles that do not require pressing such as sweaters and pile fabrics. They are also blended with wool to improve shrink resistance and shape retention.

OATMEAL: A heavy, soft linen fabric with a pebbled or crepe effect.

OFF-CLIP: See SCALLOPED SELVAGE.

OFF-SQUARE: 1. A term to describe the difference between the percentage of warp crimp and the percentage of filling crimp. 2. A term referring to a fabric in which the number of ends and the number of picks per inch are not equal.

OILCLOTH: Any fabric treated with linseed-oil varnish to make it waterproof. It comes in plain colors and printed designs and is most commonly used for table covers or shelf covering. It has now been widely replaced by plastic coated fabrics.

OILPROOF: A term describing fabrics that are impervious to oil.

OIL-REPELLENT: A term applied to fabrics that have been treated with finishes to make them resistant to oil stains.

OLEFIN FIBER: A manufactured fiber in which the fiber-forming substance is any long chain synthetic polymer composed of at least 85% by weight of ethylene, propylene, or other olefin units. Olefin fibers combine lightweight with high strength and abrasion resistance, and are currently being used in rope, indoor-outdoor carpets, and lawn furniture upholstery. (Also see POLYETHYLENE FIBER and POLYPROPYLENE FIBER.)

OLEOPHILIC: A term describing a substance that has a strong affinity for oils. OLEOPHOBIC: A term describing a substance that does not have a strong affinity for oils. OLIGOMER: A polymer molecule consisting of only a few monomer units.

OMBRÉ: A color effect in which the shade is changeable from light to dark, generally produced by using warp yarns of different tones. Ombré effects may also be produced by printing.

ONDULE: A general term for plain-weave fabrics of silk, cotton, or manufactured fiber having a wavy effect produced by weaving the warp or filling, but usually the filling, in a wavy line. An ondule reed is generally used to produce this effect, often in a leno weave to emphasize the wave. Ondule is used for dress fabrics.

ON-STREAM: The state of having been brought into production. The term is usually used for chemical and metallurgical plants or processes.

OPEN-END SPINNING: A system of spinning based on the concept of introducing twist into the yarn without package rotation by simply rotating the yarn end at a gap or break in the flow of the fibers between the delivery system and the yarn package. Because the twisting element can be compact and the mass of material to be rotated is small, very high twisting speeds can be attained. The

process, in a sense combines the traditional processes of roving and spinning in one operation. Present work is directed toward incorporating the drafting operation into the process by using card sliver as the feedstock. This can facilitate process linking.

OPEN FACE: A fabric defect consisting of an open appearance of the fabric which permits the filling to “grin” through the warp ends in the center portion of the fabric.

OPENING: 1. A preliminary operation in the processing of staple fiber. Opening separates the compressed masses of staple into loose tufts and removes the heavier impurities. 2. An operation in the processing of tow that substantially increases the bulk of the tow by separating the filaments and deregistering the crimp.

OPTICAL BRIGHTENER: 1. A colorless compound that, when applied to fabric, absorbs the ultraviolet radiation in light but emits radiation in the visible spectrum. 2. Fluorescent materials added to polymer in manufactured fiber production that emit light in the visible spectrum, usually with a blue cast.

OPTICAL PROPERTIES: A general term used to refer to the relations of yarn or fibers with light. It includes such parameters as birefringence, refractive index, reflectance, optical density, etc.

OPTIMUM TWIST: In spun yarns, a term to describe the amount of twist that gives the maximum breaking strength or the maximum bulk at strength levels acceptable for weaving or knitting.

ORGANDY: A very thin, transparent, stiff, wiry, muslin fabric used for dresses, neckwear, trimmings, and curtains. Swiss organdy is chemically treated and keeps its crisp, transparent finish through many launderings. Organdy without chemical treatment loses its crispness in laundering and has to be restarched. Organdy crushes or musses but is easily pressed. Shadow organdy has a faint printed design in self-color.

ORGANZA: A stiff, thin, plain weave fabric made of silk, nylon, acrylic, or polyester, organza is used primarily in evening and wedding attire for women.

ORGANIZE YARN: Two or more threads twisted in the singles and then plied in the reverse direction. The number of turns per inch in the singles and in the ply is usually in the range of 10 to 20 turns. Organzine yarn is generally used in the warp.

ORIENTATION: In linear polymeric structures, the degree of parallelism of the chain molecules.

ORIFICE: Generally, an opening. Used specifically to refer to the small holes in spinnerets through which the polymer flows in the manufacture of fibers.

ORTHO: A chemical prefix, usually abbreviated o, signifying that two substituents appear in adjacent positions on a benzene ring.

OSNABURG: A coarse cotton or polyester/cotton fabric, often partly of waste fiber, in a plain weave, medium to heavy in weight, that looks like crash. Unbleached osnaburg is used for grain and cement sacks, and higher grades are used as apparel and household fabrics.

OTTOMAN: Heavy, large, filling rib yarns, often of cotton, wool, or waste yarn, covered in their entirety by silk or manufactured fiber warp yarns, characterized this fabric used for women’s wear and coats.

OUTFLOW QUENCH: Air for cooling extruded polymer that is directed radially outward from a central dispersion device around which the filaments descend.

OVEN-DRY WEIGHT: The constant weight of a specimen obtained by drying in an oven under prescribed conditions of temperature and humidity.

OVERCUT: A staple fiber that is longer than nominal length. Usually, the length is a multiple of 2, 3, or more times the nominal length. An overcut is caused by the failure of filaments to be cut to the desired length during staple manufacture.

OVERLENGTH: See OVERCUT.

OVERSPRAYING: A term sometimes used to describe the application, by spraying, of a fiber lubricant to staple fibers during opening and blending.

OVER-THE-COUNTER: A term that usually refers to direct sales to a retail customer in a store, as opposed to wholesale marketing.

| OXFORD CLOTH: A soft but stout shirting fabric in a modified basket weave with a large filling yarn having no twist woven under and over two single, twisted warp yarns. The fabric is usually made from cotton or polyester/cotton blends and is frequently given a silk like luster finish. OZONE FADING: The fading of a dyed textile material, especially those in blue shades, caused by atmospheric ozone, (O3). |  |