HIGH VOLUME INSTRUMENT SYSTEM

The testing of fibres was always of importance to the spinner. It has been known for a long time that the fibre characteristics have a decisive impact on the running behaviour of the production machines, as well as on the yarn quality and manufacturing costs. In spite of the fact that fibre characteristics are very important for yarn yarn proudction, the sample size for testing fibre characteristics is not big enough. This is due to the following

- The labour and time involvement for the testing of a representativesample was too expensive. The results were often available much too late to take corective action.

- The results often depended on the operator and / or the instrument, and could therefore not be considered objective

- one failed in trying to rationally administer the flood of the rawmaterial data, to evaluate such data and to introduce the necessary corrective measures.

Only recently technical achievements have made possible the development of automatic computer-controlled testing equipment. With their use, it is possible to quickly determine the more important fibre characteristics.

Recent developments in HVI technology are the result of requests made by textile manufacturers for additional and more precise fibre property information. Worldwide competitive pressure on product price and product quality dictates close control of all resources used in the manufacturing process.

Following are the advantages of HVI testing

- the results are practically independent of the operator

- the results are based on large volume samples, and are therefore more significant

- the respective fibre data are immediately available

- the data are clearly arranged in summerised reports

- they make possible the best utilisation of rawmaterial data

- problems as a result of fibre material can be predicted, and corrective measures instituted before such problems can occur

Cotton classification does not only mean how fine or clean, or how long a fibre is, but rather whether it meets the requirements of the finished product. To be more precise, the fibre characteristics must be classified according to a certain sequence of importance with respect to the end product and the spinning process.

The ability to obtain complete information with single operator HVI systems further underscores the economic and useful nature of HVI testing.

Two instrument companies located in the US manufacture these HVI systems. Both the systems include instruments to measure micronaire, length, length uniformity, strength, colour, trash, maturity, sugar content etc.

LENGTH:

The length measure by HVI systems used by the USDA is called upper-half-mean length. This is the average or mean length of the longest one-half of the fibres in the sample. The spinlab system uses the fibrosampler device to load the fibres on needles, the motion control system uses the Specimen Loader to capture the fibres in a pinch clamp. However the preparation of the length specimen for both systems includes combin to straighten and parallel the fibres, and brushing to remove fibre crimp. The length measurement is then made by the instrument scanning along the length of the specimen to determine the length data.

The insturments are calibrated to to read in staple length. Length measurements obtained from the instrument are considerably more repeatable than the staple length determination by the classer. In one experiment the instrument repeated the same staple length determination 44% of the time while the classer repeated this determination only 29% of the time. Similarly, the instrument repeated to 1/32" on 76% of the samples, while the classer agreed on 71% of the samples to within 1/31".

The precision of the HVI length measurement has been improved over the last few years. If we take the same bale of cotton used in the earlier example and repeatedly measure length with an HVI system, over two-thirds of measurements will be in a range of only about 1/32 nd of an inch: 95% of the individual readings will be within 1/32nd of an inch of the bale average. In the 77000 bales tested, the length readings were repeated within 0.02" on 71% of the bales between laboratories.

LENGTH UNIFORMITY:

The HVI system gives an indication of the fibre length distribution in the bale by use of a length uniformity index. This uniformity index is obtained by dividing the mean fibre length by the upper-half-mean length and expressing the ratio as a percent. A reading of 80% is considered average length uniformity. Higher numbers mean better length uniformity and lower numbers poorer length uniformity.

Repeated measurements on a single bale of cotton show the length uniformity index measurement to have relatively low precision. About two-thirds of the measurements will occur within one unit of length uniformity; thus a bale with an average length uniformity index of 80 would have 68% of the readings occuring between 79 and 81, and 95% of hte readings occuring between 78 and 82. This does not seem too bad until one considers that most US upland cottons will have a length uniformity reading between 75 and 85.

Most organizations operate their HVI systems to use an average of 2 or 4 readings per bale for the length uniformity index. Using that number tests per bale, the USDA test of 77000 bales showed that laboratoriesat different locations agreed 68% of the time to within one length uniformity index unit.

In some cases low length uniformity has correlated with high short fibre content. However, in general the correlations between length uniformity index and short fibre content have not been very good. One important reason why the length uniformity index is a not a very good indicator of the short fibre content has to do with the fact that the HVI systems do not measure the length of any fibres shorter than about 4mm.

Another reason for the poor correlations between length uniformity index and short fibre content is that the short fibre content is related to staple length while the length uniformity index is fairly independent of staple length. As an example, the shorter staple cottons tend to contain higher amounts of short fibre than the longer staple cottons. Howeer, many short staple cottons have length uniformity index readings above 80.

MICRONAIRE:

The micronaire reading given by the HVI systems is the same as has been used in the commercial marketing of cotton for almost 25 years. The repeatability of the data and the operator ease of performing the test have been improved slightly in the HVI micronaire measurement over the original instruments by elimination of the requirement of exactly weighing the test specimen. The micronaire instruments available today use microcomputers to adjust the reading for a range of test specimen sizes.

The micronaire reading is considered both precise and reperable. For example, if we have a bale of cotton that has an average micronaire of 4.2 and repeatedly test samples from that bale, over two-thirds of thet micronaire readings will be between 4.1 and 4.3 and 95 %of the readings between and 4.0 and 4.4. Thus, with only one or two tests per bale we can get a very precise measure of the average micronaire of the bale.

This reading is also very repeatable from laboratory to laboratory. In USDA approx 77000 bales were tested per day in each laboratory, micronaire measurements made in different laboratories agreed with each other within 0.1 micronaire units on 77% of the bales.

The reading is influenced by both fibre maturity and fibre fineness. For a given growing area, the cotton variety generally sets the fibre fineness, and the environmental factors control or influence the fibre maturity. Thus , within a growing area the micronaire value is usually highly related to the maturity value. However, on an international scale, it cannot be known from the micronaire readings alone if cottons with different micronaire are of different fineness or if they have different maturity levels.

STRENGTH:

The strength measurement made by the HVI systems is unlike the traditional laboratory measurements of Pressley and Stelometer in several important ways. First of all the test specimens are prepared in a very different manner. In the laboratory method the fibres are selected, combed and carefully prepared to align them in the jaw clamps. Each and every fibre spans the entire distance across the jaw surfaces and the space between the jaws.

In the HVI instruments the fibres are ramdomly selected and automatically prepared for testing. They are combed to remove loose fibres and to straighten the clamped fibres, also brushed to remove crimp before testing. The mechanization of the specimen preparation techniques has resulted in a "tapered" specimen where fibre ends are found in the jaw clamp surfaces as well as in the space between the jaws.

A second important difference between traditional laboratory strength measurements and HVI strength measurements is that in the laboratory measurements the mass of the broken fibres is determined by weighing the test specimen. In the HVI systems the mass is determined by the less direct methods of light absorption and resistance to air flow. The HVI strength mass measurement is further complicated by having to measure the mass at the exact point of breaks on the tapered specimen.

A third significant difference between laboratory and HVI strength measurements is the rate or speed at which the fibres are broken. The HVI systems break the fibres about 10 times faster than the laboratory methods.

Generally HVI grams per tex readings are 1 to 2 units (3 to 5%) hihger in numerical value. In some individual cases that seem to be related to variety, the differences can be as much as 6 to 8% higher. This has not caused a great deal of problems in the US, perhaps because a precedent was set many years ago when we began adjusting our Stelometer strength values about 27% to put them on Presseley level.

Relative to the other HVI measurements, the strength measurement is less precise. Going back to our single bale of cotton and doing repeated measurements on the bale we shall find that 68% of the readings will be within 1 g/tex of the bale average. So if the bale has an average strength of 25 g.tex, 68% of the individual readings will be betweeen 24 and 26 g/tex, and 95% between 23 and 27 g/tex.

Because of this range in the readings within a single bale, almost all HVI users make either 2 or 4 tests per bale and average the readings. When the average readings are repeated within a laboratory, the averages are repeated to within one strength unit about 80% of the time. However, when comparisons are made between laboratories the agreement on individual bales to within plus or minus 1 g/tex decreases to 55%.

This decrease in strength agreement between laboratories is probably related to the difficulty of holding a constant relative humidity in the test labs. Test data indicate that 1% shift in relative humidity will shift the strength level about 1% . For example, if the relative humidity in the laboratory changes 3% ( from 63 to 66%), the strength would change about 1 g/tex ( from 24 to 25 g/tex)

COLOUR:

The measurement of cotton colour predates the measurement of micronaire, but because colour has always been an important component of classer's grade it has not received attention as an independent fibre property. However the measurement of colour was incorporated into the very early HVI systems as one of the primary fibre properties.

Determination of cotton colour requires the measurement of two properties, the grayness and yellowness of the fibres. The grayness is a measure of the amount of light reflected from the mass of the fibre. We call this the reflectance or Rd value. The yellowness is measured on what we call Hunter's +b scale after the man who developed it. The other scales that describe colour space (blue, red, green) are not measured becasue they are considered relatively constant for cotton.

Returning once again to the measurements on our single bale, we see that repeated measurements of colour are in good agreement. For grayness or reflectance readings, 68% of the readings will be within 0.5 Rd units of the bale average, and 95% within one Rd unit for the average.

As for yellowness, over two-thirds of these readings will be within on-fourth of one +b unit of the average, and 95% within one-half of one +b unit. The grayness (Rd) and yellowness (+b) measurements are related to grade through a colour chart which was developed by a USDA researcher. The USDA test of 77000 bales showed the colour readings to be the most repeateable of all data between laboratories; 87% of the bales repeated within one grayness(Rd) unit, and 85% repeated within one-half of one yellowness(+b) unit.

TRASH CONTENT:

The HVI systems measure trash or non-lint content by use of video camera to determine the amount of surface area of the sample that is covered with dark spots. As the camera scans the surface of the sample, the video output drops when a dark spot (presumed to be trash) is encountered. The video signal is processed by a microcomputer to determine the number of dark spots encountered (COUNT) and the per cent of the surface area covered by the dark spots (AREA). The area and count data are used in an equation to predict the amount of visible non-lint content as measured on the Shirley Analyser. The HVI trash data output is a two-digit number which gives the predicted non-lint content for that bale. For example, a trash reading of 28 would mean that the predicted Shirley Analyser visible non-lint content of that bale would be 2.8%.

While the video trash instruments have been around for several years, But the data suggest that the prediction of non-lint content is accurate to about 0.75% non lint, and that the measurements are repeatable 95% of the time to within 1% non-lint content.

SHORT FIBER CONTENT:

The measure of short-fiber content (SFC) in Motion Control's HVI systems is based on the fiber length distribution throughout the test specimen.

It is not the staple length that is so important but the short fiber content which is important. It is better to prefer a lower commercial staple, but with a much lower short-fibre content.

The following data were taken on yarns produced under identical conditions and whose cotton fibers were identical in all properties except for short-fiber content. The effects on ends down and several aspects of yarn quality are shown below.

| LOT -A, (8.6% SFC) | LOT-B (11.6% SFC) | |

| Ends down / 1000 hrs | 7.9 | 12.8 |

| Skein strength (lb) | 108.1 | 97.4 |

| Single end strength g/tex | 15 | 14.5 |

| apperance index | 106 | 89 |

| Evenness (CV%) | 16 | 17.3 |

| Thin places | 15 | 36 |

| Thick places | 229 | 364 |

| Minor Defects | 312 | 389 |

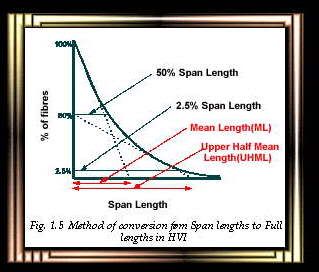

HVI systems measure length parameters of cotton samples by the fibrogram technique. The following assumptions describe the fibrogram sampling process:

- The fibrogram sample is taken from some population of fibres

- The probability of sampling a particular fiber is proportional to its length

- A sampled fiber will be held at a random point along its length

- A sampled fiber will project two ends away from the holding point, such that all of the ends will be parallel and aligned at the holding point.

- All fibers have the same uniform density

The High Volume Instruments also provide empirical equations of short fibre content based on the results of cotton produced in the United States in a particular year.

Short Fibre Index = 122.56 - (12.87 x UHM) - (1.22 x UI)

where UHM - Upper Half Mean Length (inches) UI - Uniformity Index

Short Fibre Index = 90.34 - (37.47 x SL2) - (0.90 x UR)

Where SL2 - 2.5% Span length (inches) UR - Uniformity Ratio

In typical fibrogram curve, the horizontal axis represents the lengths of the ends of sampled fibers. The vertical axis represents the percent of fiber ends in the fibrogram having that length or greater.

MEASUREMENT OF MATURITY AND SUGAR CONTENT:

Near infrared analysis provides a fast, safe and easy means to measure cotton maturity, fineness and sugar content at HVI speed without the need for time consuming sample preparation or fiber blending.

This technology is based on the near infrared reflectance spectroscopy principle in the wavelength range of 750 to 2500 nanometers. Differences of maturity in cotton fibers are recognized through distinctly different NIR absorbance spectra. NIR technology also allows for the measurement of sugar content by separating the absorbance characteristics of various sugars from the absorbance of cotton material.

Cotton maturity is the best indicator of potential dyeing problems in cotton products. Immature fibers do not absorb dye as well as mature fibers. This results in a variety of dye-related appearance problems such as barre, reduced color yield, and white specks. Barre is an unwanted striped appearance in fabric, and is often a result of using yarns containing fibres of different maturity levels. For dyed yarn, color yield is diminished when immature fibres are used. White specks are small spots in the yarn or fabric which do not dye at all. These specks are usually attributed to neps (tangled clusters of very immature fibers)

NIR maturity and dye uptake in cotton yarns have been shown to correlate highly with maturity as measured by NIR. A correlation of R=0.96 was obtained for a set of 15 cottons.

In a joint study by ITT and a European research organization, 45 cottons from four continents were tested for maturity using the NIR method and the SHIRLEY Development Fineness/ Maturity tester(FMT). For these samples, NIR and FMT maturity correlated very highly (R=0.94).

On 15 cottons from different growth areas of the USA , NIR maturity was found to correlate with r2 = 0.9 through a method developed by the United States Department of Agriculture (USDA). In this method, fibres are cross-sectioned and microscopically evaluated.

Sugar Content is a valid indicator of potential processing problems. Near infrared analysis, because of its adaptability to HVI, allows for screening of bales prior to use. The information serves to selected bales to avoid preparaion of cotton mixes of bales with excessive sugar content. COTTON STICKINESS consists of two major causes- honeydew form white flies and aphids and high level of natural plant sugars. Both are periodic problems which cause efficiency losses in yarn manufacutring

The problems with the randomly distributed honeydew contamination often results in costly production interruptions and requires immediate action often as severe as discontinuing the use of contaminated cottons.

Natural plant sugars are more evenly distributed and cause problems of residue build-up, lint accumulation and roll laps. Quality problems created by plant sugar stickiness are often more critical in the spinning process than the honeydew stickiness. Lint residues which accumulate on machine parts in various processes will break loose and become part of the fiber mass resulting in yarn imperfections. An effective way to control cotton stickiness in processing is to blend sticky and nonsticky cottons. Knowing the sugar content of each bale of cotton used in each mix minimizes day-to-day variations in processing efficiency and products more consistent yarn quality. Screening the bale inventory for sugar content prior to processing will allow the selection of mixes with good processing characteristics while also utilizing the entire bale inventory.

The relationship between percent sugar content by NIR analysis and the Perkins method shows an excellent correlation of r2=0.95. The amount of reducing material on cotton fiber in the Perkins method is determined by comparing the reducing ability of the water extract of the fiber to that of a standard reducing substance. Using the NIR method, the amount of reducing sugar in cotton is measured.

The popularity of HVI testing has steadily gained since the introduction of the technology in the early 1960s.

Timely, valuable information, promotion of communication, standardisation of measurements, optimization of processes, development of new products and cost control are the outstanding benefits of technology.