S

SAILCLOTH: Any heavy, strongly made woven canvas of cotton, linen, jute, polyester, nylon, aramid, etc., that is used for sails. Laminated fabrics are also finding use in this market. Sailcloth is used for apparel, particularly sportswear.

SAND: Used as a filter medium in fiber manufacture, particularly used in spinning packs for nylon or polyester production.

SANDWICH BLEND: A method of preparing fiber mixtures by layering them horizontally in alternating layers with all elements in the proper proportion. Vertical sections are cut and fed to the next machine in the process, where blending is effected.

SANFORIZED®: A trademark of Cluett, Peabody & Co., Inc., denoting a controlled standard of shrinkage performance. Fabrics bearing this trademark will not shrink

more than 1% because they have been subjected to a method of compressive shrinkage involving feeding the fabric between a stretched blanket and a heated shoe. When the blanket is allowed to retract, the cloth is physically forced to comply.

SANFOR-SET®: A trademark of Cluett, Peabody & Co., Inc., denoting a controlled standard of shrinkage performance originally developed for denims. Fabrics bearing this trademark will not shrink under home-wash, tumble-dry conditions because they have been subjected to a liquid ammonia treatment and compressive shrinkage.

SAPONIFICATION: Specifically in relation to manufactured fibers, saponification is the process of removing part or all of the groups from acetate or triacetate fiber, leaving regenerated cellulose.

SARAN FIBER: A manufactured fiber in which the fiber-forming substance is any long chain synthetic polymer composed of at least 80% by weight of vinylidene chloride units (-CH2-CCl2-)

(FTC definition). Saran fiber has excellent resistance to sunlight and weathering and is used in lawn furniture, upholstery, and carpets.

SASE: Acronym for stress at specified elongation; the stress experienced by a yarn or cord at a given elongation.

SATEEN: A cotton fabric made in a satin weave.

SATIN WEAVE: One of the basic weaves, plain, satin, and twill. The face of the fabric consists almost completely of warp or filling floats produced in the repeat of the weave. The points of intersection are distributed evenly and widely separated as possible. Satin-weave fabric has a characteristic smooth, lustrous surface and has a considerably greater number of yarns in the set of threads, either warp or filling, that forms the face than in the other set.

SATURATION: 1. The maximum intensity or purity of a color. If the color is as brilliant as possible, it is at saturation; if the color is subdued or grayed, it is dull, weak, and low in intensity.

2. The upper limit concentration of a solute in a solvent, i.e., no more solute can be dissolved at a fixed temperature and pressure.

SATURATION BONDING: See BONDING, 2.

SATURATION VALUE: The maximum amount of dye that can be absorbed by a textile fiber under defined conditions.

SAXONY: 1. A high-grade fabric for coats, made from Saxony Merino wool.

2. A soft woolen with fancy yarn effects, used in sport-coat fabric.

3. A highly twisted worsted knitting yarn.

4. A term describing a cut-pile carpet having highly twisted, evenly sheared, medium-length pile yarns.

SALLOPED SELVAGE: A fabric defect consisting of an abrupt, narrow place along the selvage. Principal cause is the failure of the clip on the tenter frame to engage or hold the fabric.

SCHAPPE: A yarn from partly degummed silk waste.

SCORCHING: The tendering of a fiber surface by heat so as to change the color and texture of the surface.

SCOURING: An operation to remove the sizing and tint used on the warp yarn in weaving and, in general, to clean the fabric prior to dyeing.

SCREEN: 1. A hollow, cylindrical, coarse-mesh wire device used in pickers and certain openers to form the loose staple stock into a sheet, or lap. The screen is mounted horizontally on a shaft on which it revolves freely.

2. A stencil used in screen printing. It is made of fine cloth, usually of silk or nylon, finely perforated in areas to form a design and mounted on a frame. The paste containing the dye is forced through the perforations onto the fabric, leaving the design. A series of screens, one for each color, is used for multicolored designs. (Also see PRINTING.)

SCREEN PRINTING: See PRINTING.

SCREW FEEDS: Feed systems in which the action of the screw generates pressure that causes flow. The system usually consists of a container with a closely fitting screw unit.

SCREW MELTER: 1. Screw extruder in which frictional forces between the screw and the heated barrel contribute to rapid melting of solid polymer. This configuration is capable of high throughput.

2. System in which a screw feed is used to feed polymer to a melt grid and to maintain a constant pressure at the grid.

SCRIM: 1. A lightweight, open-weave, coarse fabric; the best qualities are made with two-ply yarns. Cotton scrim usually comes in white, cream, or ecru and is used for window curtains and as backing for carpets.

2. Fabric with open construction used as base fabric in the production of coated or laminated fabrics.

SCROOP: The sound of rustle or crunch that is characteristic of silk. Scroop is a natural property of silk, but may be induced in other fabrics to a degree by various treatments.

SCULPTURED: A term describing a carpet with areas of contrasting depth produced by mixing cut pile and loops.

SEAMING: Joining the overlap of two pieces of fabric, usually near their edges.

SEAMLESS: A term that describes a tubular knit fabric without seams, e.g., seamless hosiery.

SEAM MARK: A particular type of pressure mark in the finished fabric. It is produced during finishing operations by the thickness of the seam used to join pieces for processing.

SEAM SLIPPAGE: A defect consisting of separated yarns occurring when sewn fabrics pull apart at the seams. Seam slippage is more prone to occur in smooth-yarn fabrics produced from manufactured filament yarns.

SEAM WELDING: Any stitchless procedure for joining fabrics based on the use of thermoplastic resins or the direct welding of thermoplastic materials. Seam welding is an alternative to conventional needle-and-thread seaming operations that is extremely popular in the nonwoven field.

SECANT MODULUS: The ratio of change in stress to change in strain between two points on a stress-strain diagram, particularly the points of zero stress and breaking stress.

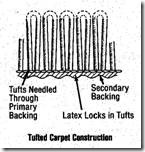

SECONDARY BACKING: A layer of material, usually woven jute, polypropylene, vinyl, or latex foam, laminated to the underside of a carpet to improve body and dimensional stability.

SECONDARY COLORS: Green, orange, and violet, each of which is obtained by mixing two primary colors.

SECONDARY CREEP: The nonrecoverable component of creep. (Also see DELAYED DEFORMATION.)

SECOND-ORDER TRANSITION TEMPERATURE: The temperature at which the noncrystalline (amorphous) portions of polymer melt or become plastic. An inflection point or change is stress-strain properties occurs at this point; however, for most fibers, this change is small.

SECONDS: 1. Imperfect fabrics (woven or knitted) containing flaws in the weave, finish, or dyeing, and sold as “seconds.”

2. See YARN QUALITY.

SECTION BEAM: 1. A large, flanged roll upon which warp yarn is wound at the beam warper in preparation for slashing.

2. Small flanged or unflanged beams assembled side-by-side on the shaft of a warp beam for further processing.

SECTION MARK: A fabric defect consisting of marks running warpwise in an evenly repeating pattern, caused by the improper setting of sections in silk system (or indirect) warping.

SEERSUCKER: Lightweight fabric, made of cotton or manufactured fiber, having crinkled stripes made by weaving some of the warp threads slack and others tight. Woven seersucker is more expensive than imitations made by chemical treatment.

SELF-TWIST YARN: An inherently twist-stable, two-ply structure having a ply twist that is alternately S- and Z-directed along the yarn.

SELVAGE or SELVEDGE: The narrow edge of woven fabric that runs parallel to the warp. It is made with stronger yarns in a tighter construction than the body of the fabric to prevent raveling. A fast selvage encloses all or part of the picks, and a selvage is not fast when the filling threads are cut at the fabric edge after every pick.

SEQUESTRANT: Any compound that will inactivate a metallic ion by forming a water-soluble complex in which the metal is held in a nonionizable form. This results in prevention of the usual precipitation reactions of the metal.

SERGE: Any smooth-faced cloth made with a two-up and two-down twill weave.

SERGING: 1. Overcasting the cut edge of a fabric to prevent raveling.

2. Finishing the edge of a carpet by oversewing rather than binding. Generally, the sides of a carpet are serged and the ends bound.

SERICIN: Silk gum. The gelatinous protein that cements the fibroin filaments in a silk fiber. It is removed in the process called degumming.

SERVED YARN: In aerospace textiles, a reinforcing yarn such as graphite or glass around which two different yarns are wound, i.e., one in the Z direction and one in the S direction, etc., for protection or compaction of the yarn bundle.

SET MARK: A fabric defect consisting of narrow bars or bands across the full width of the fabric that may appear either as a tight, loose, or corduroy effect caused by loom stops improperly reset by the weaver. Set marks are sometimes caused by the weaver ripping out filling yarn and then not properly adjusting the pick wheel to obtain the proper relation between the fell of the cloth and the reed.

SET POINT: An input in process control that defines the desired value or range of values of the variable that is being controlled.

SET YARNS: False-twist yarns stabilized to produce bulk.

SEWING THREAD: See THREAD.

SEYDEL CONVERTER: Tow-to-top processing equipment. Seydel combines the

prestretching and breaking process in one machine.

S-FINISHING: A finishing process applied to acetate and triacetate fabrics using a sodium hydroxide solution to give surface saponification; i.e., the fiber “skin” is converted to cellulose. It improves the hand and reduces the tendency to acquire a static charge.

SHADE BAR: See MIXED END and FILLING.

SHADECLOTH: A plain-weave cotton or linen fabric that is heavily sized and is often given oil treatment to make it opaque. The fabric is used for curtains and shades.

SHADED FILLING: A defect consisting of a bar running across the fabric caused by a difference in appearance of the filling yarn, and occurring at a quill change or knot.

SHADING: In cut-pile fabrics, an apparent change in color when the pile is bent, caused by differences in the way light is reflected off the bent fibers. This phenomenon is a characteristic of pile fabrics, not a defect.

SHADOW PRINTING: See PRINTING, Warp Printing.

SHAFT: 1. A term often used with reference to satins indicating the number of harnesses employed to produce the weave.

2. See HARNESS.

SHAFT MARK: A fabric defect characterized by a number of floating ends, usually caused by a broken harness strap on the loom.

SHAG CARPET: A loosely tufted carpet construction with cut pile 1 to 5 inches in length and with greater than normal spacing between tufts.

SHANTUNG: Plain-weave fabric with unevenly ribbed surface and crisp texture.

SHARKSKIN: 1. A hard-finished, twill fabric, woolen or worsted, made of simple weaves with a two-color arrangement of warp and filling yarns.

2. A plain-weave sportswear fabric made of dull-luster acetate or triacetate yarns.

SHEARING: ```A dry finishing operation in which projecting fibers are mechanically cut or trimmed from the face of the fabric. Woolen and worsted fabrics are almost always sheared. Shearing is also widely employed on other fabrics, especially on napped and pile fabrics where the amount varies according to the desired height of the nap or pile. For flat-finished fabrics such as gabardine, a very close shearing is given.

SHEATH-CORE FIBERS: Bicomponent fibers of either two polymer types, or two variants of the same polymer. One polymer forms a core and the other surrounds it as a sheath.

SHED: A path through and perpendicular to the warp in the loom. It is formed by raising some warp threads by means of their harnesses while others are left down. The shuttle passes through the shed to insert the filling.

SHEDDING: 1. The operation of forming a shed in weaving.

2. A loss of nominal length staple at any process in a staple yarn plant.

SHEERS: Transparent, lightweight fabrics of different constructions and yarns, especially those of silk and manufactured fibers. Examples are chiffons, some crepes, georgette, and voile.

SHIER: A short length of a single pick that appears to be cut out of the plane of the fabric.

SHINER: A relatively short streak caused by a lustrous section of a filament yarn. The principal cause is excessive tension applied to a yarn during processing.

SHIRE: See SHIER.

SHOE FOLD: A manner of folding fabric. The piece is folded from both ends into twelve or sixteen folds. The length of the fold depends upon the length of the piece.

SHOGGED STITCH: See RACKED STITCH.

SHORT-CUT STAPLE: Staple fiber less than 0.75-ingh long. Typically used in wet-laid nonwoven processes to make fabrics, or as reinforcement in plastics, concrete, asphalt, and other materials.

SHORT-LIQUOR DYEING: See DYEING.

SHOT: In woven pile floor coverings, the number of filling yarns per row of tufts.

SHREDDING: The separation of compressed fibers in pulp sheets prior to acetylation in acetate manufacture.

SHRINKAGE: Widthwise or lengthwise contraction of a fiber, yarn, or fabric, usually after wetting a redrying or on exposure to elevated temperature.

SHRINKAGE FORCE: The force generated by thermoplastic materials when they are subjected to elevated temperatures.

SHUTTLE: A boat-shaped device, usually made of wood with a metal tip that carries filling yarns through the shed in the weaving process. It is the most common weft-insertion device. The shuttle holds a quill, or pirn, on which the filling yarn is wound. It is equipped with an eyelet at one end to control rate. The filling yarn is furnished during the weaving operation.

SHUTTLE CHAFE MARK: A fabric defect that is usually seen as groups of short, fine lines across the fabric, often running for some distance in the piece and usually in the same area. Although these marks run in the direction of the filling, they are actually caused by the shuttle rubbing across and damaging the warp ends, producing a dull, chalky appearance.

SHUTTLELESS LOOM: A loom in which some device other then a shuttle is used for weft insertion. (Also see LOOM and WEFT INSERTION.)

SILICONE: One of a group of polymeric organic silicon compounds obtained as oils, greases, or plastics and applied to textile material as water- and heat-resistant lubricants and finishes.

SILK FIBER: A fine, strong, continuous filament produced by the larva of certain insects, especially the silkworm, when constructing its cocoons. The silkworm secretes the silk as a viscous fluid from two large glands in the lateral part of the body. The fluid is extruded through a common spinneret to form a double filament cemented together. This double silk filament, which is composed of the protein fibroin, ranges in size from 1.75 to 4.0 denier, depending upon the species of worm and the country of origin. The filament of the cocoon is softened and loosened by immersion in warm water and is then reeled off. Although raw silk contains 20 to 30% of sericin, or silk glue, and is harsh and stiff, silk is soft and white when all of the glue has been removed by steeping and boiling in soap baths. Ecru is harsher, as it has only about 5% of the sericin removed. Silk is noted for its strength, resiliency, and elasticity. The major sources of commercial silk are Japan and China.

SIMULATED SPUN YARNS: Filament yarns that have been modified to have aesthetics similar to those of spun yarns. Simulated spun yarn have looped or hairy surfaces.

SINGEING: The process of burning off protruding fibers from yarn or fabric by passing it over a flame or heated copper plates. Singeing gives the fabric a smooth surface and is necessary for fabrics that are to be printed and for fabrics where smooth finishes are desired.

SINGLE-KNIT FABRIC: Also called plain knit, a fabric constructed with one needle bed and one set of needles.

SINGLES YARN: The simplest strand of textile material suitable for operations such as weaving and knitting. A singles yarn may be formed from fibers with more or less twist; from filaments

with or without twist; from narrow strips of material such as paper, cellophane, or metal foil; or from monofilaments. When twist is present, it is all in the same direction. (Also see YARN.)

SINGLING: A yarn defect caused by the breaking of one or more strands in a plying operation with resulting unevenness in the finished product.

SINKER: In weave design, a blank square indicating a filling thread over a warp thread at the point of intersection.

SINTERING: Forming a bonded mass or fiber by heating the constituents of the mass or fiber without melting.

SISAL: A strong, white, bast fiber produced from leaves of the Agave plant, which is found in Central America, West Indies, and Africa. Sisal is used chiefly for cordage and twine.

SIZE: See SIZING.

SIZE MARK: A fabric defect that consists of a rough or frosted spin caused by uneven application or drying of the size.

SIZING: 1. A generic term for compounds that are applied to warp yarn to bind the fiber together and stiffen the yarn to provide abrasion resistance during weaving. Starch, gelatin, oil, wax, and manufactured polymers such as polyvinyl alcohol, polystyrene, polyacrylic acid, and polyacetates are employed.

2. The process of applying sizing compounds. (Also see SLASHING.)

3. The process of weighing sample lengths of yarn to determine the count.

SKEIN: A continuous strand of yarn or cord in the form of a collapsed coil. It may be of any specific length and is usually obtained by winding a definite number of turns on a reel under prescribed conditions. The circumference of the reel on which yarn is wound is usually 45 to 60 inches. (Also see HANK.)

SKEIN BREAK FACTOR: The comparative breaking load of a skein of yarn adjusted for the linear density of the yarn expressed in an indirect system. It is the product of the breaking load of the skein and the yarn number expressed in an indirect system (e.g., pounds times cotton count). A statement of the skein break factor must indicate the number or wraps in the skein, if this is not otherwise apparent. Without specifying the number of wraps, a statement of the skein break factor is meaningless.

SKEIN BREAKING TENACITY: The skein breaking load divided by the product of the yarn number in a direct numbering system and the number of strands placed under the tension (twice the number of wraps in the skein); preferably expressed in newtons per tex.

SKEIN DYEING: See DYEING.

SKEWNESS: The distance measured parallel to and along a selvage between the point at which a filling yarn meets this selvage and a perpendicular to the selvage from the point at which the same filling yarn meets the other selvage. Skewness may be expressed directly in inches or as a percentage of the width of the fabric at the point of measurement.

SLACK END: An end woven under insufficient tension.

SLACK FILLING: See SLACK PICK.

SLACK MERCERIZATION: A process for producing stretch in cellulosic fabrics.

SLACK PICK: A single filling yarn woven under insufficient tension.

SLACK SELVAGE: A self-descriptive fabric defect caused by incorrect balance of cloth structure between the ground and selvage or by the selvage ends being woven with insufficient tension.

SLACK THREAD: See SLACK END.

SLACK WARP: See SLACK END.

SLAM-OFF: See SMASH.

SLASHER: A machine used to apply size to the warp ends, while transferring the warp yarns from section beams to the loom beam.

SLASHER SIZING: See SLASHING.

SLASHING: A process of sizing warp yarns on a slasher. (Also see SIZING, 1, and SLASHER.)

SLEAZY: Thin, lacking firmness, open-meshed; usually describes poor-grade fabrics.

SLEEVING: A braided, knit, or woven product or fabric in tubular or cylindrical form that is less than 4 inches in width (i.e., 8 inches in circumference).

SLEY: The number of warp yarns per inch in a woven cloth on or off the loom.

SLIDE WASTE: A yarn defect that is similar in appearance to a slub. It consists of a mass of fiber encircling the yarn end and can be slid freely along the end.

SLIPPAGE: Sliding or slipping of the filling threads over the warp ends (or vice versa), which leaves open spaces in the fabric. Slippage results from a loose weave or unevenly matched warp and filling.

SLIT-FILM YARN: Yarn of a flat, tape-like character produced by slitting an extruded film.

SLIT TAPE: A fabric, 12 inches or less in width, made by cutting wider fabric to the desired width. Slit tapes are made primarily of cotton, linen, jute, glass, or asbestos and are used principally for functional purposes.

SLIVER: A continuous strand of loosely assembled fibers without twist. Sliver is delivered by the card, the comber, or the drawing frame. The production of sliver is the first step in the textile operation that brings staple fiber into a form that can be drawn (or reduced in bulk) and eventually twisted into a spun yarn.

SLIVER KNITTING: Circular knitting coupled with the drawing-in of a sliver by the needles to produce a pile-like fabric, usually for high-pile coats or heavy linings.

SLOUGHED FILLING: See LOOPED FILLING.

SLUB: A yarn defect consisting of a lump or thick place on the yarn caused by lint or small lengths of yarn adhering to it. Generally, in filament yarn, a slub is the result of broken filaments that have stripped back from the end to which they are attached.

SLUBBER: A machine used in textile processes prior to spinning that reduces the sliver and inserts the first twist.

SLUBBING: The product of the slubber, it is the intermediate stage between sliver and roving.

SLUBBING FRAME: See SLUBBER.

SLUB CATCHER: A mechanical or electronic device designed to aid in the detection and removal of slubs or neps in yarns, usually during coning.

SLUB YARN: Any type of yarn that is irregular in diameter; the irregularity may be purposeful or the result of error. (Also see NOVELTY YARN, NUB YARN, and SLUB.)

SLUG: A thick place in a yarn or a piece of lint entangled in yarn, cord, or fabric.

SLURRY: A watery or solvent suspension; e.g., titanium dioxide mixed with water for addition to polymers.

SMASH: 1. A relatively large hole in fabric characterized by many broken warp ends and floating picks. One cause is the breaking of one or both harness straps, permitting the harness to drop and break out warp ends.

2. The breaking of many yarn ends in a beaming operation, usually as a result of mechanical failures.

SMOKE CHAMBER TEST: See FLAMMABILITY TESTS.

SMOULDERING: A slow, flameless, smoking burning of a fabric.

SNAG: A pulled thread in knits. It is in the wale direction in warp knits and in the course direction in weft knits.

SNARL: A short length of warp or filling yarn that has twisted on itself because of lively twist or insufficient tension. The snarling may occur during or prior to the weaving process.

SNOW BALL: See BALLING UP.

SOAKING: Treatment of rayon yarns in a lubricating and sizing solution preparatory to hard twisting.

SOAP: The detergent obtained by the formation of a sodium or potassium salt of a fatty acid or mixture of fatty acids.

SOFTENER: 1. A product designed to impart a soft mellowness to the fabric. Examples are glucose, glycerine, tallow, or any one of a number of quaternary ammonium compounds.

2. A substance that reduces the hardness of water by removing or sequestering the calcium and magnesium ions.

3. A substance used to reduce friction during mixing and processing when dry powders are added to polymers.

SOFTENING POINT: The temperature at which substances without a sharp melting point change from viscous to plastic flow.

SOIL BURIAL TEST: A test of resistance of textile material to certain microorganisms present in soil. The samples are buried in soil for an extended period, then removed and measured for strength loss.

SOILING: The staining or smudging of textile materials resulting from the deposit of dirt, oil undesirable dye, etc.

SOLID-STATE POLYMERIZATION: Reaction of the active end-groups within a solid polymer. It may be intentional as in heating and drying nylon 66 to increase the final degree of polymerization; or it may be undesirable such as that which occurs in fibers under high-temperature conditions in tires that leads to increased degree of polymerization, cross-linking, and subsequent brittleness and loss of strength.

SOLUBLE: Capable of being dissolved, i.e., passing into solution.

SOLUTION-DYED: See DYEING, Mass-Colored.

SOLVENT DYEING: See DYEING.

SOLVENT SPINNING: See SPINNING, Dry Spinning.

SOURING: Any treatment of textile materials in dilute acid. Its purpose is the neutralization of any alkali that is present.

SPACE DYEING: See DYEING.

SPANDEX FIBER: A manufactured fiber in which the fiber-forming substance is a long chain synthetic polymer composed of at least 85% of a segmented polyurethane (FTC definition).

CHARACTERISTICS: Spandex is lighter in weight, more durable, and more supple than conventional elastic threads and has between two and three times their restraining power. Spandex is extruded in a multiplicity of fine filaments which immediately form a monofilament. It can be repeatedly stretched over 500% without breaking and still recover instantly to its original length. It does not suffer deterioration from oxidation as is the case with fine sizes of rubber thread, and it is not damaged by body oils, perspiration, lotions, or detergents.

END USES: Spandex is used in foundation garments, bathing suits, hose, and webbings.

SPECIFIC GRAVITY: Ratio of the mass of a material to the mass of an equal volume of water at 4°C. The range for modern fibers is not too great and is dependent to some extent on the liquid used as an immersant in measurements, because of fiber swelling and of possible absorption of liquid into fiber voids. (Also see DENSITY.)

SPECK: 1. A contaminant in polymer such as gels, metal, or dirt that shows up as a dark spot.

2. A small particle of foreign substance that has not been removed from the stock before spinning.

SPECKING: The removal of burrs, knots, and other objects that impair the finished appearance of woolens and worsteds.

SPECKY: A term used to describe dyed woolen fabric with specks of undyed vegetable matter on the face. The specks can be removed by carbonizing or covered by speck dyeing.

SPECTROGRAPH: A spectroscope equipped with a camera or some other device for recording the spectrum. (Also see SPECTROSCOPE.)

SPECTROMETER: An instrument for identifying and comparing materials by the dispersing of light and the study of the spectra formed.

SPECTROPHOTOMETER: An instrument used to measure the transmission or reflectance of light as a function of wavelength.

SPECTROSCOPE: An instrument for forming a spectrum for visual examination.

SPECTROSCOPY: The identification of materials by the analysis of their spectra.

SPHERULITE: A common form of polymer crystallization from melts or concentrated solutions. These crystallites show a radial symmetry from a central point and have a distinctive maltese cross pattern of birefringence under the polarizing microscope.

SPINDLE: A slender, upright, rotating rod on a spinning frame, roving frame, twister, winder, or similar machine. A bobbin is placed on the spindle to receive the yarn as the spindle is rotated at high speed.

SPIN-DRAWING: 1. The reduction of roving during spinning by a roller drafting mechanism similar to that used on the roving frame.

2. Combined spinning and drawing in one operation in melt-spun fibers.

SPIN FINISH: See LUBRICANT.

SPIN MULTIPLIER: See TWIST MULTIPLIER.

SPINNERET: A metal disc containing numerous minute holes used in manufactured fiber extrusion. The spinning solution or melted polymer is forced through the holes to form the fiber filaments.

SPINNING: The process or processes used in the production of single yarns or of fabrics generated directly from polymer.

1. Yarn from Staple Fiber: The formation of a yarn by a combination of drawing or drafting and twisting prepared strands of fibers, such as rovings.

2. Filament Yarn: In the spinning of manufactured filaments, fiber-forming substances in the plastic or molten state, or in solution, are forced through the fine orifices in a metallic plate called a spinneret, or jet, at a controlled rate. The solidified filaments are drawn-off by rotating rolls, or godets, and wound onto bobbins or pirns. There are several methods of spinning manufactured filaments:

Dry Spinning: The process in which a solution of the fiber-forming substance is extruded in a continuous stream into a heated chamber to remove the solvent, leaving the solid filament, as in the manufacture of acetate.

Gel Spinning: A spinning process in which the primary mechanism of solidification is the gelling of the polymer solution by cooling to form a gel filament consisting of precipitated polymer and solvent. Solvent removal is accomplished following solidification by washing in a liquid bath. The resultant fibers can be drawn to give a product with high tensile strength and modulus.

Melt Spinning: The process in which the fiber-forming substance is melted and extruded into air or other gas, or into a suitable liquid, where it is cooled and solidified, as in the manufacture of polyester or nylon.

Phase-Separation Spinning: Extrusion of polymer and solvent at high temperature into a cooling zone. During the cooling process, a phase separation occurs, usually accompanied by crystallization of the solvent. Solvent can be removed before or after drawing.

Reaction Spinning:

Process in which an initial prepolymer is formed and then extruded into a reagent bath where polymerization and

filament formation occur simultaneously. Spandex fibers can be made by this process.

Wet Spinning: The process in which a solution of the fiber-forming substance is extruded into a liquid coagulating medium where the polymer is regenerated, as in the manufacture of viscose or cuprammonium rayon.

3. Yarn from Leaf and Bast Fiber: In the manufacture of leaf and bast fiber yarns, the terms “wet spinning” and “dry spinning” refer to the spinning of fibers in the wet state and in the air-dry state, respectively.

4. Yarn from Filament Tow: The formation of a yarn from filament tow by a combination of cutting or breaking, drafting, and twisting in a single series of operations. Also known as converting.

5. Nonwoven Fabric: Fabrics can be produced directly from molten or dissolved fiber-forming substances by several continuous processes:

Flash Extrusion: The process in which a fiber-forming substance in a volatile solvent is extruded from a high-temperature, high-pressure environment into lower temperature and pressure conditions, causing the solvent to rapidly evaporate, leaving a lacy, net-like fabric.

Spray Spinning: See SPUN-BONDED PRODUCTS.

SPINNING FRAME: A machine used for spinning staple yarn. It drafts the roving to the desired size, inserts twist, and winds the yarn onto a bobbin. The term is generally used to indicate a ring spinning frame, although it does cover flyer spinning and cap spinning on the worsted system.

SPINNING SOLUTION: A solution of a fiber-forming polymer (e.g., cellulose acetate) in a suitable condition to be extruded by either dry spinning or wet spinning.

SPINNING TWIST: The twist added to yarn during spinning to give it strength and other desired characteristics.

SPIRAL YARNS: Specialty yarn made by winding heavier, slackly twisted yarn around a finer yarn with a hard twist to give a slubby appearance.

SPLICING: 1. The joining of two ends of yarn or cordage. There are several methods used, e.g., by interweaving the strands, by the use of knots, by tapering, lapping, and cementing the ends, etc.

2. A method of reinforcing knits, e.g., the heels and toes of hosiery, by introducing an additional yarn for strength.

SPLINTER: Two or more staple fibers adhering together, causing a stiff cluster that resists pulling apart in normal processing, and reacting in the yarn spinning process similarly to higher than nominal denier fiber.

SPLINTER COUNT: A measure of the number of coalesced fibers, mealy particles, or other such matter in staple fiber.

SPLIT: See REED.

SPLIT-DRAFT METIER: An extrusion cabinet for dry spinning in which the drying medium (hot air) is introduced between the jet and the yarn outlet and flows in both directions.

SPLIT END: 1. A defect in fabric caused by breakage of some of the singles yarns in a plied warp yarn.

2. A defect in manufactured filament yarn caused by breakage of some of the filaments.

SPLIT-FLOW METIER: See SPLIT-DRAFT METIER.

SPLITTING: 1. In the processing of tow, a defect in which the integrity of opened tow is disturbed by separation or division into two or more segments longitudinally. Splitting can be continuous or intermittent, long or short term.

2. In slashing, the separation of sized yarn ends before takeup on the slasher beam.

SPOOL: A flanged wooden or metal cylinder upon which yarn, thread, or wire is wound. The spool has an axial hole for a pin or spindle used in winding. (Also see BEAM.)

SPOT BONDING: See BONDING, 2, Point Bonding.

SPRAY BONDING: See BONDING, 2.

SPRAY SPINNING: See SPUN-BONDED PRODUCTS.

SPREAD STITCH: See PINHOLE.

SPRING NEEDLE: A knitting machine needle with a long, flexible hook, or beard, that allows the hook to be closed by an action known as pressing so that the loops can be cast off. The hook springs back to its original position when the presser bar is removed. (Also see LATCH NEEDLE.)

SPUN-BONDED PRODUCTS: Nonwoven fabrics formed by filaments that have been extruded, drawn, then laid on a continuous belt. Bonding is

accomplished by several methods such as by hot roll calendering or by passing the web through a saturated-steam chamber at an elevated pressure.

SPUN-DYED: See DYEING, Mass-Colored.

SPUN FABRIC: A fabric made from staple fibers that may contain one or a blend of two or more fiber types.

SPUNLACED FABRIC: A nonwoven fabric produced by entangling fibers in a repeating pattern to form a strong fabric free of binders.

SPUNLIKE FILAMENT YARNS: See SIMULATED SPUN YARNS.

SPUN SILK: See SCHAPPE.

SPUN YARN: 1. A yarn consisting of staple fibers usually bound together by twist.

2. A melt-spun fiber before it is drawn.

SQUARE CONSTRUCTION: See BALANCED CLOTH.

SQUEEGEE: The portion of a screen-printing apparatus consisting of a blade that forces the print paste through the screen onto the fabric.

SQUEEZE ROLLS: Rolls used to apply pressure for removal of water or chemicals from fabric.

STABILITY: A term used to describe the tendency of a fiber or fabric to return to its original shape after being subjected to external influence, such as tension, heat, or chemicals.

STABILIZED FIBER: Fiber that is heat or chemically treated to set the fiber properties and prevent deterioration, shrinkage, etc. (Also see HEAT STABILIZED, HEAT SETTING and UV ABSORBER.)

STAIN: See FINISHING SPOT.

STAINING: The undesired pickup of color by a fabric: (1) when immersed in water, dry-cleaning solvent, or similar liquid medium that contains dyestuffs or coloring material not intended for coloring the fabric; or (2) by direct contact with other dyed material from which color is transferred by bleeding or sublimation.

STAINLESS-STEEL FIBER: Textile fibers made of stainless steel. Steel fibers are used for antistatic purposes in carpets, for tire belt construction, and for high-temperature or heat-resistant end uses.

STANDARD ATMOSPHERE: Air maintained at 70°F (21°C) and 65% relative humidity. When international testing is involved, a standard temperature of 20°C or, by agreement, 27°C

may be used. Special humidity and temperature conditions are sometimes prescribed for the testing of certain textiles for specific service predictions, resistance to water or biological action, etc.

STANDARD CONDITION: Standard condition is that reached by a specimen when it is in moisture equilibrium with a standard atmosphere. Standard condition is seldom realized in practice since laboratory atmospheres are continually fluctuating between narrow limits, and it is not practical to wait for the attainment of moisture equilibrium which would require several days or more for tightly wound samples of high regain material. Practically, specimens are brought to moisture equilibrium in the standard atmosphere for testing as defined in these definitions. The term “standard condition” should not be used as a synonym for the concept of “standard atmosphere.”

STANDARD DEVIATION: A measure of the dispersion of a set of numbers based on the difference of the individual numbers from the mean.

STANDARD MOISTURE REGAIN: Accepted moisture allowance for textile materials expressed in percentages of their dry weight.

STANDING WIRE: A broad term describing fixed rods or strips extending through the loom reed, that control the height of the pile in a woven pile fabric.

STAPLE: Natural fibers or cut lengths from filaments. The staple length of natural fibers varies from less than 1 inch as with some cotton fibers to several feet for some hard fibers. Manufactured staple fibers are cut to a definite length, from 8 inches down to about 1-1/2 inches (occasionally down to 1 inch), so that they can be processed on cotton, woolen, or worsted yarn

spinning systems. The term staple (fiber) is used in the textile industry to distinguish natural or cut length manufactured fibers from filament.

STAPLE FABRIC: See SPUN FABRIC.

STAPLE FIBER: See STAPLE.

STAPLE PROCESSING: The conversion of staple into spun yarns suitable in evenness, size, twist, and strength for use in the weaving or knitting of fabrics. (Also see TEXTILE PROCESSING.)

STAPLE YARN: See SPUN YARN.

STARCH LUMP: See HARD SIZE.

START-UP MARK: See SET MARK.

STATIC: An accumulation of negative or positive electricity on the surface of fibers or fabrics because of inadequate electrical dissipation during processing. Static results in an electrical attraction or repulsion of the fibers relative to themselves, to machine parts, or to other materials, preventing the fiber from traveling in a normal path in the process.

STATIC ADHESION: In tire cord, the measurement of the strength of a cord-to-rubber bond under static conditions or very low strain rate.

STATIC CRACK: See SHIER.

STEAM CHEST: A steam-heated cabinet used in manufactured fiber production. Usually refers to the heated cabinet in which spin-drawing is done or to the cabinet around a stuffer-box crimper.

STENTER: See TENTER FRAME.

STICKER: 1. A distortion in the weave characterized by tight and slack places in the same warp yarns. The principal causes are rolled ends on the beam, warp ends restricted by broken filament slubs, and knots catching at lease rods, drop wires, heddles, or reeds. (Also see DRAW-BACK.)

2. See HARD SIZE.

STIFFNESS: The property of a fiber or fabric to resist bending or to carry a load without deformation. It is based on the fiber modulus.

STITCH BONDING: See BONDING, 2.

STITCHING: The process of passing a fiber or thread through the thickness of fabric layers to secure them. In composite manufacture, stitching is used to make preforms or to improve damage tolerance of complex-shaped parts.

STOCK DYEING: See DYEING.

STOCKINETTE: A knit fabric in tubular or flat form made with a plain stitch from yarns of wool, cotton, manufactured fibers, or a combination of these fibers. Stockinette fabrics are used

for underwear, industrial applications, and other purposes. In heavier constructions, dyed and napped stockinette finds apparel uses. (Also spelled stockinet.)

STOLL-QUARTERMASTER UNIVERSAL WEAR TESTER: A versatile testing apparatus for measuring wear resistance of fabrics, yarns, thread, etc. It can be equipped with either of two testing heads, one for testing abrasion resistance of flat surfaces and the other for testing resistance to flexing and abrasion. (See diagram.)

STOP MOTION: Any device that automatically stops a textile machine’s operation on the occurrence of a yarn break, a high defect count, etc.

STRAIN RECOVERY CURVE: See TENSILE HYSTERESIS CURVE.

STRAND: 1. A single fiber, filament, or monofilament.

2. An ordered assemblage of textile fibers having a high ratio of length to diameter and normally used as a unit; includes slivers, roving, single yarns, plies yarns, cords, braids, ropes, etc.

STRAW: A general term for plant fibers obtained from stems, stalks, leaves, bark, grass, etc. They are made into hats, bags, shoes, mats, etc., by weaving, plaiting, or braiding.

STREAK: A discoloration (rust, oil, dye, grease, soap, etc.) extended as an irregular stripe in the cloth.

STRENGTH COUNT PRODUCT: See BREAK FACTOR.

STRESS: The resistance to deformation developed within a specimen subjected to an external force. Typical examples are tensile stress, shear stress, or compressive stress. Stress usually reaches a maximum at the time of rupture. When a textile material is subjected to a stress below that causing rupture, the stress gradually decreases or decays with time.

STRESS-STRAIN CURVE: A graphical representation, showing the relationship between the change in dimension (in the direction of the applied stress) of the specimen from the application of an external stress, and the magnitude of that stress. In tension tests of textile materials, the stress can be expressed either in units of force per unit cross-sectional area, or in force per unit linear density of the original specimen, and the strain can be expressed either as a fraction or as a percentage of the original specimen length. (Also see LOAD-DEFORMATION CURVE.)

STRETCH BREAKING: In conversion of tow-to-top, fibers are hot stretched and broken rather than cut to prevent some of the damage done by cutting.

STRETCH GROWTH: See SECONDARY CREEP.

STRETCH SPINNING: A term used in the manufacture of rayon. Rayon filaments are stretched while moist and before final coagulation to decrease their diameter and increase their strength.

STRETCH YARN: See TEXTURED YARNS.

STRIATIONS: Streaks or bands or various nature in fibers or fabrics.

STRIÉ: A term describing any cloth having irregular stripes or streaks of practically the same color as the background.

STRINGUP: See THREADUP.

STRINGY SELVAGE: See SLACK SELVAGE.

STRIPPING: 1. A chemical process for removing color from dyed cloth by the use of various chemicals. Stripping is done when the color is unsatisfactory and the fabric is to be redyed.

2. The physical process of removing fiber that in embedded in the clothing of a card.

3. See DEGUMMING.

STUFFER BOX: A mechanism for crimping in which a fiber bundle (e.g., tow or filament yarn) is jammed against itself, causing it to crimp. By the suitable application of heat (usually wet steam) and pressure to the stuffed tow, a high and permanent crimp can be forced into the bundle. (Also see TEXTURING, Stuffer Box Method.)

STUFFERS: Extra yarns running in the warp direction through a woven fabric to increase the fabric’s strength and weight.

S TWIST: See TWIST, DIRECTION OF.

STYRENE: An unsaturated hydrocarbon, (C

6H

5-CH = CH

2), prepared from coal tar. Polystyrene is a colorless, transparent plastic used for molding various articles for insulation, transparent parts, radio parts, etc.

SUBLIMATION: A phase change in which a substance, such as a dye, passes directly from the solid to the vapor phase without passing through a liquid phase. This process is the basis for transfer printing.

SUBLISTATIC® PROCESS: A method of applying print designs to fabrics containing manufactured fibers by paper-transfer techniques. Developed by Sublistatic Corp. (Also see PRINTING, Heat Transfer Printing.)

SUBSTRATE: Fabric to which coatings or other fabrics are applied. It can be of woven, knit, nonwoven, or weft-insertion construction. Generally, substrate properties are dependent both on fiber type and fabric construction. Usually the fabric is scoured, heat-set, and otherwise finished prior to coating or bonding. Many smooth-surfaced manufactured fiber fabrics require impregnation with a latex prior to coating to ensure adequate adhesion.

SUBSURFACE STABILIZATION FABRICS: See GEOTEXTILES.

SUEDE FABRIC: Woven or knitted cloth finished to resemble suede leather, usually by napping, shearing, and sanding techniques.

SULFAR FIBER: A manufactured fiber in which the fiber-forming substance is a long chain, synthetic polysulfide in which at least 85% of the sulfide (-S-) linkages are attached to two aromatic rings (FTC definition). The raw material is polyphenylene sulfide which is melt spun and processed into staple fibers. These are high performance fibers with excellent resistance to strong chemicals and high temperature. They show excellent strength retention in harsh environments; are flame retardant; and are non-conducting. They find use in high-temperature filter fabrics, electrical insulation, coal-fired boiler bag houses, papermaker’s felt, and high-performance composites.

SULFATE PULP: See KRAFT PULPS.

SULFONATED: A term describing a material that has been reacted with sulfonic acid, usually to impart solubility, dyeability with cationic dyes, or other properties.

SULFONIC ACID: Any acid containing the sulfonic group, (SO3H).

SULFUR DYES: See DYES.

SUPERABSORBENT: A material that can absorb many times the amount of liquid ordinarily absorbed by cellulosic materials such as wood pulp, cotton, and rayon.

SURAH: A soft fabric of silk or filament polyester or acetate, usually a twill and often woven in a plaid. Surah is used for ties, mufflers, blouses, and dresses.

SURFACE CHARGE: The electrical charge on the surface of a substance.

SURFACE ENERGY: 1. The free energy of the surfaces at an interface that arises because of differences in the tendencies of each phase to attract its own molecules.

2. The work that would be required to increase the surface area of a liquid by one unit area.

SURFACE TENSION: Intermolecular forces acting on the molecules at the free surface of a liquid tend to minimize the surface area of the liquid and give the surface properties similar to those of an elastic skin under tension. When two dissimilar liquids make contact, these intermolecular forces will cause the shape of the interface to change until the potential energy of the entire molecular system is at a minimum.

SURFACTANT: A surface-active agent, i.e., a product that acts by modifying the surface or boundary between two phases.

SWATCH: A piece of fabric used as a representative sample of any fabric.

SWELLING: In textile usage, expanding of a fiber caused by the influence of a solvent or chemical agent. A property often used to facilitate dyeing.

SYNDIOTACTIC POLYMER: A polymer structure in which the atoms that are not part of the backbone chain are distributed in a symmetrical and recurring manner above and

below the backbone chain when the latter is in a single plane. (Also see ATACTIC POLYMER, ISOTACTIC POLYMER, and TACTIC POLYMER.)

SYNTHETIC FIBER: Another term for manufactured fiber.