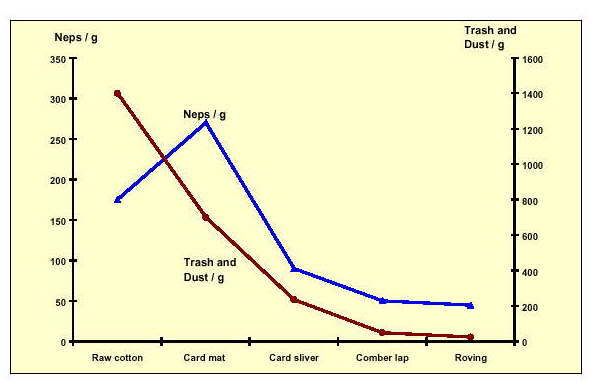

| . With all harvesting methods, however, the cotton seed, together with the fibers, always gets into the ginning plant where it is broken up into trash and seed-coat fragments. This means that ginned cotton is always contaminated with trash and dust particles and that an intensive cleaning is only possible in the spinning mill. Nep content increases drastically with mechanical harvesting, ginning and subsequent cleaning process. The reduction of the trash content which is necessary for improving cotton grade and apperance unfortunately results in a higher nep content level. The basic purpose of Blow room is to supply -

small fibre tufts -

clean fibre tufts -

homogeneously blended tufts if more than one variety of fibre is used

to carding machine without increasing fibre rupture, fibre neps , broken seed particles and without removing more good fibres. The above is achieved by the following processes in the blowroom -

Pre opening -

pre cleaning -

mixing or blending -

fine opening -

dedusting

CLEANING EFFICIENCY: Cleaning efficiency of the machine is the ratio of the trash removed by the machine to that of total trash fed to the machine, expressed as percentage Cleaning efficieny % =(( trash in feed % - trash in del %) x 100) / (trash in feed%) Following are the basic parameters to be considered in Blowroom process. -

no of opening machines -

type of beater -

type of beating -

Beater speed -

setting between feed roller and beater -

production rate of individual machine -

production rate of the entire line -

thickness of the feed web -

density of the feed web -

fibre micronaire -

size of the flocks in the feed -

type of clothing of the beater -

point density of clothing -

type of grid and grid settings -

air flow through the grid -

position of the machine in the sequence -

amount of trash in the material -

type of trash in the material -

temp and relative humidity in the blow room department - - .

PREOPENING: Effective preopening results in smaller tuft sizes, thus creating a large surface area for easy and efficient removal of trash particles by the fine openers. If MBO (Rieter) or BOW ( Trutzschler) type of machine is used as a first machine -

the setting of inclined lattice depends upon the fibre density, fibre micronaire and the tuft size fed. If smaller tuft is fed to the feeding conveyor, the fibre tufts will not be recycled many times, hence the neps will be less.

-

if the machine is with beater, it is advisable to use only disc type beater. Saw tooth and Pinned beaters should not be used in this machine, becasue the fibre damage at this stage will be very high and heavier trash particles will be broken in to small pieces.

-

It is easier to remove the bigger trash than the smaller trash, therefore enough care should be taken to avoid breaking the trash particles

If Uniflco11(Rieter) or Blendomat BDT 019(Trutzschler) is used as a first machine PRECLEANING: Precleaning should be gentle. Since removing finer trash particles is difficult , seeds and bigger trash particles should not be broken. Finer trash particles require severe treatment in Fine openers. This will lead to fibre damage and more nep generation. Therefore, precleaning should be as gentle as possible and no compromise on this. If preopening and precleaning are done properly, consistency in trash removal by fine openers is assured. Dust removal should be started in this machine. Enough care should be taken remove dust in this process. - Rieter's Uniclean B11 and Trutzschler's Axiflow or Maxiflow are the machines which does this work

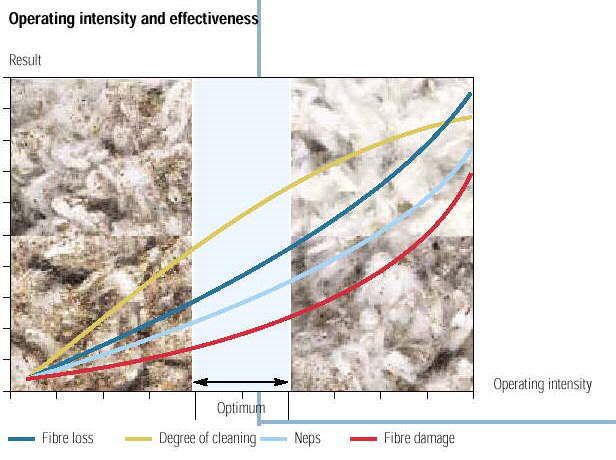

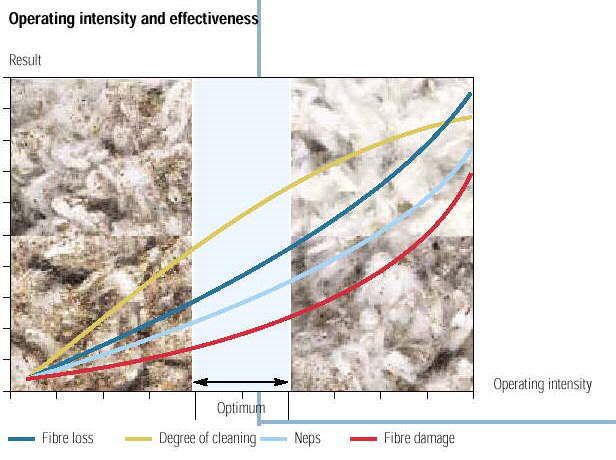

fig: from Rieter which shows , degree of cleaning, fibre loss, neps, fibre damage. -

with normal machines like Monocylinder or axiflow, a lot of trials to be conducted to arrive at optimum beater speed, air velocity(fan speed), grid bar setting and grid bar gap.

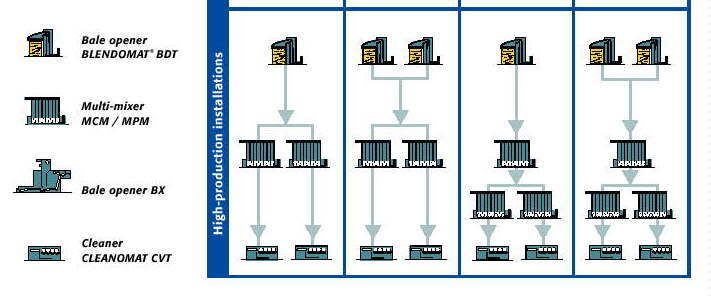

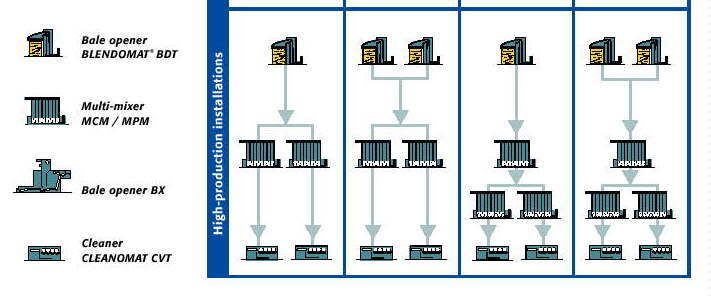

BLENDING: following fig is given by trutzschler for different mixing requirements

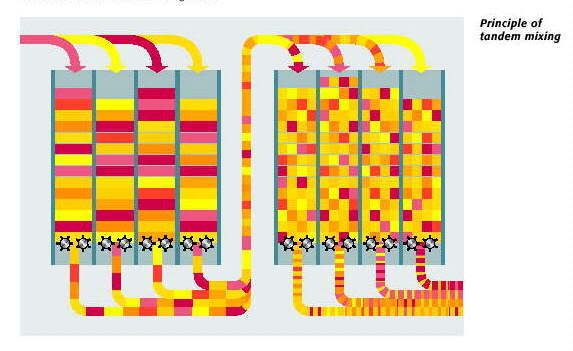

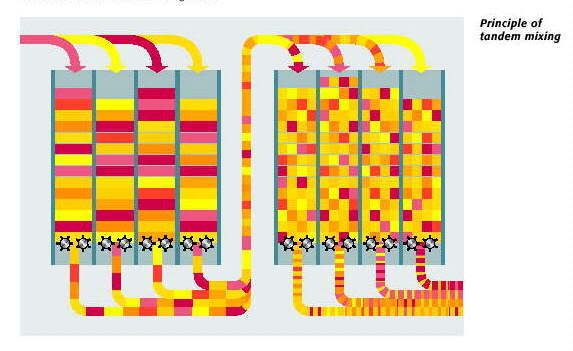

standard standar- plus high high-end FIG.Tandem mixing concept from TRUTZSCHLER:

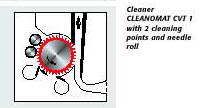

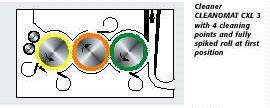

FINE CLEANING: Fine cleaning is done with different types of machines. Some fine cleaners are with single opening rollers and some are with multiple opening rollers. | TYPE OF COTTON | COTTON MICRONAIRE | PROUDCTION RATE kgs/hr | BEATER SPEED rpm | | more trash | 3.5 to 4.0 | 200 to 300 kgs /hr | 600 to 750 | | less trash | 3.5 to 4.0 | 200 to 300 kgs/hr | 600 to 750 | | more trash | 4.0 to 4.5 | 200 to 300 kgs | 700 to 850 | | less trash | 4.0 to 4.5 | 350 to 500 kgs | 1000 and above |

-

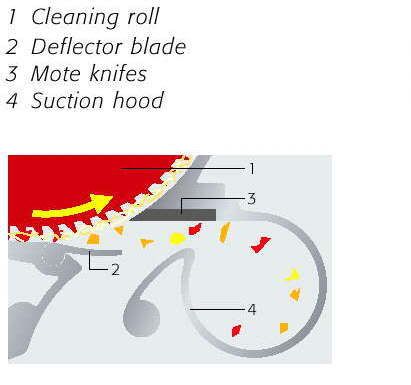

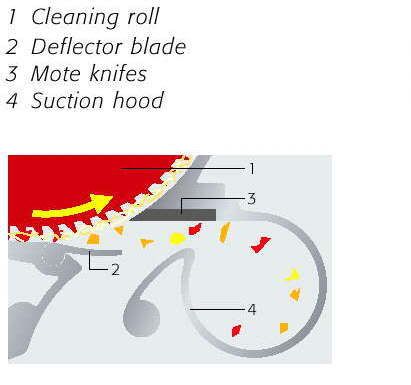

The cleaning points in CVT1, CVT3, CVT4 etc consists of opening roller, deflector blades, moteknives and suction hood. Trash particles released due to centrifugal forces are separated at the moteknives and continuously taken away by the suction. This gives better cleaning

FIG: trash removal concept in CVT cleaners:

-

Deflector blade setting can not be same for all the three rollers or four rollers. The setting for deflector blades in the panel looks like this 3, 12, 30 for 1st, 2nd and 3rd deflector blades.

DEDUSTING:

Apart from opening cleaning of rawmaterial, dedusting is the very important process in blowroom process. -

in exhausts of unimix , condensers , ERM etc, positive pressure of 100 pascal should be maintained. Exhaust fan speed and volume should be accordingly selected

OTHERS: -

if the cards are fed by CONTI-FEED system, the feed roller speed variation should not be more than 10%. If the variation is more, then the variation in tuft size also will be more. Hence the quality will not be uniform

-

If two feeding machines feed to 10 cards and the no of cards can be changed according the requirement, then frequent changes will affect the tuft size which will affect the quality, if the line is fixed with CONTI-FEED.

-

heavy particles like metal particles, stones should be removed using heavy particle removers , double magnets etc, before they damage the opening rollers and other machine parts.

-

machinery selection should be based on the type of cotton and proudction requirement. If the production requirement of a blowroom line is less than 200 kgs, CVT-4 cleaner can not be recommended, instead CVT-1 can be used.

-

the nep increase in each opening machine should be checked with different beater speeds and settings, and the optimum parameters should be selected. But please remember that everything should be based on yarn quality checking. e.g. if nep increase in blow room is more and the beater speed or feed roller setting is changed, the tuft size will become more. This may result in bad carding quality. Sometimes if the neps are slightly more and the fibre is well opened, the neps can be removed by cards and combers and the yarn quality may be better. Therefore all trials should be done upto yarn stage.

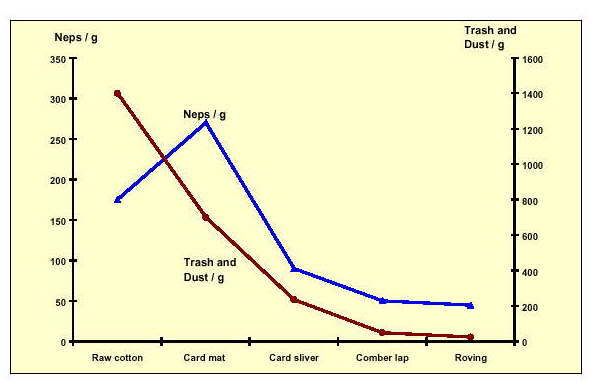

No of neps and trash particles after different processes is given below.(an approximate value)

A best blowroom can be achieved by selecting the following machines: 1.RIETER UNIFLOC- A11 ( pre opening) 2.RIETER UNICLEAN B11 ( pre cleaning) 3.TRUTZSCHLER MPM 6 + MPM6 ( two mixers for blending) 4.TRUTZSCHLER CVT-1 ( for roller ginned cotton) CVT-3 ( for saw ginned) 5.CONTAMINATION DETECTOR from either BARCO OR JOSSI 6.TRUTZSCHLER DUSTEX-DX ( for dedusting) 7.TRUTZSCHLER CONTI-FEED and others But enough care should be taken to synchronise the machines for better performace , and to run the line without any electrical system breakdowns. |