The two main forms of knitting [Fig. 2.1] are:

1. Weft knitting, and

2. Warp knitting

Weft knitting is a method of forming a fabric in which the loops are made in horizontal way from a single yarn and intermeshing of loops take place in a circular or flat form on acrosswise basis. In this method, feeding is one yarn at a time, to a multiplicity of fashion. Most of the weft knitting is of tubular form.

Warp knitting is a method of fabric forming in which the loops are made in a vertical way along the length of the fabric from each warp yarns and intermeshing of loops takes place in a flat form of lengthwise basis. Here, numerous ends of yarns are being fed simultaneously to individual needles placed in a lateral fashion. Most of the knitted structures are flat or open width form.

2.2 TERMS OF KNITTING (Fig. 2.2)

Open Loop: The open loop is one in which the loop forming yarns does not cross at the bottom of the loop.

Closed Loop: In Closed loop, the legs of the loop cross so that the loop closing takes place.

Face Loop: During loop formation, when the new loop emerges through the old loop from back to the face (or front) side, it is called as face loop or weft knit loop.

Back Loop: If the new loop passes from the face side to the back side of old loop, it is called as back loop or weft purl loop.

Technical Face: The side of the knitted fabric that consists all of face or knit loops, is called technical face of the fabric.

Technical Back: The side of the knitted fabric having full of back or purl loops is called needle loop. Normally the reverse side of the technical face is the technical back.

Needle Loop: The upper part of the loop produced by the needle drawing the yarn is called as needle loop.

Sinker Loop: The lower part of the knitted loop is technically referred as sinker loop. It is the connection of two legs belonging to the neighbouring stitches lying laterally.

Course: The series of loops those are connected horizontally, continuously are called as courses. Wales: The series of loops that intermeshes vertically are known as wales.

Stitch density: It is the number of stitches per unit area of a knitted fabric. It determines the area of the fabric.

Over lap: This term refers mainly to warp knitting. Lateral movements of the guide bars on the front side (or hook side) of the needle is called over lap. This movement is normally restricted to one needle space.

Under lap: This term also refers to warp knitting. Lateral movements of the guidebars at the backside of the needles are called under lap. This movement related to the needle space is variable according to the construction of the fabric.

Single Jersey: The weft knitted fabrics produced with one set of needles (both in tubular or flat forms) are called as single jersey or plain knitted fabrics.

Double Jersey: Weft knitted fabrics (tubular/flat) produced with two sets of needles mounted in two needle beds are called as double jersey or double knit fabrics.

2.3 MACHINE DESCRIPTION 2.3.1 Frame

The circular knitting machine consists three major sections viz., yarn supply, knitting elements and fabric take~down. The Fig. 2.3 shows the machine frame, indicating its various parts. The knitting elements such as needles, sinkers, cylinder, cams and feeders are supported at the centre called as knitting zone. Yarn packages are mounted at the overhead creels and yarns are fed to knitting zone through yarn guides, stop motions and feeders. The knitted fabric goes down inside the cylinder towards the centre of the machine, drawn into the take down device and finally collected on a roll winding mechanism. A fabric spreader gradually converts the tubular fabric into a double layer folded fabric by preventing the formation of pleats or creases. At the knitting zone, single knit plain machines are fitted with a cylinder and sinker ring, whereas the double knit machines have cylinder and dial.

2.3.2 Drive

The drive to the knitting machine is simple and direct. The motor imparts rotary motion to the rotating needle beds, such as cylinder and dial and also to the take~down and cloth winding mechanisms.

2.4 NEEDLES (Figs. 2.4 & 2.5)

The needles are the most important stitch forming elements. They are displaced vertically up and down and are mounted into the tricks or cuts of the knitting cylinder. There are three types of needles namely:

1. Latch needle

2. Spring bearded needle, and 3. Compound needle.

2.4.1 Latch Needle

It consists of a hook portion at the top and a latch riveted at certain distance from the needle head. Latch needles are given sliding movements in individual grooves called tricks of the cylinder. The latch swing freely and the stem is a straight portion with a protruding butt. Through the butt the reciprocating movement to the needles is given. The latch needles are self acting, and requires only previous loop on the stem and do not require any outside agency to close the hook. The swinging latch has a cup at its end and is riveted to the stem. Therefore, the total thickness of the needle cannot be reduced and hence these needles are coarser in dimensions than the bearded needles.

2.4.2 Spring Bearded Needle

This needle consists of a top hook curved downwards with a finished tip and the downward continuation is called beard. A small eye or groove is cut in the stem, to receive the point of the needle beard when it is closed. It does not require latch, it is finer in cross section and more number of needles per unit space can be and hence finer machine gauge can be achieved (gauge is the number of needles per inch). It requires additional element to close the needle which is done by a presser. The bearded needle produces superior knitted stitches than the latch needle.

2.4.3 Compound Needle

The speed of the bearded needle machine is restricted by two factors. The presser required to close or open the beard and the length of the beard. The swinging action of the latch may cause damages to fine filament yarn and also latch needles are much expensive to manufacture.

To overcome the above difficulties, compound needles are developed. It consists of a hollow steel tube of fine gauge in which a hook-closing element which is also a steel tube of finer gauge, is inserted. To the tip of the upper element, a needle hook is arranged. It claims the advantages of both bearded and latch types. There is no yarn strain and the movement required to form a loop is half to that of other needles. Both pieces have straight movement instead of swinging. Hence the high speed and high productivity.

2.4.4 Loop Forming Sequence of Latch Needle [Fig. 2.6]

In the running position, the held old loop rests on the top of the open latch. Clearing occurs as the held loop slips of the latch and on to the stem as the needle moves upwards. A downward movement enables the needle hook to engage a new piece of yarn. This is known as feeding. As the needles continue downwards the latch is forced to close under the influence of the held loop. Knock over occurs as the help loop disengages from the needle. Following knock over, the loop pulling occurs and a new knit loop is formed. The needle must return now to the running position to complete the cycle. This is essential, otherwise, cleaning, knock over and loop pulling would not take place. Control of the held loop is usually achieved by the use of sinkers or by the application of the fabric tension.

2.4.5 Loop Forming Sequence of Spring Bearded Needle [Fig. 2.7]

The held loop is initially just below the tip of the beard in the running position. The upward movement by the needle repositions the held loop further down the stem, at which time a new yarn can be fed to the needle i.e., feeding occurs. The needle moves down until the newly fed yarn enters the hook. An auxiliary element known as presser closes off the hook to unable the held loop to leave the needle by deflecting the beard tip into a recess cut in the needle stem. The movement when the held loop is securely located to the outside of the beard is known as the landing position. As the needle continues downwards, knock over and loop pulling take place after which the needle returns to the running position to complete the cycle.

2.4.6 Loop Forming Sequence of Compound Needle [Fig. 2.8]

The held loop is shown on the needle stem in the running position. The hook and tongue elements move upwards to that a new yarn may be presented to the hook and hence feeding occurs. Both elements descend, although at different velocities, which causes the tongue to close-off the hook. Thus the heldloop is free to leave the needle, knock over pulling occurs. The needle now returns to the running to complete the cycle. As the needle returns to its starting position, the hook and tongue elements once again move at different velocities resulting in the opening of the hook.

Sinker is a thin metal plate with action at right angles to and fro between adjoining needles. It may perform one or more of the following functions:

1. Loop formation

2. Holding down, and

3. Knocking over.

The main object of a sinker is to assist the needles in loop formation by sinking or knitting the newly laid yarns into a loop. As its forward edges of catch [c] advantages between the two adjoining needles. This is only for bearded needle where as in case of latch needles and warp knitting loop formation is not the function of sinkers.

It also holds down the loops at a lower level of the needle stems and prevents the old loops from being lifted as the needles raise to clear them for their hooks.

The third function is a knocking over at which the needle passes through the old loop by drawing a new loop.

2.5.1 Sinkers Operation [Fig. 2.10]

1. The held loop is positioned in the throat of the sinker when the sinker moves forward and the needle moves upward for clearing. The held loop is held by the throat and hence its movement along the needle is restricted.

2. The sinker remains at its forward position when the needle attains its clearing position.

3. The sinker retracts when the needle comes down after feeding. At this stage, due to sinkers retraction, fabric or held loop is eased out. Also the sinker belly supported the fabric or held loop and hence its movements along the needle is prevented.

4. Sinker remains in backward position and the needle descends to its lowest position drawing the new loop through the old one.

5. Before the needle ascends, the sinker moves forward to push the knitted fabric a little and to hold the old loop away from the head of the needle and to be in a position to control the fabric.

2.6 CYLINDER (Fig. 2.11)

The cylinder is a steel circular bed having grooves/tricks/cuts on its outer periphery into which the needles are mounted. With reference to the tricks, the needles move vertically up and down by their butt being in contact with the cam track. The number of tricks per inch i.e., number of needles per inch decides the gauge of the machine. Machines are built as low as 4 NPI to as high as 32 NPI. Based on the machine gauge, the fineness of the yarn to be knitted can be varied. The diameter of the cylinder also varied based on the type and width of the fabric, and a maximum of 75 cm diameter machines are available.

2.6.1 Dial

Dial is the upper steel needle bed used in double knit machines. Into the grooves of the dial, the needles are mounted horizontally and are allowed to move radially in and out by their dial cams. The number of grooves per unit space conforms with the cylinder gauge in most of the cases.

2.7 CAMS

The knitting cams are hardened steels and they are the assembly of different cam plates so that a track for butt can be arranged. Each needle movement is obtained by means of cams acting on the needle butts. The Fig. (2.12) shows the simplest cam design.

The upward movement of the needle is obtained by the rising cams or clearing cams. The rising cam places the needle at a certain level as it approaches the yarn area. Cams controlling the downward movement of the needles are called stitch cams. The stitch cam draws the needle down below the knitting level, thereby drawing a loop formed by the fed yarn through the loop already on the needle. The lowest point to which the needle is drawn by the stitch cam is called the "cast-off" position. They are screwed to the cylindrical cam ring and are adjustable in vertical direction. If the stitch cam is raised, then shorter loop is drawn below the sinker level and a tighter fabric will result. With lowering of stitch cam, a reverse result is obtained.

Guard cams keep the needle butts in their race-way.

Running cams or [up throw cams] the needle butts at a low level until they meet the next rising cam.

Sometimes, swing cams (Fig. 2.13) or auxillary cams are placed between the rising cams and the stitch cams to change the path of the needle butts to form a raceway and the needle butts travel in this restricted path according to different stitch requirements.

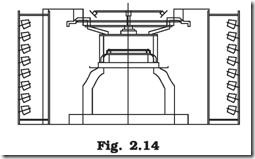

2.8 CREELS (Fig. 2.14)

Creels are the knitting elements which carry the yarn packages to feed the knitting zone. The number of feeders in the knitting machine is equal to the number of cones in the creels. Reserve cones also can be placed in each position. In accordance with the number of feeders, two cone supports per feed are equidistantly fixed on a ring over the circumference of the machine is mounted in the lower part. On machines having yarn meters or yarn storage devices, an additional ring is mounted in the lower part. Fan blade with motors, oiling system for needles and sinkers, knot catchers and stop motion are also mounted on creel section.

Apart from the over head ring creels, depending on the number of feeders and space availability, creels are arranged on two or three sides of the machine. These construction keep off fibre fly from the machine and are more suitable for high speed circular knitting machines. Differences in yarn tension due to variation in yarn length from the cone to the feeder can be eliminated with these side creels compared to overhead creels. Yarn guiding via yarn guide tubes normally reduce the yarn tension than the open guiding system. Closed yarn guiding also reduces fibre fly and yarn entanglements. Side creels also make easier threading in operation.

2.9 FEEDERS/STRIPERS

Feeders are the yarn guides (Fig. 2.15) placed close to the needles to the full circumference of the knitting zone. The feeders feed the yarn into the needle hooks and control the needle latches in their open position while the needle attain their clearing position. They consist of a yarn guiding hole and a bevel edge to guard the latches of the approaching needles. They are slightly curved to the corresponding curvature of the needle bed. Feeders may have two holes also for the purpose of plating.

The feeder brackets can be adjusted to set their distance from the needle and to ensure yarn feed into needle hooks.

Stripers are the feeders designed to deliver two or more yarns individually to the same feed. They can be considered as moving guide replacing the holes of fixed guides. In a two colour striper (Fig. 2.16), two different coloured yarns are supplied by two stripper fingers and their engagement is controlled by an endless control chain which governs the guide change at the appropriate feeds. At each revolution, a counter may select the movement of all the striper chains. The stripers are used on both single and double bed machines.

2.10 FABRIC SPREADER

In circular knitting, the tubular fabric descends from the needles is converged into flattened double layer and rolled into yard goods. During such conversion, irregular tensions are developed throughout the fabric due to distance variations which leads to unwanted wrinkles, crease marks and stitch deformations. They can be only removed with great difficulty during fabric finishing. To overcome this problem knitting machines are equipped with spreaders which apply a more uniform tension to the fabric.

A simple fabric spreader (Fig. 2.17) is a solid wooden plate, placed above the takedown rollers and held in position by the fabric tube.Another type of fabric spreader (Fig. 2.18) consists of two curved metal bars with adjustment for their length. The device is placed secured inside the fabric roll.

It is important that the spreaders should not bend the courses and increase the takedown tension. Heavy tension on the fabric affects the life span of the knitting elements such as needles, cams and needle bed.

Cadratex (Fig. 2.19) an advanced spreader consists of an internal and external guide clamp. Because of the rectangular shape of this spreader, the circumference of the fabric tube, obtained directly after knitting, is not altered over the entire distance upto the take down rollers. This results in the required evenness of the take down tension of the knitting machines and leads to a uniform stitch shape across the entire fabric width.

2.11 TAKE DOWN AND WINDING MECHANISM

This mechanism withdraws the fabric from the needles and winds them into the cloth roll. The takedown mechanism consists of grooved rollers through which the fabric is nipped and pulled downwards. The roll winding mechanism facilitate the convenient storage of fabric in which the flat, double ply fabric is wound on a revolving square bar. The take~down and winding devices are either driven mechanically by the main drive of the motor or through an additional direct current motor.

2.11.1 Mechanical Drive (Fig. 2.20)

At the take down, the fabric is nipped between two rollers or with some devices having three rollers. The pressure between the rollers is readily adjustable. The lower part of the machine frame is fitted with a circular rail or ring with the same central axis as the cylinder, but positioned inclined to the horizontal. There are two rollers or followers placed diagonally opposite and ride over the rail as the cylinder rotates. The running of the follower over the rail gives oscillating motion to the lever to which they are fixed. The levers inturn drives a toothed ratchet wheel by means of a pawl. This ratchet wheel is fixed to the grooved takedown roller and thus drives the same. A fixed pawl prevents the ratchet wheel from the reversing while the lever oscillates. The extent of the rail inclination governs the withdrawal rate of fabric through the take down rollers. Exactly similar mechanism is extended to the cloth roll through connecting levers from the takedown oscillating lever. Similar kind of ratchet wheel with driving pawl and fixed pawl rotate the cloth roll and wind the fabric.

2.11.2 Electrical Drive (Fig. 2.21)

A separate motor drives the take down and winding devices. The fabric takes down and fabric wind on form a compact unit and are as such attached to the rotating base plate in the lower machine frame. The unit consists of two lateral supports, between which the three take down rollers, the winding roll and the fabric winding spindle are provided.

The fabric is led through the take~down rollers which are driven by a gearing motor over a chain gear. The take~down tension can be infinitely and sensitively set on the control panel with a potentiometer without disturbing the machine running. The fabric encircles the take down rollers and is then led down to fabric winder and wound into fabric roll.