The act or processing of converting staple or short lengths of fiber into continuous yarns.

Dictionary.com

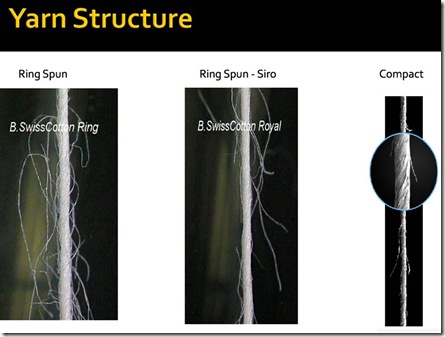

*Ring Spinning

*Compact

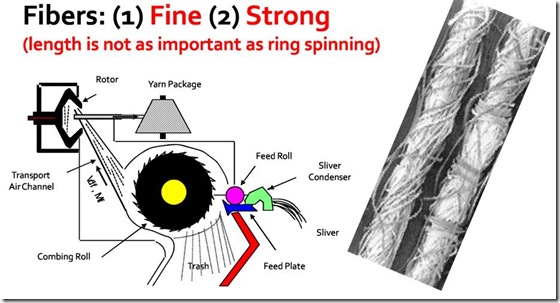

*Open End

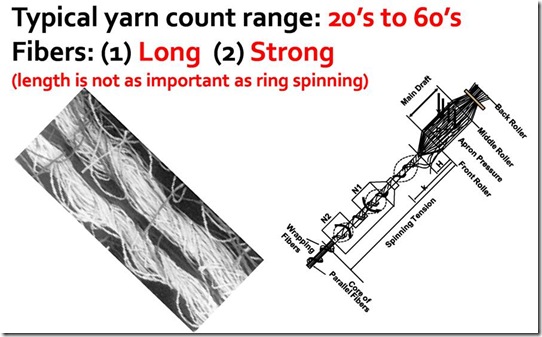

*Air jet

Yarn count ranges: 6’s to 250’s

Fibers: (1) Long (2) Fine (3) Strong

Yarn count range: 6’s to 250+

Fibers: (1) Long (2) Fine (3) short

• Very good pilling values and durability

(Pilling (Martindale) improved by 1.0 to 1.5 grades)

· Less surface hairiness, clear mesh structure

· Excellent evenness of knit fabrics

· Less fiber accumulations knitted into the fabric

· Luster

· Great alternative to plied yarns

· Less energy

· Softerthan plied yarns

· More economical than plied yarns

Open End - Schlafhorst

Typical yarn count range: 6’s to 30’s

Open End Spinning

Murata Vortex

Spinning Efficiency and Endsdown:

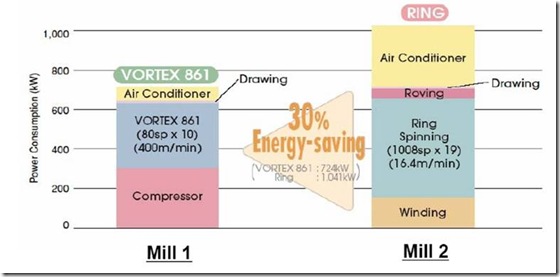

Energy Comparison

Energy Savings

Yarn Count : Ne40 (15/1tex) Combed cotton 100% for weaving

Production volume : 265kg/h (580Ib/h)

Do all yarns within the same spinning system require

the same type and quality of fibers?

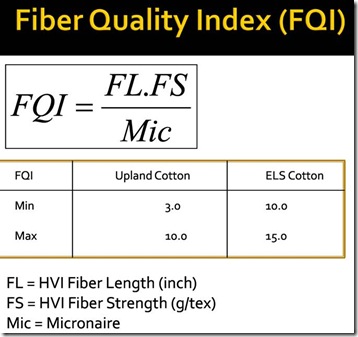

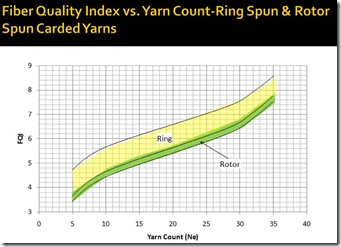

DifferentYarn Counts Require

Different Fiber Indexes

Is Cotton just Cotton or a Different Cotton can Make a World of Difference?

Different Cotton can Result in substantial difference in Quality and cost

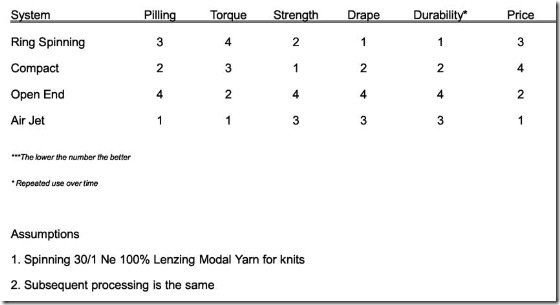

There are literally hundreds of variables in the spinning process which influence the outcome of fabric and garments.

Where is the source of fiber?

Do you have a relationship with the fiber producer and spinner?

What are the parameters in which the spinner purchases the fiber?

Does the fiber perform to expectations in relation to yarn count and fabric properties?

How is my garment impacted by fiber cost?

Do you have a relationship with the machine manufacturer?

What are the machine’s unique features?

Does the manufacturer of the machines offer excellent service, adequate training, and able

to respond quickly to parts and repair needs?

Is the spinner willing to partner with you and your the supply chain to improve the quality

and performance of fabrics?

Same goes with the machinery manufacturer?

Will your fabric supplier be open to the idea of you stating the spinner you want to use?

■ There may be bonds which need to be broken for this to happen..

• Dr. Yehia El-Moga hzy,Au burn University

■ yehiae@eng.auburn.edu

· Rob Beal, Oerlikon

■ rob.beals@oerlikon.com

· Mark Lingerfelt, Muratec

■ mlingerfelt@muratec-usa.com

· Hans Rothen, Rieter

■ Hans.rothen@rieter.com