PROJECT GOAL

The goal of this project is to create the fundamental knowledge needed to develop more efficient machines and novel processes that can potentially decrease the number of process steps by a factor of 2 to 3 in short staple yarn manufacturing.

ABSTRACT

To develop more efficient machines for short staple yarn manufacturing that can significantly shorten the processing line, we are currently conducting research in the following two interrelated areas: (1) to analyze the motion dynamics of fiber clumps and particles in an airflow field, and (2) to develop a single-step process (Card-Spinning) to incorporate multiple spinning heads into a carding unit. This involves a fundamental analysis and understanding of web uniformity monitoring, measurement, and regulation, web division, and feeding of web ribbons into yarn spinning heads positioned at the front end of the card.

We have built a prototype of the yarn spinning head system and have modified opening and carding machines to demonstrate the concept. A series of yarns has been made with the spinning head system by varying the process settings. Evaluation of these yarns indicates that the technology is promising and further development is underway.

We have frequently interacted with our industrial partners including yarn producers and machinery manufacturers to share information on the project and to learn the state of the art practice in the industry. Studies are underway on theoretical and experimental analysis of airflow, and on the development of the Card-Spinning system.

INTRODUCTION

In the past decades, yarn manufacturing has transformed from a labor intensive operation to a capital intensive one. This change has allowed the US to remain competitive in the global marketplace. Although the productivity of current manufacturing systems continues to increase,

a significant improvement requires major breakthroughs and new innovations, which can only be achieved with a better understanding of the fundamental principles of the processes.

Staple yarn manufacturing involves four essential operations: fiber separation, parallelization, attenuation, and consolidation. Currently, several machines (about 10) in sequence are needed for these tasks. We are developing the fundamental knowledge base that can lead to more efficient machines, shorter production lines, and novel processes. Our first major task in this project is the study of the motion dynamics of fiber clumps and particles in an airflow field. The second major task aims at developing a novel process (Card-Spinning) by incorporating multiple spinning heads on the carding machine itself.

AIRFLOW IN OPENING AND CLEANING

The opening and cleaning process is the first part in a staple yarn manufacturing line. It opens fiber bales into small tufts, removes most of the impurities, and blends fibers together. Airflow plays a very important role in determining the efficiency and quality of the opening/cleaning operations. Fiber opening, cleaning, and transport in the opening and cleaning processes are achieved through interactions among airflow, inertia forces, gravity, fiber/particle configurations, barrier arrangements (mote knives, grid bars, plates, etc.), beating actions, carding actions, among others. Although some studies have been conducted in this area (e.g., [1] on opening and cleaning and [2,3,4] on carding), the depth has been limited due to the complexity of the problem.

The airflow with particles and fibers in these processes is typically a two-phase, unsteady viscous flow. Our studies include experimental analysis using flow visualization techniques and computational fluid dynamics (CFD) analysis. The experiments were designed to determine the effect of fibers on airflow pattern, and to determine the condition when fibers can be neglected in a CFD analysis. Some of the test results have been used to build a two-phase flow model in CFD. One of the uses for the model is for predicting the flow characteristics and improving the design of textile machinery.

Test setup and pressure distribution

The test setup, shown in Figure 1, is designed so that the test section can be changed to obtain typical flow patterns such as parallel, diverging, converging and flow over a bent section. It is an enclosed system consisting of a fan, test section and connection pipes. The test section is a rectangular channel (1.5 m X 0.15m X 0.31m), the top of which can be adjusted or replaced to change the shape of the channel. It is built with plexiglass panels to enable flow visualization using a high-speed video camera. Forty pressure sensors arranged in four rows are installed to monitor the flow pattern.

The pressure in the test section was measured with the flow channel in the expansion type flow configuration. With this configuration, a pressure increase should be seen along the flow direction. The experimental results were compared to those of the CFD model (Figure 2). The trends seen in the experimental results agreed well with those of the model, however, a difference in the magnitude of the pressures was seen. The difference in magnitude was not of concern, since a more meaningful comparison is done by looking at the slopes of the experimental and model results. This comparison shows good agreement between the CFD model and the experimental observations. Upon further investigation, a temperature increase was observed in the test system. This causes a reduction in the density of air, which changes flow rate. When the influence of this temperature increase is included in the modeling, the results are only 12% different than the experimentally observed data.

A series of tests were conducted to determine the sensitivity of the flow field to increases in the amount of fiber present. The amount of fiber in the test setup was changed (approximately 35 g, 69 g, 98 g,119g and 141 g) for each series of experiments. To determine the velocity of fibers in the airflow in the test section, a high-speed video camera is used to capture images of airflow with a foam particle which is similar in dimensions to the fiber clumps. Results showed that the velocity of the foam particle ranged from 7.52 to 16.8 m/sec with an average of 12.6 m/sec. The average velocity of the air flow in the test setup without the particle was 11 m/sec. These results have been analyzed and found to be reasonable.

In summary, we have built a test setup that captures many of the characteristics of flow fields present in textile machinery. We have demonstrated that CFD models can be used to predict the trends seen in the pressure distribution for the test setup for both air and air-fiber flow. The trends in the experimental data for varying amounts of fiber in the flow were captured by the model. However, the models do not predict the exact values of the pressures. Further

development of the models will lead to better predictions of the experimental data. In the future, the results of the models will be used to design new textile processing equipment.

CARDING

In a traditional process, carding individualizes fibers, removes fine impurities and neps, and forms a sliver. By incorporating multiple spinning heads on the carding machine itself, the novel Card-Spinning machine will replace the traditional card, two draw frames and the yarn-spinning machine.

Web monitoring

One of the major problems in spinning multiple yarns directly from a card web is that the cross-machine web density must be monitored and the divided sections must be controlled. Although some studies on web uniformity have been conducted for nonwoven processes [5,6,7,8,9], there is no available data on cross-machine uniformity for the card in yarn production line since the web is typically condensed into a single sliver and only the overall linear density is important. When one decides to split the web into multiple sections to feed directly to spinning heads, the variability of the web takes on great importance.

A system has been integrated with the card to monitor the web density on-line. It employs a computer, line-scan camera and high-speed frame grabber board (Figure 3). This system will enable real-time monitoring across the full width of the web. This is important for monitoring the input quality of the web to the yarn-spinning head. The system is capable of monitoring 100% of the web or just sampling a subset of the web. An image of the web is created line-byline with the scanning rate of the camera synchronized with the web motion when 100% monitoring is required. In this way a picture of the web is obtained. For process monitoring and control, a statistical sampling can be taken to analyze variation in any given section (strip) of web. An extensive literature search did not find published data on web variability and this work should add to the body of knowledge.

Web splitting

A proof-of-concept device has been designed and the first prototype was built. The principles involve positive control of the web sections during division via belts that squeeze the web, and through differential speeds, shear the web longitudinally in a short distance. Servomotors with digital control were added to the device (Figure 4). Initially, the belts were divided into two groups with slower and faster speeds, each set driven by one servomotor. It was found that the slower motor’s speed was influenced due to frictional drags caused by the adjacent faster moving pulleys. The device was then modified to use timing pulleys and belts to ensure an accurate speed difference. Effort to synchronize the speeds of the web divider, card, and yarn spinning heads is underway. When the concept is finalized, the apparatus can be easily expanded to 10 or more strips. The limitation, of course, is in the uniformity of the web across the

machine. It is expected that uniformity of polyester staple fibers will produce a reasonably uniform web. A cotton web would be much more of a challenge. The web will be made as heavy as possible in order to create the linear density needed for a coarse yarn.

YARN FORMATION BY CARD-SPINNING

In a traditional staple yarn spinning system, fibers are opened, cleaned, carded, drawn and reduced to a roving before spinning (twisting). One of the objectives of this project is to design a system where the short staple fibers in the carded web can be spun directly into a yarn before the web is consolidated into a sliver. A literature research (e.g., [10,11,12,13]) shows that efforts have been made to shorten the systems to convert short staple (cotton type) fibers into yarns, and that in the shortened systems, carded or drawn sliver is processed into either a ring spun, a rotor spun or an air jet spun yarn, thus eliminating the extra step of drawing and/or roving.

We have assembled a flexible "hybrid nozzle" spinning device with the objective of straightening the fibers, twisting the bundle with high efficiency and low air consumption, and producing a smooth and strong yarn. Figure 5 shows a schematic drawing of the spinning device, and Figure 6 shows a photograph of the device. The device is designed to have the maximum flexibility in processing conditions. It is placed on a height-adjustable table with wheels. The speeds of the feeding rollers, delivery rollers and the winder can be independently set.

In conventional airjet spinning machines, a draft system is used to draft and to feed the fiber strand into the spinning nozzle. For example, MJS801 air-vortex spinning machine by Murata has 3-roll drafting system while MJS802 has a 4-roll system. In our Card-Spinning system, because the card web is split to provide the necessary linear density, there is no need to draft the web ribbon. Therefore, a pair of normal feeding rollers are used to control the rate of feeding the web ribbon into the spinning nozzle. The vortex air spinning unit is composed of a Murata 802 MJS, twin air jet spinning nozzle, and utilizes a service air system. A negative air pressure is formed in the first nozzle to aspirate the fiber sliver. The second nozzle twists the outer fibers free from fiber core to wrap around the core and form a yarn. A pair of delivery rollers and a winder is used to wind the yarn into a cone shape that is suitable for further experimental tests and production.

Before this spinning device is directly attached to the web splitting device under development (see previous section), we tested its operation by feeding it with separately prepared thin slivers. The feed strand is aspirated into the spinning unit via a transfer channel. The fiber bundle is twisted to form a yarn, which is then wound onto a paper cone.

In a conventional airjet spinning process, drawn slivers are used as the feeding stock. Whereas for the Card-Spinning device, card web will be fed to the spinning device directly. To study the effect of feed stock, we have conducted a study to compare the yarn characteristics using both drawn sliver and card sliver as the feed material. The feed slivers, of the same linear density, were fed into our spinning device to produce yarns under the same spinning parameters: air-

pressure of spinning nozzles, feed speeds, delivery speeds and windup speeds. The analysis on the final yarns shows that yarns spun from card sliver are not as uniform as that of yarns from drawn sliver. However, the card sliver, due to its loose structure, is easier to twist.

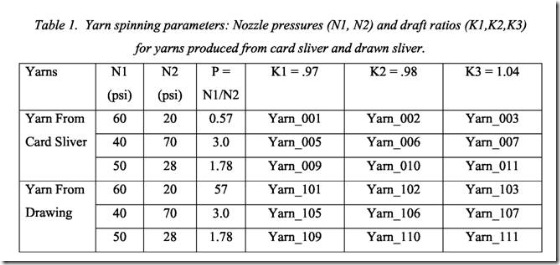

The main factors influencing the final yarn qualities include: super feeding ratio (affecting winding tension); condenser size; distance from front roll to spinning nozzle and air pressures. Three air-pressure conditions and two super feeding ratios were used to produce yarns with drawn sliver and card sliver (Table 1). The effect of feed ratio, pressure ratio, and feeding stock on yarn breaking strength is shown in Figure 7.

For the carded sliver yarns, a nozzle pressure ratio of 0.57 yielded a yarn with better final yarn quality than the yarn produced with other ratios. For example, the tensile strength of yarns with

P= 0.57 ranged from 1.6 to 2.0 kgf, while those produced with P = 1.78 and P = 3.0 were significantly weaker (0 to 0.5 kgf). Yarn elongation and tenacity exhibited a similar trend.

For the drawn sliver yarns, a value of P=1.78 yielded the highest tenacity and elongation. A feed ratio of 0.98 was shown to produce the highest quality yarns.

In analyzing the effects of drawing on yarn characteristics, it was shown that for P ratios of 1.78 and 3.0, the drawn sliver produces a better quality of yarn. However, for P = 0.57, the carded sliver yields better yarn quality. This was determined by evaluating the yarn strength, yarn elongation and yarn tenacity. This result is significant. It means that if the fiber alignment and desired regularity of a sliver are achieved by carding machine modification, the spinning of yarn directly from carded web may be practical. The expensive drawing process could then be eliminated from the staple yarn production line. Further details are presented in the thesis derived from this systematic study of processing parameters [14].

SUMMARY

This project focused on the motion dynamics of fiber clumps in an airflow field and the development of a prototype Card-Spinning unit, which combines carding and yarn spinning in a single machine. We have demonstrated its feasibility in producing coarse yarns. Continuing effort is underway on experimental and theoretical analysis of air flow, web uniformity regulation, system integration/enhancement, and yarn characteristics studies.

We are pleased that the project has received significant interest and support from the textile and the machinery industries. The interaction with industrial partners plays a significant role in the success of this project.

Investigators: Youjiang Wang (leader), Mary Lynn Realff, Radhakrishnaiah Parachuru, J.

Lewis Dorrity, Fred L. Cook, Jim Brazell, Xi Chen (Georgia Tech)

Bhuvenesh C. Goswami, David A. Zumbrunnen (Clemson)

Students: Shumin Zheng, Fan Zhao, Hua Huang (Georgia Tech)

Kai Liu, John Mike Wolf (Clemson)