P. Negrea, G. Mosoarca, M. Ciopec, L. Lupa

University „Politehnicall Timisoara, Faculty of Industrial Chemistry and Environmental Engineering,

Victoria Square, no.2, 300006, Romania, E-mail: lavinia.lupa@chim.upt.ro

Key words: PFG, clinker, incineration, waste management

ABSTRACT

The production evolution of the unsaturated and armed polyesters fiber glass (PFG) is determinate by the advantages offered by this material: weight reduction of the pieces, resistance to the chemical agents and bad weather as against the metals objects, energy consume reduction needed for the finite pieces obtaining by simplification and removal of a lot of production phases, increased work productivity, accessible price of the materials.

The prime materials used to the production of the plastic armed materials with glass fiber are: unsaturated polyester resin, styrene, initiator (per benzoate tert butyl), inhibitor (parabenzquinones), viscosity reduction, zinc stearate, filling materials (aluminium hydroxide, calcium carbonate), pigments (zinc sulphur, titan dioxide, and iron trioxide), thickened (magnesium oxide in resin, fiber glass, polyethylene folly).

The use domains of these materials are: body elements, compounds for automobiles, compounds for micro wave, and boxes for electric junction, stadium chairs, and waters basins.

The chemical analyze, caloric content and thermal analyze made on this armed polyester fiber glass wastes shows the incineration possibilities of these in the furnace of the cement obtaining, the resulted oxides inlet in the clinker composition.

1. INTRODUCTION

The man, in his researching of study and use of new materials, which can replace the traditional materials sometimes with unsatisfactory proprieties and which are more often hard to procure, find the unsaturated and armed polyesters fiber glass.

The unsaturated polyesters resins, in the commercial form are a solution of unsaturated polyesters in a monomer (solvent reagent) with who copolymerise making a reticular structure (the reaction of the polyesters strengthening).

The thermo active macromolecular compounds are synthetic resins of poly condensation, with not such a big molecular mass, which contain groups capable to react by adding of some suitable components or under heat action.

The proprieties of the thermo reactive polymers to pass, under heat action, in an insoluble and infusible form, constitute the base of these products. By mixing with different adding, under pressure, at a specific temperature, the material become plastic, take the form of the stamp, of the vessel in which is put and, because of the reaction which take place, is obtained the product with three-dimensional structure.

The processing of different objects and bench-mark from unsaturated polyesters resins can be realised using very different technologies, in which the resins reticulation takes place at the ambient temperature or at heating, in stamp made by different materials, function of the choose technology.

The armed polyester constitute in present the most important apply of the unsaturated polyesters resins. For the use of the polyesters in others purposes is necessary to begin with the preparing of some compositions and half-finished in discontinue regime of processing.

The resin material used to the obtaining of some armed bench-mark with glass fiber is named Sandwich Material Compounds (S.M.C.).

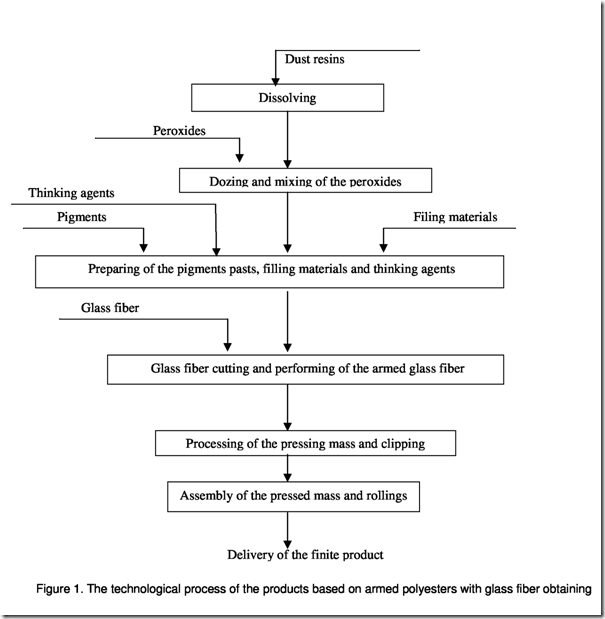

The preparing of this is made after the next phases:

- The dissolving of the dust resins;

- The dissolving and mixing of the peroxides;

- The cutting of the glass fiber and performing of the glass fiber armed;

- The processing of the pressing ass and rolling;

The purpose of the paper is the studies regarding the reuse of the armed polyester with glass fiber (PAFS) wastes. For this were made chemical analyses of the prime materials and of the resulted wastes after the technologic process of S.M.C. obtaining.

The resulted wastes are of three types:

- the wastes resulted after clipping

- the wastes resulted because of the unsuitable (S.M.C.) material from the quality point of view - the wastes resulted because of the rebut which appear during the technological flow.

For the obtaining of pastes ease to mix is used pigment based on zinc sulphur (with colour) and iron oxides (yellow and red colour).

The selected technological process (Figure 1) contains the next two steps:

a) the preparing of the working material, of the armed polyester with glass fiber;

b) the processing of the armed polyester with glass fiber in stamp;

2. PHYSICAL-CHEMICAL ANALYSE OF THE PRIME MATERIAL

It is weight in a melter a well defined quantity of the used pigment. The melter is put in a burning furnace, in the first phase at 500°C and than at 800°C for the removing of the organic part of the pigment. It is determined the loss at the burning. The resulted product after the burning was dissolving in HCl solution at heating. After dissolving the metals (Fe and Zn) are analysed by atomic absorption spectrometry using a spectrophotometer Varian SpectrAA 110.

The obtained results after the physical-chemical analyse are presented in table 1.

3. THERMAL AND IR ANALYSE OF THE PAFS WASTES

The obtained product is submit to the thermal analyse, using a thermo gravimetric balance Netzsch TG 209, in the view of final temperature of burning establishment.

Figure 2 illustrates the thermal behaviour of the product. When the product is non-isothermally heated with a constant heating rate of 5°C/min up to 1000°C, in the sample take place two processes with mass loss. The first procces occurs in the range of temperature 170-487°C with a mass loss of 33.67% in three steps with maximum rates at 233, 333 and 425°C. The second process takes place between 618-772°C, with maximum rate at 717°C and a mass loss of 12.21%. At 985°C the residue is of 50.80%.

4. THE PAFS WASTES ANALYSES

It is weight a determined quantity of the wastes (PAFS) in a melter, which next is put in a furnace at 800ºC for the removing of the organic impurities present in the waste. The obtained mass after burning was dissolving in HCl solution at heating. The resulted solution after filtration is analysed. The experimental data obtained are presented in table 2.

5. CONCLUSIONS

The processing process generates important quantities of PAFS wastes which could not be direct reused.

Having in the view the chemical composition of these waste these can be incinerated in the furnace of the cement obtaining, because they have a good caloric capacity, and from the incineration process the major resulted oxides are: calcium oxide, silicium dioxide and a series of other oxides in small quantities.

The resulted wastes must divide and compacted in the view of the facilitate the introduction in the cement obtaining furnace.