An overview of yarn formation technologies

During the 1970s, there appeared to be a myriad of spinning systems, such as twistless spinning, self-twist spinning, fasciated yarns, composite yarns, wrap-spun yarns, pot spinning, continuously felted yarns; and the many possible variants in open-end spinning such as rotor, electrostatic, friction spinning, and vortex spinning (the original “Polish” system). At the same time, there were continued developments in ring spinning, with ventures into rotating ring and traveler systems, individual spindle drives, high draft systems, modified travelers, double roving spinning, and hybrid systems.

A look at today’s industry reveals that while some systems have established a successful but small niche — wrap spinning for fancy yarns, and friction spinning for specialty industrial markets — very few systems have survived. Indeed, this is also true of the manufacturers of these machines.

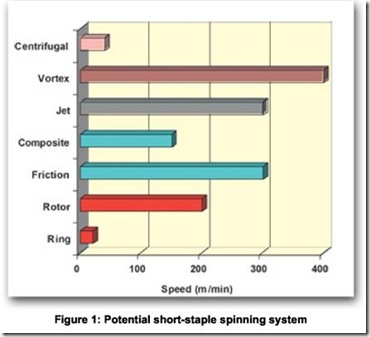

Figure 1 represents the current offerings in spinning machines and their comparative spinning speeds.

Table 1 summarizes the number of spinning positions for the major technologies, together with their share of the spun yarn market. It is evident that, when judged from the perspective of the number of installed spindles, ring spinning is still the most dominant spinning system — there are about three times more spindles than installed rotors. If judgment is based on the quantity of yarn produced, it is clear that even though there are only one-third as many positions of rotors installed, rotor spinning produces three times more yarn than ring spinning.

Ring Spinning

The technology behind ring spinning has remained largely unchanged for many years, but there have been significant refinements. Changes, which on their own offered only slight advantages, provided the following synergies when combined:

· The introduction of longer frames reduced the relative costs of automatic doffing.

· The combination of spinning frame and winding (link winders) further enhanced the adoption of automation.

· The introduction of automatic doffing meant that doffing time was reduced and thus package (and ring) size was less critical.

· The introduction of splicing on the winder meant that yarn joins became less obtrusive — again offering the potential of smaller package.

· Smaller rings meant that for a limiting traveler velocity (40 meters per second [m/s]), higher rotational speeds (and hence twisting rates) could be achieved.

These combinations meant that the potential maximum speed of ring spinning was raised from about 15,000 to 25,000 revolutions per minute.

There also have been several other proposed developments that have met with mixed success.

Drafting systems: While double apron drafting dominates, the system can be tweaked to enable higher drafts. Recent exhibitions have featured machines operating at potential drafts of 70 to 100. The use of high drafts has significant impact on the economics of the total system.

Individual spindle drives: Several manufacturers demonstrated this possibility in the 1980s. While the concept offered advantages with respect to lower energy requirements, less noise and better control of speed, it suffered higher initial costs and bigger spindle gauge.

Ring Design

Several approaches to reducing the limitations of traditional rings and travelers have been proposed. Orbit ring: This development from Rieter was aimed at increasing heat dissipation from the traveler.

Ceramic rings (Ceratwine system): The combination of a ceramic ring and ceramic-coated traveler offered the promise of significantly better wear resistance, which translates into long traveler life. More consistent yarn quality and shorter break-in time are other claimed benefits.

Rotating rings: This idea was tried by several ring frame manufacturers in the 1970s. Other ventures into this area included systems such as Cerifil, Magnetic Spinning and Super Traveler Spinning. The problem with these types of devices is, while they appear to operate at lower spinning tensions, and thus potentially offer lower end breakage rates, they suffer the drawbacks of short duration and high-magnitude tension peaks because of the inertia of the twisting element, which is significantly higher than a traveler.

Spindle identification (Schlafhorst, Barco): The tracking of spindles from the ring frame has great potential for process quality control. This enables the identification of those spindles on the ring frame that are responsible for producing defective yarns, as assessed on the winding frame. It is believed this type of system will result in improvements not only in yarn quality, but also in efficiency, by more readily indicating faulty positions on the spinning frame.

Longer machines: Improvements in the drives used on spinning frames have enabled the number of spindles per machine to be further increased up to 1,488 (Zinser). This has a positive impact on the cost per spindle. Additionally, as indicated above, longer machines favor the use of automation, particularly link-winding.

Compact spinning: Systems that use additional drafting components and pneumatics to create yarns that are less hairy and stronger are available from several machinery m akers. The many claims made for these systems are usually mutually exclusive in that one can either have a stronger yarn or spin at higher production speeds with lower twist. Moreover, there is a significant increase in the cost of these machines, and the yarn thereby produced, when compared to traditional spinning frames. While the use of compact spinning machines is claimed to have made significant inroads in Europe, the system has not been well-received in the United States. It is evident that several other machinery makers will venture into this market, such as Marzoli and Cognetex, and this added competition may result in reduced machinery costs.

Rotor Spinning

Rotor or open-end spinning is now a mature technology, and since the 1960s, it has seen a five-fold increase in twisting speeds. During the early stages of development, debates concerned such questions as:

· Were self-pumping or evacuated systems better?

· Was roller drafting feed superior to a beater opener?

· Was spin through better than feed and withdrawal from the same face of the rotor?

· Were twin disc bearings the best solution for higher speeds?

These issues were seemingly resolved, and most modern rotor machines are very similar in layout with relatively subtle differences between mac hines from the major manufacturers. These differences are typically associated with the aerodynamics of the transfer tube, rotor design and navel design.

While it is still possible to obtain low-tech rotor spinning frames, present state-of-the-art machines have significant integrated automation such as doffing, piecing, cleaning and process/product monitoring. Additionally, the machine can be part of a material handling system from sliver through to packaged yarn.

It is generally accepted that, while rotor yarns are different from ring-spun yarns, they tend to offer advantages in processing through weaving and knitting. This difference is a result of structural differences introduced during yarn formation. This structure — which is responsible for the lower strength of rotor yarns, but improved hairiness and yarn abrasion — is an inherent feature of the system. While it is possible to control the formation of wrapper fibers by optimizing rotor and navel designs, it is impossible to eliminate them. Unfortunately, while smaller rotors are required for higher processing speeds, this also negatively impacts wrapper fibers, and thus higher speeds often carry the penalty of a reduction in yarn quality.

Developments in rotor spinning include the use of longer machines. Additionally, there is interest in potentially using rotor technology to produce core yarns and using additional components to create effect yarns.

Fasciated Yarns

While initially there were several potential manufacturers of machines for this technology, the market has been dominated by Murata, with its jet spinning and vortex spinning systems.

Murata Jet Spinning (MJS) gained a small, but significant, share in the polyester/cotton yarn market. The advantage of the system was that it offered high-speed production of finer-count yarns and thus did not directly compete with rotor spinning. Since its commercial launch as MJS, several variants have been introduced, including Murata Twin Spin (MTS) and Roller Jet Spinning (RJS). Different jets also were offered to accommodate different yarn styles.

These offerings were to extend the use of jet spinning, with particular respect to fiber type and yarn count. Jet spinning has the major disadvantage of not being able to produce acceptable 100-percent cotton yarns. Furthermore, MJS is restricted to finer counts because yarn tenacity reduces as the yarn becomes coarser.

For optimum processing, there also are higher quality requirements on the feed sliver with extra drawing or combing operations. Despite these limitations, and the necessity to optimize finishing in order to promote an acceptable hand, jet spinning is a viable system in the United States because of high productivity — 250 meters per minute (m/min) for the MJS 802H — and adequate yarn and fabric quality. As a bonus, the core sheath structure of the yarn tends to minimize hairiness, which in turn reduces pilling propensity, often a major problem with polyester-rich blends.

Murata Vortex Spinning

Murata Vortex Spinning (MVS) is best judged as a development of jet spinning specifically created to overcome the limitations of fiber type. The major marketing feature of MVS was that it was capable of spinning uncombed cotton slivers into acceptable yarns at speeds that were significantly higher than with any other system. The yarn structure is different from jet-spun yarn with many more wrapper fibers, and in parts the vortex yarn resembles a two-fold yarn. There were concerns that there is excessive fiber loss using this spinning machine. But, even though the fiber loss may be about 8 percent, most of this is short fiber, which would not contribute to yarn quality.

MVS was introduced with a remarkable potential processing speed of 350 to 400 m/min. Successful spinning systems historically have had a significant increase in production speed within a few years of introduction. If this trend were to be true of MVS, it is possible that the industry could have a staple spinning frame capable of speeds in excess of 500 m/min.

Even though it is claimed that MVS is capable of processing 100-percent cotton, it is believed that the major use of this system is in the processing of cotton-rich blends with polyester. The machine utilizes a roller drafting system working at high drafts and high speeds. There is proof that indicates these systems may give rise to unacceptable yarn variations, which become apparent in terms of fabric defects or weak spots in the yarn. This is a problem that could be addressed by using the rotor spinning beater opener.

New developments likely for MVS include modifications to enable the production of coarser counts and a possible re-examination of the concept of spin assembly winding, where yarns from two spinning positions are combined onto one package that is subsequently two-for-one twisted. It is also evident, from a cursory review of patents, that other machinery makers have invested in significant research into technology similar to vortex spinning and perhaps there soon may be alternative machines available.

It is clear that at the present time, there is a lull in investment in new spinning machinery in the United States. This could be explained partly by a downturn in the industry, which seems to be supported by the reduction in positions shown in Table 1, and partly by the fact that the current technologies are mature.

An additional factor in this consideration is that as spinning machines become more productive, the number of machines needed to satisfy a particular market will decline. It is quite evident from the data shown in Table 2, that among all the major spinning technologies used in the United States, there has been a very substantial increase in productivity over the past 10 years. The table does not include the impact of changing from jet spinning to vortex spinning, which would show an even greater increase in productivity for this type of yarn.

Editor’s Note: William Oxenham, Ph.D., is associate dean for academic programs at North Carolina State University’s Department of Textile and Apparel Technology and Management, Raleigh, N.C. Oxenham received both a B.Sc. and Ph.D. from the University of Leeds, England, and is regarded as an international expert in the area of yarn manufacturing.