Yarn Spinning Combining staple fibers into yarns Spinning Systems

• Spinning systems- produce a yarn based on fiber characteristics of fiber

Cotton System (staples less than 2.5 inches)

- Opening

- Carding

- Picker: •

- Fibers made parallel, oriented. Short fibers removed. Blending can take place here. Layer pulled into “SLIVER”

Cotton System

- Combing

- Drawing

- Redrawing

- This is an optional step. Only used in making certain cotton yarns. Fibers made more parallel. Short fibers removed. Smoother, superior yarns result.

- Several card slivers combined for uniformity. Fibers made more parallel

- Slivers combined for uniformity

Cotton System

- Roving (twisting)

- Spinning

- Sliver attenuated (drawn out to finer diameter) and twisted. “ROVING”

- Roving attenuated and twist inserted

Combed/Carded Yarns

- Yarns made with the combing step included are called •

- Yarns made with the combing step •

- Combed yarns are of higher quality, and are more expensive than carded yarns.

- Combing is not necessary •

- Combed/Carded Yarns

- In a combed polyester/cotton blend yarn, only the cotton portion needs to be combed.

- A 50/50 polyester/combed cotton yarn is of higher quality than a 50/50 polyester/cotton yarn.

- Combing is necessary for the production of high-count (fine) cotton yarns, like those used in pin point oxford cloth, but is not necessary for low-count cotton yarns, like those used in denim.

Spinning

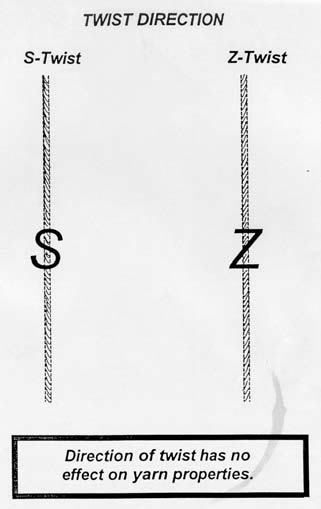

- Depending upon the direction of rotation of the spindle during yarn manufacture, yarns may have either S-twist (left hand twist) or Z-twist (right hand twist).

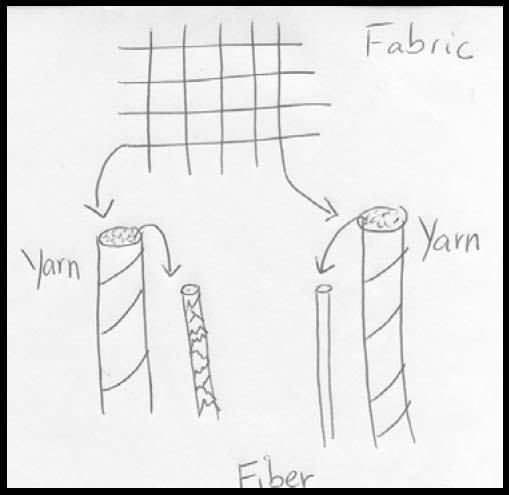

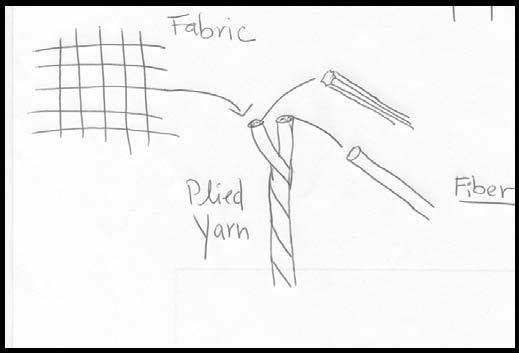

- Single yarns, either combed or carded, may be combined by twisting two

or more together, to produced plied yarns. The ply twist is usually opposite the yarn twist.

Ring Spinning any staple fibers <2.5” size="+3">Newer Spinning Processes

• Two more modern spinning processes have been increasing in popularity, because they produce yarn at a faster, more economical rate:

Open-End Spinning

- Also called break spinning, this process produces yarns at least 3X faster than ring spinning, depending upon the fineness of the yarn.

- Carded

- Omits roving formation.

Open-End Spinning

- Compared to an equivalent size ring-spun yarn, open-end spun yarn is weaker but more uniform. The yarn has a smooth even surface. bulkier, rougher, more absorbent, more uniform in strength, less likely to pill

- Only low and medium-count yarns can be made by this process.

Open-end Ring spun Air-Jet Spinning

- Production rate is up to 10X that of ring spinning, and at least 2X that of open-end spinning.

- Sliver is •

- Air-Jet Spinning

- Medium to •

- Air-jet yarns are weaker than either ring spun or open-

end spun yarns. Long staple spinning systems

• Two spinning systems exist for the spinning of the long

staple (2” to 10”) fibers into yarn. •

- Worsted System (fibers 2-10” long)

- Machinery is different, but process is similar to combed cotton production. Fibers are highly parallelized prior to twisting into yarn.

- Yarns are used for slacks, sport coats, suits, overcoats, some sweaters, and carpet.

- They are stronger and firmer

Woolen System

- Totally different

- Yarns are softer, warmer, bulkier, and weaker than

- worsted yarns. •

- Woolen/Worsted Yarns

- The warmth of any apparel or textile product is mainly due to its ability to maintain dead-air space within the yarns.

- Because of the high degree – –

- The worsted spinning of wool fibers does achieve good alignment, but at a much higher cost than in woolen spinning.

- The warmth of any apparel or textile product is mainly due to its ability to maintain dead-air space within the yarns.

Examples of Cotton System Yarns:

- 100% Cotton, for denim

- 100% Combed Cotton, for Blouses

- 65% Polyester/35% Cotton, for Slacks

- 50% Polyester/50% Combed Cotton for Shirts

- 50% Polyester/50% Rayon, for Shirts

- 70% Polyester/30% Acrylic, for Knits

Examples of Woolen System Yarns:

Examples of Worsted System Yarns:

- 100% Wool, for Suits

- 55% Polyester/45% Wool, for Suits

- 65% Polyester/20% Rayon/15% Acrylic, for Slacks

- 100% Nylon, for Carpet

- 100% Polyester, for Carpet

Fiber Blends in Yarns Blend-

![]() Different fibers are present in the same yarn in planned proportions

Different fibers are present in the same yarn in planned proportions

Mixture

- Mixture- yarns •

- (warp of one type, fill of another)

Combinations

- Combinations-

- Why Blend Fibers

- Fabrics have a better combination of performance characteristics- •

- Improve spinning, weaving, finishing, uniformity

- To obtain better fabric appearance- rabbit hair for certain appearance

- To minimize fiber cost-

- To obtain unique color effects-

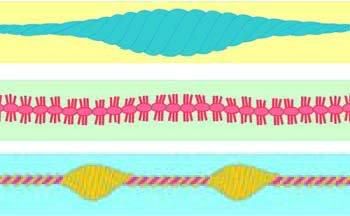

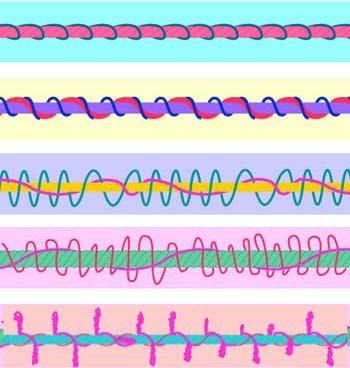

Compound and Fancy Yarns Complex Yarns (Novelty Yarns, Fancy Yarns)

- Complex yarns are used to provide visual interest and surface texture to a fabric. Only 5 to 10% of all yarns manufactured fall into this category.

- Complex yarns are • •

- Plied complex yarns usually include an effect yarn (E), a core yarn (C), and sometimes a binder yarn (B).

Continued . . . . .

- Named •

- Plied, but seldom add strength to fabric

- If used in only one direction they are used in the fill

- Usually the smaller the novelty effect the more durable the fabric (less effected by abrasion, less snagging)

- Tweed-

- – Flecks of short colored fibers twisted into the yarn, often wool WHY?

- Slub- single, spun, fancy yarns, varying yarn diameters along their length; these are usually singles.

- True slub- twist varied at regular intervals (thicker less twist)

- Elongated tufts of fiber into yarn at regular intervals with a core or binder yarn

Types of complex yarns

- Thick and thin – • •

- Chenille – Resembles a caterpillar in appearance.

- Flock or flake, fleck –

Types of complex yarns

- Spiral and Corkscrew – •

- Gimp and Ratiné – E and C are plied around each other; E is larger than in ratiné than for gimp, effect ply is twisted around ground. At intervals the effect yarn kinks out and back on itself.

- Crepe highly twisted simple yarn

- Bouclé, loop, and snarl –

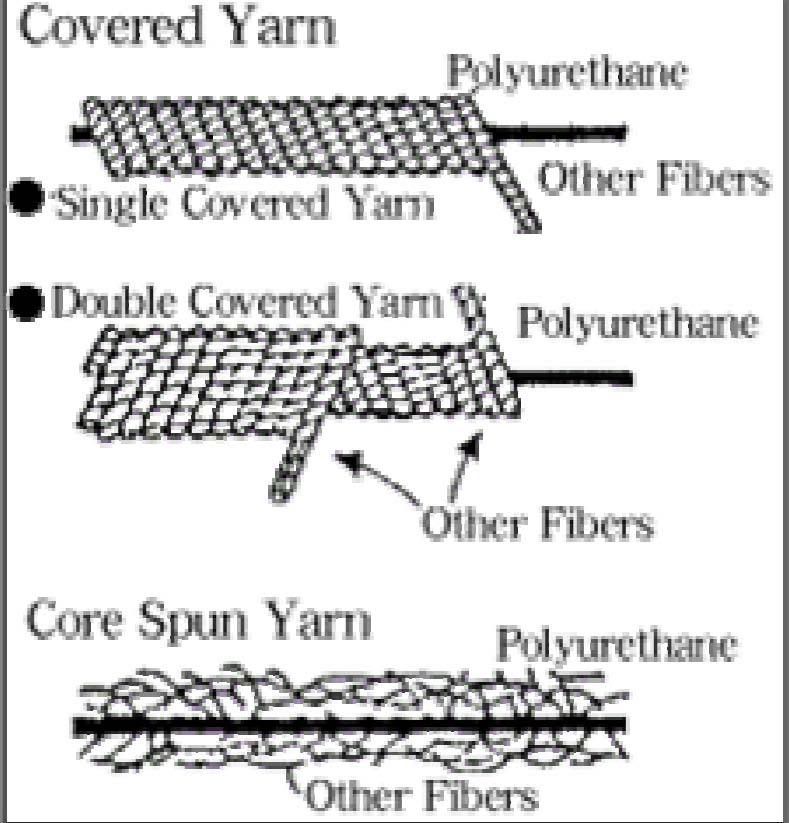

Compound or CompositeYarns

- Regular in appearance along length

- Covered Yarns: central yarn that is completely covered Core wrapped with 1 or more yarns

- Core Spun Yarns: Core wrapped with fiber

Yarn Quality

- Will it be strong enough to withstand the stress of the loom

- Better quality-