Yarns: Yarn Properties and Wrapper Fibres

Abstract

Wrapper fibres (WFs) and their formation mechanisms, as well as their effects on the properties of open-end rotor spun yarns, have been investigated. For this purpose, different yarn samples (100% PES) were produced under different operating conditions. The tight belts on the surface of the selected yarn samples were counted, and the mean number of wrapper fibres per unit length was evaluated. The effect of rotor diameter and rotor speed on the occurrence of tight belts has been examined systematically.

Key words: wrapper fibres, open-end rotor spun yarn, twisting yarn properties, polyester yarn.

Erdem Koç,

Carl Anthony Lawrence*,

Cherian Iype*

Çukurova University

Textile Engineering Department

Adana, Turkey

e-mail: erdemkoc@cu.edu.tr.

*University of Leeds

The School of Textile Industries

Leeds, U.K.

■ Introduction

Open-end (OE) rotor spun yarns have certain characteristics which differentiate them from conventional ring-spun yarns. This is because of differences which can be noted between their production method and structure [ 1-7]. In contrast to ring spinning, twisting during rotor spinning takes place from the inside onwards. In rotor yarns, the outer layer or the surfaces of the yarn have WFs or belts, which is a typical characteristic of rotor-spun yarns [1-3]. OE rotor-spun yarns, unlike ring-spun yarns, are basically of a three-part construction: a densely packed core of fibres substantially aligned (straight) with the yarn axis, more loosely packed fibres twisted around the core, and WFs on the outside. The presence of WFs on the yarn surface is an identification feature of OE spun yarns. Figure 1 shows the outer yarn structure for both the rotor and ring spun yarns.

WFs are those that are not completely tied into the yarn, and have a free end that wraps itself around the yarn periphery and causes constriction of the yarn. This is a defect peculiar to rotor-spun yarns. It appears that the stiffer and coarser fibres tend to become ‘wrapper’ surface fibres. WFs or belts are formed by fibres that are trapped from the wrong direction i.e., from the section the yarn has just left, or by fibres that are fed directly onto the yarn forming point and by the yarn between the doffing tube and rotor groove as it comes into contact with airborne fibres. Fibres floating inside the rotor can be caught by the yarn to form WF, and one of the functions of the doffing tube is to reduce the number of freely floating fibres [ 8].

In order to investigate the effect of WFs on the properties of OE rotor spun yarns, several yarn samples (100% PES) were produced on an OE-rotor spinning unit under different operating conditions with selected machine parameters. The occurrence of tight belts on the yarn surfaces examined, and the mean number of WFs or belts per unit length was evaluated for different running parameters. Selected results have been given here. The effect of such fibres on the yarn properties is discussed.

Formation of Wrapper Fibres on Rotor Spun Yarns

Formation and frequency of WFs

The formation of WFs is largely affected by several machine-related and fibre-related factors including: rotor speed, rotor diameter, fibre length, friction between the fibre and rotor groove and aggressiveness

of the navel. The formation of so-called ‘wrapper fibres’ or ‘bridging fibres’ is illustrated in Figure 2. Here, the sequence can be noted as follows: (a) a fibre entering the rotor, (b) this fibre beginning to wrap around the body of the yarn rather than being twisted into the tail of the yarn, (c) the fibre continuing to wrap, and (d) the final

view of such a bridging fibre [6,8]. The

fibre peeling point which moves slightly clockwise during the above sequence may also be illustrated. With increasing rotor speed, the levels of both false twist and the

yarn rotation becomes higher; hence, the WFs are wrapped around the core more often. At higher speeds, the rotor diameter or the navel should be changed to reduce false twist; otherwise, the yarn qualities will deteriorate.

OE rotor-spun yarns are described basically as two-zone structures comprising a core of fibres that are aligned with the helix of the inserted twist and form the bulk of the yarn, then an outer zone of WFs occurring irregularly along the core length [9]. Figure 3 illustrates the typical WF formation. The twisting torque is in the direction for inserting S-twist into the fibre ribbon; as a fibre slides down the rotor wall into the rotor groove to become a bridging fibre, its leading end will be caught by the twist insertion point. This causes the length landing on the peripheral twist extent to become wrapped in the Z-twist direction around the yarn. When this short, twist length is peeled from the rotor groove, the bridging fibre length becomes folded, and its trailing end is lifted from the gap and the tail end of the ribbon to form a catenary (Figure 3b, c). The twist torque initially wraps the trailing length around the yarn at almost 90° to the yarn axis, giving a belt-wrap appearance; then the remaining length is wrapped in the S-twist direction, the angle of S-wrap varying as the yarn moves toward the doffing tube.

When the yarn length reaches the doffing tube, the reverse twisting (Z twisting) of the false twist removes S-twist not only from the yarn core but also from what had been the trailing length of the WF. However, the leading length of the WF receives further Z-twist, and binds more tightly onto the yarn.

Some papers [ 8,10] review the work done on WFs and covers various aspects concerned with their formation. The length of the yarn-formation zone has a decisive effect on the incidence of WFs; the longer the zone, the greater is the incidence. For both long- and short-staple yarns, an increase in WFs results in a deterioration in yarn strength and yarn quality in general. Fibre length and the friction between the fibre and the rotor groove affect the formation of WFs. It is claimed that longer fibres cause a more unfavourable formation of WFs on the yarn core [ 8].

Barella et al. [11] found that the WF

length and the distance between successive WFs increase as the rotor diam-

eter increases, whereas their tightness decreases. WF separation follows the Gumbel distribution law; the number of WFs in any given length follows the Poisson law, and the WF length follows a logarithmic law. For small rotor diameters, belts (WFs) are compact, but when the rotor diameter increases, they are less tightly coiled round the core of the yarn.

A detailed work on the surface structure of rotor yarns show that the variation of surface appearance along the yarn length can be classified into six groups [12]: ordered, loosely wrapped, hairy, multiple wraps, opposingly wrapped, tightly wrapped and belts. With respect to these classifications, it has been shown that the yarn consisted largely of the first three classes, and it was evident that steel doffing tubes with groove navels resulted in more WFs and surface hairs.

The wrappers may be considered as defects in the rotor yarn structure [9], and the belt-type WFs in particular are known to register as neps in the Uster irregularity tester [13]. Several factors will influence the degree of wrapping, the frequency of belts and the Z- and S-wrap angles of the WFs [13,18]. The higher the level of the false twist, the longer the tying-in zone which reduces the end breaks and gives spinning stability, but also increases the number of WFs and the level of Z-wraps. Increased frictional drag by the rotor and ribbon tail on the trailing length of the bridging fibre will increase the level of S-wraps; the longer fibres also increase S-wraps.

Grosberg & Ho [ 14] predict the fre quency of WFs and estimate the effect of processing parameters on rotor-spun yarn strength. If it is assumed that the mean fibre extent equals rotor radius, then it can be shown that there must be at least 16% of hooked fibres formed at withdrawal, even if the fibres were straight and parallel when assembled on the collecting surface. For a given fibre type and rotor design, the number of WFs formed will be related to the peripheral twist extent.

The spinning stability of the OE rotor system has been studied from the overlapping points of view of (wrapper) fibres [ 15]. It was shown that the greater number of overlapping fibres at the yarn peel-off point in the rotor groove resulted in poorer spinning stability with smaller rotor diameters. The number of overlapping fibres is dependent on rotor diameter and fibre length, and their percentage of the total fibre quantity may easily be calculated. It was shown that the number of fibres deposited over the yarn peel-off point at each rotor revolution increases as the rotor diameter decreases.

It has been observed that the number of WFs per cm of yarn produced increases linearly with the peripheral twist extent, and is independent of the speed of spinning or count of the yarn. Hence it may be concluded that the higher twist level in the yarn crank, contributed by true or false twisting effect, increases the peripheral twist extent [ 16,17] and hence increases the number of WFs [ 14,18]. Kampen et al. [ 18] report the factors that influence the structure of the outer yarn layers, in particular those affecting the occurrence of WF. The number of WF formed increases with larger rotor diameters owing to a greater degree of false twist. A long tying-in zone (PTE) enhances the spinning stability, i.e. reduces the end breakage rate, but results in more WFs.

Wrapper fibres and yarn properties

The influence of fibre shrinkage potential on the formation of belts and the influence of belt frequency on yarn tenacity and elongation were studied by Naik & Lopez-Amo [ 19]. They attempted to characterise the belts in four different categories. The results show that the wrapper frequency has no significant influence on yarn strength and elongation at break. Wrapper frequency is affected by the degree of fibre crimp. Sengupta etal [20] studied the formation of belts and their influence on tenacity of rotor-spun yarns. The frequency of belts increases with the increase in twist density. This is because of the extension of the tie-in zone with the increase in twist. The influence of belts on tensile properties of rotor-spun yarn has been examined experimentally

[21 ]. It is reported that a small percentage of long-fibre belts in a short-staple rotor-spun yarn improves the strength of the yarn, due to the reinforcement of the yarn matrix through belts. Louis [22] reports that WF and yarn strength are inversely related for any given cotton, and rotor speed affects WF formation much more than it affects yarn strength. The structure of fibre assembly during yarn formation in rotor spinning has been investigated, and the incidence of WFs has also been examined elsewhere [23].

The WFs were classified into three different groups as follows: class A, a single fibre forming a loose belt, class B, a group of fibres forming loose belts and class C, a group of fibres forming tight belts [24]. It was found that class C belts (tight belts) can be positively correlated with yarn

strength. Hashish [25] found a strong linear relationship between the mean overall fibre extent, the belt characteristics and yarn properties. It was noticed that the increase in the number and extent of WFs resulted in a deterioration of all the measured yarn properties, i.e. strength,

extension and regularity. Eljack [26] has used the same WF classification adopted

by Ibrahim [24] during his study on the influence of fibre properties on the quality of rotor-spun cotton yarns. It was shown that the total number of WFs increased with yarn linear density. The longer fibres were found to produce more of the tight classes of WFs, and this was more pronounced in finer yarn. It was reported that yarn strength appears to improve with PTE and WFs, and furthermore the yarn regularity was found to improve with an increased number of WFs.

It has been shown that the number and size of WFs in the yarn are closely related to the size of the feed sliver and the yarn count being produced [27]. Since the WFs contribute little to yarn strength, yarn tenacity is therefore reduced as the WF content increases. The findings may suggest that there is a possibility that some types of WF contribute to the yarn strength rather than decreasing it, while the remainder of the belts may have an opposite effect.

It was shown that a staple-fibre core would give a lower CV% than filament core [28]. This means that there is good cohesion between the staple-fibre core and wrapper fibre sheath. The amount of WFs is critical to yarn strength, since they hold the internal parallel fibre bundle tightly together, and this effect is more critical for cotton fibres [29]. The higher tenacity values of vortex yarns can be attributed to the higher number of WFs in these yarns. One possible explanation for the reduction in elongation is the decrease in fibre slippage due to better grip by the WFs.

Experimental Assessment of Wrapper Fibres

Sample yarns produced

In order to investigate the occurrence of WFs and their characteristic parameters, and the effect of such fibres on the properties of OE rotor spun yarns, different yarn samples were produced under different running conditions using different rotor diameters (32 mm to 56 mm) with different rotor speeds ranging from 52,200 rpm to 69,920 rpm on a Rieter R1 OE-Rotor Spinning Unit. The yarn samples were 100% PES and had approximately 25 tex linear density; the sliver used in the production was a 5 ktex polyester. The polyester fibres in sliver had 1.5 dtex linear density, and the mean fibre length was 38 mm. The draft was fixed at 200 and the twist given to the yarn was 1100 tpm, while the beater speed was adjusted to 7700 rpm. With these operating and machine parameters, spinning was carried out and a series of yarn samples (11 different sets) were obtained. The sample yarns with their labels are identified as in Table 1.

The standard steel rotors with standard groove form (S) were chosen by following the manufacturer’s instruction for setting the machine, and the speed range was adopted as shown in Table 1. The maximum speed for the 56-mm rotor was set at 60,070 rpm due to the limitations on operation, although the machine operating instructions permitted maximum running speeds of 80,000, 65,000 and 55,000 rpm for 40 mm, 48 mm and 56 mm rotors respectively. Because of these limitations, only three rotor diameters were used with a maximum speed of 69,920 rpm. These limitations to rotor speed and rotor diameter confirm the results given earlier [13].

Experimental set up and wrapper fibre assessment

The WFs could be assessed by their frequencies (their distribution along the yarn core) and by their configuration and behaviour around the yarn surface. The present experimental study focused only on tight belts on the yarn surface, and initially the mean number of WFs per unit length was the only parameter to be examined.

The yarn samples produced were subsequently prepared on glass slides and then examined under a microscope. The test procedure was carried out on yarn samples prepared in such a way so as to lie in parallel on one face of a glass slide (1’x 3’). The slide was fixed firmly on

the microscope stage by the use of two special clamps. Yarn samples of 50 mm, chosen at random, were mounted on the glass slides as mentioned above, and the belts along the length of the specimen were counted using a colour microscope and a CCD camera [30]. When viewed through this microscope a good depth of field is obtained, which makes counting of belts easy. For each yarn sample, at least 2 slides with 5 yarn specimens fixed on them (with 50 mm length) were observed, giving a total length of 500 mm over which the belts were counted. The WFs (tight belts) were consequently counted and the mean number of WFs was then converted to mean wrappers per cm.

The experimental set-up consists mainly of a Charge Couple Device (CCD Camera), a light microscope and a light source, a TV monitor, a video recorder and computer hardware. The CCD Camera enables live pictures of test samples to be viewed on the TV monitor. A video recorder was used for recording the images of the samples, and the computer hardware was used for data storage and analysis. A colour JVC CCD Camera, to which a

colour monitor was attached, was used for a better and more well-defined image of the yarn surface being examined. The monitor was provided with video inputs to produce bright and sharp pictures.

An Olympus system BHS optical microscope using transmitted light was used in the study. A twin-fibre-optic light source was also adopted in the system. The lighting provided by the microscope was found to be insufficient most of the time, so the light source was necessary to illuminate the yarn on the glass slide. The intensity of light could be manually controlled.

Experimental Results and Discussions

The properties of yarns produced

The Statimat Yarn Strength Tester (Textechno Statimat M) was used to measure yarn strength and elongation at break. For each yarn sample, 25 tests were carried out. The gauge length (the spacing of grips in the tension tester) was 500 mm, the test speed was 200 mm/min and the load cell was set to 10 N. The test results were printed out as breaking force, work

to rupture, elongation at break, tenacity, breaking time and the relevant statistical values. The results obtained from the mean of 25 observations with CV% values are shown in Table 2.

The effects of rotor speed and rotor diameter on yarn tenacity are shown in Figure 4. It may be seen that with the smallest rotor (32 mm), speed increases the yarn tenacity. With the larger rotors (40 and 48 mm), a drop in yarn tenacity was observed as the rotor speed was increased from 60,070 rpm to 69,920 rpm. In the largest rotor used, the increasing rotor speed results in a sharp drop in yarn tenacity. In general, it appears that the smaller rotor produces yarn with higher tenacities than the larger rotors at the running speed of 65,000 rpm and over. Similar findings were observed by other research workers [18,24]. The spinning-in coefficient decreased as the rotor diameter increased; this is expected to be partially responsible for the deterioration in yarn strength.

Kampen et al [ 18] proposed that the deterioration of yarn tenacity at higher rotor

speed and rotor diameter, could be attributed to the increased false twist effect at these speed and the fact that the more false twist inserted the more frequent WF formation and the more loosening-up of

the yarn sheath due to yarn twist-back at doffing tube would occur. The effect of rotor diameter on the yarn tenacity can be seen more clearly in Figure 5. It appears that the rotor of 40-mm diameter produced yarns with higher tenacities than the larger rotors. The smallest rotor gave relatively lower tenacities than the other rotors with the running speed of 52,200 rpm and 60,070 rpm. Generally, a smaller rotor diameter gives a higher yarn strength [1,15], and rotor speed has a deteriorating effect on yarn tensile properties [31,32]. There is a slight decrease in strength with the increase in speed, but there is a considerable decrease in the elongation at break [9]. In order to obtain a yarn spun at high rotor speed, it is necessary to use a small rotor diameter. The tension in the yarn is largely the result of centrifugal forces, and is proportional to the square of the product of the rotor speed and rotor diameter. For optimal yarn tension, a rotor speed and rotor diameter of 80,000 rpm and 40 mm respectively were suggested [9,31 ]. Because of excessive yarn breaks, the rotor speed at which polyester/cotton blended yarns can be spun is limited [15].

It can be noted from Figure 6 that yarn elongation at break is in general decreased as the rotor speed is increased. The decrease effect is more marked for the larger rotors (48 and 56 mm). This variation can be attributed to the increase in yarn tension at higher speeds and with bigger rotor diameters. Spinning tension has a considerable effect, and lower tension results in higher yarn elongation at break [15]. Elongation at break decreases with increased rotor speed because of the increasing spinning tension, which causes a permanent strain in the yarn [9]. One possible explanation for the reduction in elongation is the decrease in fibre slippage due to better grip by the WFs [29].

The Uster Tester III was used to measure the irregularity and imperfection level of sample yarns produced. The variation in the yarn mass per unit length was evaluated within 2.5 minutes testing time, the yarn speed was fixed at 400 m/min and the percentage coefficient of variation CVm% was recorded. Table 3 shows the observed yarn unevenness or imperfection values corresponding to 11 different yarn samples tested.

Figure 7 demonstrates the variation of CVm% with rotor speed for different rotor diameters. A deterioration of yarn quality (yarn irregularity and imperfection) as the rotor speed increased from 52,200 to 69,920 rpm can be observed in the figure. The increase in CVm was more marked at the largest rotor diameter of 56 mm. The deterioration of yarn regularity can be attributed to the formation of more WFs as the rotor speed increases. With the smaller rotors (32 and 40 mm), the yarn irregularity at the low speed seems to be worse in comparison with the results obtained under other running conditions. Figure 7 also demonstrates that the larger rotor

produced a more regular yarn than the smaller one. The regularity of the yarns produced on the larger rotor is mainly attributed to the higher number of doublings with this rotor. From the figure, it can be seen that the yarn irregularity increased consistently for the larger rotor diameters (48 and 56 mm) as the rotor speed was increased. This seems to be because the relative speed of the fibres decreases with respect to the rotor wall as the rotor speed increases. The incoming fibres may consequently disturb the order of the fibres already laid in the rotor groove, resulting in a deterioration in yarn regularity.

It is reported that yarn irregularity (mass variation) CVm% improvement results from a larger rotor diameter, lower rotor speed, higher draft (thicker sliver) and a rough opening roller surface. It is also shown that yarn imperfections (thin & thick places and neps) in rotor yarns are generally considerably fewer in number than those of ring-spun yarns, apart from 100% man-made fibres [15]. The lower irregularity for rotor yarns is dependent on rotor speed [9]. Increased rotor speed can lead to increased yarn irregularity in particular; with the use of high rotor speeds for spinning fine rotor yarns, the yarn irregularity can become greater than that for ring-spun yarns.

The wrapper fibre results

By adopting the experimental procedure outlined in the previous section, the yarn surface images were recorded and the relevant data was then processed in order to examine the tight belt configuration on the surface of the yarns considered. Some of the selected recordings have been given here. Figure 8 illustrates selected WFs on a certain section of the yarn surface. It may be seen that the running speed of the rotor was fixed at 60,070 rpm while the rotor diameter was varied from 32 mm to 56 mm. The surface irregularity is apparently due to the irregular WFs on the yarn surface. The tight belts (WFs) can easily be noticed on each trace. Figure 9 shows the similar tight belts and yarn surface configuration under different running conditions.

An attempt was made to count the tight belts (tight WFs) on the surface of the individual yarn, and the occurrence of the WFs or their frequency as the mean number of the WFs per unit length was evaluated. The Spinning conditions (operating parameters), the number of WFs per unit length and the effect of such tight belts on the properties of yarns produced have been investigated. The selected results are discussed in this section of the work.

Figure 10 shows the variation in the mean number of WFs per cm (MNWF/cm) with rotor speed for different rotor diameter. It may be seen from the figure that in the majority of cases increasing rotor speed increases the amount of WFs. This variation is more marked at 32-mm and 48- mm rotor diameters than the other rotor diameters. This increase in the number of WFs with the increase in rotor speed is thought to be due to the effect of the PTE inside the rotor. It was reported that the Peripheral Twist Extent (PTE) increases with rotor speed [16]. As a result, with a longer PTE, more fibres that are originally straight or hooked will come into contact with it and become WFs.

The effect of rotor diameter on the MNWF/cm has been examined, and the results obtained have been given in Figu-

re 11. The effect of the rotor running speed may also be noticed from the figure. It is apparent that increasing the rotor diameter for all rotor speeds decreases the amount of WFs. This may be explained by the fact that the longer length of the yarn crank of the larger rotor can lead to more WFs. When using the small rotor there are more possibilities for the belts to occur in greater frequencies than with the larger rotor; this is in agreement with the findings of other research workers [24-26].

It has been found that the number of WFs increases with smaller rotors, and rotor diameters whereas with large rotors the individual WFs appear to be wound much more tightly around the yarn core with a greater number of wraps [18]. This was attributed to the higher spinning tension and greater insertion of the false twist. These tight WFs may act as a reinforcement of the yarn core, thus resulting in higher yarn strength.

Figure 12 shows the effect of MNWF/cm on the tenacity of the yarns examined for different rotor diameters and rotor running speeds (the dependents are built on the basis of results from Figures 10 and 11). In each trace the rotor diameters are marked in mm. It may be seen that with a 32-mm rotor the number of belts per unit length increased with running speed, as explained before, and that increasing the rotor diameter from 40 mm to 56 mm in general decreases the yarn tenacities for all running speeds. Also, it may be noticed from the figure that increasing the number of WFs (by decreasing the rotor diameter up to 40 mm) increases the yarn strength.

Figure 13 shows the effect of MNWF/ cm on the yarn elongation at break for different running conditions (the dependencies are built as in Figure 12). It may be seen from the figure that increasing the tight belts increases the elongation at break. Relatively larger elongation may by noticed at lower rotor speed for a certain rotor diameter. The larger rotor diameter gives a smaller number of WFs, as was expected.

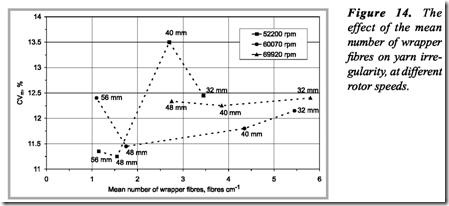

Figure 14 demonstrates the variation of yarn irregularity with the MNWF/cm for both different rotor speeds and rotor diameters. The effect of three parameters on the variation in the yarn mass per unit length was not easy to evaluate. However, it may be noted that with the increasing rotor speed, the frequency of WF formation increases (following the general trends and the points corresponding to the individual rotor diameter on each speed curve). This may be explained by the possibility that each time the peel-off point passes the exit of the fibre delivery tube, a bridging fibre will be wrapped around the body of the yarn.

It is generally accepted that rotor-spun yarns are superior in terms of evenness to the equivalent ring spun-yarns, which is largely attributed to the doubling effect which takes place inside the rotor. However, the presence of WFs is believed to

contribute unfavourably to the measured yarn evenness, since a locally concentrated group of fibres on the yarn body will as such increase the mass per unit length in that section of the yarn [ 1,2,26]. Although the configuration seems to be complex, increases in rotor speed in general lead to a deterioration in yarn properties irrespective of the rotor diameter. The fibre individualisation was lower for the smaller rotor, so that it is quite possible that the ring of fibres deposited in the groove of the smaller rotor experiences a greater false twist instead of real twist, thereby producing an irregular yarn [33].

Statistical analysis

The experimental results have been statistically evaluated by using the Design Expert analysis of variance (Anova) software, albeit with some degree of difficulty. A proper Anova run could not be conducted in some cases, since the lack of replications prevents us from estimating the magnitude of pure experimental error independently. One way of enabling us to conduct an F test is to treat the interaction between design variables such as rotor speed and rotor diameter as error. However, this approach would not be appropriate since this approach might erroneously show an important factor to be insignificant [34].

For instance, the previous figures 4 and 5 clearly illustrate that rotor diameter is the most influential factor on the tenacity, and the effect of rotor speed is very limited. Furthermore, the interaction between rotor speed and rotor diameter appears to be significant. Due to this fact, an F test for the significance of main factors would erroneously show rotor diameter to be insignificant. Therefore, in statistical analysis we have also considered the contributions of rotor speed and rotor diameter to the variation in the response variables, as summarised in Table 4.

The rotor diameter explains 70.67% of the total variation in MNWF/cm, whereas rotor speed alone is not an important factor, contributing to only 22.38% of the total variation. Since the contribution of the interaction to variation in MNWF/cm is very small (6.95%), an F test could be conducted. The F test provides us with similar results for MNWF/cm, indicating that rotor diameter is significant, with a p-value of 0.0047, and rotor speed is insignificant with a p-value of 0.0794. If there were enough replications to estimate ex-

perimental error, we would expect stronger significance levels for rotor diameter effects on elongation, thick places and CVm%, in parallel to the graphic analysis results given in previous sections.

The tenacity of the yarn has been found to be highly dependent on the rotor diameter, as the greatest portion of variation (62.27%) in tenacity is explained by the rotor diameter. The contribution of rotor diameter to variation in elongation at break is also significant, with a 70.50% contribution. On the other hand, the interaction between rotor diameter and rotor speed accounts for 63.28% of the total variation in yarn irregularity (CVm%). Similar levels of interaction can be seen for the neps, thin and thick places that determine the yarn imperfections. The rotor diameter explains 47.86% of the total variation in thick places, whereas the speed and diameter interaction explains 50.36% of the total variation. The main effects of speed and rotor diameter on thin places are very limited, as indicated by the low contribution percentages of 10.97% and 9.11% respectively.

Conclusions

As a result of the experimental investigation into the WF and their formation mechanisms in OE rotor-spun yarns, the following conclusions can be drawn.

§ It appears that the smaller rotor produces yarn with higher tenacities than the larger rotors at running speeds of 65,000 rpm and over. Yarn elongation at break generally decreases as the rotor speed increases. This variation may be attributed to the increase in yarn tension at higher speeds and with bigger rotor diameters.

§ The yarn quality (yarn irregularity and imperfections) tends to deteriorate as the rotor speed increases from 52,200 to 69,920 rpm. The deterioration of yarn regularity can be attributed to the formation of more WFs as the rotor speed increases.

§ In general, it has been found that increasing rotor speed increased the mean number of WFs per unit length. For the 32-mm rotor, the yarn produced at 52,200 rpm gave 3.5 tight belts per cm, whereas the same yarn contains approximately 6 tight belts per cm at a running speed of 69,920 rpm. When the rotor diameter was increased to 48 mm, the mean number of WFs per cm was determined as 1.5 and 2.8 respectively. Increasing the rotor diameter for all rotor speeds decreased the amount of WFs.

The yarn strength generally increased with the number of WFs. It was found that the number of belts per unit length increased with relatively smaller rotors. The smaller rotors (apart from the 32-mm rotor) produced yarn with higher tenacities than the larger rotor.

With increasing rotor speed, the frequency of WF formation increased. In general, increases in rotor speed lead to a deterioration in yarn properties, irrespective of the rotor diameter.

The presence of WFs seemed to contribute unfavorably to the measured yarn evenness.

Increasing tight belts increased the elongation at break. The lower rotor speed gave a relatively larger elongation for certain rotor diameters. The larger diameters gave a smaller number of WFs, as expected.