with a New Algorithm of Operation

Abstract

These studies concern the work of a modernised autoleveller whose algorithm of operation allows for the phenomenon of sliver retardation after short-term regulation. The autoleveller’s effectiveness at standard and corrected controlling signals was compared. Measurements were made for cotton, viscose and polyester fibres, applying three different drafts in the autoleveller. It was demonstrated that the levelling capacity of the new autoleveller is much better than that of the traditional one.

Key words: autoleveller, card, evenness of mass.

Introduction

Long-term analyses of the operation of short-term regulation systems [2, 3] have shown that the regularity of the linear density of slivers levelled by means of a short-term autoleveller is a function of time, and only its direct measuring in an on-line system enables immediate and reliable conclusions to be drawn about the effectiveness of the regulation process. The results of the studies conducted confirmed the need for a short-term autoleveller whose algorithm of operation would allow for the phenomenon of sliver retardation. Analyses of sliver retardation phenomenon and of a typical algorithm of the operation of a short-term autoleveller led to changes in the autoleveller controlling system, aimed at achieving the minimum possible variations in the linear density of sliver before it is introduced to the next machine in the technological process. The new

algorithm of operation is presented in Equation (1)

where:

R ’(t) – the momentary draft in the autoleveller with the correction of the controlling signal;

R(t) – the momentary draft in a classical autoleveller;

a, b, c – coefficients of the equation of sliver retardation;

k – the limiting draft at which sliver

retardation does not occur.

Changes were made to a typical autoleveller taking Equation (1) into account. The new algorithm was realised digitally, on the basis of the correction system, in the form of a computer with relevant software. It was assumed that

only after retardation would the sliver reach the lowest value of irregularity of linear density, below CV = 2.7% acc. to Uster, at a linear density of about 4 ktex. At longer lengths, the values of CV coefficient should not exceed CV1m = 0.8%, CV3m = 0.5%.

Subject of analysis

The subject of our analysis was a modified short-term card autoleveller constructed as a separate test stand, independent of the card. It is presented in Figure 1.

Modification of the stand consisted in including a corrector of a controlling signal into the autoleveller controlling system. The main aim of this corrector is to change the autoleveller’s algorithm of operation.

Some of the more important constant parameters in these studies are:

the speed of the measuring feed rollers: Vz= 1.33 m/s (80 m/min);

the length of the drafting zone: 62 mm; n the measuring range of the inductive

linear displacement sensor: ± 0.7 mm;

the linear density of the feeding sliver:

6 ktex.

Variable parameters in the studies are:

raw material:

medium-fibre cotton (BS)

viscose fibres (WI)

polyester fibres - Elana (PE);

nominal drafts in the autoleveller:

1.2, 1.4, 1.6.

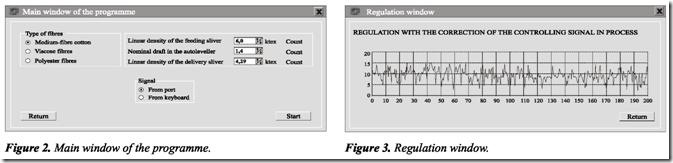

The program continuously corrects the value of a controlling voltage signal. It was written on the basis of the Delphi system by Borland. Figure 2 shows the main window of the programme where the user can set the parameters necessary to perform the regulation process cor-

rectly; in Figure 3 we see the regulation window with the correction of the controlling signal.

The programme works by continuously taking the voltage signal U(t) transmitted from the power amplifier to the drawing wobble-plate engine, and processing it in such a way so that the engine is supplied with voltage U’(t), that is, allowing for the sliver retardation phenomenon.

Results of analysis

27 variants of slivers were analysed. They were made of 3 raw materials at 3 different drafts in the autoleveller (1.2, 1.4, 1.6) Each sliver was made in the following three ways: regulated according to the typical operation algorithm, regulated with correction of the controlling signal, and non-regulated. The slivers were tested three times on a Uster Tester 3: immediately (U 0), 1.5 hours (U 1.5) and 3.5 hours (U 3.5) after leaving the autoleveller; 81 measurements were made in total.

in the example diagrams in Figures 4 and 5.

R - regulation at correction of controlling signal off;

K - regulation at correction of controlling signal on.

The dependencies and tendencies observed in the changes of the analysed parameters of slivers showed very great congruity both for different raw materials and for different drafts in the autoleveller.

The autoleveller works much better with the modified operation algorithm. As early as 1.5 hours after the regulation process, the value of the coefficient of linear density variation CV acc. to Uster decreases (to a level lower than for the sliver regulated in a standard way) and the coefficient of levelling capacity increases. After 3.5 hours, the structure of regulated slivers stabilises after regulation (measurements made later did not show any significant changes in the analysed parameters). The irregularity CV% of the slivers tested falls to the level of about 2.5-3.4%, that is, the values for all slivers are below the level recommended by Uster of CV=3.5%. By evaluating the levelling capacity of the autoleveller, we obtain values η above 30% (even up to obtain values η above 30% (even up to about 45%), which are within the range of satisfactory regulation. So far it has not been possible to obtain such high values during standard regulation, even when evaluation is made directly after regulation.

The nominal draft in the autoleveller

during regulation with correction of the controlling signal does influence the measurement results obtained. Draft R=1.4 turned out to be the best. With this draft, the lowest values of irregularity of linear density were obtained for all tested lengths. The levelling capacity of the autoleveller was also the best.

Figure 6 shows some diagrams obtained from the analysis on the Uster Tester 3 apparatus for the best sliver variant.

Summary

Correcting the controlling signal during short-term regulation of draft considerably improved the regularity of the linear density of slivers with stabilised internal structure. If short-term regulation is performed correctly, it is possible to achieve the desired quality parameters of slivers.

The limit level CV=2.7% is a very restrictive value. The Uster Company accepts CV=3.5% as the maximum value for slivers of typical linear densities. If we follow Uster’s requirements, all the analysed slivers regulated with correction of the controlling signal meet the qualitative criteria.

Although the autoleveller works on short lengths, good results of sliver irregularity were also obtained on longer lengths. It was possible to obtain the desired parameters for several variants. In all other cases, the above-mentioned values were only slightly exceeded.

It was not possible to achieve the required level of irregularities of linear density of slivers levelled by a short-term autoleveller for polyester slivers, but the values CV=2.94%, CV1m=0.86% and CV3m= 0.60%, which were obtained for one of the variants, are very difficult to achieve in the case of the autoleveller’s standard work, that is, without any correction of the controlling signal.

It was found that the best nominal draft in autoleveller was R=1.4 for cotton and viscose slivers, and R=1.2 for polyester slivers. Once more it was demonstrated that in order to obtain a low irregularity of regulated slivers, it is necessary to use small drafts in short-term autolevellers.