VOUK Nova

Blowroom Machinery

· Superblender B12N

· Duocleaner B39N

· Automixer B143N - B142N

· Dust Separator B44N

· Fine Opener B38N - B37N

· Motor Fan B151N - B152N

· Weighing Bale Opener B13N

· Tuft Blender B23N

· Bale opener and premixer B14N

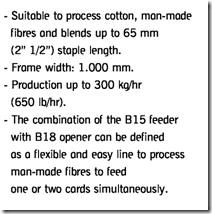

· Blending Feeder B15N

· Feeder with Opener B15N + B18N

· Opener for man-made fibres B134N

· Chute Feed B139N

Card Section

· C601SN

Complete Spinning Systems

BLOWROOMMACHINERY

High Productivity With Low Operational Cost

Electronic Machine

Reduction Of Maintenance Cycles

Production Setup And Control By Software

Marzoli new Blowroom line allows

to process all textile fibres,

cotton staple length, such as follows

- All types of cotton

- Man made and synthetic fibres

- Shaddy materials

- Short wool - Flax

- Gin motes Improvement of the opening and cleaning level, thanks to innovation and introduction of new parts touching the fibres; increase of productivity of the single machine for Blowroom line producing up to 800 kg/h.

Continuous improvement of qualitative features of the final product;

efficient dedusting of the fibres,

low neps content, soft and intensive handling of the fibres to avoid dameges, reduction in waste,

high blending quality during the blending process.

All the parameters are entered

and set through an electronic panel on the board of the machines.

Easy machines handling

and maintenance thanks to optimal accessibility of working organs.

B12N SUPERBLENDER

Highly Reliable Easy to use

-Smooth and continuous material plucking all the way down to the floor thanks to the free and upright movement of the detacher and

to the moveable conveying rollers. -Very small flocks are achievable thanks to 2 beaters, each with 254 tips and to 2 moveable conveying rollers that controls the material during plucking.

- High reliability and safety.

High and flexible production

The B12N bale plucker is used

for the take-off of various assortments of cotton or man-made fibres.

The maximum production is up to 1600 kg/hr (according to the

processed fibres) feeding one single blowroom line and with a detacher with a working width of 2250 mm.

The detacher follows freely the contour of the lay down and plucks the raw material all the way down to the floor, leaving no material lying on the ground at the end of the lay down thanks to the moveable conveying rollers.

Reliability and Safety

The safety elements consist of light barriers surrounding the working area of the bale plucker.

High reliability comes from a plentiful sizing of the mechanical parts and from an extremely easy operation. The tungsten-carbide tips of the beater can be replaced.

Ideal Cleaning Preparation Production up to 1600 kg/h

B39N DUOCLEANER

Great Dedusting Process and Very Heavily Contaminated Raw Material Cleaning Dual Zone

-A very efficient opener for cleaning and dedusting, placed directly after the Superblender.

The fiber is dedusted by the cage condenser placed on it.

-Production up to 1200 Kg/hr (2650 lb/hr) according to processed fibres.

-Fibres are dragged by the two beaters for 6 times on the cleaning grid. Soft opening and cleaning of the fibres.

- Each grid has an independent setting.

-Beater with different rotating speed and tips number.

-Total surface of the grid 30% greater than the competitors. -Total dedusting surface 125% greater than the competitors.

Low fibre stress

Efficient cleaning is only possible directly after an opening process. Trash particles, fibre fragments and dust are removed by the Duocleaner. The advantage of the mini-tufts provided by the Superblender

is used effectively.

Since the Duocleaner has no nipping point, low fibre stress and nearly

no neps formation are achieved. High flexibility for all production requirements

If the Superblender B12N is workin with different fibres assortments the Duocleaner automatically adjusts itself to the preset working positions All settings are recorded and can

be reproduced at any time.

Optimized cleaning

The parameters for optimized cleaning can be entered via the control panel. Specifically:

- Cleaning intensity which is affected by the rotating speed of the two cleaning rolls.

- Relative amount of waste

which is determined by the angles of the two grids.

The waste is transferred through the two bucket wheel locks

to a continuous centralized suction system.

Efficient dedusting

Dust and sand cause many problems in the spinning mill.

To extract these particles directly after the Superblender B12N

a B45N cage condenser is combined with the B39N Duocleaner.

Adjustable Cleaning Efficiency

Production up to 1200 Kg/h

Different Speed of Cleaning Rolls

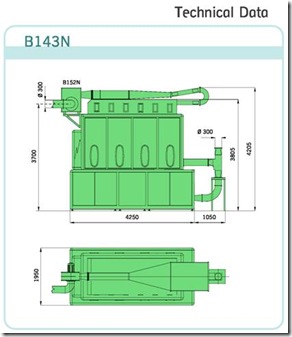

B143N AUTOMIXER

For all Application Without Fiber Conveyor

-6 mixing chambers.

-Production up to 1200 kg/hr (2700 lb/hr).

-Easy and reliable machine without fiber conveyor belt and deviating blade.

-Low maintenance.

-Dedusting on an area of 8 m2

Reliable performance

A smooth air stream simultaneously feeds fibre tufts into the six vertical filling chutes.

This distribution works without mechanical parts and ensures

that an instantaneous blend of every bale is deposited uniformly

in all chutes where the material is pneumatically compacted.

A pair of grooved delivery rolls

and an opening roll for each blending chamber open the stock which is sucked by the air stream of the cage condenser after the Automixer.

B142N AUTOMIXER

Automixer for Small Lots Low Cost

-Feeding through a built-in cage condenser.

-Upper lattice to progressively feed the cells.

-A couple of conveying rollers per cell, with different speed, driven by an electronic speed variator with potentiometer.

-An opening roller per cell, with adjustable speed.

-Four blending cells with capacity

of 20 to 50 kg of material each cell. -Adjustment and control of

cell filling by means of photocells. -Electric drivers synchronized

in sequence with the centralized control panel.

-Total dedusting surface 125% greater than the competitors.

Production up to 800 Kg/h High Dedusting Surface

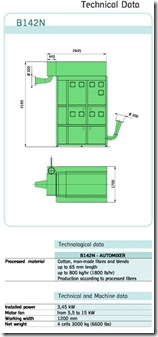

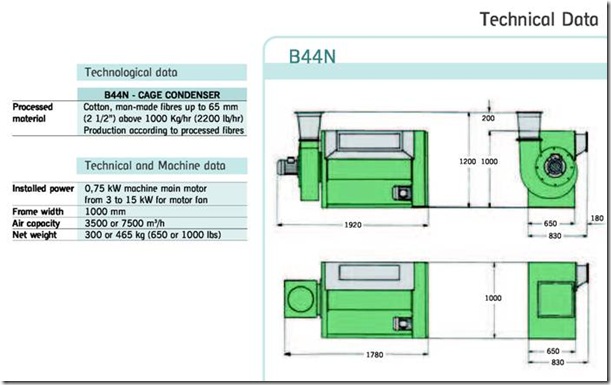

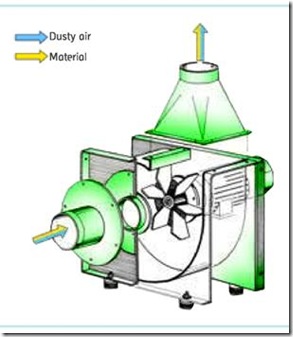

B44N DUST SEPARATOR

High Dedusting Surface No Neps Creation

The system with perforated cylinder reduces by 15% the neps creation in respect to the fiber transport by fan.

-Production above 1000 Kg/h

(2200 lb/h).

-The B44N cage condenser eliminates dust while conveying, pneumatically, the material processed.

-The dedusting effect is highly

efficient since it is carried out at various stages along the blowroom line on tufts which have become progressively smaller and lighter.

-Furthermore the transfer of material takes place with suction without curling or damaging the fibres

in any way.

- Dedusting surface is 1 m2

- The B44N cage condenser

is available with:

-An incorporated motor fan.

-With a motor fan installed separately.

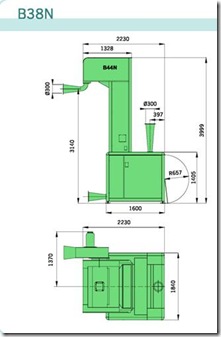

B38N FINE OPENER

Gentle, but Intensive opening High Dedusting Surface

Bigger Cleaning Roll

-Production up to 800 kg/hr

(1750 lb/hr).

-Suggested for cottons or man-made fibres. -Optimal accessibility and low maintenance costs.

-Optimal opening.

-High flexibility of processing.

-Optimized cleaning. -Efficient dedusting.

Optimal opening

The B38N fine opener is suitable for either roller for long staple cotton or for man-made fibres (up to 65 mm staple length).

Its gentle yet intensive

opening action minimizes neps and loss of good fibres.

Optimized cleaning

The parameters for optimized cleaning can be entered via the control panel. Specifically:

-Cleaning intensity which affects the speed of the cleaning roll.

-Relative amount of waste which is determined by the setting of the motorized deflector blades whose position determines the quality and quantity of the waste.

High flexibility

The flexibility of the B38N fine opener is obtained with three different opening rolls (pinned, needle and sawtooth) chosen according to the type of material processed.

Efficient dedusting

The B44N cage condenser determines a dedusting action of the processed material before entering the B38N fine opener.

In addition trash particles and dust generated during the opening action are conveyed by the suction hoods to a centralized suction system. Permanent suction considerably improves the dedusting of the cotton.

B37N FINE OPENER

High Cleaning Efficiency

Cleaning Technology for any Cotton Quality High Dedusting Surface

-Production up to 800 kg/hr

(1750 lb/hr)

-Suggested with cotton

with medium trash

-Optimal accessibility and low maintenance costs

-Optimal opening

-With three different opening

rolls combination

-High flexibility of processing -Optimized cleaning -Efficient dedusting

Optimal opening

The B37N is the essential fine opener in any blowroom line processing saw ginned cottons with a high trash content.

The use of this fine opener shortens the opening line and its intensive opening action minimizes the loss

of good fibres.

The B37N is used when producing either open end or jet spun yarns.

Optimized cleaning

The parameters for optimized cleaning can be entered via the control panel. Specifically: -Cleaning intensity which affects

the speed of the cleaning roll. -Relative amount of waste which is determined by the setting of the motorized deflector blades whose position determines the quality and quantity of the waste.

Dedusting efficiency

The B44N cage condenser determines a dedusting action of the processed material before entering the B37N fine opener.

In addition trash particles and dust generated during the opening action are conveyed by the suction hoods to a centralized suction system. Permanent suction considerably improves the dedusting of the cotton.

B38N + B37N FINE OPENER

Three Different Opening Roll Production up to 800 Kg/h

Processing of fibres with a lot of trash

- The B38N is combined with the B37N in order to prepare

the fibre to the intensive treatment of the B37N itself.

- The double dust separator B44N. determines a very high dedusting surface suitable for very dirty raw materials.

- The combination of a beater with big diameter (B38N) and three beaters with small diameter (B37N) grants the total elimination of all the trash contained in such a kind of row materials.

- The maximum flexibility is obtained through a by-pass for the alternative operation the two machines.

B151N - B152N MOTOR FAN

Speed Controlled

The Fan Geometry is Optimized for a Gentle Fibres Treatment.

The B151N and B152N are specific motor fan for the passage of the fibres inside.

The B152N sucks and blows

the material from one machine to the other in the opening lines.

The B151N sucks and blows in the card chute feeding.

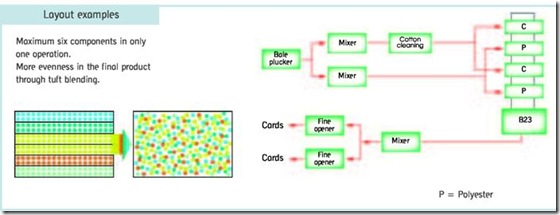

TUFT BLENDING INSTALLATION

The Quality of Blending is Far Better

than Other System

-Tuft blending indicates

a combination, in the blowroom line, of different components with preset ratios and successive carding of the resulting blend.

- Optimum weighting precision - Self-calibration of the balance

Simple operations and monitoring

-microcomputer control guides

the operator with simple messages. -help contest in line: malfunctions cause and remedies, instruction manual.

- working programs once entered can be stored for repeats.

- display shows target and actual weights, cv values, production rates of shifts.

- all operating data can be printed or stored in ms dos compatible disc (p.c).

- automatic actual weight correction.

High level of accuracy at weighting

- Pre-fill at high speed. - Fill up at low speed.

High production

- Abundant material reserve. - Large capacity of weigh-pans results in a smaller number of weighting operations.

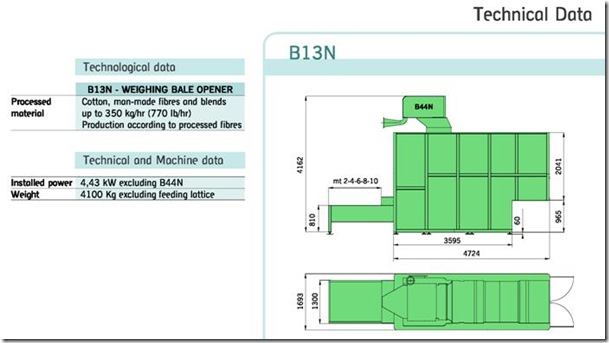

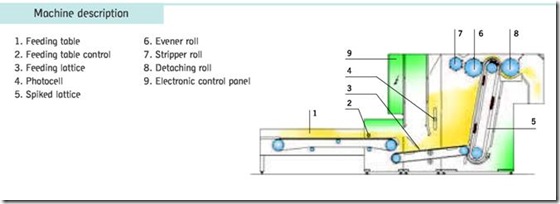

B13N WEIGHTING BALE OPENER

Tuft Blending Installation

for Precise and Intimate Blends

B13N + B23N

- Automatic calculation

of the production and of the weights number

- Every 50 weights the CV calculatio is automatically activated (CV%). The machine automatically adjust the setting if the CV is beyond the preset tolerance value.

-Automatic control of the turbolences produced by the fall of the

material on the balance.

- Possibility to operate continuously with open balance.

- Possibility to choose up to 10 working programs.

- Possibility to automatically

set the machine production with the evener roll.

- Automatic emptying of the

B13N + B23N system.

-Frame width: 1200 mm.

-The B13N weighting bale opener can be fed manually and is therefore suitable for processing small lots. The length of the feed table can be adapted to the space available. -The weighting bale opener B13N can be fed also automatically (through cage condenser B44N)

and is therefore also

suitable for processing large lots.

- Consequently the B13N is the ideal solution for highly flexible installations which can be used to process large lots as well as occasional small lots.

- Indirect discharge of the tufts into the weigh pan avoids weighting mistakes.

B23N TUFT BLENDER

Up to 6 Components Can Be Weighted for Precise and Intimate Blends

B23N Tuft Blender with one delivery

- Maximum production up to

1000 kg/hr with a frame width of 1000 mm.

- A tuft blender B23N can be fed by up six weighting bale openers B13N. The weighting feeders discharge

the material onto the conveyor belt of the tuft blender.

The different blend components are placed on top of each other in layers. -The tuft blender B23N can be equipped with a device or devices for the uniform spray application

of oils or marker colours. The spraying nozzles are installed between two weighing bale openers B13N and they are activated

in accordance with the

movement of the conveyor belt of the tuft blender.

From Marzoli Only:

a Further Step Towards the Installation Flexibility

B23N Tuft Blender with two delivery

- The B23N with two deliveries with a “jolly” B13N feeder (C) is the ideal solution for a better flexibility of the installation and for

plants where the blend is changed frequently.

- The line 1 can operate with

three feeders A+B+C, the line

2 with two feeders D + E or alternatively the line 1 with A+B and the line

2 with C+D+E. - In this case the minimum

gauge (S) between the B13N

feeders is 4.200 mm;

the maximum gauge (S) is 5.400 mm. - The 3.000 mm gauge (S) is not available.

B14N BALE OPENER AND PREMIXER

Bale Opener for any Application

Production up to 1000 Kg/h

Ideal Compromise Between Production, Cost and Space Needed

-Suitable for processing cotton and man-made fibres up to

65 mm (2 1/2”) staple length. -Frame width: 1200 mm. -Production:

-up to 1000 kg/h (2200 lb/hr) with manual feeding.

- up to 800 kg/h (1750 lb/hr) with automatic feeding from B12N. -The length of the feed table can be adapted to the space available

- It is advisable, from an economic point of view, to use the B14N

bale opener and premixer when processing very small lots or when only reduced space is available.

-When the B 14N, in the processing line, is placed behind an automatic bale plucker, the tufts fed from the B12N are also preblended in the

premixer which, in combination with a mixer in the cleaning line, provides a very homogeneous blend.

-The B 14N, in the version for cotton, is equipped with 11 adjustable knives grid and suction unit to eliminate the trash.

B15N BLENDING FEEDER

The Ideal Solution for Small Lots

B15N + B18N FEEDER WITH OPENER

The Best Combination of Feeder and Opener for Small Lines

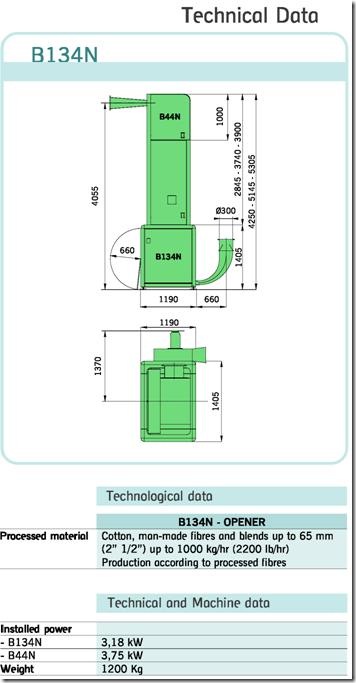

B134N OPENER FOR MAN-MADE FIBRES

The Flexible Machine for All Fibres ad Very High Productions

CONTROL FEED

The Card Chute - CONTROL FEED -

Ensures the Constant Feeding of the Material from Last Fine Opener in the Blowroom Line to the Cards

- Cotton, man made fibres and blends up to 65 mm (2 1/2”) staple length can be processed with a maximum production of 600 kg/hr

(1350 lb/hr). - Up to 12 cards per feed duct

can be fed with either one or two assortments

- The control feed system is also adaptable to other makes of cards.

B139N CHUTE FEED

An Improvement of Sliver Regularity

An Improvement of Web Evenness

Simplified Maintenance - Reduction Of Operational Costs

The B139N chute feed operates on the two-trunk system with continuous regulation of the web of tufts.

In the feed duct the material passes over the chute feeds where the tufts are separated by purely aerodynamic means to fill the upper material

reserve trunk.

The movable feed roll transfers the material from the upper trunk via a feed pan to the opening roll.

The material is conveyed to the lower trunk and condensed by an airstream generated by the fan.

A pressure transducer adjusts the speed of the feed roll in accordance with the varying pressure of the

bottom reserve trunk. The exhaust air from the upper trunk is conveyed into a dust extraction duct whereas the exhaust air from the lower trunk is retrieved and recycled by the fan.

C601SN

New Mechanical Design Quality Control By Software

A machine completely redisigned in order to reach unprecedented production and quality standard.

As a result the C601SN model guarantees:

- 30% higher production for same quality levels

- Reduced investment costs - Lower operational costs

- Production rates well up to 150 Kg/hr

- Newly designed B139N tuft feeder integrated into the card

- New drive concept which guarantees low maintenance requirements

- Individual large diameter licker in - Improved carding quality through usage of aluminum cylinder covers and flexible cleaning units

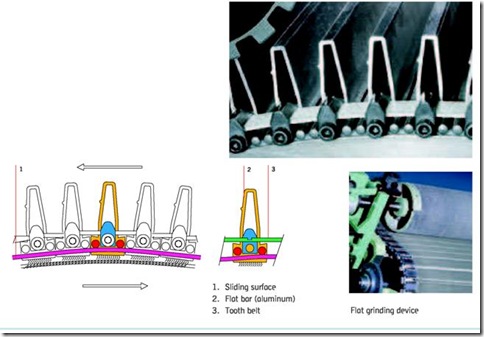

- Individual flat bars made of aluminum profiles and driven by tooth belts

- The drafting unit, within the sliver former system, serves to parallelize the fibres and to autolevel the sliver over very short lengths

- The card can be equipped either with the MTA (medium short term) or the STA (short term) autolevelling system

- Direct and continuous suction

- Can coiler developed for high speeds and pneumatic can changer available also for link up to can transport systems

- Connection to Marzoli’s spinvision data collection and monitoring systems.

Indipendent Motor Drive

Opening and High Trash Removal

New Suction System For High Dust Removal

Drives

An inverter driven AC motor drives the licker in, the cylinder and the flats. Transmission is by means of special maintenance free belts which guarantee a long life time.

The doffer and the web doffing system are equipped with a separate variable drive in order to operate with the ideal draft at any speed thus ensuring the

highest degree of sliver regularity. The motors for the feed roll and the drafting unit are brushless type and

therefore completely maintenance free.

C601SN

90 Movable Flats

32 in Working Condition

Cylinder area

The carding quality is directly influenced by the air current on the cylinder surface.

In order to avoid turbulence which would deteriorate the evenness of the web,

high precision aluminum profile covers

are used around the cylinder and the doffer. These elements have the following advantages: - completely smooth surface

- wear resistant and underformable

- quick disassembly during reclothing

1. Flat cleaning device

2. Revolving flats

3. Dedusting knife with suction hoods

4. Pre-carding segments

5. Post-carding segments

6. Cylinder covers (aluminum profile)

7. Doffer covers (aluminum profile)

8. Suction hood

The pre-carding area

is composed of 6 carding sectors and 2 cleaning knives to grant the best feeding of the fibres

to the carding zone.

Total length of the pre-carding area: 720 mm.

90 movable flats, of which 32 working, to grant a perfect carding.

The cleaning of the movable flats is fully automatic.

The flats are driven by a timing belt. Total length of the carding

area: 1120 mm.

The zone after the main carding is composed of 3 carding sectors

and 1 cleaning knife to grant the best preparation of the fibres for their feeding on the doffer.

Total length of the after-carding area: 550 mm.

Always 3 carding segment strips

are combined into one compact module in order to exchange them quickly

and cheaply.

Each cleaning unit is made

up of a dedusting knife with hood under permanent suction which determines

a thorough dedusting effect.

Aluminum covers and direct suction in the lower card section replace traditional grids with the following benefits:

- problem free processing

of sticky cotton

- lower card section always clean - cylinder speeds up to 650 RPM

Flats Moved with Special Tooth Belts with

No Wear Lubrification and Maintenance

A Versatile Sliver Former System

Flat drive

The individual aluminum flat bars, driven by two tooth belts,

are light and extremely strong.

The flats, hooked into the tooth belts, are securely fastened and operate

smoothly with no wear and maintenance over a sliding surface which doesn’t need any lubrication thanks

to a special coating.

A flat grinding device ensures

an effective and precise grinding

of the flats on the card.

Sliver former system by calander roller

The MARZOLI web doffing sliver forming system condenses the web and guides it through a funnel

to calander unit.

This system permits the sliver formation of every type of fibre.

In order to facilitate sliver insertion during start up or an optical inspection of the web quality or to take samples, calander unit

can be moved automatically forward and the sliver former can be swivelled downwards.

C601SN

MTA (Medium-Short Term) Autoleveller STA (Short Term) Autoleveller

Medium-short and short term autoleveller

In order to control sliver count variations

and to provide a great improvement in the evenness of the card sliver, the C601SN card can be equipped, as a standard, with the MTA (medium-short).

The STA (short) autoleveller is an optional supply.

Medium-short term autoleveller

The MTA leveller senses the thickness of the feeding material (weight) and its variation determines a continuous variation of card draft.

This system functions over a medium-short.

1. Feed roll

2. Feeding material

3. Feed table

4. Levers

5. Displacement sensor

6. Controller

7. Feed roll drive (brushless motor)

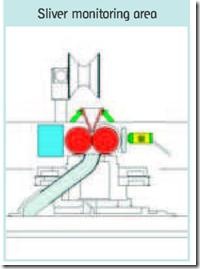

Short term autoleveller (optional)

The STA leveller senses the web thickness (weight) through a grooved rollers and the sensor located and its variation determines a continuos

variation of sliver draft at the inlet of the draft unit. When using the STA leveller a basic value

of card draft is set via microcomputer and may vary if the web weight (thickness) exceeds by ± 10% its basic value.

1. Feed roll

2. Feed roll drive

3. Controller

4. sensor

5. Drafting unit drive

6. Drafting unit

Suction System Requires a Small Vacuum Quantity Can Coiler and Can Changer for High Delivery Speed

Suction system

The suction system has been realized with unbreakable ABS plastic pipes which can be easily removed for maintenance purposes. All cleaning and dedusting points

of the C601SN card are under direct and continuous suction in order

to completely remove deposits of waste and dust.

This new suction system requires only a small vacuum quantity thereby

significantly reducing the expenditure for the filter installation. A standard feature of the C601SN model is the connection,

above or under floor, to a central suction system.

The suction of the card is constantly monitored and in case of breakdown the card is stopped.

Can coiler and can changer

The can coiler and sliver distributor have been completely redesigned

to consent very high delivery speeds, extremely low maintenance

and automatic sliver cutting during the substitution of the cans without machine stoppage.

The can changer is pneumatic and may be predisposed also for an automatic can transport system. The can coiler has been designed for can diameters from 18” to 40” (450 to 1000 mm) and for

can heights from 36” to 60” (900 to 1500 mm).

Sliver monitoring

A continuous control and monitoring of the sliver is located on the last area of compacting

of the sliver to grant the constant quality during all the

processing range.

C601SN

3 Over 3 Drafting Unit (Optional) for High Quality Sliver Special Fibres Processing

3 over 3 drafting unit (optional)

The new drafting unit 3 over 3 is made to assure an optimum quality and evenness of the sliver.

It allows the direct feeding of the sliver to spinning process. The draft rollers are driven

by independent motors

and the parameters are entered through an electronic panel

on the machine.

Top rollers operate with pneumatic pressure, individually adjustable. The automatic motion

of the drafting unit allows an easy insertion of the sliver during

the start-up.

Delivery for small cans

Sliver coiler and rotating automatic can changer with feeding rollers, suitable for cans of 18” and 20”

to be used in case of direct feeding to Open-End machines.

Special fibres processing

-Set of components to process chemical fibres (cleaning and waste removing area, pre-carding and post-carding area with feature suitable to obtain a perfect carding action with reduced waste percentage).

-Set of components to process fibres for the high-pile process.

- Set of special components to process

fibres for the non-woven fabrics, medical, etc.

Production Setup And Control By Software Top components from major supplier

User Friendly Interface

The C601SN card is managed by a modern PC microprocessor: all the production data and the working parameters are controlled and saved during the production cycle.

The multi-language touch screen is user friendly and permits a simple use with clear diagrams, detailed monitoring pages and step-by-step troubleshooting procedures.

Cooperation with other partners

An intense collaboration between Marzoli and his partners permits

to reach high quality results regarding production and quality, only top suppliers are involved in the project.

C601SN

Technical Data

Each customer receives localized support, by means of local agents and a knowledgeable team of technicians, trained in Marzoli and then ready

to assist and counsel our customers all around the world.

Experience must always be combined with Technology, and this is why

we always organize training sessions, demonstrations and product tests

in our Showroom and Testing Lab. Marzoli fuels its commitment through a leadership in ideas and knowledge, always combined with the passion

to share them with the heart of our factory: our customers.

Marzoli has reduced the time for spare parts delivery thanks to a strong agreement with its sub-suppliers which guarantee prompt action in the local markets.

The parts which are manufactured in Marzoli are always available and ready-to-be-shipped.

With our new fully automatic warehouse the customer has just to give the code number, and we will dispatch the part in a blink of an eye!

Marzoli gives short staple spinning customer a proposal of modern technology with wholly innovative solutions.

The range of the Nova machines allows great versatility and production

flexibility, improving the working process always aiming at the highest qualitative standards at the final product.

Marzoli and Vouk supply a complete and coordinate line of spinning machines. From a unique factory the best offer

of integrated mills resulting from the perfect integration of the different sections.

MARZOLI

VOUK Nova