Airflow Stimulation Approach

ABSTRACT

In this paper we report on the investigation of hairiness control using nozzles at ring frame. Airflow simulation inside the nozzles gives some insight into the mechanism of hairiness reduction. To solve the three-dimensional airflow field inside the nozzles, a CFD (computational fluid dynamics) model has been developed to simulate the airflow pattern using FLUENT 6.1 software. Swirling effect of the air, caused by the design of the nozzles seems to be main reason behind hairiness reduction. 10, 20 and 30 tex Z-twisted ring spun yarns were produced with and without nozzles and tested for hairiness, tensile and evenness properties. The total number of hairs equal to or exceeding 3 mm (i.e. the S3 values) for yarn spun with nozzles is nearly 38-59% less than that of ring spun yarns, while both the yarn types show little difference in evenness and tensile properties. Nozzle angle (angle of auxiliary inlets) plays a significant role in reducing the S3 values as evident from large reduction of hairs with varying the same. The change in yarn channel diameter plays lesser role in reducing the S3 values than the changes in nozzle angle of auxiliary inlets.

Keywords: Airflow, Hairiness, Nozzle angle, NozzleRing, S3 values, Simulation, Yarn channel diameter.

Introduction

Hairiness inevitably occurring during the spinning process is one of the most serious causes of inefficiency in sizing, weaving and knitting. Higher number of hairs on the surface of fabrics makes the appearance fuzzy and prone to pill formation. Yarn hairiness is a key factor affecting properties and processability of yarn as well as fabrics. Hairiness can be reduced by conventional techniques such as sizing for short staples and two-folding for long staples. Some new technologies, which have been developed to reduce hairiness of ring spun yarn, are compact spinning [1-5] and using air-nozzle (in other words nozzle) in ring spinning (JetRing spinning) [6-11]. JetRing spinning combines features of ring and air-jet spinning technology. The single nozzle placed below the yarn formation zone, acts in a way similar to the first nozzle

in air-jet spinning. The swirling air current inside the nozzle is capable of wrapping the protruding hairs around the yarn body, thereby reducing yarn hairiness [6-7, 11]. Simulation of airflow pattern, by means of fluid dynamics inside the nozzle, can provide a much better insight into the actual mechanism of hairiness reduction. Different nozzle parameters, such as nozzle angle and nozzle inner diameter, affect airflow characteristics and also the hairiness reduction of yarns of different linear density. There is a lack of published information on these aspects. In the present work, a CFD (computational fluid dynamics) model has been developed to simulate the airflow pattern inside the nozzles using FLUENT 6.1 software, to solve the three-dimensional flow field [12]. Influence of nozzle parameters viz., angle of auxiliary inlet, and yarn channel diameter and yarn linear density on hairiness reduction has been investigated. Tensile and evenness properties of nozzle spun yarns are compared with conventional ring yarns to check whether there is any deterioration in yarn quality.

Experimental Work

In the present study, Z-twisted carded cotton yarns with linear density of 10, 20 and 30 tex were produced at the ring frame. We use two series of experiments. For the first series of experiment (angle series), nozzles having a constant yarn channel (nozzle inner wall) diameter of 2.2 mm with auxiliary inlets having different angles 40

0

, 45

0 & 50

0 were selected (J1-J9 in Table I). For the second series of experiment (diameter series), nozzles with different yarn channel diameters of 1.8, 2.2 & 2.6 mm, but having a constant 40

0 angle of auxiliary inlets were selected (J10-J18 in Table I). To create a swirling effect of air in all the nozzles, four auxiliary inlets each having 0.4 mm diameter were made tangential to the inner walls of the nozzles.

A nozzle placed in a nozzle-housing was mounted between the front roller nip and lappet eye at distance of 10 cm from the front roller nip, on a Lakshmi LG-5/1 ring frame. Compressed air was supplied to the nozzles through pipes with a pressure-regulator and an air-filter which enters the yarn channel through four auxiliary inlets. A frame to mount the nozzle housing was fabricated after studying the geometry of the ring frame for exact positioning of the nozzles without altering the yarn path. A small ceramic guide was fixed at the bottom of the frame to keep the yarn in centre of the nozzles. The nozzles were placed in a way that front roller nip, axes of nozzle, yarn and ceramic guide lie in a straight line. Appropriate ring spinning parameters were selected for yarns of each count as practiced by the commercial spinners.

For producing yarns using nozzles, air pressure in all nozzles was kept at 0.5 bar (gauge). The axial direction of airflow in the nozzles was kept opposite to the direction of yarn movement. Front view of the nozzle is shown in Figure 1.

Figure 1. Front view of the nozzle along

with housing

The hairiness of yarns was tested on the Zweigle G 566 hairiness tester. From this instrument, number of hairs protruding from yarn, N1, N2, N3, N4, N6 and N8 that are equal to or exceeding 1 mm, 2 mm, 3 mm, 4 mm, 6 mm and 8 mm respectively were obtained. S3-hairiness value is the summation of N3, N4, N6 and N8. For each sample, 800 m length of yarn was tested for hairiness at a speed of 50 m/min. Statimat ME tensile tester was used to test the tensile properties of yarns using a gauge length of 500 mm and cross head speed of 200 mm/min. Thirty readings were taken for each sample. Evenness characteristics of yarns were tested on the Uster Evenness tester UT-1. 1000 m length of yarn was tested at a speed of 200 m/min. The sensitivity settings used for thick, thin and neps were +50 %, -50 % and +200 % respectively. Leica quin software was used to measure the yarn diameter from Leica

MZ6 microscope. Yarn diameters were measured randomly at 1000 places along the yarn. Yarn samples were kept in standard testing condition for 24 hours prior to testing.

Simulation Method

We have used a fluid flow analysis package, FLUENT 6.1, which uses finite volume method for airflow simulation inside the nozzles. The flow in the nozzle is turbulent and hence the standard

k-e model of turbulence along with standard wall functions was used. The Reynold’s Averaged Navier-Stokes equation and continuity equations along with energy, turbulent kinetic energy and

e equations were solved in ‘Segregated solver’ [12-13]. It has been assumed that the air flow inside the yarn channel affects the yarn but the presence of yarn has no effect on the air flow patterns and hence yarn was not modeled. The cross-sectional area occupied by yarn is very small compared to that of yarn channel of the nozzle (1:100). There are issues related to meshing of the zone near the yarn surface, hence it is directly not modeled in the simulation. High pressure and velocities of the air coupled with the considerably low volume of the yarn compared to that of the yarn channel also justifies this assumption. A typical mesh design of the nozzle is shown in Figure 2. The mesh is build of 50000 to 60000 finite volumes depending on the complexity and curvatures of the object geometry. Yarn inlet and outlet along with arrows shows the direction of travel of yarn, where as nozzle inlet and outlet along with arrows shows the direction of airflow, which is opposite to yarn movement. It is a three-dimensional simulation model, because of the positioning of auxiliary inlets, air velocity is resolved into three components viz., axial (x-direction), tangential (y-direction) and inward radia l velocities (z-direction). Swirling action in the nozzle is created by the tangential and axial velocity components. We got a very negligible amount of radial velocity because of the fluctuations in the Z-axis is very small as compared to fluctuations in the X and Y-axis.

In the present configuration, auxiliary inlet boundaries are assumed to be “Pressure Inlet” type while outflow boundaries are assumed “Pressure Outlet” type. At the auxiliary inlet, the air pressure is 0.5 bar (gauge). At the nozzle outlet, the pressure is supposed to be the external pressure (one atmosphere). At the inner wall of the nozzle

no slip boundary condition is applied. Although the high velocity of air stream is a heat source that will increase the temperature inside the nozzle, the nozzle is very short and the process occurs in a very short time. For simplification, we assume that the process is adiabatic i.e. with no heat transfer through walls. The flow model assumes viscous, compressible airflow.

The airflow inside the nozzle depends on the following factors: angle at which air enters in the yarn channel and pressure of the air at entry to the yarn channel. The configurations viz., diameter and angle of auxiliary inlets, diameter of yarn channel and height of yarn channel are studied in FLUENT 6.1. All the nozzles used are of same length and outer diameters of the nozzles are also kept constant for experimental purpose.

Results & Discussion

Influence of Angle of Auxiliary Inlets & Yarn Linear Density on S3 Hairiness Values

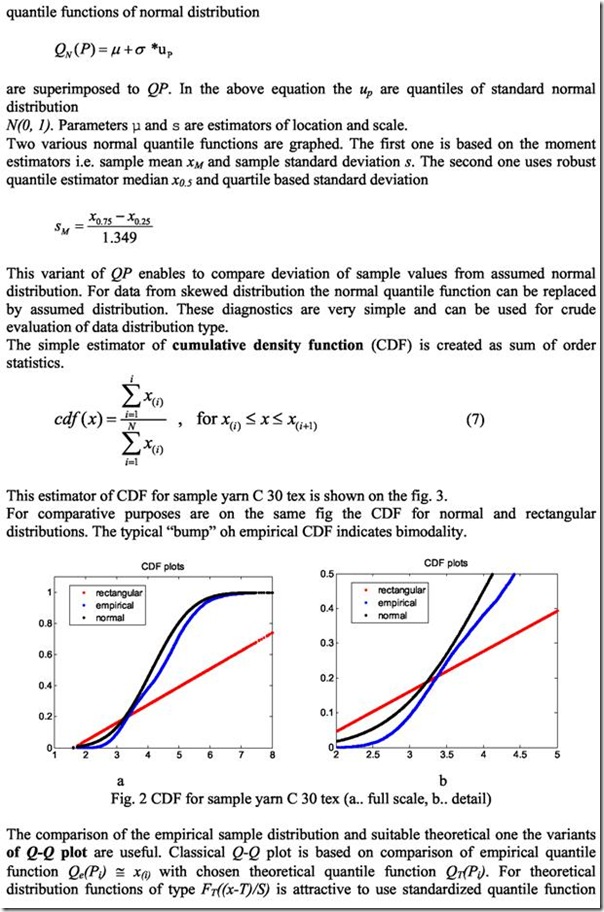

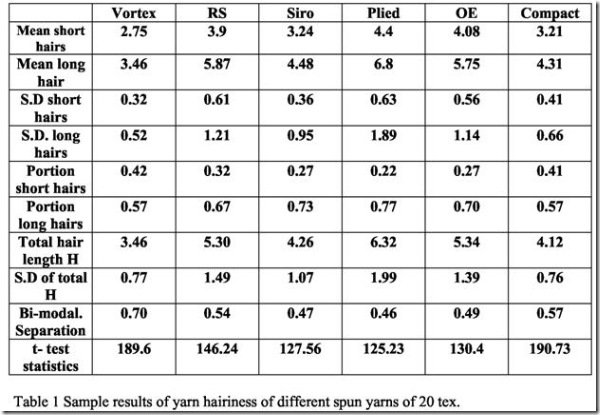

Table I shows hairiness values of NozzleRing and conventional spun yarns. NozzleRing spun yarns have lesser number of hairs than the corresponding ring yarns. We describe the mechanism of hairiness reduction by CFD analysis.

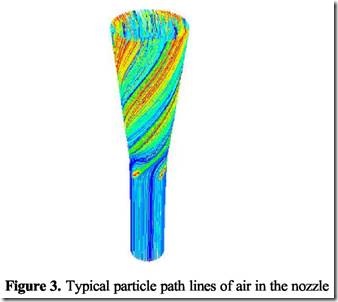

Figure 3 shows the path of lines of air at bottom plane of the nozzle and also that released from auxiliary inlets swirling in counterclockwise direction when viewed from the top. Air velocity can be resolved into 3 components viz., axial, tangential and radial. This swirling action is created by the tangential and axial velocity components of air velocity. Absence of staggering of auxiliary inlets helps to generate swirling flow. Divergent portion in the upper section of the nozzles also assists in swirling.

Mechanism of hairiness reduction

There are ten sections cut at a distance of 1 mm, along the axis of the nozzle (Figure 4). We have considered the throat (section of nozzle from where the diverging portion starts) as origin (x = 0 and y = 0). In the nozzle, main body of the yarn passes through the core, i.e. at the center of the nozzle, where as protruding fibers are on the surface, i.e. near the inner wall of the nozzle. From Figure 3, it is observed that the flow is swirling in the anticlockwise direction. Due to the action of this vortex or the swirling motion, yarn body is untwisted at the core of the nozzle as it enters the nozzle. Because of the false twisting action of swirling air currents on the yarn, original twist in the yarn is restored. This process leads to the wrapping of protruding hairs and hence reduces yarn hairiness.

The number of hairs in all the hair length groups for NozzleRing yarns is lower than for the ring spun yarns. The reduction in hairiness brought out by NozzleRing spinning is most likely due to the wrapping of the surface fibers around the yarn body, by the swirling air current in the nozzles. The hairiness reduction brought about by NozzleRing spinning in short hairs N1 and N2 (shorter hairs of 2 mm and below) are smaller compared to reduction in S3 values. It can be ascribed to the fact though the folding and wrapping of relatively stiff short hairs by air is difficult but the wrapping of longer hairs may readily cover up the short ones and reduce the number of short hairs [6, 11].

Reduction in S3 values (longer hairs of 3 mm and above) obtained by NozzleRing spinning is higher for coarser yarns than for finer yarns. This can be attributed to the fact that with the increase in yarn linear density, number of fibers in the yarn cross-section increases, more numbers of fiber-ends are available, giving rise to more hairiness. As more hairs are presented to the nozzle; there is reduction of hairiness by the nozzle.

For the nozzle angle series of experiment (J1-J9 in Table I), the nozzle with auxiliary inlets having 45° angle gives the best results in terms of reduction in S3 values followed by nozzles with auxiliary inlet having angles of 40° and 50°, when the yarn channel diameter is kept constant at 2.2 mm. This trend is the same for all the yarns of 10, 20 and 30 tex. We use CFD modeling in describing the results by comparing the best nozzle having 45° angle with the worst nozzle having 50° angle. For this purpose, 10 tex Nozzle Ring yarn was taken and its diameter was measured on a microscope using Leica quin software. The measured diameter of yarn is found to be 0.132 mm. As mentioned previously in the simulation section, it is assumed that the yarn does not have much influence on the flow. However, at the end of airflow measurement calculation, we created a post processing surface of a solid cylinder having diameter of 0.132 mm (analogues to yarn) kept inside the nozzle coaxial to nozzle axis to analyze various velocity parameters acting on the yarn surfaces as this option is available with the FLUENT 6.1 software. Yarn was modeled only at the post processing stage.

constant at 40º. This trend is observed for all the yarn counts. We use CFD modeling in describing the results by comparing the best performing yarn channel diameter of 2.2 mm with the least best performing yarn channel diameter of 2.6 mm.

For both nozzles, magnitude of tangential air velocity which is responsible for swirling action, performs on the yarn body is different. The nozzle having a yarn channel diameter of 2.2 mm gives slightly higher tangential air velocity (8 m/s) as compared to yarn channel diameter of 2.6 mm (5 m/s) as shown in Figure 7 (a) and (b). Due to higher tangential velocity, it give rise to higher swirling in former case as compared to later case, thereby more wrapping of fibers around the yarn body and thereby reducing yarn hairiness. For both nozzles there is some negative tangential velocity acting (negative tangential velocity rotates the yarn in clockwise direction). This negative tangential velocity may create ballooning in yarns similar to two nozzles in air jet spinning, where the vortexes are counter rotating [14]. Due to this ballooning action yarn positioning at the center of the nozzle would be difficult and hence wrapping of surface fibers and untwisting of the yarn would suffer. Some additional surface fibers may be generated by rubbing action due to the tendency of the yarn whirling towards the inner wall of the nozzle by the presence of the gradient of tangential air velocity (increasing tangential velocity from nozzle axis to inner wall of the nozzle). Due the above action, few hairs on yarn surface may escape partly from the wrapping process. The nozzle having yarn channel diameter of 2.2 mm gives best results in terms of hairiness reduction as the number of sections in the nozzle where ballooning action is created is three as compared to nozzle with channel diameter of 2.6 mm, where the numbers of such sections are four as shown in Figure 7 (a) and (b). As the yarn spent somewhat longer duration in the ballooning region in the nozzle with yarn channel of diameter 2.6 mm, which reduces the efficiency of hairiness reduction by this nozzle. Though the magnitude of this negative tangential velocity is small (-1 m/s for 2.2 mm nozzle and -2 m/s for 2.6 mm nozzle), it does play a significant role in affecting yarn hairiness reduction due to the above mentioned reasons.

The nozzle with medium yarn channel diameter (2.2 mm) shows somewhat better reduction of S3 values as compared to the nozzle with the largest yarn channel diameter (2.6 mm). Between the nozzles of lowest and medium yarn channel diameters, the percentage reduction in S3 values is not significant. The above trend is observed for all the yarns.

Nozzle Ring spun yarns produced with nozzles of various auxiliary inlet angles have less hairiness in all the hair length groups compared to ring yarns. Reduction of S3 values by nozzles of various auxiliary inlet angles is more for coarser yarn than for finer yarns. From the changes in the values of hairiness with respect to changes in auxiliary inlet angle and yarn channel diameter of nozzles, it is evident that the nozzle auxiliary inlet angle plays a major role in hairiness reduction than the yarn channel diameter.

Comparison of Conventional & NozzleRing Spun Yarns for Tensile & Evenness Characteristics

NozzleRing and conventional ring spun yarns were compared for tensile and evenness properties in Table II. The tenacity of NozzleRing spun yarns is slightly better than that for the ring yarns. The slight improvement in tenacity is probably due to the tight wrapping of the surface fibers around the yarn body, which contribute to the yarn strength [6, 11]. There is also not much difference between the breaking elongations of NozzleRing and ring spun yarns. There are no significant differences between the tensile properties of the NozzleRing and ring spun yarns.

There is a slight increase in the unevenness of NozzleRing spun yarns in comparison with the conventional ring spun (Table II), but this increase in unevenness is not significant. The overall change in yarn evenness is probably due to the concentration of the mass ni a very short length brought about by the swirling action of nozzle [6, 11].

Conclusions

There is a slight increase in the unevenness of NozzleRing spun yarns in comparison with the conventional ring spun (Table II), but this increase in unevenness is not significant. The overall change in yarn evenness is probably due to the concentration of the mass in a very short length brought about by the swirling action of nozzle [6, 11].

Asis Patnaik, R.S. Rengasamy, V.K. Kothari, Anindya Ghosh

Indian Institute of Technology, Department of Textile Technology

Hauz Khas, New Delhi 110016, India

rsrengasamy@yahoo.in

Hemant Punekar

Fluent India Private Limited,

Pune 411057, India