Effects of yarn structures in composite

spun silk yarns

The tensile properties of composite spun silk yarns and the compression properties of the fabrics were studied with a view to analyze the effects on yarn structure. Twin spun yarns, core spun yarns and doubled yarns were made by different spinning methods. It was then observed that the mechanical properties of composite yarns and fabrics varied according to the kinds of combined fibers. They were also considerably affected by the yarn structure, namely the number and direction of the twisting, even if the combination and the content of the fibers were constant. It was also found that the fabric made of the cotton/silk composite yarn might have a unique handling.

We studied the mechanical properties of the composite spun silk yarns and fabrics in previous papers (Matsumoto

et al., 1986, 1987), and since then we have continued studying them. Our final aim is to improve the stiffness of the spun silk fabrics whose soft handle is said to be a fatal defect, and to better the nature of spun silk yarn. The composite yarns are core spun yarns made from both a filament yarn in the core and the spun silk fiber as the skin layer. But there is a limitation in the production when the components used are filament yarn and staple fiber. Therefore, further study is required for composite yarns made from the combination of the staple fibers.

We tried making different composite yarns using staple fibers as a constant, and then examined the tensile properties of the yarns and the compression properties of the fabrics.

Materials and Methods

1. Materials

Table 1 lists the mean length of staple fibers used in the composite yarns. The combinations used in the yarn were : polyester/silk I, cotton/ silk I and silk II/silk I. The composite yarns contained about 70% silk I by weight, which were the twin spun yarn, the core spun yarn and the doubled yarn. The single yarns were also made of the fibers, in order to compare with the composite yarns. The British yarn count of all the yarns was 10, and the twist factor and the twist direction are listed in Table 2.

Furthermore, these yarns as the weft (density =17 picks/cm) were woven across the polyester filament warp (50 d/36 f, density=64 ends/cm) in a plain weave

2. Making of composite yarn

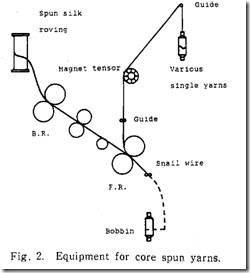

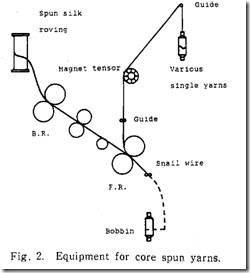

In the spun silk ring spinning frame which is shown in Fig. 1, two rovings are drafted on each drafting zone and are then twisted together to form a yarn. The drafting part is equipped with an apron device for the short staple fibers, namely, polyester, cotton and silk II. This yarn is called the twin spun yarn.

As shown in Fig. 2, a single yarn is used in the core, tension is provided by a magnet tensor applied to the front roller to combine with a roving as the skin layer, and then they are twisted together. This yarn is called the core spun yarn.

Furthermore, the doubled yarn is combined by twisting together two single yarns.

The cross sectional structure of yarns will be referred to in detail in the latter part of this paper and some examples are shown in Fig. 8.

3. Methods

The stress-strain curves of the yarns were measured using the constant-rate of elongation tester (Instron type) when the test length was 27 cm, the extension speed was 10 cm/min, and the number of testing times per yarn was 100. The compression properties of the fabrics were measured by the rolling method utilizing rolling friction from a solid cylinder (Shinohara and

Go, 1961). As shown in Fig. 3, it is possible by this method to measure the rolling path when the solid cylinder rolls on the fabric at a constant initial velocity. The compressional modulus of fabric can be estimated from the size of the rolling path since the rolling path varies according to the stiffness of the fabric. The rolling path in the weft direction was measured using a sample that was 5 x 20 cm, and tested 10 times. And it was provided in the measurement that the angle between the slope and the horizontal plane of the sample was 1°, the length of the slope was 4 cm, and that the size of the roller, made of brass, was about 1.8 cm in diameter, 4 cm in length and 86.8 g in weight.

Results and Discussion

All the composite spun silk yarns used here were composed of silk I and the other staple fibers. Therefore, the produced yarns can be classified into three fibers, polyester, cotton and silk II. The yarns made from each of the fibers are single yarn, twin spun yarn, core spun yarn and doubled yarn. Using graphs let us tentatively connect the single yarn with a composite yarn by a broken line and connect the composite yarns with each other by a solid line. The vertical (y) axis varies according to each graph. The horizontal (x) axis of the graph is the arrangement of yarns, and it was set to cor respond with the number of twisting times because all twist directions were Z. As for the number of twisting times used to make a yarn, the single yarn was one, the twin spun yarn was one, the core spun yarn was two because the single yarn in the core had been twisted, and the doubled yarn was three for combining two single yarns.

Fig. 4 shows the count strength product from the produced yarns. The polyester/silk I composite yarn is smaller than the single polyester yarn, but the cotton/silk I composite yarn is larger than the cotton single yarn, and the silk II/silk I composite yarn is larger than the silk II single yarn. The strength of single yarns indicates a strength decrease in the following order, polyester, silk I, silk

II and cotton. In general, the strength of a composite yarn is given by the sum of the strength generated by the two combined fibers. Thus, the composite yarns may be characterized as follows : In the case of polyester/silk I, a weak fiber of silk I

is added to a strong single yarn of polyester. In the case of cotton/silk I or silk II/silk I, a strong fiber of silk I is added to a weak single yarn of cotton or silk II. Using this explanation, it is possible to understand the variations of the strength which compared the composite yarn with the single yarn.

Furthermore, the strength of composite yarns tends to decrease in the following order, the twin spun yarn, the core spun yarn and the doubled yarn. When the number of twisting times in the same direction is increased in the making of composite yarns, it brings about many twists in the yarn. It is known that as yarn twist is increased, yarn strength rises to a maximum value at some optimum twist and then falls. The tensile behavior of twisted staple yarns can be explained by the effects of fiber obliquity with respect to the yarn axis combined with the effects of fiber slippage (Bogdan, 1956). Therefore, it is found that the tendency to decrease is clearly due to the effects of fiber obliquity in the yarn.

Fig. 5 shows the elongation of the produced

yarns. The comparison between the composite yarns and the single yarns, in the problem of elongation can be solved by a similar method to that used for yarn strength. It can also be observed that the elongation of composite yarns

increases in the following order, the twin spun yarn, the core spun yarn and the doubled yarn. Since the twisting required to make a yarn always has the same direction, the increase in the number of twisting times means that of the twist angle of fibers with respect to the yarn axis. Here, if the yarn extension is a

y, the extension of the fiber in the yarn is

Ef, and the twist angle is

0, the relation is expressed by, E

y=ef/cos

20 (Hearle

et al., 1969). Consequently, it was found that the tendency to increase is clearly due to the increase in the twist angle.

The experimental results of the rolling path on the fabrics made from the cotton/silk I composite yarns and the single cotton yarn are shown in Fig. 6. Preliminary results using 150 rollings showed that after 70 rollings, the rolling path made a significant difference in the produced fabrics, but made little difference in each fabric. So, it is assumed that the fabrics have a constant value for the rolling path when the number of rollings is more than 70. We adopted a mean value of the rolling path of which the number of rollings is from 71 to 80. Fig. 7 shows the mean value of the rolling path in the produced fabrics. It is probably possible to compare the rolling path of the fabrics made from the composite yarn with that of the fabrics made from the single yarn as mentioned above. In the composite fabrics made from polyester/ silk I and silk II/silk I, the rolling path tends to decrease in the following order, the twin spun yarn, the core spun yarn and the doubled yarn. In proportion to the increase of the number of twisting times in the same direction, the fiber obliquity with respect to the yarn axis varies. The twist has a noticeable effect on the inward pressure of the yarn. As the twist is increased, the lateral force works for compressing the yarn and bringing the fibers closer together. So, the composite yarn becomes tighter. As the weft yarn becomes stiffer, the surface of the fabric also becomes rougher. Consequently, it seems that the rolling path has a decreasing tendency on the composite fabrics.

The mechanical properties of the composite yarns are as follows : For any combination used, the maximum value for strength and elongation is given by the twin spun yarn and the core spun yarn, respectively. But the maximum value for the rolling path is shown by the twin spun yarn, using polyester/silk I or silk II/silk I, and by the core spun yarn, using cotton/ silk I. That is to say, even if the kinds of combined fibers and the content percentage is constant, the form of the fiber and the yarn structure affect the handling of fabric. Specifically, it should be noted that the fabric made from the cotton/silk composite yarn has a unique handling characteristics in comparison with the other fabrics made from polyester/silk and silk/silk.

Furthermore, in order to obtain different handling, we tried combining the raw silk yarn as the filament yarn with the cotton/silk twin spun yarn as the staple fibers. It was done by joining the two production methods, namely the twin spun yarn and the core spun yarn. That is to say, by using the production method for the core spun yarn we tried inserting a raw silk yarn (21 d x 2, twist factor=0.3, Z) into the drafting part of the cotton fibers for making the twin spun yarn. The yarn contained about 8% raw silk, 28% cotton and 64% silk I because the British yarn count was 10. We call this yarn the, 'core twin spun yarn'. The mechanical properties of the yarn and its fabric are shown in Table 3. The advantages of this yarn become clear when compared with the other composite yarns made from cotton 30%/ silk I 70% as shown in Figs. 4, 5 and 7. It was also found that the filament yarn is important in the composite yarn. Therefore, we must carry out further examinations of cotton/silk composite yarns including the core twin spun yarn.

Finally, some examples of yarn cross section are given in Fig. 8. (1) shows a single cotton yarn : the yarn lacks the coherence of fibers and has many spaces among the fibers. In the composite yarns using cotton 30%/silk I 70%, the yarn structures vary, shown in (2), (3) and (4). (2) shows a twin spun yarn : the component fibers are divided by a straight line. (3) shows a core spun yarn : the circular cross section is formed with the skin fiber and a single cotton yarn which has a circular form made by the single twist and is wrapped in the skin fiber. The staple fiber yarn was not given a high core tension because the elastic limit is so small. Therefore, it was very difficult to set the core yarn in the center of the yarn cross section. (4) shows a doubled yarn : the cross section is a distorted shape with a gap between the yarns, because each component yarn had already been twisted. Finally (5) shows a core twin spun yarn containing raw silk 8%/cotton 28%/silk I 64%: the cross section is similar in form to both those of the twin spun yarn and the core spun yarn above, however the spun silk fiber is twisted together with the cotton fiber wrapping around the raw silk yarn.

Acknowledgement : We are grateful to our colleague Mr. Norishige Kayama for his cooperation.

YO-ICHI MATSUMOTO, IKUO TSUCHIYA and HIDEHIKO KYUMA

Faculty of Textile Science and Technology,

Shinshu University, Ueda 386

![clip_image024[3] clip_image024[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgF03hHzowmoNGMXZnbro3IoDNHT-yyiggDvRxXlmyEiD8tNABdTak8E4rQUD6CHZVuS6LlmPnvQUUGhunmUlo9XDbChhP30X9dvSTOmA3tHa-uz_P9-jws1uM12hPcGUcpV_cpzgZEzEkm/?imgmax=800)