The Impact of Carding Micro-climate on Cotton Moisture Content

and Fiber and Yarn Quality

David D. McAlister III*, David T.W. Chun, Gary R. Gamble, Luther C. Godbey,

Dean R. Cobb, and Everett E. Backe

ABSTRACT

Temperature and relative humidity are important considerations for carding cotton in textile manufacturing. It has been suggested that high relative humidity decreases the stiffness of fibers and increases the moisture content of the fibers. With the recent interest in moisture addition at the gin, it is important to determine if increased fiber moisture content in the cotton bale will also benefit the textile manufacturer. In this study, a standard carding atmosphere and a modified atmosphere of low temperature and high humidity were used as the treatments. Bales of the same cultivar and module were ginned sequentially in order to reduce the variability in the fiber properties. All cotton was processed on the same textile equipment. The only variable was the atmospheric conditions surrounding the card. The results of this work indicate that increasing the degree of saturation of the air surrounding the card by cooling the air and increasing the relative humidity minimizes the loss in moisture content of the cotton fiber through carding and reduces short fiber content in carded and finisher drawing sliver. Rotor yarn processing and quality were not affected by the treatment. Ring yarn processing efficiency, and ring and vortex yarn quality was improved in the cooler, moister environment surrounding the card.

Strang (1954) suggested that the air currents within the card affect the operation of the machine, and determined that the air surrounding the card was influenced by changes in vapor pressure, temperature, and humidity. Additionally, his work suggested that temperature (>10 °C) and relative humidity (50 to 55%) are important considerations for carding, but he did not discuss the effects of temperature and relative humidity on cotton fiber moisture content during carding. Sengupta et al. (1983) investigated the impact of various variables on carding forces (the force required to individualize fibers from tufts of fibers), and concluded that increased relative humidity resulted in decreased carding forces, which they attributed to the reduction of the flexural rigidity of the cotton fibers as a result of an increase in the moisture content of the fibers. The reduction in flexural rigidity of fibers as a result of increased moisture also reduced the breakage rate of fibers at carding (Sengupta et al., 1982). Increased relative humidity resulted in a reduced end breakage rate at spinning (Walker, 1964). In fact, McCreight et al. (1997) stated that the amount of water that fibers contain can greatly affect their physical properties. The absorption of moisture by cotton fibers changed the mechanical and frictional properties of the cotton, which affected the behavior of the fibers in processing (Morton and Hearle, 1997).

Although the research above cited increased relative humidity as a factor in improved carding, they did not indicate what the moisture content of the cotton is under the treatments investigated. In fact, there was no discussion in the scientific literature on temperature and relative humidity (RH) at the various processing stages of opening and carding of cotton fiber along with the moisture content of the fiber. It is reasonable to assume that the temperatures of certain components of a card, primarily the cylinder, will increase due to forces generated in overcoming friction, which in turn will increase the temperature of the local ambient, i.e. alter the microclimate. Since production areas in a mill are conditioned for temperature and humidity rather than for the micro-climate of each individual machine, a rise in temperature of the microclimate of the machine at a constant room RH would increase the drying capabil-

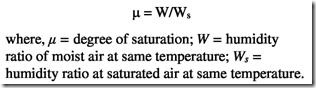

ity of the air. Brooker et al. (1975) cite an example of this in the grain drying process. If ambient air at 29.4 °C is heated to 37.8 °C and passed through the grain to be dried, the humidity ratio (grams of water/grams of dry air) of the air after passing through the grain is higher. The removal of moisture from the grain is cited as the reason for the increased humidity ratio of the air after passing through the grain. A better explanation of this concept is provided by Esmay (1974) through an explanation of the degree of saturation of air. Degree of saturation is defined as the ratio of the humidity ratio of moist air to the humidity ratio of saturated air at the same dry bulb temperature and vapor pressure; therefore, the higher the degree of saturation, the less moisture can be removed from a material as the air passes through it (Esmay, 1974). Following this logic, the standard atmosphere for a typical carding area in a mill (24.0 °C and 55% RH) would have a degree of saturation of 54.264%. In order to increase the degree of saturation, it is necessary to reduce the temperature and/or increase the relative humidity. The objective of this study was to determine the effects on cotton fiber moisture content and fiber and yarn quality as cotton is processed in a standard ambient environment compared to an environment which minimizes the drying of the cotton fiber in processing.

MATERIALS AND METHODS

Eight bales of cotton were selected from one module that had been ginned sequentially on the same day. From these bales, 136.36 kg of fiber were taken from each bale for testing and spinning. Each 136-kg sample was split into two 68-kg lots, one for each of the two treatments. The treatments in the study were carding at ambient conditions (24.0 °C and 55% RH; designated AMBIENT), and carding in an environment that maximizes the degree of saturation based on the capability of the conditioning system in the carding room. This treatment was designated COOL and was achieved by cooling the air to a temperature of 15.6 °C and raising the relative humidity to 75%. The cotton from each bale for each treatment was processed on the same equipment, including an opening and cleaning line consisting of blend hoppers (Fiber Controls; Gastonia, NC), an Axi-Flow (coarse cleaner), GBRA (mixer), RN (coarse cleaner), RST (fine opener), and DX (deduster) (all Truetzschler; Monchengladbach, Germany). Once through the cleaning line, the cotton was carded at 27.27 kg/hr (60 lbs/hr) on a Saco-Lowell card (Saco-Lowell; Easley, SC), which was located in a confined room in order to control the temperature and humidity surrounding the card. This older model card was chosen simply because it does not have the large volumes of air removed from around the cleaning point (as is common on modern carding), which would have prohibited the manipulation of the ambient air surrounding the card. The card sliver produced was 4,961 tex (70 grains/yd). Along the processing points in opening, cleaning, and carding, temperature readings of the ambient air surrounding the equipment, the air inside the equipment, and the connecting duct work used for transporting the cotton were taken every 10 min during the processing of each lot for each treatment. In addition, the temperature and humidity of the carding room was measured every 10 min during the processing of all lots, and the moisture content of the cotton samples for each lot per treatment was determined by the oven drying method (ASTM, 2001). Cotton samples were taken at the hoppers from the bale (before feeding), at the GBRA, at the RST, and at the coiler of the card.

After opening, cleaning, and carding, the resultant card sliver for each lot of each bale for each treatment was split three ways for processing into drawing sliver in preparation for spinning on ring, rotor, and vortex spinning systems. The rotor spinning sliver received one pass of drawing on an RSB draw frame (Rieter; Winterthur, Switzerland) with a leveler producing 4,961 tex (70 grain/yd) sliver and subsequently spun on a Schlafhorst SE-1 1 rotor spinning machine (Saurer Group; Charlotte, NC). Yarn was spun at 117,000 rotor rpm and a combing roll speed of 8,000 rpm with a G30 rotor and a twist multiple a of 115.14 producing a 29.53 tex (20/1 Ne) yarn.

Ring spinning sliver was processed through two passes of drawing; the first on an SB-951 (Rieter; Winterthur, Switzerland) (unleveled) and the second on the RSB draw frame (leveled) producing 4,252 and 4,961 tex sliver (60 and 70 grain/yd sliver), respectively. The finisher drawn sliver was then processed into roving on a Zinser 660 roving frame (Saurer Group; Charlotte, NC) producing a 787.4 tex (0.75 hank) roving at a flyer speed of 1200 rpm and a twist multiple a of 39.39. Yarn (29.53 tex (20/1 Ne)) was subsequently spun from the roving on a Zinser 321 ring spinner (Saurer Group; Charlotte, NC) at a spindle speed of 16,500 rpm and with a twist multiple a of 116.66.

Sliver for vortex spinning was processed through three passes of drawing, with the first two on the SB951 (unleveled) and the third on the RSB (leveled) producing 4,606, 4,252, and 3,898 tex sliver (65, 60, and 55 grain/yd sliver), respectively. The finisher drawn sliver was then spun into 20/1 Ne yarn on a Muratec MVS 851 (Muratec; Charlotte, NC) vortex spinner at 350 meters/min.

All waste from opening, cleaning, carding, drawing, roving, and spinning was collected and weighed. Fiber length, uniformity, strength, micronaire, and color for each bale were measured on a High Volume Instrument (HVI) (Uster Technologies; Knoxville, TN). Test results for each treatment are shown in Table I. In addition, fiber length and short fiber content were measured from in-process fiber and sliver on a Peyer AL-101 (Peyer; Knoxville, TN). Yarn processing efficiency was determined by recording the number of ends down during the processing of each lot for each treatment. In addition, yarn evenness, regular occurring yarn faults (thick places, thin places, and neps), irregular yarn faults (major, minor, long thin places, long thick places), and yarn tensile strength were measured.

The design for this experiment was completely random with 8 bales, 2 temperature treatments, and 3 spinning systems resulting in a total of 48 spinning lots. Each lot was assigned a lot number (1 through 48) and the lots were run in random order by selecting the lot order through a random number generator. All data were subjected to analysis of variance (SAS Institute; Cary, NC) to determine any significant effect of the treatments on the dependent variables (cotton moisture content, fiber properties, spinning efficiency, yarn properties). Significant differences between the means of the affected variables were determined by Duncan’s multiple range test (P = 0.05).

RESULTS AND DISCUSSION

Cotton fiber moisture content in the card sliver was affected by the environmental conditions in carding room (Table 2). The resultant sliver from the cool treatment retained most of its original moisture con tent in the bale, unlike the ambient treatment, which lost 0.5% of its original moisture content. The cooling effect of the cool treatment in the carding room did, in fact, reduce the temperature by approximately 7.5 °C under the card where the cylinder is located and over 9.0 °C at the doffer (Table 3). In addition,

the temperature of the sliver at the coiler was reduced by approximately 4.0 °C. It appears that the reduced drying capability of the cool environment resulted in little to no loss in the moisture content of the cotton through carding. In fact, the calculated degree of saturation of the cool versus ambient treatment is 74.66% and 53.98%, respectively. These values are based on actual average temperatures and relative humidity for each treatment of 15.81 °C and 75% RH for the cool treatment and 23.79 °C and 54.71% RH for the Ambient treatment. The degree of saturation numbers were calculated by the formula defined by Esmay (1974) as follows:

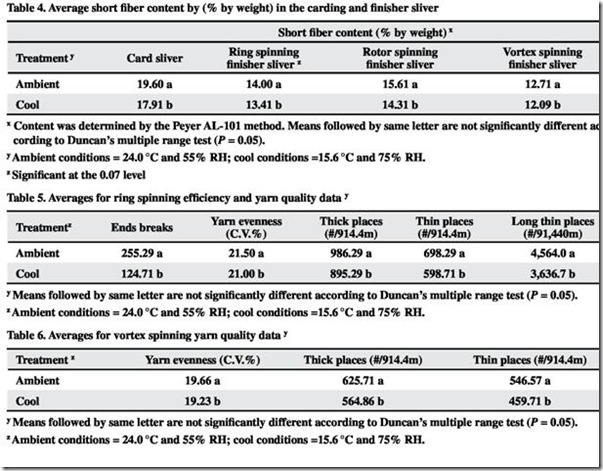

Fiber length was affected by the cool treatment in the form of reduced short fiber content (Table 4). There was a reduction of 1.69% at carding, 0.59% at ring spinning finisher drawing, 1.3% at rotor spinning finisher sliver, and 0.62% at vortex spinning finisher drawing. This result follows the conclusions by Sen gupta (1982) that the reduction in flexural rigidity of fibers, as a result of increased moisture, caused a reduction in the breakage rate of fibers at carding.

Yarn processing and quality for rotor spinning were not affected by the treatments, but ring spinning and vortex spinning were affected (Tables 5 and 6, respectively). The reason yarn processing and quality for rotor spinning was not affected may lie in the fact that the fibers in the sliver fed to rotor spinning are combed and individualized by the combing roll, then drafted in a high-draft air stream through the fiber channel and reassembled in the rotor cup for yarn formation. It is widely known that rotor spinning tends to be more tolerant of short fiber content than ring and vortex spinning. Therefore, it is theorized that the improvement in the short fiber content of the sliver for the cool treatment for rotor spinning was not enough to override the favorable treatment of short fiber by this spinning system.

Ring and vortex spun yarn were affected in a similar manner by the cool treatment. Ring spinning in the cool environment improved spinning efficiency and yarn evenness and reduced yarn faults. Vortex spinning in the cool environment improved

yarn evenness and a reduced yarn faults. It is widely known that short fibers affect spinning efficiency, yarn evenness, and yarn defects, especially in roller drafting systems like ring and vortex spinning. Unlike rotor spinning, the fibers in the sliver are not individualized and then reassembled for yarn formation. A reduction in short fibers in slivers processed through a roller drafting system decreases the number of uncontrolled fibers in the drafting zone, which alters the mass evenness of the yarn and creates thick and thin places along the length of the yarn. In some cases, where the number of thin places is substantial, end breaks can occur. Yarn strength was not affected by the treatments, so it will not be discussed.

CONCLUSIONS

Reducing the drying capability of the air surrounding the card by increasing the degree of saturation of the surrounding ambient air (cool treatment) minimized the loss of moisture in the cotton fiber. As a result of minimizing the loss in moisture, short fiber content is reduced in card sliver and finisher drawing sliver regardless of the number of passes of drawing. This reduction in short fibers, as a result of the treatment, did not translate into improved rotor spinning performance or yarn quality. On the contrary, in the cool treatment yarn evenness was improved and yarn defects reduced for vortex and ring spinning, and efficiency was improved for ring spinning.