Prof.Dr. A.Kirecci

The drawframe contributes less than 5% to production costs of the yarn.However, its influence on quality, especially evenness, is all the greater for this.

Further, if the drawframe is not properly adjusted, there will also be effects on yarn strength and elongation. Secondly, a defect arising at the drawframe itself can exert an effect of significant proportions on the overall process.

High performance drawframes currently produce over 200 kg of sliver per hour at each delivery. Therefore, it should be noted that, very large quantities of poor quality sliver will be produced in a certain time before discovery of the defect.

There are two main reasons for the considerable influence of the drawframe on evenness. Firstly, within the sequence of machines in the cotton spinning mill, the drawframe is the definitive compensation point for eliminating errors.

Inadequacies in the product leaving the drawframe not only pass into the yarn, they are actually reinforced by drafting effects following the drawframe.

The yarn is never better than the drawframe sliver.

'Autolevelling drawframe RSB-D 30

(Rieter) Drawframe SB-D

Auto Leveller Drawframe

Model RSB 851(Lakshmi)

Sophisticated Sliver

Guiding System

Breaker Drawframe

Card slivers fed to the drawframe have a degree of unevenness that cannot be tolerated in practice.

The drawframe has the task of creating this parallel arrangement.

It fulfils this task by way of the draft, since every drafting step leads to straightening of the fibers.

The value of the draft must be adapted to the material, i.e. to several fiber parameters (here, mainly the staple length) and also

to:

1. the mass of the fibers;

2. the volume of the strand;

3. the degree of order (parallel disposition).

This result is exploited in particular in the production of blended yarns comprising cotton/synthetic or synthetic/synthetic blends.

At the drawframe, metering of the individual components can be carried out very simply by selection of the number of slivers entering the machine.

For example, to obtain a 67:33 blend, four slivers of one component and two of the other are fed to the drawframe.

Dust removal can only be carried out where there is fiber/fiber fiber/metal friction, since dust particles adhere relatively strongly to the fibers.

A high performance drawframe with a sufficient number of suction point is a good dust-removing machine.

The feed roller pairs are carried in a creel frame or table and each is positively driven. The slivers runs into the drafting arrangement, subjected to a draft of 4 to 8 and leave it as a web lacking significant cohesion.

In order to avoid disintegration of the web, which would other wise be unavoidable at the high operating speeds currently in use, it is condensed into a sliver immediately after the drafting arrangement.

This sliver is then guided through a tube (4) via a passage (6) of the tube gear into a can (7), in which it must be laid in clean coils with optimal utilization of the space in the can.

To enable the can to take up as much material as possible, the sliver is compressed by passing it through calendaring or grooved railers (5).

1. false drafts are avoided;

2. the machine stops upon occurrence of a sliver break;

3. sliver breaks can be dealt with easily, comfortably and safely.

For this purpose, it is necessary to provide a rotatable roller or roller pair above each can, one for each sliver.

A guiding device for leading the slivers into the drafting arrangement is also required. A table with rollers, or simply a line of rollers, can provide the required guidance.

Rollers alone are preferred in rapidly operating high-draft drawframes, since friction is lover when transport is effected by means of rolling than when it relies upon sliding.

The in-feed roller pairs also serve as electrical contact rollers for monitoring the sliver.

If a sliver breaks, the metal rollers come into contact when the insulating

sliver is no longer present between them, and the machine is stopped.

Normally, slivers may be fed in from up to eight cans per drawing head, and the cans may have diameters up to 1000 mm.

which exerts the most decisive influence on quality. The requirements

placed on the drafting arrangement in general are correspondingly high:

1. simple, uncomplicated construction;

2. stable design with smooth running of the rollers (centricity);

3. a mode of operation giving a high-quality product even at high

running speeds;

4. high degree of flexibility. i.e. suitability for all raw materials, fiber

lengths, sliver hanks, etc..

5. optimal control over the movement of the fibers during the drafting operation;

6. high precision both of operation and adjustment;

7. rapid and simple adjustability of roller spacings and draft levels;

8. ease of maintenance and cleaning;

9. optimal ergonomic design.

Factors dependent upon the fiber material

1. mass of fiber in the strand cross-section;

2. degree of order of the fibers;

3. shape of the cross section of the fiber strand;

4. compactness of the fiber stand;

5. adhesion between the fibers dependent upon surface structure,

6. crimp,

7. fiber length,

8. twist in the fiber strand;

9. compression of the strand;

10. evenness of distribution of fiber lengths (staple form) .

Influences on the draft

Factors dependent upon the drafting arrangement:

1. diameter of the rollers;

2. hardness of the top rollers;

3. pressure exerted by the top rollers;

4. surface characteristics of the top rollers

5. fluting of the bottom rollers;

6. type and form of fiber guiding devices, such as pressure rods, pin

bars, aprons, condenser etc.;

7. clamping distances (roller settings);

8. level of draft;

9. distribution of draft between the various drafting stages.

Elements of drafting arrangements

a)Bottom roller

Bottom rollers are made of steel and are mounted in roller stands or in the frame by means of needle, roller or ball bearings. They are positively driven from the main gear transmission.

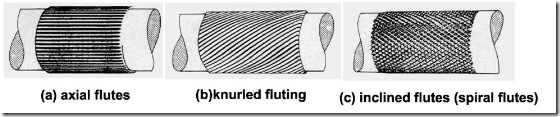

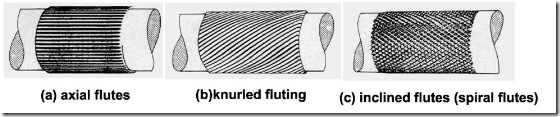

In order to improve their ability to carry the fibers along, they are formed with flutes of one of the following types,

> axial flutes (a),

> knurled fluting (b),

> inclined flutes (spiral flutes) (c).

Elements of drafting arrangements

a)Bottom roller

Knurled fluting is used on rollers receiving aprons, to improve transfer of drive to the aprons.

Other rollers have axial or, increasingly, spiral fluting. The latter gives quieter running and more even clamping of the fibers compared with axial fluting.

Rolling of the top rollers on spiral flutes takes place in a more even manner and with less jerking.

The diameter of the bottom rollers can lie in the range 20 - 90 mm, but normally diameters between 25 and 50 mm are used.

A drafting arrangement includes three to six such rollers. In long machines (e.g. ring spinning machines) the bottom rollers are made up by screwing together short lengths.

Distances between the rollers of the drafting arrangement are usually adjustable and can then be adapted to the fiber lengths.

a) Top rollers

The top rollers are not positively driven. They can be either one-piece rollers (spinning preparation machines) or twin rollers (roving frames, ring spinning machines).

Ball bearings are used almost exclusively in the roller mountings.

The thick coating forming the roller surface is made of synthetic rubber.

An important characteristic of this coating is its hardness.

Soft coats surround the fiber strand to a greater extent than harder ones and thus guide the fibers better.

Top roller pressure

To clamp the fibers, the top rollers must be forced at high pressure towards

the bottom rollers. This pressure be generated by:

>loading by means of dead weights (now obsolete)

>spring weighting (the most usual form)

>hydraulic systems (hardly used)

>pneumatic weighting (the Rieter company)

>magnetic weighting (the Saco Lowell company).

Forms of drafting arrangement

Processing is carried out almost exclusively in two drafting zones. In extreme cases the break drafts lie between 1.05 and 2.5, but usually they are between 1.25 and 1.8. Extreme total drafts lie between 3.5 and 12

but the normal total draft lies between 4 and 8.

In many modern drawframes the draft is no longer adjusted by exchanging gear wheels but by simple setting of variator or stepping drives. The adjustment may be continuous or discrete steps.

Modern drawframes are more flexible in terms of the raw material they can process, and setting operations have been simplified 3-over-4 roller drafting arrangements

The characteristic feature of this arrangement is engagement of the middle pressure roller with two bottom rollers. The two bottom rollers are carried in a common cradle and are not adjustable relative to each other. The basic concept can be improved by the inclusion of a pressure bar in the main drafting field.

This type of arrangement is now found mainly in the combing room,

but also still to some extent on drawframes, for example in the Marzoli and Vouk machines.

3-over-3 roller drafting arrangemenTs with pressure bars

This form was first developed by Platt in the 1960s and is still in use today

in fact, the pressure bar arrangement is probably the most widely used

form of drafting arrangement for drawframes.

The starting point in the development of this design is the realization that

the drafting arrangement runs more smoothly the larger its rollers.

3-over-3 roller drafting arrangements with pressure bars

This applies especially to the front rollers. The effect is due not simply to

stability; for a given circumferential speed, larger rollers can be operated at

lower speeds of revolution. However, enlarging the rollers simultaneously

increases the nip spacings.

Accordingly, in the main drafting zone, a special guide system is needed,

at least for short fibers; this is the guide rail or pressure bar. It can operate

from below or from above. Similar arrangements have been or are built by

Rieter, Schubert & Salzer and Toyoda.

4-over-3 roller drafting arrangements with pressure bars

Strictly speaking, this is also a 3-roller, pressure bar drafting arrangement,

but a fourth roller with somewhat lower loading is added to the delivery

roller to act as a guide.

This leads the web in a curve round the grooved roller directly into the

delivery trumpet, thereby facilitating the formation of the sliver.

The top rollers are uniform in

diameter and are large in order to

keep the strain imposed on them

low.

5-over-4 roller drafting arrangements

In this arrangement five pneumatically loaded pressure rollers rest on two large (90 mm) and two small (28 mm), non-adjustable bottom rollers.

The pressure rollers are suspended from two yokes. They have diameters of 39 mm, although the three middle rollers may be replaced by rollers of 28 mm diameter depending upon the circumstances.

5-over-4 roller drafting arrangements

Drafting is carried out in Field B (breakdraft) and in Field A (main draft). The nip spacing can be read from a scale and can be adjusted to suit the fiber length by simple radial shifting of rollers 2 and 4.

In the main drafting field, a pressure bar ensures firm guidance, especially for short fibers. The drafting arrangement is aligned on a curve; this permits proper guidance of the web material flow from the vertical into the horizontal. The curved disposition makes the system easy to service.

Suction systems for the drafting arrangement

One of the tasks of the drawframe is dust removal. Release of dust occurs almost exclusively in the drafting arrangement and this should be totally enclosed so that dust does not pass into the surrounding atmosphere.

The dust-laden air must be extracted by suction.

Each roller of the arrangement has an associated cleaning device so that fly and fibers tending to adhere to the rollers can also be carried away.

The air drawn away is passed via tubes directly into the exhaust ducts of the air—conditioning system, or to filters within the machine.

The filtered air should preferably be returned to the exhaust ducting, but can also be blown out into the atmosphere of the room.

Condensing

Downstream from the trumpet, the sliver runs between two calender rollers which are pressed towards each other.

This condensing of the sliver enables more material to be fitted into the cans.

Several manufacturers replace the fluted or smooth cylindrical calender rollers with grooved or stepped rollers.

Since these latter rollers do not permit the fibers to escape laterally, a still better condensing effect is achieved.

In this way, the total filled weight of the can may be increased by up to 20%.

Grooved or stepped rollers can be used simultaneously as measuring devices for autolevelling systems.

Coiling

As already described for the card, two rotational movements are required for cycloidally coiling of the sliver.

Modern high—performance drawframes are usually fitted with automatic can changers.

These reduce the burden an the personnel, enabling more machines to be allocated to one person reduce the necessity for attendance of the operative at the machine, and (the chief effect) also increase efficiency.

Read more...

The drawframe contributes less than 5% to production costs of the yarn.However, its influence on quality, especially evenness, is all the greater for this.

Further, if the drawframe is not properly adjusted, there will also be effects on yarn strength and elongation. Secondly, a defect arising at the drawframe itself can exert an effect of significant proportions on the overall process.

High performance drawframes currently produce over 200 kg of sliver per hour at each delivery. Therefore, it should be noted that, very large quantities of poor quality sliver will be produced in a certain time before discovery of the defect.

There are two main reasons for the considerable influence of the drawframe on evenness. Firstly, within the sequence of machines in the cotton spinning mill, the drawframe is the definitive compensation point for eliminating errors.

Inadequacies in the product leaving the drawframe not only pass into the yarn, they are actually reinforced by drafting effects following the drawframe.

The yarn is never better than the drawframe sliver.

'Autolevelling drawframe RSB-D 30

(Rieter) Drawframe SB-D

Auto Leveller Drawframe

Model RSB 851(Lakshmi)

Sophisticated Sliver

Guiding System

Breaker Drawframe

Tasks of the Drawframe

Equalising

One of the main tasks of the drawframe is improving evenness over short, medium and, especially, long terms.Card slivers fed to the drawframe have a degree of unevenness that cannot be tolerated in practice.

II-Parallelizing

To obtain an optimal value for strength in the yarn characteristics, the fibers must be arranged parallel in the fiber strand. ,The drawframe has the task of creating this parallel arrangement.

It fulfils this task by way of the draft, since every drafting step leads to straightening of the fibers.

The value of the draft must be adapted to the material, i.e. to several fiber parameters (here, mainly the staple length) and also

to:

1. the mass of the fibers;

2. the volume of the strand;

3. the degree of order (parallel disposition).

III-Blending

In addition to the equalizing effect, doubling also provides a degree of compensation of raw material variation, by blending.This result is exploited in particular in the production of blended yarns comprising cotton/synthetic or synthetic/synthetic blends.

At the drawframe, metering of the individual components can be carried out very simply by selection of the number of slivers entering the machine.

For example, to obtain a 67:33 blend, four slivers of one component and two of the other are fed to the drawframe.

IV-Dust removal

Dust is steadily becoming a greater problem both in processing and for personnel involved. It is therefore significant to remove dust in every possible step in the process.Dust removal can only be carried out where there is fiber/fiber fiber/metal friction, since dust particles adhere relatively strongly to the fibers.

A high performance drawframe with a sufficient number of suction point is a good dust-removing machine.

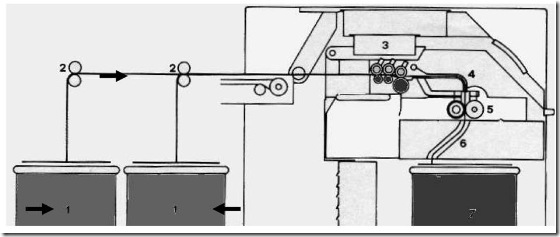

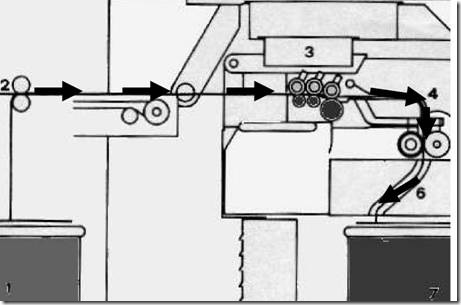

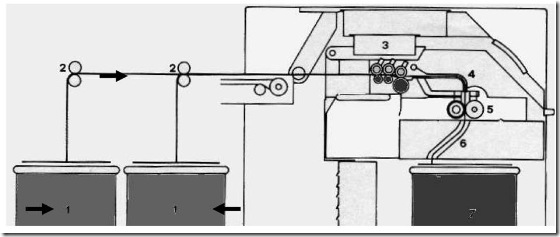

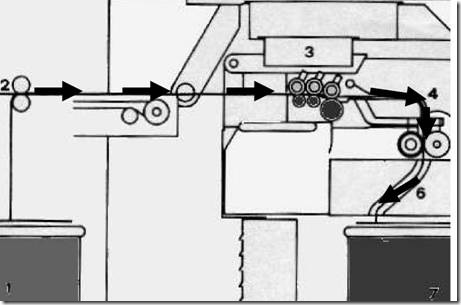

Operating Principle of the Drawframe

Four to eight card or drawframe slivers are fed to the drafting arrangement (3). A feed roller pair (2) is located above each can (1) to enable the feed step to be performed in a controlled manner without false drafts.

The feed roller pairs are carried in a creel frame or table and each is positively driven. The slivers runs into the drafting arrangement, subjected to a draft of 4 to 8 and leave it as a web lacking significant cohesion.

In order to avoid disintegration of the web, which would other wise be unavoidable at the high operating speeds currently in use, it is condensed into a sliver immediately after the drafting arrangement.

This sliver is then guided through a tube (4) via a passage (6) of the tube gear into a can (7), in which it must be laid in clean coils with optimal utilization of the space in the can.

To enable the can to take up as much material as possible, the sliver is compressed by passing it through calendaring or grooved railers (5).

Operating Devices

Creel (sliver feed)

In particular, the creel must be designed so that:1. false drafts are avoided;

2. the machine stops upon occurrence of a sliver break;

3. sliver breaks can be dealt with easily, comfortably and safely.

For this purpose, it is necessary to provide a rotatable roller or roller pair above each can, one for each sliver.

A guiding device for leading the slivers into the drafting arrangement is also required. A table with rollers, or simply a line of rollers, can provide the required guidance.

Rollers alone are preferred in rapidly operating high-draft drawframes, since friction is lover when transport is effected by means of rolling than when it relies upon sliding.

The in-feed roller pairs also serve as electrical contact rollers for monitoring the sliver.

If a sliver breaks, the metal rollers come into contact when the insulating

sliver is no longer present between them, and the machine is stopped.

Normally, slivers may be fed in from up to eight cans per drawing head, and the cans may have diameters up to 1000 mm.

The drafting arrangement

The drafting arrangement is the heart of the drawframe and thus the partwhich exerts the most decisive influence on quality. The requirements

placed on the drafting arrangement in general are correspondingly high:

2. stable design with smooth running of the rollers (centricity);

3. a mode of operation giving a high-quality product even at high

running speeds;

4. high degree of flexibility. i.e. suitability for all raw materials, fiber

lengths, sliver hanks, etc..

5. optimal control over the movement of the fibers during the drafting operation;

6. high precision both of operation and adjustment;

7. rapid and simple adjustability of roller spacings and draft levels;

8. ease of maintenance and cleaning;

9. optimal ergonomic design.

Influences on the draft

In all types of drafting arrangement, the factors that affect the draft are as follows.Factors dependent upon the fiber material

1. mass of fiber in the strand cross-section;

2. degree of order of the fibers;

3. shape of the cross section of the fiber strand;

4. compactness of the fiber stand;

5. adhesion between the fibers dependent upon surface structure,

6. crimp,

7. fiber length,

8. twist in the fiber strand;

9. compression of the strand;

10. evenness of distribution of fiber lengths (staple form) .

Influences on the draft

Factors dependent upon the drafting arrangement:

1. diameter of the rollers;

2. hardness of the top rollers;

3. pressure exerted by the top rollers;

4. surface characteristics of the top rollers

5. fluting of the bottom rollers;

6. type and form of fiber guiding devices, such as pressure rods, pin

bars, aprons, condenser etc.;

7. clamping distances (roller settings);

8. level of draft;

9. distribution of draft between the various drafting stages.

Elements of drafting arrangements

a)Bottom roller

Bottom rollers are made of steel and are mounted in roller stands or in the frame by means of needle, roller or ball bearings. They are positively driven from the main gear transmission.

In order to improve their ability to carry the fibers along, they are formed with flutes of one of the following types,

> axial flutes (a),

> knurled fluting (b),

> inclined flutes (spiral flutes) (c).

Elements of drafting arrangements

a)Bottom roller

Knurled fluting is used on rollers receiving aprons, to improve transfer of drive to the aprons.

Other rollers have axial or, increasingly, spiral fluting. The latter gives quieter running and more even clamping of the fibers compared with axial fluting.

Rolling of the top rollers on spiral flutes takes place in a more even manner and with less jerking.

The diameter of the bottom rollers can lie in the range 20 - 90 mm, but normally diameters between 25 and 50 mm are used.

A drafting arrangement includes three to six such rollers. In long machines (e.g. ring spinning machines) the bottom rollers are made up by screwing together short lengths.

Distances between the rollers of the drafting arrangement are usually adjustable and can then be adapted to the fiber lengths.

a) Top rollers

The top rollers are not positively driven. They can be either one-piece rollers (spinning preparation machines) or twin rollers (roving frames, ring spinning machines).

Ball bearings are used almost exclusively in the roller mountings.

The thick coating forming the roller surface is made of synthetic rubber.

An important characteristic of this coating is its hardness.

Soft coats surround the fiber strand to a greater extent than harder ones and thus guide the fibers better.

Top roller pressure

To clamp the fibers, the top rollers must be forced at high pressure towards

the bottom rollers. This pressure be generated by:

>loading by means of dead weights (now obsolete)

>spring weighting (the most usual form)

>hydraulic systems (hardly used)

>pneumatic weighting (the Rieter company)

>magnetic weighting (the Saco Lowell company).

Forms of drafting arrangement

Processing is carried out almost exclusively in two drafting zones. In extreme cases the break drafts lie between 1.05 and 2.5, but usually they are between 1.25 and 1.8. Extreme total drafts lie between 3.5 and 12

but the normal total draft lies between 4 and 8.

In many modern drawframes the draft is no longer adjusted by exchanging gear wheels but by simple setting of variator or stepping drives. The adjustment may be continuous or discrete steps.

Modern drawframes are more flexible in terms of the raw material they can process, and setting operations have been simplified 3-over-4 roller drafting arrangements

The characteristic feature of this arrangement is engagement of the middle pressure roller with two bottom rollers. The two bottom rollers are carried in a common cradle and are not adjustable relative to each other. The basic concept can be improved by the inclusion of a pressure bar in the main drafting field.

This type of arrangement is now found mainly in the combing room,

but also still to some extent on drawframes, for example in the Marzoli and Vouk machines.

3-over-3 roller drafting arrangemenTs with pressure bars

This form was first developed by Platt in the 1960s and is still in use today

in fact, the pressure bar arrangement is probably the most widely used

form of drafting arrangement for drawframes.

The starting point in the development of this design is the realization that

the drafting arrangement runs more smoothly the larger its rollers.

3-over-3 roller drafting arrangements with pressure bars

This applies especially to the front rollers. The effect is due not simply to

stability; for a given circumferential speed, larger rollers can be operated at

lower speeds of revolution. However, enlarging the rollers simultaneously

increases the nip spacings.

Accordingly, in the main drafting zone, a special guide system is needed,

at least for short fibers; this is the guide rail or pressure bar. It can operate

from below or from above. Similar arrangements have been or are built by

Rieter, Schubert & Salzer and Toyoda.

4-over-3 roller drafting arrangements with pressure bars

Strictly speaking, this is also a 3-roller, pressure bar drafting arrangement,

but a fourth roller with somewhat lower loading is added to the delivery

roller to act as a guide.

This leads the web in a curve round the grooved roller directly into the

delivery trumpet, thereby facilitating the formation of the sliver.

The top rollers are uniform in

diameter and are large in order to

keep the strain imposed on them

low.

5-over-4 roller drafting arrangements

In this arrangement five pneumatically loaded pressure rollers rest on two large (90 mm) and two small (28 mm), non-adjustable bottom rollers.

The pressure rollers are suspended from two yokes. They have diameters of 39 mm, although the three middle rollers may be replaced by rollers of 28 mm diameter depending upon the circumstances.

5-over-4 roller drafting arrangements

Drafting is carried out in Field B (breakdraft) and in Field A (main draft). The nip spacing can be read from a scale and can be adjusted to suit the fiber length by simple radial shifting of rollers 2 and 4.

In the main drafting field, a pressure bar ensures firm guidance, especially for short fibers. The drafting arrangement is aligned on a curve; this permits proper guidance of the web material flow from the vertical into the horizontal. The curved disposition makes the system easy to service.

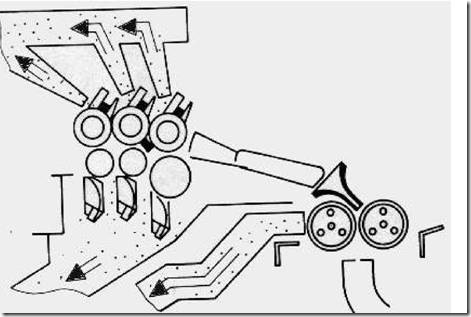

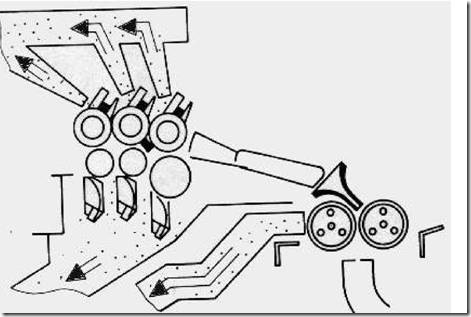

Suction systems for the drafting arrangement

One of the tasks of the drawframe is dust removal. Release of dust occurs almost exclusively in the drafting arrangement and this should be totally enclosed so that dust does not pass into the surrounding atmosphere.

The dust-laden air must be extracted by suction.

Each roller of the arrangement has an associated cleaning device so that fly and fibers tending to adhere to the rollers can also be carried away.

The air drawn away is passed via tubes directly into the exhaust ducts of the air—conditioning system, or to filters within the machine.

The filtered air should preferably be returned to the exhaust ducting, but can also be blown out into the atmosphere of the room.

Condensing

Downstream from the trumpet, the sliver runs between two calender rollers which are pressed towards each other.

This condensing of the sliver enables more material to be fitted into the cans.

Several manufacturers replace the fluted or smooth cylindrical calender rollers with grooved or stepped rollers.

Since these latter rollers do not permit the fibers to escape laterally, a still better condensing effect is achieved.

In this way, the total filled weight of the can may be increased by up to 20%.

Grooved or stepped rollers can be used simultaneously as measuring devices for autolevelling systems.

Coiling

As already described for the card, two rotational movements are required for cycloidally coiling of the sliver.

Modern high—performance drawframes are usually fitted with automatic can changers.

These reduce the burden an the personnel, enabling more machines to be allocated to one person reduce the necessity for attendance of the operative at the machine, and (the chief effect) also increase efficiency.

This sliver is then guided through a tube (4) via a passage (6) of the tube gear into a can (7), in which it must be laid in clean coils with optimal utilization of the space in the can. To enable the can to take up as much material as possible, the sliver is compressed by passing it through calendaring or groovedrailers (5).

This sliver is then guided through a tube (4) via a passage (6) of the tube gear into a can (7), in which it must be laid in clean coils with optimal utilization of the space in the can. To enable the can to take up as much material as possible, the sliver is compressed by passing it through calendaring or groovedrailers (5).

![clip_image002[4] clip_image002[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEi3TePda01ZmXB-xEkAxcAXIZy14353F07QQVw78t-fkVELtb-AGPxAEJP8XkMl5_XTWCfSIv-GjJQOBrdQdnDv6ssSulgmhm-eJwG4NMy_eBRa8yOfpIIyyw_TpcRr4zZsiRYnpTXS2DtZ/?imgmax=800)

![clip_image004[4] clip_image004[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhLR9F7QXt9nDy6ln3xmaN_RfTFupJ6fNzT94OxaNpoSdo5Kkacmf_0SPhmNrpzMfiAEiaI6FIANtRuRBmarz20sOPQAWK38H4iQClpTNe6xBPFzALUwdgJ43WYXrt1LiiqN5cAfQIlYg-R/?imgmax=800)

![clip_image006[4] clip_image006[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhNVX3SZVVTIMeRnobjGkO7WsVhimqV94SR222E0vIBK6Wp351gLBaTDjqBxMThSTvSqM2mfdGIm8eW644KwUTaDTune6TF05KtpkNw9aifEz9pS7oFFyRttVneDFUsi8GlDBISf2762eAv/?imgmax=800)

![clip_image008[4] clip_image008[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgr3L59W_q7d0vjfQtwXcgdxIINJohXWKjobX8e230_mIOgQZqDAykGMHKEnlt5CYNMM_5WKu7SWkt5Djyg1HNfI_pjlTMEXYFO227mkyzZp0bKu0V2JWcYFvYRk0M3j9Y87Fn3IM5ktqKP/?imgmax=800)

![clip_image010[4] clip_image010[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhVC8x-ojas8JEm-IO4QkqwoUJYByXTZH4wBUGZAA-kFpy8nj92rvrdm2J-S0pGDkYfKphaAKBY49_iXQpyxWkJPozDXEJHS86JcXLvdE4NwgBBAMPYAsgTYD4JM3AOwruhCducofdAApJl/?imgmax=800)

![clip_image012[4] clip_image012[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEiVncLPRVM-Y5Tt7wHdRSLtYKwkjFjdmi8YpkSiucVQcOdF2Jd8U_4c-tNT-dw1B8xOgM_xqYJHmLoBD5hp7Npi1BnVhExTUQzoyvRp7YkeNGW9LoBCsjYIjru90Jane9_HmrKGXXe2rxKm/?imgmax=800)

![clip_image014[4] clip_image014[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhU4FiLgqOAva1r8X_38pm39pRG0a5nDaq3NlTJM9fuIut3dk4wkMp3M8uNG7zeDhE8EQMCpb2OMKs6P5KWMDIEXjGS5thjueVo1lxM01lP5jz0DWmdjmT3M6nqK_o_vcpoExgHuDn0mJ5s/?imgmax=800)

![clip_image016[4] clip_image016[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjUqW8QFqCREMlr5xKR5TgNeQmAK5NLEbCBlxJExfkLvImjJqobufoDD2-YPYltO7muwTnTtaZoOi-X84rw7ExzeyAJT3mNMzEK719_n_3iBdLG5UIh8V37SOY8KMuULwZzpwDDwUlDSnMw/?imgmax=800)

![clip_image018[4] clip_image018[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjAKMv3dE1ePeVkgRrNLXJKA31L1j2mu02zQg3l1B9HjQNjmk3aeSeB7bpd1Qp8ptEj_wMJV50JaRheGzZ7AG0zhdfpSXpwzpYeqZF1vTeOEBOQwob732IzfDIP5BYwhcp0RekPVIt03F49/?imgmax=800)