JACK: 1. A blade having high and/or low butts used to actuate the movement of latch knitting needles. 2. Part of a dobby head designed to serve as a lever in the operation of the harness of a loom.

JACKET: 1. A woven or felted tubular sleeve for covering and shrinking on a machine roll. 2. A short coat. 3. In polymer manufacture, an external shell around a reaction vessel. For example, jacketed vessels are used when heat-transfer medium is circulated around the vessel.

JACQUARD: A system of weaving that utilizes a highly versatile pattern mechanism to permit the production of large, intricate designs. The weave pattern is achieved by a series of punched cards. Each card perforation controls the action of one warp thread for the passage of one pick. The machine may carry a large number of cards, depending upon the design, because there is a separate card for each pick in the pattern. Jacquard weaving is used for tapestry, brocade, damask, brocatelle, figured necktie and dress fabrics, and some floor coverings. A similar device is used for the production of figured patterns on some knit goods.

JASPÉ: 1. A fabric used for suiting, draperies, or upholstery characterized by a series of faint stripes formed by dark, medium, and light yarns of the same color. 2. A term describing carpets having a faint striped effect.

J-BOX: A J-shaped holding device used in continuous operations to provide varying amounts of intermediate material storage such as in wet processing of fabrics and in tow production. The material is fed to the top and pleated to fill the long arm before being withdrawn from the short arm.

J-CUT: In tufting cut-pile carpet constructions, uneven cutting of the loops caused by poor adjustment of knives and hooks or excessive tension.

JEAN: Cotton twill fabric, similar to denim, but lighter and finer, in a 2/1 weave for sportswear and linings.

JERK-BACK: See PULLED-IN FILLING. JERKED-IN FILLING: See PULLED-IN FILLING.

JERSEY: 1. A circular-knit or flat-knit fabric made with a plain stitch in which the loops intermesh in only one direction. As a result, the appearance of the face and the back of a jersey fabric is wholly different. 2. A tricot fabric made with a simple stitch, characterized by excellent drape and wrinkle recovery properties.

JET: 1. A device used to bulk yarns by introducing curls, coils, and loops that are formed by the action of a high velocity stream, usually of air or steam. (Also see TEXTURING, Air Jet Method.) 2. See SPINNERET.

| JET DYEING MACHINE: A high-temperature piece- dyeing machine that circulates the dye liquor through a Venturi jet, thus imparting a driving force to move the fabric. The fabric, in rope form, is sewn together to form a loop. JET LOOM: A shuttleless loom that employs a jet of water or air to carry the filling yarn through the shed. (Also WEFT INSERTION.) |  |

| JIG: A machine in which fabric in open width-form is transferred repeatedly from one roller to another, passing each time through a bath of relatively small volume. Jigs are used for scouring, dyeing, bleaching, and finishing. JUTE: A bast fiber used for sacking, burlap, and twine as a backing material for tufted carpets. |  |

preparing jute for market. The fibers are 0.4 to 1 inch in length. Jute butts are used in twines and coarse bagging.

JUTE COUNT: The weight in pounds of a spindle of 14,400 yards of yarn.

K

KAPOK: Short, lightweight cotton-like fibers from the seed pod of trees of the family Bombacabeae. A very brittle fiber, it is generally not spun. It is used for stuffing cushions, mattresses, etc., and for life jackets because of its buoyancy and moisture resistance.

KERATIN: The basic protein constituent of wool and other hair fibers.

KERSEY: A heavily fulled or milled woolen fabric having a high lustrous nap and a “grainy” face, kersey is frequently used in overcoats.

KHAKI: 1. A light yellowish brown. 2. A khaki-colored cloth of cotton, wool, or combinations of these fibers with manufactured fibers used primarily in military uniforms and workclothes.

KIER: A large metal tank, capable of being heated uniformly, used for wet processing.

KIER BOILING: Process of boiling cellulosic materials in alkaline liquors in a kier at or above atmospheric pressure.

KINK: 1. In fabrics, a place where a short length of yarn has spontaneously doubled back on itself. 2. In yarn, see SNARL.

KINKING: The doubling back of yarn on itself to relieve torque imparted by twisting or texturing.

KINKY THREAD: See KINK.

KNEE BREAK-OUT TEST: A method to evaluate the performance of fabrics, especially boys’ wear, when subjected to abrasion, stretch, and impact forces under conditions which simulate ordinary wear at the knee.

KNEEING: Abnormal behavior of a spinning threadline (especially in melt spinning) in which one or more filaments form an angle (knee).

KNIT-DE-KNIT: See TEXTURING, Knit-de-Knit Method.

KNIT FABRIC: A structure produced by interlooping one or more ends of yarn or comparable material. (Also see KNITTING.)

KNIT-MISS: A form of tricot knitting in which yarns on each bar of a two-bar machine are knit at alternate courses only. This type of knitting permits the use of heavy-denier yarns without creating undesirable bulkiness in the fabric.

KNITTING: A method of constructing fabric by interlocking series of loops of one or more yarns. The two major classes of knitting are warp knitting and weft knitting, as follows:

1. Warp Knitting: A type of knitting in which the yarns generally run lengthwise in the fabric. The yarns are prepared as warps on beams with one or more yarns for each needle. Examples of this type of knitting are tricot, milanese, and raschel knitting.

Milanese Knitting: A type of run-resistant warp knitting with a diagonal rib effect using several sets of yarns.

Raschel Knitting: A versatile type of warp knitting made in plain and Jacquard patterns; the latter can be made with intricate eyelet and lacy patterns and is often used for underwear fabrics. Raschel fabrics are coarser than other warp-knit fabrics, but a wide range of fabrics can be made. Raschel knitting machines have one or two sets of latch needles and up to thirty sets of guides.

Tricot Knitting: A run-resistant type of warp knitting in which either single or double sets of yarn are used. (Also see TRICOT.)

2. Weft Knitting: A common type of knitting, in which one continuous thread runs crosswise in the fabric making all of the loops in one course. Weft knitting types are circular and flat knitting.

Circular Knitting: The fabric is produced on the knitting machine in the form of a tube, the threads running continuously around the fabric.

Flat Knitting: The fabric is produced on the knitting machine in flat form, the threads alternating back and forth across the fabric. The fabric can be given shape in the knitting process by increasing or decreasing loops. Full-fashioned garments are made on a flat- knitting machine. (Also see FLAT-KNIT FABRIC.)

KRAFTCORD: This yarn produced by tightly twisting plant fiber is sometimes used in carpet backings.

KRAFT PULPS: Pulps prepared in the alkaline liquor consisting of sodium hydroxide, sodium carbonate, and sodium sulfide. Also called sulfate pulp.

KRAFT YARN: A yarn made by twisting a strip of paper manufactured from kraft pulp.

KROY® SHRINKPROOFING PROCESS: Continuous process for shrinkproofing wool tops in which there is a direct chlorination step with no intervening chemical reaction followed by anti-chlorination and neutralization. Provides better hand and strength than does conventional shrinkproofing.

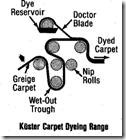

KUSTERS DYEING RANGE: Continuous dye range for carpets. The unit wets the carpet, applies dyes and auxiliary chemicals by means of a doctor blade, fixes the dyes in a festoon steamer, and washes and dries the carpet in one pass through the range. An optional auxiliary unit may be installed to randomly drip selected dyes onto the background shade for special styling effects. This process is called TAK dyeing.