WITH ANTIBACTERIAL ACTIVITY

G. Salvio

MONTEFIBRE SpA (ITALY)

Introduction.

Since the last part of the century an increasing improvement in qualitative standards of human lifestyles has brought to a greater sense of comfort, and cleanliness. People are more and more looking for fresh public living surroundings and a higher level of hygiene in home areas. A wide class of micro-organisms coexists in a natural equilibrium with human body and living environments, but a rapid and uncontrolled multiplication of even non pathogenic microbes can seriously compromise the hygienic and healthy personal standards. Because of their capillary spread in the human living spaces, the textiles have been involved in this research of a growing quality of hygienic living conditions.

Actually, several combinations of temperature, humidity and other climate factors added to the presence of dust, soil and fat-stains on the textile surfaces can transform the textiles themselves in an optimal enrichment culture for a rapid multiplication of micro-organisms. In such a case two contemporary effects occur: the first is an uncontrolled proliferation from textile surfaces into the surrounding environment with a consequent increase of bio-burden level and potential health risks or, at least, of discomfort for the unpleasant odours produced by high concentrations of micro-organisms; the second one is the onset of degradation phenomena as colouring and discoloration of the textile

fibres. Many efforts have been performed by textile industry with the aim to score two goals: the protection of the living environments and of the textile fibres from an uncontrolled proliferation of microorganisms like bacteria.

2) – Micro-organisms action on textile surfaces.

In the broad spectrum of existing bacteria there are pathogenic and non-pathogenic organisms. Both of them can multiply abnormally on the textile surfaces with an accumulation that compromises the hygienic cleanliness.

Tab.1 shows some examples of pathogenic and non pathogenic microorganism.

The proliferation of pathogenic micro-organisms has to be fought for

the physiologic impact to the human health, while non pathogenic micro-organisms have to be controlled for the visual, olfactory and tactile effects produced by their metabolism.

The textile materials, on which source of nutrients are present (food contamination, oil, fat, protein, sugar, skin secretions like sweat and sebum etc.) become a medium for a rapid multiplication of microorganisms. Many bacterial colonies produce, in their metabolism, coloured pigments that protect them against light and UV radiation.

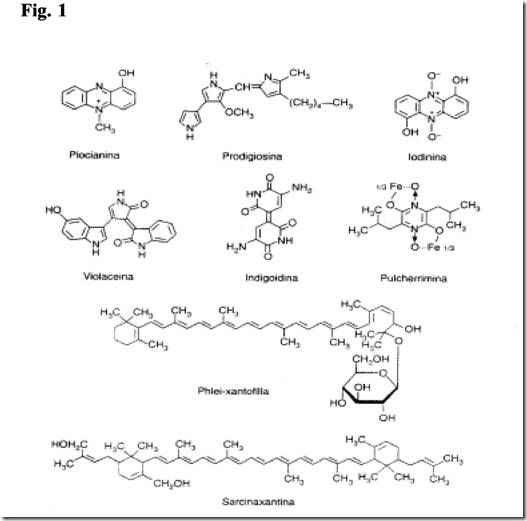

In fig. 1 some colouring pigments, synthesized by different bacteria, are reported:

These substances cause colouring of textiles through adhesion to the surface. The pigments attached to the fibre cannot be adequately

removed by normal washing and, as time passes, colour stains firmly bond to the textile with no possibility of removal, even after repetitive washings. In some cases, according to the type of fibre material and attached pigment, only bleaching agents can be helpful, but it is quite difficult remove the pigment even by the oxidation and reduction reactions of the bleaching process.

In their growth on a fibre, micro-organisms can produce volatile compounds of unpleasant odour as decomposition by-products of their feeding. Spilled foods and drinks, dirt, dust, organic stains, secretions from the human body like sweat and sebum are decomposed from bacteria with a production of bad smelling components like : fatty acids (acetic, propionic, butyric, valerianic, caproic), n-methylamines, ammonia, aldehydes, sulfides, mercaptans, aromatics and lactones. Other micro-organisms transform the human steroid hormones in foul ketones and steroids with the same odour of urine.

3) – Bio-active fibres.

A general term that is adopted to indicate the textile fibres with activity against micro-organisms growth is “bio-active fibres”. A distinction can be made according to the possible end-uses: hospital uses, home textiles, carpets, furnishing, mattress and pillows fillings, air-liquid filters, nonwovens, protective clothing, sportswear etc. Each of these application fields will demand a different bioactivity performance from the fibre. Man-made antibacterial fibres are manufactured by two basic methods: the first is kneading antibacterial additive during the spinning stage and the second is an after-treatment method in which an antibacterial agent solution is used.

In the mixed spinning technology, the antibacterial agent is supplied

into the polymer stream before the spinneret or blended into the spinning polymer feeding. The additive characteristics have to be compatible with spinning conditions (e.g. particle diameter, heat and chemical stability, no degradation interactions with polymer, lack of adverse effects on fibre quality). A reserve of antibacterial additive is englobed into the fibre and, after migration to the surface, it can practise its bioactivity against micro-organisms.

In the post-process finishing technology, the most common techniques to apply antibacterial agents are: spraying, immersion, padding and coating. The textile surfaces are often treated in the final dyeing and finishing stages of their manufacturing process. Antibacterial agent is linked to the surface through physical bonds or anchored by a cross-linking on the fibre. The most used additives are based on organic compounds like halogenated salicylic acid, anilides, organotin compounds, quaternary ammonium compounds, organosilicon quaternary ammonium salts, and quaternary ammonium sulphonamide derivatives . Since most of them are highly water soluble and weakly anchored to the fibre surface, they have to be constantly reapplied.

According to the manufacture technology and the antimicrobial agent nature, the antibacterial fibres can exhibit two kinds of bioactivity mechanism: an elution mechanism and a non-elution mechanism. In the first the additive gradually migrates out from the fibre to the solvent external medium, while in the second mechanism it does not dissolve out. Although, sometimes, the two kinds of mechanism coexist in the antimicrobial activity of a bioactive fibre, generally, one of them is the predominant.

4) – Antibacterial activity tests .

Antibacterial activity of bioactive fibres is not immediately evident, but it can be evaluated by opportune test methods. Since the early appearance of bioactive fibres, several standard methods have been defined and, at the moment, there is not a unique test protocol that is suitable for all the sorts of the antibacterial fibres. Each of the existing methods has its own approach and application field, so that, if two of them are adopted to characterize the same antimicrobial textile, they often show opposite results.

A first overall classification is carried out on the basis of the kind of the evaluation of the micro-organism population reduction: quantitative and qualitative. In the quantitative methods the number of bacteria, still living after an opportune contact time, is counted. Besides, the quantitative evaluation can be differentiated further in other two classes according to the main test conditions. For example, a small amount of liquid culture medium is used to cover a specimen in the static method ATCC 100, while the fibre specimen is immersed in a larger amount of liquid culture when the dynamic Shake Flask Test Method is carried out.

In the qualitative methods the test specimen and an untreated control are pressed into intimate contact with an agar culture medium inoculated with the test bacteria solution. If antibacterial activity is present, it will be possible observe a clear zone around the treated sample comparing to the zone of bacterial growth around and over the untreated control sample after the same contact time.

These qualitative methods provide a formula to measure the inhibition zone width, but this is a qualitative evaluation and it can not be considered as a quantitative indication of the antibacterial activity.

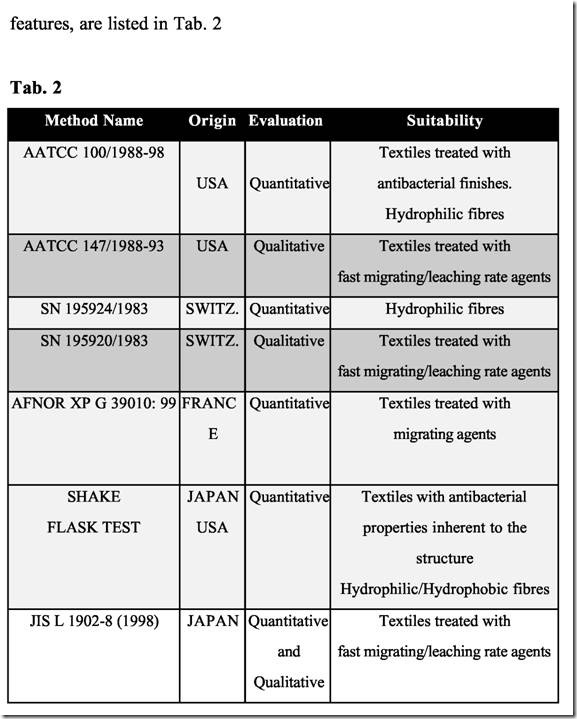

The most important antibacterial activity test methods, with their main

The results that these methods can give depend strongly on the antibacterial additive mechanism of activity and on the hydrophobic or hydrophilic nature of the bioactive fibre. In each analysis, the measurement of the activity of a reference sample of nature similar to the antibacterial fibre but without additive must be carried out.

After the time contact, three cases of bioactivity can present as result

of testing a textile:

1) a significant increase of the initial bacteria population

2) an inhibition of the bacteria growth comparing the antimicrobial product with the control sample for which there is a multiplication of test bacteria population inoculated at the beginning of the time contact.

3) a quantitative reduction of the number of test bacteria inoculated at the beginning of the time contact.

The second and the third cases indicate an antibacterial activity from the bioactive fibre and the terms used to differentiate the two performances are biostatic and biocide.

5) – Montefibre Terital Saniwear.

Only inorganic compounds can be used as antibacterial agents to add bioactive functionality to the polyester fibre directly in the spinning stage due to heat-resistance limitations.

Montefibre has now developed an its own technology to impart antibacterial activity to the regular TERITAL polyester staple fibre. The required amount of antibacterial additive is mixed to the melt polymer stream before spinning.

The additive used in TERITAL Saniwear manufacture has a high surface area of active ingredient so that it is possible to reduce the overall loading of antimicrobial agent. That means no impacts onto fibre quality and environmental benefits. The additive is a photo stable inorganic powder and it essentially consists of an active ingredient deposited on a core particle which has bio-activity as well. Due to its inorganic nature the antimicrobial agent has a high heat and chemical stability. The easy dispersion in the polymer matrix and a barrier layer

that avoids an uncontrolled release of the active ingredient are two key elements for the long-lasting antimicrobial effect provided to the fibre. In Tab. 3 some MIC values (Minimum Inhibitory Concentration) of the antimicrobial additive used for Terital Saniwear are reported:

Antimicrobial additive is EPA approved, FIFRA registered and shows low toxicity.

Metal ions inhibit the multiplication of micro-organisms by two mechanisms. In the first, they destroy or pass through the cell membrane, and bond to the –SH group of cellular enzymes. The consequent critical decrease of enzymatic activity produces an alteration of the micro-organism metabolism and a suppression of their growth, up to the cell death.

In the second possible mechanism, the formation of active oxygen occurs according to the following scheme:

The metal ions catalyse the production of oxygen radicals that destroy

molecular structure of bacteria. Such a mechanism does not need a direct contact among antimicrobial ingredient and bacteria, because the active oxygen diffuses from fibre to the surrounding environment. Bacteria are not exposed permanently to radicalic oxygen and, thus, this ionic additive, with its activity mechanism, does not seem to facilitate the selection of resistant strains.

5.1) – Terital Saniwear properties.

Studying the antibacterial product, Montefibre has initially started individualizing two main potential application areas: the cotton type spinning-weaving and the filling sectors. Thus, two classic fibre counts have been chosen in the first development stage: 1.7dtex for the cotton type and 6.7 dtex for the fibrefill type.

In Tab. 4 textile properties of standard TERITAL polyester staple fibre and TERITAL SANIWEAR are showed. There is no significant decrease in mechanical characteristics of the fibre and, thus, it can be transformed along the textile chain like regular polyester.

The mechanical wadding properties remain practically constant passing from the standard to the antibacterial fibre.

Saniwear can be used in mixture with standard thermo-bonding fibre, as the regular fibre, for thermo-linked wadding. Dynamic-mechanical performances of the obtained samples are compared in Fig. 2

Antimicrobial additive tends to give a slight yellowing of the fibre, but, in the case of Terital Saniwear, the kind of added agent does not produce a dramatic variation. Colorimetric characteristics of the

5. 2) – Antibacterial Test Method for Terital Saniwear.

To evaluate the antibacterial properties of all the samples containing TERITAL Saniwear, the Shake Flask Test was adopted. The choice of this method is connected to the hydrophobic nature of polyester fibre

and to the additive activity mechanism.

SN 195920 and AATCC–147, being static methods, are directly dependent on the rapid leaching rate of the antibacterial agent from the fibre into surrounding environment. The additive used by Montefibre is basically immobilized and slowly diffusing. It does not diffuse at an efficacious rate, under normal conditions of testing, and, thus, these methods are not appropriate for the TERITAL Saniwear.

Besides, the high ratio liquid/fibre in the Shake Flask method allows the right testing condition for a hydrophobic surface as is the case of polyester. Finally, this method ensures (by a constant agitation) an intimate contact between the micro-organisms and the antibacterial textile surface and, for this reason, it is the most suitable in the evaluation of blended fibre samples.

In the operating procedure 75 ml of a bacteria inoculum are added to a test flask containing 0.75 g of the test specimen. After sampling at time zero, the number of the bacteria are counted by placing and incubating on an agar plate. The same procedure is repeated for a control sample. Then, all the flasks are shaken for 24 hours and the number of living bacteria are counted. A percent reduction of bacteria is determined using the following formula:

Reduction (%) of bacteria: (B-A)/ B * 100

where: A = CFU/ml (units forming bacteria colonies/ml) after 24 h. B = CFU/ml (units forming bacteria colonies/ml) at 0 h.

5. 3) – Terital Saniwear’s antibacterial activity.

In Tab. 8 the antibacterial effect of TERITAL Saniwear against some bacteria strains is reported as percentage reduction obtained in the Shake Flask Test. In each determination a reference non-antibacterial sample is tested showing a bacteria growth after the same time contact.

The antibacterial effect of TERITAL Saniwear is maintained also when it is blended with other natural or synthetic non-antibacterial fibres, as regular polyester and cotton. The results of the bacteria reductions obtained at different level of Saniwear in the blends are showed in Tab. 9 (polyester blends) and Tab. 10 (cotton blend):

Testing the antibacterial activity of blended fabrics after bleaching, dyeing and finishing stages shows that Terital Saniwear is still effective in the inhibition of bacteria growth (Tab. 11):

5. 4 ) – Durability.

Terital Saniwear has a long lasting activity for the slow diffusion rate of the antibacterial additive kneaded in the fibre.

As measured in Montefibre laboratories, the release of the bioactive agent from the interior fibre surface, in the dyeing and washing processes, is really minimum and experimental data (reported in Fig. 5) confirm this evidence:

This controlled migration of the additive is confirmed by washing tests according to the standard EN 26330, using a ECE-detergent at 40 °C. Evaluation of the antibacterial activity after repeated washes, carried out on fabric samples containing Terital Saniwear, points out a permanent effect against multiplication of bacteria; some examples are reported in Tab. 12. A change in the surface dispersion of the antimicrobial agent can occur during washing cycles so that a new fresh amount passes from the interior reserve to the external fibre surface with a slight improvement of the antibacterial activity after the first washing steps.

5. 5) – Potential end uses and possible developments.

A broad variety of potential and interesting end-use applications of Terital Saniwear is described in Tab. 13, while the available antibacterial fibre types and some new Montefibre’s bioactive products - at the time being under development- are showed in Tab. 14:

6) CONCLUSIONS

Beyond some untenable claims, it is by now a widespread opinion - experimentally proved - that the antimicrobial textiles can contribute to the cleanliness and hygiene standard quality in the every day human life. The Terital Saniwear is an inherent, safe antibacterial fibre showing an effective barrier against micro-organisms proliferation on the textiles in which it is added.

The mechanical performances are very similar to those of the regular Terital and the durability of the antibacterial effect is ensured by the additive activity mechanism joined to the manufacture technology of the modified fibre. Saniwear can be used at a blending ratio suited to the application fields and to the requested level of antibacterial activity (bacterio-static/cidal).

Montefibre’s R&D, with its analytic-technical support, is really desirous and motivated to follow the customer’s creativity in exploring

all the possible market developments, in defining together the best transformation conditions of the new Terital Saniwear and in engineering fibre for specific end-use applications.