OF CIRCULAR WARP KNITTING MACHINE

T.S. Stoilov Y.K. Kyosev

Technical University of Sofia, Dept. of Textile Engineering,

8, Kliment Ohridski Blv, 1797 – Sofia, Bulgaria,

E-mails: yordan_kyosev@gmx.net jkiossev@tu-sofia.bg tstoilov@tu-sofia.bg

Introduction

The design of the circular warp knitting machines is actual, because such machines produce circular tubes or cables, quite suitable for some medical or technical applications, like arteries, veins, ropes etc [1,2,3]. These machines are rarely produced and their design is generally open problem. Our investigation shows, that there is one principal construction for machines with very small diameter, with different modifications [4,5,6]. Here we investigate the main points of the machine design – determining the number of needles, position and rotation angle of the yarn guide mechanism. This work differs from [7], as here is used cylindrical needle bed instead of conical one, presented in [7].

Minimal Rotation Step of the Yarn Guide

For the circular weft knitting machines is not efficient to be used forced yarn overlapping – it leads to some complications in the construction and the price. Instead of this, is used the relative motion between needle and yarn. This motion is realized by rotation of the yarn guide eye relative to the axe of the needle's cylinder.

In order the yarn to be laid in the needle hook, the yarn guide should make at least one minimal rotation step. This rotation step depends on the needle geometry and yarn diameter. The yarn with conditional diameter d should go trough the needle hook touching the needle stem and the point of the needle's hook, that are with diameter 2R.

The relation between these parameters and the needle parameter c is given by the

overlapping angle Θ , see Fig.1 :

Yarn Guide Position

The yarn covers the needle as a result of the relative motion between them. The position of the yarn guide (height) is important for this process. On the Fig.3. is presented an axonometric projection of the yarn AE, where the point E is the yarn guide eye, and A is the point where lies the last needle. The yarn guide height is denoted as H, and the height,

where the yarn touches the needle is h = DB .

Needle Density

The needle density is determined on the condition that the yarn has to overlap only one needle by one step of the yarn guide. The cylinder of the needles with radius r and the width of the hook c (Fig. 1) is presented on the Fig.4. The yarn has built a loop at the needle Nr. 1 on the Fig.4, and is going through needle Nr. 2, till point 3, that is behind the needle Nr. 3. Here the thickness of the yarn and the needle are neglected.

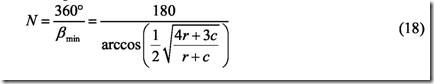

The second and the third solutions have different signs, which doesn't influence their physical meaning. From the minimal central angle between the neighbouring needles could be determined the maximal number of needles for cylinder with diameter 2r and

the needle width is c, following

Consideration of the needle and yarn diameters in this equation will result in some corrections in equations (7)-(18). These corrections will change the results with the same size as the error derived by yarn overlapping (approx. 0.5mm) and therefore they are not included.

Conclusions

From the condition, that the yarn to overlap only one needle, is calculated the minimal central angle between needles and the maximal number of needles for given cylinder diameter. It is determined, that it is possible to be realised opposite overlapping, independent on the needle density. The height of the yarn guide and its rotation angle are also determined. All these equations are important when designing the circular warp knitted machines.