GABARDINE: A firm, durable, warp-faced cloth, showing a

decided twill line, usually a 45° or 63° right-hand twill.

GAGE: See GAUGE.

GAITING: The spacing of the needles in the dial and cylinder in relation to each other on rib (double-knit) and interlock knitting machines. In rib gaiting, the dial needles are midway between the cylinder needles. For interlock gaiting the dial and cylinder needles are in direct alignment.

GALATEA: A sturdy, serviceable, warp-effect, five-shaft, left-hand twill-weave fabric, frequently cotton or a cotton blend, used for children’s play clothes.

GAMMA CELLULOSE: One of the three forms of cellulose. With beta cellulose it is called hemicellulose. (Also see ALPHA CELLULOSE and BETA CELLULOSE.)

GARNETTING: A process for reducing various textile waste materials to fiber by passing them through a machine called a garnett, that is similar to a card.

GAS FADING: A change of shade of dyed fabric caused by chemical reaction between certain disperse dyes and acid gases from fuel combustion, particularly oxides of nitrogen.

GASSING: See SINGEING.

GAUGE: 1. A generic term for various measurement instruments such as pressure or thickness gauges. 2. The number of needles per given distance in a knitting machine. 3. The thickness of the knitting needle in the shank and the hook. 4. The number of wales per inch in a knit fabric. 5. On spinning or twisting frames, the distance from the center of one spindle to the center of the next spindle in the same row.

GAUGE WIRE: Used with an extra filling yarn during weaving, this type of standing wire controls the height of fabric pile.

| GAUZE: A thin, sheer-woven fabric in which each filling yarn in encircled by two warp yarns twisted around each other, gauze is similar to cheesecloth. It may by made of silk, cotton, wool, or manufactured fibers. Cotton gauze is primarily for surgical dressings. GEAR CRIMPING: See TEXTURING, Gear Crimping Method. |  |

continuous phase to produce a viscous, jelly-like product. 2. Degraded polymer occurring in process lines. Usually seen as specks in polymer or yarn.

GEL DYEING: See DYEING.

GEL SPINNING: See SPINNING, 2.

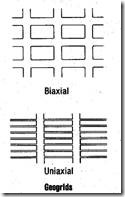

GEOGRID: Manufactured polymer constructions characterized by large openings made by one of the following methods: (1) coating woven or knit products to form a grid; (2) welding oriented strands to form a grid; (3) punching holes in flat sheets then drawing them to align the polymer molecules. Used for soil stabilization, drainage, and erosion control applications. (Also see GEOTEXTILES.)

GEOMEMBRANE PROTECTION FABRIC: See GEOTEXTILES.

GEOTEXTILES: Manufactured fiber products made into fabrics of various constructions for use in a wide variety of civil engineering applications including several described below.

Asphalt Overlay Fabrics: Fabric systems installed between the old and new asphalt layers during pavement resurfacing. The fabric absorbs the tack coat sprayed on the old surface thus forming a permanent moisture barrier to protect the subgrade from strength loss due to water intrusion. The fabric system also helps retard reflective cracking by serving as a flexible layer to diffuse stress.

| Drainage Fabrics: Fabrics used as filter media or separators in subsurface drainage systems. The fabric is installed around the drainage pipe, or coarse stone in the drain; it allows water to pass freely from the soil to the drain, but prevents soil particles from migrating into the drain system. These fabrics are also used as outer coverings in prefabricated drainage composites and serve the same function as a filtering medium. |  |

Geomembrane Protection Fabrics: Fabric systems used in the construction of landfills to protect the membrane liner from puncture and installation damage. The fabric may be installed on one or both sides of the liner. It can also be used in the leachate collection system since it is permeable to fluids and gases.

Reinforcement Fabrics: Fabric system used in the construction of steep slopes and retaining walls. By stabilizing the soil mass, they reduce the stress on the retaining wall with corresponding decrease in load-bearing requirements for the wall design. In slope reinforcement, the stabilization permits steeper slope construction than would be possible based on soil properties.

Subsurface Stabilization Fabrics: Fabrics used in the construction on access roads, railroads, parking and storage areas over soft, unstable soil. The fabric is placed between the subgrade and the stabilizing fill material where it provides separation of subsoil and

fill, filtration of moisture at the subsoil/fill interface, and added tensile reinforcement of the compacted fill.

GIGGING: See NAPPING. GILLING: See PIN DRAFTING.

GINGHAM: A woven fabric characterized by a block or check effect produced by weaving in dyed yarns at fixed intervals in both the warp and the filling.

GLACÉ: A lustrous, glossy effect imparted to fabrics by finishing.

GLASS FIBER: A manufactured fiber in which the fiber-forming substance is glass (FTC definition). In the continuous filament process, glass marbles are melted in an electric furnace and the liquid flows in fine streams through small orifices at the bottom of the melting chamber. The resultant filaments are caught and drawn by a high-speed draw- winding mechanism. In the staple fiber process, the streams of molten glass are attenuated into fibers by jets of high-pressure steam or air. These fibers are gathered on a revolving drum and them wound on tubes to form staple fiber sliver or bands that can be drafted, twisted, and plied.

CHARACTERISTICS: Glass fiber is incombustible and will tolerate heat up to 1000°F without material damage. Potential strength is not realized in woven fabrics or even in yarns, because the fiber is brittle and fracture points may develop, but nevertheless, very high tensile strength is obtained in woven fabrics, and is retained at elevated temperatures. The fiber originally was difficult to color but methods have been developed to accomplish this. Moisture absorption is low. Electrical and insulation resistance is high.

END USES: Glass fiber is used for heat and electrical insulation, filter cloth in the chemical and dye industries, reinforcing belts in tires, novelty fabrics, tablecloths, and fireproof draperies. Because of its brittleness, it is not used in wearing apparel or in household fabrics that have to withstand frequent flexing.

GLASS TRANSITION TEMPERATURE: See SECOND-ORDER TRANSITION TEMPERATURE.

GLAZING: 1. A finishing process that produces a smooth, highly polished, or lustrous surface on a fabric such as chintz. The fabric is treated with starch, glue, paraffin, or shellac, then friction calendered. Synthetic resins are used for a more permanent finish. 2. A shiny fabric appearance produced unintentionally, e.g., by pressing at excessive temperature.

GLOBAL RADIATION: The wavelength distribution of sunlight under a given environment (e.g., under windowpane glass).

GODET ROLL: Roll used for transporting and controlling the movement of bundles of fibers and yarns in the processing of these materials.

GOUT: Foreign matter that is accidentally woven into a fabric. It is usually fly or waste that drops into the loom during weaving or that catches in yarns during spinning.

GRAB STRENGTH TEST: A method for measuring the breaking strength of a fabric sample by mounting the sample in the tensile tester so that only a part of the width of the specimen is gripped in the clamps.

GRAFT COPOLYMER: A copolymer having branches of varying length made up of different monomer units on a common “backbone” chain.

GRAM BREAK FACTOR: See BREAK FACTOR.

GRAPHITE FIBER: Although the terms carbon and graphite are used interchangeably to describe these fibers, graphite fibers are more accurately defined as fibers that are 99+% carbonized while the term carbon is used for any fiber carbonized to 93 to 95% or more. (See CARBON FIBER.)

GRAY FABRIC: See GREIGE FABRIC.

GREEN TACK: A term used in fabric bonding for the preliminary bond created in the first stage of curing by the wet adhesive process. At this point, the bond is not fully cured and hence is “green.”

GREIGE FABRIC: An unfinished fabric just off the loom or knitting machine.

GRENADINE: 1. A fine, loosely woven fabric in leno weave made with dyed filling yarns and having a clipped dobby design. 2. A silk cord constructed by twisting together several twisted strands.

GREX: 1. A unit of linear density equal to the weight in grams of 10 kilometers of yarn, filament, fiber, or other textile strand. 2. The system of yarn numbering based on the use of grex units. (Also see YARN NUMBER.)

GREY FABRIC: See GREIGE FABRIC.

GRINNING: 1. A flaw in fabric, especially a ribbed fabric, that occurs when warp threads show through the covering filling threads or when the threads have slipped leaving open spaces on either side. 2. A condition that occurs when the carpet backing shows through the pile. 3. A printing term referring to either poor cover where the background shade shows through the print, or to the “two-tone” appearance of a shade printed with incompatible dyes.

GRIPPER LOOMS: Shuttleless looms. These looms employ a projectile with a jaw that grips the end of the filling yarn during the insertion of the pick.

GROSGRAIN: A heavy fabric with prominent ribs, grosgrain has a dressy appearance and is used in ribbons, vestments, and ceremonial cloths.

GROUND COLOR: A term describing the plain background color against which a design is created.

GROWTH: See SECONDARY CREEP.

GUIDE BAR: A mechanism on a warp-knitting machine that directs warp threads to the latch needles.

GUIDES: Fittings of various shapes for controlling the path of a threadline.

GUILLOTINE: Cutting device that consists of a single blade that descends between guides for chopping fibers, plastic strands, etc.

GUM: A term covering a wide range of substances. Strictly, gums are carbohydrate high polymers, either soluble or dispersible in water, that are derived from vegetable origins. Loosely, the term gum is used to mean resins, saps, natural rubber, chicle, starch, cellulose derivatives, and many other products. In textile printing, the term refers to print-paste thickeners.