Shanghai Crosrol Pacific Machinery Co.,Ltd.

Only Correct Fibre Preparation leads to Ultimate Carding efficiency

Only Correct Fibre Preparation leads to Ultimate Carding efficiency

Crosrols long involvement at the forefront of Carding technology has taught us of the importance that only correct Fibre Preparation leads to effective Carding; the new Crosrol opening line gently opens and cleans the fibres in a systematic way resulting in maximum cleaning whilst preserving the natural characteristics of the fibre for the Carding process.

The Crosrol range of modular Blowroom machinery enables an opening line to be individually tailored to suit the unique fibre processing needs of our valued customers, Opening & Cleaning functions are performed in a controlled step by step sequence with individual Blowroom machines maximizing the use of 'Air-flow' to significantly contribute to overall cleaning efficiencies, This gentle opening and cleaning concept ensures that the courser impurities are removed from the fibre rather than been broken up thus leading to ultimate Carding been achieved.

Every Crosrol Blowroom machine in the opening line is designed and manufactured to the same high degree of standards

that Crosrol has used for carding machines during our 70-year history.

Effective Machine Design & Operation Result In Major Energy Savings

The successful integration of traditional stages of Opening & Cleaning into Multi-functional machines results not only in

Floor space savings but significantly reduces the need to transport the Fibres from one machine to another, This multi-functional approach not only ensures a low-nep supply of tufts to the Cards but a significant reduction in direct power usage,

As today's industries focus on ever increasing power costs, The Crosrol Blowroom utilizes only European Drive motors and Gearboxes, this together with the use of only Japanese Bearings we ensure that the consumed electrical energy is converted into Opening & Cleaning power at the highest possible efficiencies.

European Technology with Worldwide Reliability

The new European designed Crosrol opening line incorporates the very latest in design technology utilizing latest generation solutions to ensure that consistent and reliable results are guaranteed every time.

The Crosroi philosophy of employing simple design solutions for machinery, together with only using the very highest quality European I Japanese components with worldwide availability gives you our customer the confidence of a Blowroom line which will operate problem free for many years to come.

The blend of using high quality international components, European Design technology and Cost effective production

methods enables the Crosrol Blowroom line to offer security and the promise of a rapid return on investment - the perfect choice for today's modem high-tech spinning unit.

Automatically Control and Continuous Feeding System

For the first time all Opening & Cleaning machines in the Crosrol Blowroom machinery range are able to be operated and fully adjusted at a touch, With Dial-in (Inverter controlled) Beater and Feed rate settings, Automatically adjusting Cleaning arrangements and in-built cleaning programmes, Operational settings can be adjusted during production and even automatically when two or more assortments are been processed simultaneously.

With the Crosrol continuous feeding system, individual machine production rates are optimized to give continuous material flow between all Blowroom machines and the Cards thus ensuring maximum machine utilization and Opening / Cleaning efficiencies.

All Opening & Cleaning machines utilize a universal user-friendly touch screen display, European PLC based operating

system and European electrical drive components for reduced spares stock inventory, these features together with the Crosrol Central Electrical Control system (CECS), Machine operation and Fault monitoring are all automatically monitored and adjusted to ensure functionality, reliability and maximum line operating efficiency at all times.

ABO Crosrol Automatic Bale Opener

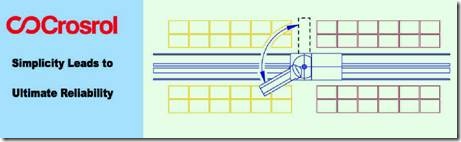

The Crosrol Automatic Bale Opener (ABO) provides the simplest automatic solution to Bale opening; the unique construction of the machine enables ultimate reliability to be realized through simplicity of design.

With the facility to operate on up to four different bale groups of differing heights (Programmable version) together with virtually unrestricted track lengths and multiple head widths at production rates of up to 1500kg's per hour the Crosrol Automatic Bale Opener provides the perfect solution for today's modern spinning unit.

The most important feature of any Automatic Bale Opener is reliability, only through radical design can this be truly achieved.

Only the Crosrol Automatic Bale Opener can truly claim to satisfy this demand for reliability, with over 700 units in the world, trouble-free operation can be assured.

Key features which lead to its simplicity

Detacher Head

Twin contra-rotating opening

I detaching rollers together with a specially developed grille spacing result in only small tufts been plucked, The unique Crosrol design ensures that there is no need for support rollers thus ensuring trouble free running.

Suction Hood

No fans or moving parts are used, Only a simple self-cleaning reinforced flexible duct from the suction hood to the fibre transportation channel, No telescopic sections, No rotating connections, No electrostatic build-up,

Flexibility

Flexibility

The programmable version of the Automatic Bale Opener provides the ultimate in flexibility, Together with the machines unrestricted track length users are able to lay down as many as 200 bales in four groups on each side of the machine, This enables up to four

different assortments to be processed automatically at pre-selected take-off speeds and with the required production volume.

Turning Mechanism

Turning Mechanism

Only the Detacher Head assembly rotates rather than the whole machine tower (No turntable required), this enables the internal workings of the Bale Opener to become maintenance free.

Material Cover Belt

The heavy duty cover apron over the fibre transport channel has a uniquely simple path giving maximum durability and unrestricted track length, The Crosrol method removes the need for restrictive rolling / unrolling of the cover apron negating the need for complex drive systems.

Track System

The large diameter wheels running of tall section transport rails significantly reduce the

number of stoppages caused by fibres falling on to the track.

Standard Features

2. The Single Blend version of the Automatic Bale Opener is for feeding from pre-levelled bales, using two pre-set depths of cut, The deeper bite is used for the softer tops of the bales, then, after a predetermined number of traverses the opening

I detaching rollers revert to normal bite depth.

Detaching head available in lengths of 1.1N1 and 2.3M, the unique head design allows for plucking right up to sidewatls and down to floor level leaving no residual fibre.

Opening I detaching rollers fitted with immensely durable Boron steel plucking teeth for long life, opening rollers can be easily removed for service.

All drive motors incorporate temperature sensors and brakes.

Inverter driven traverse speed is automatically reduced on encountering a hard bale.

Standard European programmable controller ensures reliability.

Multi-Blend Features

The Multi-blend version of the Automatic bale opener has all the extensive capabilities of the Standard single blend version and its additional ultra-powerful programmable logic controller provides a range of further facilities?

* Automatic powered pivoting of the detaching head.

5. Memorizes bale heights and adjusts cut depth to ensure that all bale blocks are exhausted simultaneously. * Production monitoring, depth of cut is adjusted to optimise running time, If more than one demand stoppage per outfretum traverse the bite is reduced, if less than one stoppage bite is increased.

6. New bales can be introduced without so-called blend shock, Less dense material from new bales can be automatically intermingled with denser current production

1 Up to 4 different blends can be pre-programmed permitting multiple opening lines to be simultaneously fed.

Central Electrical Control System (CECS)

Central Electrical Control System (CECS)

With the option of the Crosrol Central Electrical Control system (CECS) the complete opening lines operation can be coordinated from a single point, Integrated within the Automatic Bale openers control system, or as a stand-alone system when a Crosrol Automatic Bale Opener is not supplied, The Crosrol CECS not only provides full control to all opening line machines but also systematically monitors and adjusts individual machine operation to maximize line-operating effcencies.

Touch screen operation showing individual machine status and fault detection giving audio and visible alarm signals.

Cif Co-ordinates the sequential starting and stopping (Including emergency stop) of up to 10 machines in a single or

twin processing line.

1. Production rate optimisation ensuring continuous material flow between all Blowroom machines and the Cards. L, Simple interconnection with individual machines by two-wire serial communications cable resulting in enormous

savings in installation costs.

2. Optional central control of machine Bypass valves.

CPC - Crosrol Pre-Cleaner

CPC - Crosrol Pre-Cleaner

The Crosrol Pm-Cleaner (CPC) is an highly effective opening, cleaning & dust-removal machine generally used as the first opening / cleaning machine in the blowroom line,

Designed to take advantage of the exceptionally efficient pm-opening of the Automatic Bale Opener the Crosrol Pre-Cleaner through its unique "single sheet" material processing technique gives not only exceptional Cleaning but also maximum fibre yield with minimal Nep generation when compared to other first stage cleaners currently available.

The machines high processing capacity (2000Kg's per hour) together with its in-built cleaning programmes allow multiple opening lines processing varying materials blends to be fed from a single Crosrol Pre-Cleaner (CPC).

1.

Dust Removal:

A large Perforated Hood separates the incoming material from the air stream and provides a substantial surface area for the removal of the liberated Dust and fine Trash particles.

2.

Feed Control: The material reserve section in conjunction with the inverter driven Feed rollers ensure a constant & controlled feed to the Opening Beater.

Opening 8 Cleaning:

A large single cylinder Inverter controlled beater with helically positioned Opening prongs opens & forms the material into a low density uniformed sheet of material ensuring optimum opening & cleaning of each and every Fibre Tuft.

3.

Micro Dust Removal: The opened material passes a secondary perforated screen for highly effective removal of small trash particles and dust.

Control and Flexibility:

Newly developed remotely controlled Grid bars are formed into two independently adjustable banks which provide optimum Cleaning with maximum Fibre yield for any given material been processed.

Waste Extraction:

Liberated trash particles fall into a pressure controlled waste collection chamber and are extracted via the Air-lock wheel.

.4)

Protection of Fibre Parameters:

After a single interaction with the Grid bar area, the sheet of low density fibres are efficiently stripped from the Beater so as to negate the need for unnecessary over-working of the fibres at this early stage of the opening line.

Flexible and Economical Solution

Flexible and Economical Solution

The Crosrol Pre-Cleaners in-built cleaning programmes together with its high production capabilities enable multiple opening lines to be fed from a Single Pre-Cleaner machine thus leading to much reduced capital investment, Lower space requirements and significantly reduced operating costs.

Up to four separate mixes can be pre-programmed via the user-friendly touch screen operator display with complete control over the following features:

Material Feed Rates

Seater Operating Speeds

Grid Bar Settings (Primary & Secondary Grid Banks)

By accurately setting the above three mentioned operating parameters the cleaning intensity of the machine can be precisely set for any type of material been processed.

Multi-Blend Operation

On receiving a demand signal from a specific opening line the Crosrol Pre-Cleaner automatically self adjusts to the related pre-programmed cleaning program without the need for operator intervention thus ensuring that optimum fibre processing conditions are always guaranteed. The fully automatic reproducible settings provide a high level of operating convenience when frequent batch changes are required.

When the Pre-Cleaner is linked to a Crosrol Programmable Bale Opening machine the machines feeding rates are automatically optimised in line with the ABO to suit the current production rate required by down-stream opening machines.

The Crosrol singular low-density sheet format ensures that all Trash Particles are fully exposed to the cleaning actions of the machine.

Trash particles are concealed inside multiple dense rolls of material with other similar available types of first stage

cleaning machines.

Material processed in a Singular Low-Density Sheet format

Material processed in a Singular Low-Density Sheet format

Unlike other first stage cleaners that have multiple random attempts to open & clean the material, The Crosrol Pre-Cleaner (CPC) processes a singular sheet of low density material which ensures that each singular tuft of material is subjected to exactly the same degree of opening and cleaning as the next tuft,

This unique working principal ensures that all trash particles are fully exposed to the cleaning actions of the machine rather than been concealed (as with other similar types of machines) inside multiple dense rolls of material, this unique feature of the Crosrol Pre-Cleaner also ensures that nap generation and fibre damage are kept to an absolute minimum.

CBO - Crosrol Blending Opener

The range of Crosrol Blenders with their unique combination of advanced design features have for many years provided massively enhanced blending power in comparison with conventional serial-fill blenders.

Now the latest generation of Crosrol Blending Openers (C80) offer the possibility of incorporating a uniquely flexible Opening Module, which can provide additional Opening & Cleaning for types of fibres where additional cleaning is required all within the same one Blending unit resulting in major space, energy and investment savings.

Opening Module for Complete Flexibility

The newly introduced Crosrol Pinned Opening Module (POW provides added flexibility to any opening line; with its unique adaptation to the standard range of Crosrol Blending Openers a complete flexible solution for

any type of fibre can be quickly achieved.

Material Feeding

A loose layer of tufts from

the upper mixing chambers are transported via a secondary (upper) conveyor and condensed before been lightly gripped by the Opening Modules precision feed rollers.

Opening & Cleaning Configuration

The inverter driven Spirally Pinned opening beater opens fibres and loosens the trash, the loosened trash particles are removed by a bank of automatically (Dial-in settings) adjustable grid bars.

Flexibility Through Design

The complete Pinned Opening Module can be removed from the Crosrol Blending Opener within only a few minutes allowing for the unit to be 'Bypassed' from the opening line process when the material been does not warrant the additional cleaning that the Opening Module provides.

Unique Blending Power

* Random filling of the chambers avoids the complexity of the conventional 'flap' distribution system and effectively doubles

the blending capacity of serial fill blenders.

1 Control Feed rollers at the base of each chamber operate at different speeds in ratios of up to 1:1.4.

I!. Columns of fibre in each chamber are of differing heights, in conjunction with the 'sandwich' blending on the conveyor belt

further enhances blending power.

Advanced Features as Standard Lead to

Excellent Machine Performance

4.

Four & Six chamber versions with various heights in the range of 4.0M to 6.0M ensure an optimum mixing system can be achieved for any individual application.

5. Dust is continuously removed through perforated screens in the upper chamber; extensive surface aids effective cleaning.

1. Entire system designed to preserve the very small tuft sizes achieved by up-stream opening machines, Special Spirally Pinned aluminium opening beaters in conjunction with feed rollers in each blending chamber further reduces tuft sizes.

* Belt conveyor provides direct feed to down-stream cleaning machines saving space, energy and investment costs, Air Doffed applications are available as an option if required.

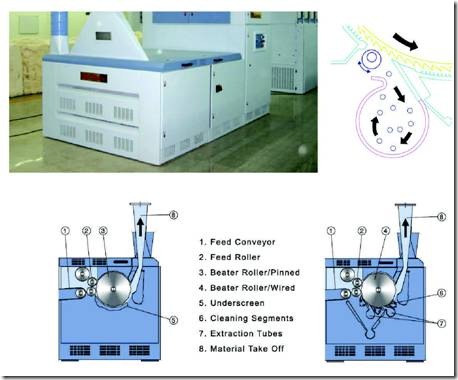

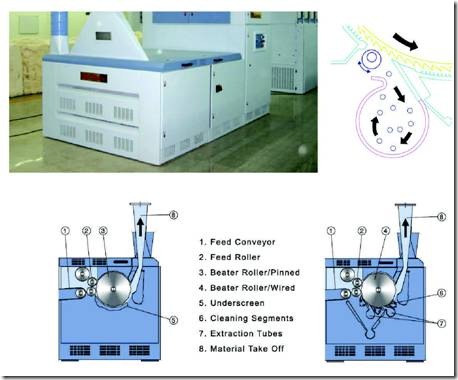

CFC - Crosrol Fine Cleaner

CFC - Crosrol Fine Cleaner

The Crosrol Fine Cleaner (CFC) is usually regarded as the final Cleaning point in an Opening line and is used to process both Natural and Synthetic fibers, The 1500mm working width (Standard with all Crosrol Blowroom machines) ensures a gentle action with the additional ability to give very high production rates (Up to 750Kg' s per hour).

The single beater roll concept significantly reduces the negative side effects familiar with Multi-roll intensive cleaners — i.e. higher nep counts and loss of good fibres, This together with a wide range of Pinned and Wired beaters ensures that the

Crosrol Fine cleaner range of machines gives optimum Cleaning and increased fibre yield during this vital stage of the opening line.

Pinned Opener / Cleaner (CFC-P)

MATERIAL Feed System:

The machine is fed by Feed Conveyor from the preceding machine, the speed of the conveyor is Inverter driven with simple dial-in speed changes made from the Touch screen display so as to optimise the production and cleaning capabilities of the machine, The wired covered feed roller ensures gentle yet effective controlled fibre feeding to the beater roller.

(a) Opening & Cleaning Configuration:

The Inverter driven single cylinder Pinned (6-lag fully pinned or 3-lag kirschner) beater roll (dial-in speed control) interacts with trash removal knives or solid under-screen (as applicable) to provide gentle opening of the fibres.

Wired

Opener I Cleaner (CFC-W)

Opening & Cleaning Configuration:

The Inverter driven single cylinder wired beater roll (dial-in speed control) interacts with specially developed multiple pinned combing segments and trash removal knives (where applicable) to provide gentle opening and maximum release of dust and entangled trash particles.

Waste Control System:

Waste removal levels are controlled by air control Kars located before each of the trash knives, These simple yet robust control devices can be adjusted during normal production.

Mounted directly adjacent to the trash knives are individual extraction tubes. The system of direct suction offers considerable advantages over conventional waste chambers with increased dust removal values giving a positive effect on yarn quality and operating efficiencies in open end spinning.

CDR - Crosrol Dust Remover

The Crosrol Rotary Dust Remover (CDR) is a purposely-designed unit for the removal of fine & micro dust found in cotton material, the unique design of the Crosrol Rotary Dust Remover ensures unsurpassed cleaning efficiencies are achieved. Effective De-dusting of the material is paramount to running efficiencies in down stream machines specifically in rotor spinning applications. A good de-dusting also leads to considerably higher efficiencies (fewer yarn breaks) in the winding room, Knitting & Weaving mills.

With the unique design of the Crosrol Rotary Dust Remover, not only are positive pressures used to de-dust the material but also significantly high negative pressures are applied so as to obtain the ultimate in De-dusting.

At the heart of the Crosrcil Dust Removal Unit is the rotating perforated disc. The tufts of fibre are blown on to the upper sector of the rotating disc's surface under positive pressure. To the rear of the disc a negative pressure is applied which holds the material on to the disc assisting in the removal of the fine dust particles.

CFT - Crosrol Feed Tower

The Crosrol Feed Tower (CFT) is primarily used to feed the range of Crosrol Fine Cleaners when the blending function of a Crosrol Blending Opener is not required, it can also be used as a stand-alone unit to provide material storage so as to ensure a consistent and even feed of material to down stream machines (Chute Feed Lines).

Multiple Feed Towers can be fed from a single source (similar to Chute Feeds) without the need for Distributing valves thus ensuring consistent teed and lower exhaust air than with other manufacturers of Feed towers.

Material Feed System

The air borne material is fed into the pressure controlled reserve chamber via a standard material transport fan (MTF). The material is separated from the dust laden air by means of large perforated screens which results in highly effective de-dusting of the material.

Opening & Cleaning Configuration

The inverter driven feed rollers ensure a constant and controlled feed is delivered from the reserve section. The Spirally Pinned opening beater interacts with the fully adjustable Pinned Combing bar to open and loosen trash particles from the material, The loosened trash is removed by means of the multiple grid bars, who's settings can be adjusted with one single action enabling simple adjustments lobe made to waste removal levels.

Material Doffing

The Opened and Cleaned material can be doffed from the machine via conveyor belt to a connecting machine or simpty by air (Air-doffed).

As the disc rotates the tufts of fibre move from the upper to the lower sector of the disc, The lower sector is isolated from the negative pressure thus allowing the Fibre to be freely released from the disc surface.

By adjusting the disc's rotational speed an ideal density of fibres can be formed on the disc's surface for any given production rate.

Unique Key features

Specifically developed stationary inlet duct distributes the in-coming fibres over a large area of the rotating disc,

Simple Rotating Perforated Disc (Inverter controlled) to transfer the fibres through negative and positive quadrants of the unit.

Minimal moving parts ensure simple operation with ultimate reliability of the unit assured.

tl Machine operation insensitive to pressure changes negating the need

for additional fans thus significantly reducing power consumption.

CHB - Crosrol Hopper Blending Opener

CHB - Crosrol Hopper Blending Opener

Where the scale of type of blowroom does not require an Automatic Bale Opener, the Crosrol Hopper Blending Opener (CHB) opens B blends material hand-fed from bales, The machine produces fine open tufts of fibre, delivered by apron conveyor directly to a beating machine or alternatively it may be air-doffed to the next machine in the opening line.

Feed conveyor of virtually unrestricted length, in 2.5M increments for maximum pre-mixing of bale material.

Large mixing chamber ensures thorough mixing of the tufts.

Surplus material brushed from the lifting lattice by evening roller accumulates in the reserve chamber, blending with newly fed material until height adjustable photo-electric sensors indicates that the required maximum capacity is reached. Degree of opening may be increased by reducing the clearance between evener roller and the lifting lattice.

roller with four pinned bars removes, mixes and opens the material from the lifting lattice and drops it down

on to the delivery unit.

Machine can be supplied with fibre condenser for automatic feeding of material to the machine.

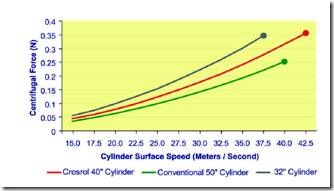

HPS - Heavy Particle Separator

Crosrol Heavy Particle Separators (HPS) offer not only a simple solution to the removal of foreign parts but a unique and highly effective way of removing larger trash particles from the material been processed. With no electrical power usage the Crosrol Heavy Particle Separator ensures that there is no simpler or cheaper solution.

Utilizes centrifugal action to remove loose impurities and foreign matter heavier than here tufts from a stream of air-doffed material, with minimum loss of good fibre.

No moving parts individual adjustable grid bars at the foot of a 'U' bend deflect the heavier particles down into a large collection chamber.

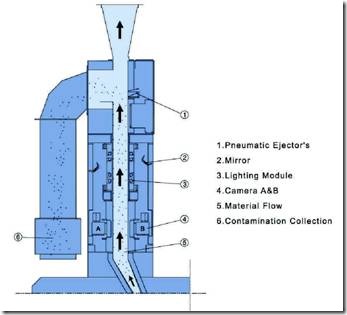

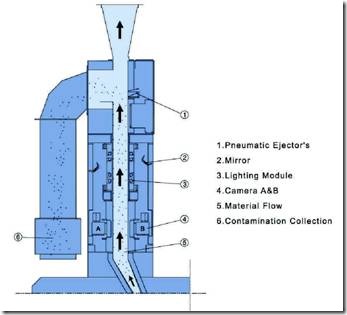

CSN - Croscan Foreign Fibre Detector

CSN - Croscan Foreign Fibre Detector

The range of Croscan Foreign fiber detector's aim to provide an effective and economical solution to your foreign matter contamination.

Croscan utilizes high resolution image processing European cameras. This new image acquisition and processing concept allows high speed image reading at 7000 lines per second with 2560 colour pixels per line per camera.

This type of high resolution is the only practical way to be sure of detecting even the smallest contaminants found in the opening process, and is vital to maintain consistent detection levels even with the slightest colour variation.

Sensitivity is easily adjustable for various raw material parameters.

Positioning of the Croscan Unit

Due to the small size of the Croscan unit, it can usually be mounted directly onto the last opening machine in the blowroom line eliminating the need for additional floor space and the unnecessary long duct runs which ultimately lead to blockages and nes generation that are generally seen with other types of foreign matter detector systems.

Illumination and Scanning Zone

Illumination and Scanning Zone

The fibres pass an enclosed glass section which incorporates the lighting tubes and mirrors. The whole assembly is designed so that it can be quickly withdrawn from the machine for cleaning. Optional Ultra-violet lighting is available for certain applications.

Integrated Electronic (Camera) operating System

The machines electronic operating system is fully built into the high speed European colour camera's, which use highly iota grated components, No PC / circuit boards / windows software are used in Croscan thus ensuring more reliable and consis tent detections are always achieved.

Pneumatic Ejection Valves for Minimum Lint Removal

The foreign matter is ejected using large European pneumatic nozzles to 32 per machine) so as to ensure effective

removal of the contaminates from the high-speed fibre flow.

Operator Controls

The Croscan uses a mouse operated LCD colour display screen to input the detecting parameters and to display the actual operating data. The display can be mounted either on the machine or remotely positioned in a local supervises office. Fitted to the machine are only four key operated Rotary switches, which allow the user to make simple operating changes such as:

- Camera Display

- Ejection levels for different blends - Size of contaminates to be ejected

Excess Air Box (AIREX)

Excess Air Box (AIREX)

A simple means of extracting excess transport air and any air-borne dust. The Airex Box is typically installed after the Automatic Bale Opener in Synthetic installations.

Air (and dust) from the material transport system passes along a perforated section of ducting inside the airex box. The excess air and dust are extracted through perforations to the central filter, Adjustable damper controls the amount of air extracted.

Double Magnet Traps (DMT-Z)

Extra powerful Z type Magnetic separator usually fitted at an early stage of the opening line to remove significant metal objects from the material flow.

Double deflection of airflow deposits ferrous debris on two pairs of powerful magnets.

Cs Magnets mounted on hinged panels for easy removal of debris. Inspection windows provided for visual inspection of waste debris,

Which has been deposited on the magnetic surfaces.

Pneumatically Operated Distribution Valves (2WD 1 3WD)

Pneumatically Operated Distribution Valves (2WD 1 3WD)

The Crosrol range of two and three way pneumatically operated distribution valves are used primarily for distributing the material flow from a singie source into multiple opening lines.

These types of valves operate automatically (Programmed) in conjunction with up-stream and down-stream opening machines without the need for operator intervention offering

a simple yet effective solution to material handling.

Double Magnet Traps (DMT-S)

Magnetic separators offer basic yet reliable protection against ferrous debris in the material flow, usually f tied at the end of the opening line so as to protect venerable down stream processing machines.

Double deflection of airflow deposits ferrous debris on two pairs of powerful magnets.

Magnets mounted on hinged panels for easy removal of debris.

Manual Diverter Valves (MDV)

Manual Diverter Valves (MDV)

Where installations process a wide range of different materials, Manual Diverter Valves are supplied and fitted within the ductwork to allow complete bypass of a particular opening machine.

T Piece Distributor (TPD)

When two lines of carding machines are to be fed from a single opening line, a T Piece Distributor is used so as to evenly

distribute the material flow into the two separate chute lines.

Material Transport Fan (MTF)

A graduated range of material Transport Fans are available suitable for all instances within the opening line, the fan geometry is optimised for a material-protecting throughput of fibres.

Fill Depending on the application, the fans operate at a constant speed or are controlled by Invertorsm, the necessary motor power is individually calculated for each fan resulting in minimal power usage.

All Crosrol Material Transport Fans use only high-grade aluminium impellers to ensure efficient operation with much reduced chance of spark generation.