Comparative Performance Analysis of Blowroom Cleaning Machinery for Cotton

Fibre Length Characteristics

Abstract: The effect of beater speed, grid bar setting and cotton trash percentage upon Uniclean (B 11) and Giant cleaner setup were studied for quality characteristics of cotton. The results in respect of fibre length and uniformity ratio showed highly significant differences in the mean values for different combination of settings as well as cleaning segments. Uniclean exert swift gentle but firm action of less stress on fibres whereas the action of Giant cleaner is very aggressive and severe during its cleaning action, which is detrimental to fibre staple.

Key words: Uniclean, Blowroom, Cotton Fibre Length, span length, Uniformity Ratio

Introduction

The cotton textile industry enjoys a highly significant position in the economy of Pakistan. For today's rapidly advancing textile industry and quality conscious international market, the comprehensive information about the characteristics of lint cotton, which is the raw material of the industry is a dire need for producing quality goods at competitive costs by way of reducing wastage and improving productivity level.

Since mechanized spinning industry came into being various opening and cleaning machines were developed most of which are now obsolete. With the passage of time and with the advent of new technologies high-speed machines were designed having more opening and cleaning efficiency. In the past a typical blow room line for the cleaning of cotton consists of four to six, and in some cases even seven beating points. The underlying idea was to open and clean the material slowly and gradually. But during the last decade, the trend has shifted to minimize the number of machines in the blow room line. Now in modern cleaning line only two to three beating points are available. This became possible only due to the introduction of machines with higher degree of opening capabilities.

Most of the spinning mills in Pakistan are equipped with conventional cleaning set-up in blow room. Step or Giant cleaner for example is used for excellence in opening and cleaning of cotton through the combination of the action of opposing spikes and the beating action. In this machine, the material falls into the feed hopper and passes to the first beater. From there, it is transported upwards by six beating rollers, each carrying profiled bars, the beaters are arranged on a line inclined upwards at 45°. The elimination of impurities takes place during the continual passage of the material over the grid arranged under the rollers. The grids are always adjustable and usually the beater speed is also adjustable. In Giant cleaner, progressive increase

in speed results in a directly proportional increase in waste extraction. The proportions of lint and trash in the dropping are independent of speed up to about 550 rev/min, so that a much greater cleaning efficiency is achieved at these higher speeds. At speed greater than 550 rev/min, however the lint loss is much greater as compared to the trash extraction.

Some reports are available regarding the effect of cleaning machinery upon fibre characteristics. Behery (1992) narrated that opening and cleaning machines removes short fibres and effect the change in fibre length due to fibre/machine interaction, whereas Schneider (1995) advocated that the Rieter Uniclean performs three main functions equally well viz; efficient cleaning at the start of the blow room lines, integration of an efficient dedusting elements and exceptionally gentle treatments of fibres. Similarly Klein (2000) lamented that Uniclean leads to a higher degree of cleaning, a better cleaning efficiency, and less stress on the fibres. Also Liu

et al. (2001) commented as the large variation of single fibre properties within a single variety suggests a very strong influence of growth conditions and development.

Materials and Methods

The present research was initiated in the Department of Fibre Technology, University of Agriculture, Faisalabad and conducted at Resham Textile Industries Limited Pattoki District Kasoor during the year 2002. The details of the material used and methods applied to test the raw material and to measure various quality characteristics are briefly described here under.

Material Used

Lint cotton samples with different level of trash was collected from running material at M/S Resham Textile Industries Limited, cotton samples were subjected to the physical testing.

Spinning Process

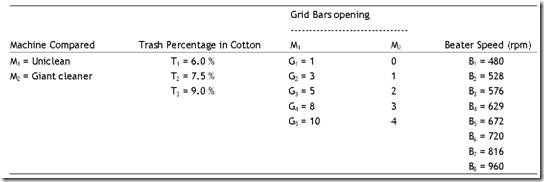

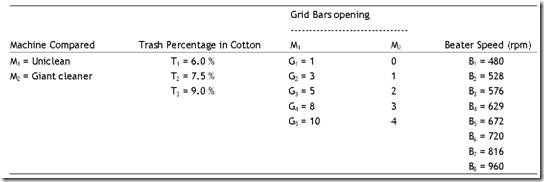

Lint cotton with different levels of trash was processed at Trutzschler blow room line with and without Reiter Uniclean set-up, and following mechanical changes were undertaken at Uniclean as well as Giant cleaner in blow room.

After every possible combination of above variables at Uniclean as well as Giant cleaner, samples from the duct were collected and tested for the basic fibre characteristics along with the quality evaluation tests for staple length and uniformity ratio.

Atmospheric Conditions

Atmospheric Conditions

The testing work was carried out under the standard laboratory conditions, which were maintained at 65+2% relative humidity and 20±2°C temperature.

Statistical Analysis

Four Factor Factorial Completely Randomized Design was applied in the analysis of variance for testing differences among various quality characters studied in this investigation. Duncan's Multiple Range Test was also applied for individual comparison of means among various quality characteristics as suggested by Steel and Torrie (1980). The data thus obtained was subjected to statistical manipulation on computer employing M-Stat micro computer program as devised by Freed (1992).

Results and Discussion

Span Length

The statistical analysis of variance regarding to span length of cotton for different settings at Uniclean as well as Giant cleaner in blow room is given in Table 1. The effects of Machines (M) and Beater Speed (5) are found highly significant. However the effects of trash percentage in cotton upon span length and of interactions are non-significant.

The comparison of individual mean values for machines in blow room on fibre span length is presented in Table la. Which indicated that the highest fibre span length of value 27.48 millimeter is obtained for Uniclean (M

1) and the lowest value of staple length 27.43 mm is obtained for Giant cleaner (M

2). Hence these machines differ significantly for their action upon cotton. On the basis of above results, it is crystal clear that Uniclean exert swift gentle but firm action of less stress on fibres whereas the action of Giant cleaner is very aggressive and severe during its cleaning action which is detrimental to fibre staple. Similarly views were put forth by Klein (2000) who lamented that Uniclean leads to a higher degree of cleaning, a better cleaning efficiency, and less stress on the fibres. Identical observation were presented by Schneider (1995) who advocated that the Rieter Uniclean performs three main functions equally well viz; efficient cleaning at the start of the blow room lines, integration of an efficient deducting elements and exceptionally gentle treatments of fibres. Hence it can be very well visualized from the present research of that the cleaning action Uniclean is exceptionally smart and safe, less injurious to fibre for fibre cleaning operation in comparison with/to Giant cleaner.

As regards to the trash percentage the comparison of individual means revealed that best value of staple length (27.47 mm) is recorded at T

1 followed by T

nand T

3with their respective means as 27.45 and 27.44 mm and these values are at par. The above results indicate that trash record independent effect upon staple length. Some previous researchers indicated that mill cleaning opens the cotton to small tuft size and extract as much trash as possible before the cotton goes to card and proper cleaning protects the staple length (Bel

et al., 1991).

Duncan's multiple range test for individual comparison of mean values reveals, that beater speed, starting from B

1 (480 rpm) till B

e (960 rpm) recorded highly significant difference in their mean values. At B4 (629 rpm) maximum value of fibre length is observed followed by B3, B5, B6, B2, B7, Be and B

1, respective mean for staple being 27.50, 27.49, 27.48, 27.46, 27.44, 27.44,27.42 and

27.41 millimeter. The above results express that for too high or too low beater speeds, the corresponding fibre length decreases, while the moderate speed B

4 (629 rpm) recorded best results. The present research findings get full confirmation from the work of Iqbal (2002) who concluded that fibre length decreased both at too low and too high beater speeds.

As regard to grid bar settings, best mean value of fibre length is recorded at (G

5) followed by G4, G3, G2 and G

1 with their respective mean values of length as 27.47, 27.46, 27.46, 27.45 and 27.44 millimeter. These values indicate nill effect of grid bar settings upon fibre length. Similarly previous researcher Maqsood (2000) postulated that grid bar settings at scutcher has a nonsignificant effect on fibre length. Whereas Behery (1992) advanced this statement that opening and cleaning machines removes short fibres and effect the change in fibre length due to fibre/machine interaction. From the above all results it can be inferred that grid bar opening angle has no effect upon the staple of cotton because it only facilitate the drain of non-lint elements.

Length Uniformity Ratio

Length Uniformity Ratio

The statistical analysis of variance regarding to length uniformity ratio of cotton for different settings at Uniclean as well as Giant cleaner in blow room is given in Table 2a, which indicate that the effects of Machines (M), Beater Speed (5) and Grid bar settings (G) are highly significant whereas the effect of trash percentage in cotton and all interactions are non-significant.

The comparison of individual mean values for machines in blow room on length uniformity ratio is presented in Table 2b. Which indicate that maximum length uniformity ratio of 47.49 percent is obtained for Uniclean (M

1) and the lowest value of 47.17 percent is obtained for Giant cleaner (M

2). Hence these machines significantly differ from one another. From the above discussion it is evident that the performance of Uniclean is for better then Giant cleaner. Similar views were put forth by Schneider (1995) who mentioned that the Reiter Uniclean performs three main functions equally well viz efficient cleaning at the start of the blow room lines, integration of an efficient deducting elements and exceptionally gentle treatments of fibres. Similarly Anonymous (2000) argued that the Uniclean B„ is a machine for cleaning and extracting for cotton of any origin. Impurities are removed gently and effectively. The raw material is feed through without nipping. Hence it can be very well visualized from the present research, that cleaning action of Uni-clean is exceptionally smart and safe, less injurious to fibre for fibre cleaning operation in comparison with Giant cleaner.

The individual comparison for trash percentage recorded non-significant differences in their mean values. Maximum value of length uniformity ratio is recorded at T, followed by T2 and T3 with their respective mean values as 47.42, 47.32 and 47.36 percent. The above results indicate that trash in cotton does not record any significant effect upon length uniformity ratio. Previous researcher agreed that cotton yarn irregularity was considerably influenced by the properties of fibre from which uniformity was the most important property Ramey and Beaton (1989).

The individual comparison of means values reveals that various beater speeds starting from B, (480 rpm) till B, (960 rpm) recorded highly significant differences in their mean values. At B

4 (629 rpm) maximum value of length uniformity is observed followed by B3, B5, B2, B6, B1, B7 and B8 with their respective means being 47.64, 47.59, 47.48, 47.36, 47.28, 47.19, 47.16 and 46.96 percent. The above results express that uniformity ratio gradually decrease with the increase in beater speed. At high speed more short fibre are produced which may cause reduction in uniformity ratio. The present finding get full confirmation from the work of lqbal (2002) who noted that at higher beater speed more short fibres are formed which may cause reduction in uniformity ratio. In earlier work Backe (1986) reported that as uniformity increased, the short fibre content decreased.

The individual means of grid bar opening differ significantly from each other for the length uniformity ratio of cotton fibre. Best value of uniformity ratio (47.79%) is recorded at G

5 opening followed by G4, G3, G2 and G, with their respective mean values as 47.56, 47.33, 47.09 and 46.90 percent. The present results show that at wider opening of grid bar, the uniformity ratio may improve due to the removal of short fibre. Similar views are given by Maqsood (2000) who elucidated that short fibre content may reduce as the more opening of grid bar and uniformity ratio may improve. Likewise Ghani (1997), reported that uniformity ratio of fibres is increased due to removal of short fibres.

Beating action of both machines M

1 (Uniclean) and M, (Giant cleaner) negatively affected fibre quality characteristics. However, the performance of Uniclean B

11 was exceptionally good for fibre span length and length uniformity ratio. Different intrinsic trash levels have no effect upon fibre span length and length uniformity ratio. Too low and too high speed negative effect upon span length and uniformity ratio. The effect of changing grid bar setting has non-significant effect on span length while the highly significant effect on uniformity ratio.

Sh. Muhammad Nawaz, Babar Shahbaz, Assad Farooq and Muhammad Asif

Department of Fibre Technology, University of Agriculture Faisalabad, Pakistan

Atmospheric Conditions

The testing work was carried out under the standard laboratory conditions, which were maintained at 65+2% relative humidity and 20±2°C temperature.

Statistical Analysis

Four Factor Factorial Completely Randomized Design was applied in the analysis of variance for testing differences among various quality characters studied in this investigation. Duncan's Multiple Range Test was also applied for individual comparison of means among various quality characteristics as suggested by Steel and Torrie (1980). The data thus obtained was subjected to statistical manipulation on computer employing M-Stat micro computer program as devised by Freed (1992).

Results and Discussion

Span Length

The statistical analysis of variance regarding to span length of cotton for different settings at Uniclean as well as Giant cleaner in blow room is given in Table 1. The effects of Machines (M) and Beater Speed (5) are found highly significant. However the effects of trash percentage in cotton upon span length and of interactions are non-significant.

The comparison of individual mean values for machines in blow room on fibre span length is presented in Table la. Which indicated that the highest fibre span length of value 27.48 millimeter is obtained for Uniclean (M1) and the lowest value of staple length 27.43 mm is obtained for Giant cleaner (M2). Hence these machines differ significantly for their action upon cotton. On the basis of above results, it is crystal clear that Uniclean exert swift gentle but firm action of less stress on fibres whereas the action of Giant cleaner is very aggressive and severe during its cleaning action which is detrimental to fibre staple. Similarly views were put forth by Klein (2000) who lamented that Uniclean leads to a higher degree of cleaning, a better cleaning efficiency, and less stress on the fibres. Identical observation were presented by Schneider (1995) who advocated that the Rieter Uniclean performs three main functions equally well viz; efficient cleaning at the start of the blow room lines, integration of an efficient deducting elements and exceptionally gentle treatments of fibres. Hence it can be very well visualized from the present research of that the cleaning action Uniclean is exceptionally smart and safe, less injurious to fibre for fibre cleaning operation in comparison with/to Giant cleaner.

As regards to the trash percentage the comparison of individual means revealed that best value of staple length (27.47 mm) is recorded at T1 followed by T nand T 3with their respective means as 27.45 and 27.44 mm and these values are at par. The above results indicate that trash record independent effect upon staple length. Some previous researchers indicated that mill cleaning opens the cotton to small tuft size and extract as much trash as possible before the cotton goes to card and proper cleaning protects the staple length (Bel et al., 1991).

Duncan's multiple range test for individual comparison of mean values reveals, that beater speed, starting from B1 (480 rpm) till Be (960 rpm) recorded highly significant difference in their mean values. At B4 (629 rpm) maximum value of fibre length is observed followed by B3, B5, B6, B2, B7, Be and B1, respective mean for staple being 27.50, 27.49, 27.48, 27.46, 27.44, 27.44,27.42 and

27.41 millimeter. The above results express that for too high or too low beater speeds, the corresponding fibre length decreases, while the moderate speed B4 (629 rpm) recorded best results. The present research findings get full confirmation from the work of Iqbal (2002) who concluded that fibre length decreased both at too low and too high beater speeds.

As regard to grid bar settings, best mean value of fibre length is recorded at (G5) followed by G4, G3, G2 and G1 with their respective mean values of length as 27.47, 27.46, 27.46, 27.45 and 27.44 millimeter. These values indicate nill effect of grid bar settings upon fibre length. Similarly previous researcher Maqsood (2000) postulated that grid bar settings at scutcher has a nonsignificant effect on fibre length. Whereas Behery (1992) advanced this statement that opening and cleaning machines removes short fibres and effect the change in fibre length due to fibre/machine interaction. From the above all results it can be inferred that grid bar opening angle has no effect upon the staple of cotton because it only facilitate the drain of non-lint elements.

Atmospheric Conditions

The testing work was carried out under the standard laboratory conditions, which were maintained at 65+2% relative humidity and 20±2°C temperature.

Statistical Analysis

Four Factor Factorial Completely Randomized Design was applied in the analysis of variance for testing differences among various quality characters studied in this investigation. Duncan's Multiple Range Test was also applied for individual comparison of means among various quality characteristics as suggested by Steel and Torrie (1980). The data thus obtained was subjected to statistical manipulation on computer employing M-Stat micro computer program as devised by Freed (1992).

Results and Discussion

Span Length

The statistical analysis of variance regarding to span length of cotton for different settings at Uniclean as well as Giant cleaner in blow room is given in Table 1. The effects of Machines (M) and Beater Speed (5) are found highly significant. However the effects of trash percentage in cotton upon span length and of interactions are non-significant.

The comparison of individual mean values for machines in blow room on fibre span length is presented in Table la. Which indicated that the highest fibre span length of value 27.48 millimeter is obtained for Uniclean (M1) and the lowest value of staple length 27.43 mm is obtained for Giant cleaner (M2). Hence these machines differ significantly for their action upon cotton. On the basis of above results, it is crystal clear that Uniclean exert swift gentle but firm action of less stress on fibres whereas the action of Giant cleaner is very aggressive and severe during its cleaning action which is detrimental to fibre staple. Similarly views were put forth by Klein (2000) who lamented that Uniclean leads to a higher degree of cleaning, a better cleaning efficiency, and less stress on the fibres. Identical observation were presented by Schneider (1995) who advocated that the Rieter Uniclean performs three main functions equally well viz; efficient cleaning at the start of the blow room lines, integration of an efficient deducting elements and exceptionally gentle treatments of fibres. Hence it can be very well visualized from the present research of that the cleaning action Uniclean is exceptionally smart and safe, less injurious to fibre for fibre cleaning operation in comparison with/to Giant cleaner.

As regards to the trash percentage the comparison of individual means revealed that best value of staple length (27.47 mm) is recorded at T1 followed by T nand T 3with their respective means as 27.45 and 27.44 mm and these values are at par. The above results indicate that trash record independent effect upon staple length. Some previous researchers indicated that mill cleaning opens the cotton to small tuft size and extract as much trash as possible before the cotton goes to card and proper cleaning protects the staple length (Bel et al., 1991).

Duncan's multiple range test for individual comparison of mean values reveals, that beater speed, starting from B1 (480 rpm) till Be (960 rpm) recorded highly significant difference in their mean values. At B4 (629 rpm) maximum value of fibre length is observed followed by B3, B5, B6, B2, B7, Be and B1, respective mean for staple being 27.50, 27.49, 27.48, 27.46, 27.44, 27.44,27.42 and

27.41 millimeter. The above results express that for too high or too low beater speeds, the corresponding fibre length decreases, while the moderate speed B4 (629 rpm) recorded best results. The present research findings get full confirmation from the work of Iqbal (2002) who concluded that fibre length decreased both at too low and too high beater speeds.

As regard to grid bar settings, best mean value of fibre length is recorded at (G5) followed by G4, G3, G2 and G1 with their respective mean values of length as 27.47, 27.46, 27.46, 27.45 and 27.44 millimeter. These values indicate nill effect of grid bar settings upon fibre length. Similarly previous researcher Maqsood (2000) postulated that grid bar settings at scutcher has a nonsignificant effect on fibre length. Whereas Behery (1992) advanced this statement that opening and cleaning machines removes short fibres and effect the change in fibre length due to fibre/machine interaction. From the above all results it can be inferred that grid bar opening angle has no effect upon the staple of cotton because it only facilitate the drain of non-lint elements.

Length Uniformity Ratio

The statistical analysis of variance regarding to length uniformity ratio of cotton for different settings at Uniclean as well as Giant cleaner in blow room is given in Table 2a, which indicate that the effects of Machines (M), Beater Speed (5) and Grid bar settings (G) are highly significant whereas the effect of trash percentage in cotton and all interactions are non-significant.

The comparison of individual mean values for machines in blow room on length uniformity ratio is presented in Table 2b. Which indicate that maximum length uniformity ratio of 47.49 percent is obtained for Uniclean (M1) and the lowest value of 47.17 percent is obtained for Giant cleaner (M2). Hence these machines significantly differ from one another. From the above discussion it is evident that the performance of Uniclean is for better then Giant cleaner. Similar views were put forth by Schneider (1995) who mentioned that the Reiter Uniclean performs three main functions equally well viz efficient cleaning at the start of the blow room lines, integration of an efficient deducting elements and exceptionally gentle treatments of fibres. Similarly Anonymous (2000) argued that the Uniclean B„ is a machine for cleaning and extracting for cotton of any origin. Impurities are removed gently and effectively. The raw material is feed through without nipping. Hence it can be very well visualized from the present research, that cleaning action of Uni-clean is exceptionally smart and safe, less injurious to fibre for fibre cleaning operation in comparison with Giant cleaner.

The individual comparison for trash percentage recorded non-significant differences in their mean values. Maximum value of length uniformity ratio is recorded at T, followed by T2 and T3 with their respective mean values as 47.42, 47.32 and 47.36 percent. The above results indicate that trash in cotton does not record any significant effect upon length uniformity ratio. Previous researcher agreed that cotton yarn irregularity was considerably influenced by the properties of fibre from which uniformity was the most important property Ramey and Beaton (1989).

The individual comparison of means values reveals that various beater speeds starting from B, (480 rpm) till B, (960 rpm) recorded highly significant differences in their mean values. At B4 (629 rpm) maximum value of length uniformity is observed followed by B3, B5, B2, B6, B1, B7 and B8 with their respective means being 47.64, 47.59, 47.48, 47.36, 47.28, 47.19, 47.16 and 46.96 percent. The above results express that uniformity ratio gradually decrease with the increase in beater speed. At high speed more short fibre are produced which may cause reduction in uniformity ratio. The present finding get full confirmation from the work of lqbal (2002) who noted that at higher beater speed more short fibres are formed which may cause reduction in uniformity ratio. In earlier work Backe (1986) reported that as uniformity increased, the short fibre content decreased.

The individual means of grid bar opening differ significantly from each other for the length uniformity ratio of cotton fibre. Best value of uniformity ratio (47.79%) is recorded at G5 opening followed by G4, G3, G2 and G, with their respective mean values as 47.56, 47.33, 47.09 and 46.90 percent. The present results show that at wider opening of grid bar, the uniformity ratio may improve due to the removal of short fibre. Similar views are given by Maqsood (2000) who elucidated that short fibre content may reduce as the more opening of grid bar and uniformity ratio may improve. Likewise Ghani (1997), reported that uniformity ratio of fibres is increased due to removal of short fibres.

Length Uniformity Ratio

The statistical analysis of variance regarding to length uniformity ratio of cotton for different settings at Uniclean as well as Giant cleaner in blow room is given in Table 2a, which indicate that the effects of Machines (M), Beater Speed (5) and Grid bar settings (G) are highly significant whereas the effect of trash percentage in cotton and all interactions are non-significant.

The comparison of individual mean values for machines in blow room on length uniformity ratio is presented in Table 2b. Which indicate that maximum length uniformity ratio of 47.49 percent is obtained for Uniclean (M1) and the lowest value of 47.17 percent is obtained for Giant cleaner (M2). Hence these machines significantly differ from one another. From the above discussion it is evident that the performance of Uniclean is for better then Giant cleaner. Similar views were put forth by Schneider (1995) who mentioned that the Reiter Uniclean performs three main functions equally well viz efficient cleaning at the start of the blow room lines, integration of an efficient deducting elements and exceptionally gentle treatments of fibres. Similarly Anonymous (2000) argued that the Uniclean B„ is a machine for cleaning and extracting for cotton of any origin. Impurities are removed gently and effectively. The raw material is feed through without nipping. Hence it can be very well visualized from the present research, that cleaning action of Uni-clean is exceptionally smart and safe, less injurious to fibre for fibre cleaning operation in comparison with Giant cleaner.

The individual comparison for trash percentage recorded non-significant differences in their mean values. Maximum value of length uniformity ratio is recorded at T, followed by T2 and T3 with their respective mean values as 47.42, 47.32 and 47.36 percent. The above results indicate that trash in cotton does not record any significant effect upon length uniformity ratio. Previous researcher agreed that cotton yarn irregularity was considerably influenced by the properties of fibre from which uniformity was the most important property Ramey and Beaton (1989).

The individual comparison of means values reveals that various beater speeds starting from B, (480 rpm) till B, (960 rpm) recorded highly significant differences in their mean values. At B4 (629 rpm) maximum value of length uniformity is observed followed by B3, B5, B2, B6, B1, B7 and B8 with their respective means being 47.64, 47.59, 47.48, 47.36, 47.28, 47.19, 47.16 and 46.96 percent. The above results express that uniformity ratio gradually decrease with the increase in beater speed. At high speed more short fibre are produced which may cause reduction in uniformity ratio. The present finding get full confirmation from the work of lqbal (2002) who noted that at higher beater speed more short fibres are formed which may cause reduction in uniformity ratio. In earlier work Backe (1986) reported that as uniformity increased, the short fibre content decreased.

The individual means of grid bar opening differ significantly from each other for the length uniformity ratio of cotton fibre. Best value of uniformity ratio (47.79%) is recorded at G5 opening followed by G4, G3, G2 and G, with their respective mean values as 47.56, 47.33, 47.09 and 46.90 percent. The present results show that at wider opening of grid bar, the uniformity ratio may improve due to the removal of short fibre. Similar views are given by Maqsood (2000) who elucidated that short fibre content may reduce as the more opening of grid bar and uniformity ratio may improve. Likewise Ghani (1997), reported that uniformity ratio of fibres is increased due to removal of short fibres.

Beating action of both machines M1 (Uniclean) and M, (Giant cleaner) negatively affected fibre quality characteristics. However, the performance of Uniclean B11 was exceptionally good for fibre span length and length uniformity ratio. Different intrinsic trash levels have no effect upon fibre span length and length uniformity ratio. Too low and too high speed negative effect upon span length and uniformity ratio. The effect of changing grid bar setting has non-significant effect on span length while the highly significant effect on uniformity ratio.

Sh. Muhammad Nawaz, Babar Shahbaz, Assad Farooq and Muhammad Asif

Department of Fibre Technology, University of Agriculture Faisalabad, Pakistan

Beating action of both machines M1 (Uniclean) and M, (Giant cleaner) negatively affected fibre quality characteristics. However, the performance of Uniclean B11 was exceptionally good for fibre span length and length uniformity ratio. Different intrinsic trash levels have no effect upon fibre span length and length uniformity ratio. Too low and too high speed negative effect upon span length and uniformity ratio. The effect of changing grid bar setting has non-significant effect on span length while the highly significant effect on uniformity ratio.

Sh. Muhammad Nawaz, Babar Shahbaz, Assad Farooq and Muhammad Asif

Department of Fibre Technology, University of Agriculture Faisalabad, Pakistan