Twist traps (soft twist tube/torque stop) for lower twist/

higher efficiency

Doff tubes/Take off tubes of ceramic

Yarn guides

Twin discs /supporting discs for Schlafhorst Autocoro

and Rieter RU machines (equally for high speed)

Reflector rings for twin discs

Take off rollers with different shore-hardness, with or without bearing Tension rollers for Autocoro and RU machines

Coupling gear wheels

Drive sleeves and main drive cylinders for drum shaft Autocoro

Fiber channels for SE 7, SE 8 and SE 9

Face plate/ channel plates Autocoro

Worm gear shafts

Rotor break pads

Wicking felt Button box Covers for opening rollers

Sealings

Gear wheels Paper roll

Oil container

Various additional spare parts upon request

Take advantage of our know-how – Do not hesitate to contact us

Please send us your detailed inquiry together with a sample

of material you wish to process or call us. We would be glad to help you assemble your required equipment.

www.burckhardt.com

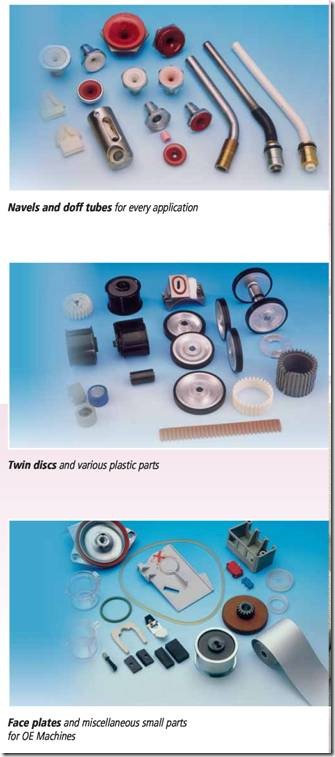

OE Spinning

Parts for Rotor Spinning Machines

Parts for OE Spinning Machines

We have a long experience in the production of various parts for different Open End spinnning machines.

Thanks to this, we do not only offer most standard parts, but we also advise you if you want to

produce a yarn with special fibres which creates problems with your standard parts

produce a special yarn with effects, slubs etc.

achieve any other improvement or change of your yarn quality

Take advantage of our know how

Most of our parts are offered in all versions for Autocoro, Rieter RU, Rieter M1/1, M2/1 and BD machines

Rotors

We produce all rotor types with diameters from 28 to 135 mm, with all standard groove types.

You may get our rotors with boron diamond (BD) or diamond (D) coating, with boron treatment (B), and alu rotors also anodized. All our rotors are equiped with a ceramic tip on the shaft end. We design special rotors according to your requirements with

new grooves/ diameters to produce specific yarn types (for DENIM, knitting or others), all of them with the suitable coating.

Characteristics of rotors with: Boron-diamond or diamond coating

good yarn values

wear resistant

applicable for all diameters/rotor types

Boron treatment

very wear resistant

very easy cleaning

only for steel rotors with mostly larger diameters Opening rollers

Opening Rollers Syst. Burckhardt or conventional for all OE machine types, standard wire types (OB 20, OS 21, B 200) as well as pin rings are offered according to your requirements.

2-part head syst. Burckhardt with interchangeable pin or wire rings of brass, steel or aluminium, with various coatings or treatments, with numerous wire or pin configurations. The most flexible system available on the market for all machine types

“press-on” version with flanges for Autocoro

conventional 1-part or ring versions for any other machine type

All wire rings can be DN coated (diamond coated with nickel overlay) to improve the service life. Other surface tratments are offered upon request.

Burckhardt HVF/ N treatment for steel wire rings

Thanks to the special hardening treatment the lifetime can be increased considerably, without the high cost of diamond coating. All HVF/N wire rings are nickel plated for a smoother treatment of the fibres.

OE pin rings for synthetic fibres

Some synthetic fibre qualities (mostly PES) create problems with wire/solid rings. To avoid fibres sticking on the opening rollers and to reduce the powder production in the spinning process, PIN RINGS often are the right solution. Explain us your problem – we will establish a proposal!

Special pin rings for effect yarn

The special pin arrangement allows you to create a unique OE – slub yarn. The irregularly distributed effects are creating a perfect DENIM, or “rustic” character (for curtains, furniture etc).

For detailed information please ask for our special leaflet.