A new dimension in drawframe technology

With the new RSB-D 40 autoleveler drawframe and the SB-D 40 drawframe Rieter has again achieved a quantum leap in draw-frame technology. The drawframe is the fi nal stage in the spinning process in which quality can be signifi cantly improved. Fluctuations in mass that are not eliminated on the drawframe reappear undiminished in the yarn. This is where the new Rieter drawframes reveal their decisive advantages – and

at delivery speeds of up to 1 100 m/min.

SUPERIOR YARN REGULARITY (USTER CV%)

· Further improved scanning precision and control dynamics

· Self-adjusting autoleveling function AUTOset

· Precise fi ber guidance in the drafting system

· Gentle web condensing with new web nozzle

SUPERIOR LONG-TERM COUNT MAINTENANCE (A%)

· Precise autoleveling, even with fl uctuating infeed quality

· Accurate autoleveling operation from start to fi nish

· Sliver coiling without false draft thanks to patented tube geometry

ENHANCED YARN CLEANLINESS

· Novel suction system with periodically lifting cleaning lips on the top rollers

· Uniform cleaning effi ciency due to automatic fi lter cleaning

· Neat coiling of manmade fi ber slivers and their blends using the CLEANcoil coiler

CONSISTENT QUALITY

· Stable, climate-resistant sensor technology

· Consistently short scanning length at all speeds

· Independent autoleveling system due to the single-head principle

· Rapid load relief on the top rollers in the event of lap formation

· Load relief on the top rollers in the event of machine stoppages

· Rieter Quality Monitor (RQM) online quality monitoring system

These advantages are based on wide-ranging experience with more than 24 000 Rieter drawframes that have been successfully installed in 100 countries.

High spinning effi ciency at low capital cost

The RSB-D 40 and SB-D 40 signifi cantly raise quality standards in spinning mills at minimal capital cost. You achieve rapid payback of invested capital as a result of the high quality and signifi cantly improved running properties in subsequent processes.

HIGH PRODUCTIVITY

· Delivery speeds of up to 1 100 m/min in mill operations

· Delivery speed at least 10% higher than the previous model, with equal – in most cases even better – yarn quality

· High effi ciency due to faultless running, large can formats and short downtimes

· Up to 10 tonnes of sliver per day and drawframe

(sliver weight 7 ktex)

LOW OPERATOR EFFORT

· Superior accessibility through wide-opening hoods

· Perfect running behavior of the Rieter 4-over-3 drafting system

· Fast lap removal through rapid load relief on the top rollers

· Pneumatic sliver threading aid

· Easy operation with illustrated graphic display

· Automatic can changer with empty can feed for up to 8 cans

· Reduction in can transports due to large can formats up to 1 000 mm in diameter on the SB-D 40

LOW CLEANING EFFORT

· Novel cleaning lips keep top rollers clean

· Sliver path with suction system

· Automatic fi lter cleaning

· Long cleaning intervals when processing manmade fi bers

due to the honeycomb structure of the CLEANcoil coiler

LOW MAINTENANCE EFFORT

· Readily accessible central lubrication system

· Maintenance-free AC drive technology

· Low laboratory eff ort due to online quality monitoring

by the Rieter Quality Monitor (RQM)

· AUTOhelp integrated spectrogram diagnosis for rapid trouble-shooting

· SLIVERprofessional expert system on CD for setting recommendations and fault analysis

· Operating instructions and spare parts catalog on CD with video fi lms for better understanding

RAPID BATCH CHANGE

· Central setting of drafting distance without gauges

· AUTOset self-adjusting autoleveling

· Batch data management by MEMOset

LOW ENERGY CONSUMPTION

· Belt drives instead of complex gear arrangements

· Small number of motors and inverters compared to other drive concepts

· Lower masses and fewer drive elements reduce energy consumption by up to 10% compared to the predecessor model

COST SAVINGS IN DOWNSTREAM PROCESSING

· Small number of roving or fi ber ends down on the roving frame and fi nal spinning machine due to excellent sliver regularity

· Fewer clearer cuts on the winder or rotor spinning machine as a result of fewer yarn defects

· Good running properties in weaving operations due to low variation in yarn tenacity

· No quality outliers

Rapid response to market requirements

Flexibility in raw material selection and machine utilization is an important prerequisite for a successful spinning mill. You can respond rapidly to your customers‘ needs with the RSB-D 40 and SB-D 40.

HIGH FLEXIBILITY

· 70% of all applications with only one pair of scanning discs

· CLEANcoil – the coiler for all materials

· Integrated, non-mechanical sliver separation function for processing manmade fi bers

· Short-staple cotton can also be processed very well

· Batch data management by MEMOset

· Uniform operating philosophy on all Rieter machine displays for fl exible personnel assignment

· Variable drawframe layouts for optimum utilization of space available in the spinning mill

Advantages of the concept

RIETER – THE TRENDSETTER

Rieter was the fi rst manufacturer to introduce the concept of single-head drawframes some 25 years ago. This concept off ers quality, flexibility and operating advantages and has since continued its victorious progress even in traditional double-head drawframe markets.

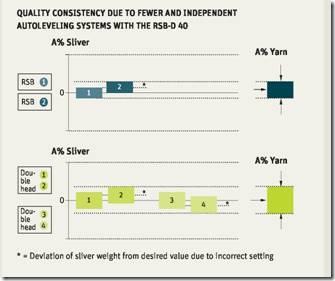

SUPERIOR QUALITY DUE TO INDEPENDENT AUTOLEVELING SYSTEM

The RSB-D 40 single-head autoleveler drawframe stands out for its high autoleveling and thus high sliver quality. This is also guaranteed by the independent operation of the autoleveling system. By contrast, a double-head autoleveler drawframe has the disadvantage – due to its design – that the drives of both autoleveling systems are connected via a common drawframe system delivery roller. The two autoleveling systems therefore infl uence each other and this results in inferior sliver quality.

A crucial factor in sliver quality is the accurate coordination of mechanical systems, drive, electronics and software. An experienced and well-coordinated development team resolved this decisive issue at Rieter. Double-head drawframes with autoleveling components from diff erent manufacturers do not produce even remotely comparable autoleveling results.

The signifi cantly better sliver regularity and coiling free of sliver breaks on the RSB-D 40 result in higher productivity on roving frames, spinning machines and winders as well as higher roving and yarn quality.

CONSISTENT QUALITY DUE TO FEWER AUTOLEVELING SYSTEMS Especially when several autoleveler drawframes are producing sliver for one yarn blend, accurate adjustment of the required sliver count on each individual drawframe is of highest importance. Any incorrect setting of the required sliver weight, caused for example by errors in determining the weight in the laboratory, directly increases variances in yarn count throughout the blend. In mill operations this is frequently a reason for fl uctuations in yarn count.

Due to the high productivity of the RSB-D 40, the number of autoleveling adjustments is much smaller than on double-head drawframes running slowly and with lower effi ciency. Consequently, the risk of personnel-induced fluctuations in sliver count and thus yarn count is reduced with the RSB-D 40.

PRODUCTIVITY DUE TO HIGH DELIVERY SPEED AND HIGH EFFICIENCY

The productivity of the RSB-D 40 single-head drawframe compared to a double-head drawframe is incorrectly rated when the calculation is simply based on speeds quoted in sales literature and the number of heads. In the case of the RSB-D 40, delivery speeds of 850 m/min are already standard in mill operations when processing carded cotton in ring spinning applications. In rotor spinning applications even higher delivery speeds are already reality.

In addition to the signifi cantly higher delivery speeds of the RSB-D 40 in mill operations, production effi ciency is 10% to 20% higher than that of double-head autoleveler drawframes. At each sliver break in a feed can, can change at the infeed or delivery end, machine malfunction or maintenance operation, only one drafting system head is stopped on the RSB-D 40 – instead of two heads in the case of the double-head drawframe. This advantage increases with rising delivery speed. In addition, the empty can magazine with up to 8 reserve cans, the robust rotary can changer, trouble-free running and long cleaning intervals in the drafting system zone result in high effi ciency. Productivity is therefore also more independent of operators‘ infl uence.

SIMPLICITY DUE TO VERY GOOD ACCESSIBILITY

Accessibility is considerably better on the Rieter single-head drawframe than on any double-head drawframe, i.e. operating, adjusting and maintenance work can be performed more easily and therefore faster. This simplicity also motivates personnel to carry out optimization and maintenance operations willingly – quality and machine availability are assured.

FEWER TRANSPORT MOVEMENTS AND SLIVER PIECINGS DUE TO LARGE CAN FORMATS

The use of large feed cans with a diameter of 1 000 mm in a short, 2-row feed creel only makes sense on single-head drawframes in terms of the accessibility of the slivers and thus productive working methods.

The SB-D 40 (without autoleveling) enables 1 000 mm diameter delivery cans to be fi lled. Double-head drawframes of Asian design can only fi ll cans up to 400, 500 or 600 mm in diameter. This amounts to as many as 200 000 fewer can transport movements and sliver piecings a year with the Rieter drawframe and gives corresponding benefi ts in terms of operator eff ort and quality. For example, the number of cuts on the winder is reduced by using larger can formats.

New RSB concept – even more precise, faster and more fl exible

THE RSB AUTOLEVELING PRINCIPLE

Fluctuations in sliver weight of up to ± 25% can be balanced by means of digital, high-precision RSB autoleveling. Fluctuations in the mass of the feed slivers are detected by „tongueand-groove“ scanning discs. In this case the signals are collected at short, constant intervals, thus ensuring very high precision, even at maximum speed. The autoleveling processor uses the measured signals to compute a required speed for the highly dynamic AC servo drive. This value is transmitted to the drive exactly when the length of sliver measured reaches the drafting point in the main drafting zone. The result is a sliver with outstanding short, medium and long-term regularity.

PERFECT AUTOLEVELING STARTS WITH SCANNING ACCURACY Perfect autoleveling starts with the accuracy of feed sliver scanning. Errors made here can be corrected neither by a control algorithm nor by higher drive dynamics. Compared to other tongue-and-groove scanning systems, RSB scanning stands out for its very high precision. The vibration-damping structure of the scanning unit, the use of a belt drive instead of sluggish bevel gears and the use of absolutely temperature-stable sensors are only a few of the features on which the legendary RSB precision is based.

The RSB scanning system‘s pair of rotating „tongue-andgroove“ scanning discs measure the feed slivers without friction. There are therefore no deposits – in contrast to a stationary measuring lever – and the sensor system provides precise readings over a long period without the need for maintenance.

The RSB sensor system applies higher scanning forces and can therefore also accurately scan fi ber slivers of diff ering bulk. This is especially useful when feed cans are in intermediate storage for diff ering periods, since fi ber sliver bulk then diff ers especially from can to can. Only RSB scanning guarantees correct scanning readings and thus the highest possible sliver count consistency, independently of the infl uence of operating personnel or material fl ow.

QUALITY DUE TO FURTHER IMPROVEMENTS IN SCANNING New and geometrically further optimized „tongue-and-groove“ scanning discs are used in the RSB-D 40. Measured-value resolution and thus the accuracy of mass readings has therefore

been signifi cantly improved. Scanning disc loading with a newly developed, high-precision spring instead of compressed air ensures extremely robust autoleveling. Scanning force is constant, i.e. no adjustment to the raw material specifi cation is necessary. Some 70% of all applications can be covered with one pair of scanning discs.

DIGITAL AUTOLEVELING SYSTEM WITH HIGHLY DYNAMIC DRIVE

Processing and implementing the precise scanning signals

right through to the drafting system calls for special know-how. The autoleveling processor processes the signals on the basis of a sophisticated computing algorithm and transmits them to the highly dynamic, maintenance-free AC servomotor. A planetary gear superimposes the variable speed of the servo drive on the constant basic speed of the main motor. The servomotor therefore only has to produce the output necessary for autoleveling and can thus be considerably smaller and therefore more dynamic than in concepts featuring individual drive motors. Piecings in combed slivers and coilers can also be leveled out reliably in this way.

FURTHER IMPROVEMENT IN AUTOLEVELING QUALITY ON THE RSB-D 40

The new drive concept ensures that the even more precise scanning readings are also transmitted right through to the drafting system, resulting in better sliver quality. The smaller mass of the dynamically powered drive elements compared to the previous model contributes to this. The drive concept with two fewer belts and the use of low-wear, ribbed V-belts improve power transmission accuracy. Supported by the high dynamics, this concept ensures that even the shortest sliver defects are reliably leveled out, even at delivery speeds of

1 100 m/min. With the new model, delivery speeds can be increased by at least 10% for all materials, in most cases also with signifi cantly improved or equal yarn quality.

AUTOset self-adjusting autoleveling

AUTOMATIC ADJUSTMENT OF THE LEVELING ACTION POINT The leveling action point is the most important setting value in autoleveling. It specifi es the point at which a defect detected between the scanning discs is leveled out in the main drafting zone of the drafting system. Defi ning the leveling action point is a complicated process and calls for know-how on the part of operating personnel. An incorrectly set leveling action point will even make sliver quality worse than in the process without autoleveling. To date, several sliver samples had to be produced with diff erent settings, taken to the laboratory and examined on the regularity tester until the optimum leveling action point was found. AUTOset makes this complicated process a thing of the past.

At the push of a button, AUTOset automatically runs through all leveling action points in approx. 1 minute. At the same time the Rieter Quality Monitor records the resulting quality values of the sliver produced. An algorithm (patent pending) automatically calculates the optimum leveling action point. The proposed value is accepted by the push of a button – and that‘s it! This saves valuable time and ensures correct settings and thus superior sliver quality, even with inexperienced personnel.

MEMOSET ARTICLE MANAGEMENT

The RSB-D 40 takes a further step toward simplifi ed operation with MEMOset article management. MEMOset enables operating personnel to use preset parameters based on a sound foundation of several thousand customer settings. For example, autoleveling intensity has had to be calculated by means of the so-called sliver test to date. This involved ascertaining the delivery sliver weight with diff erent numbers of feed slivers, e.g. 5-fold, 6-fold or 7-fold doubling, and adjusting autoleveling intensity on the basis of the result. Now the machine proposes a value depending on fi ber type, and this can be accepted at the push of a button. Manual optimization of the value is still possible.

MEMOset article management also enables diff erent machine settings to be stored. The machine control system can store a total of up to 20 diff erent articles. This speeds up material changes and increases machine availability.

Unparalleled cleanliness in sliver and yarn

THE DRAWFRAME ACTING AS A CLEANING MACHINE

During the drafting process fi ber/fi ber friction releases very short fi bers, dust and other attendant fi brous material in the drafting system. It is important to extract these substances reliably, immediately after they have been released.

The new generation of drawframes stands out for cleanliness in sliver and yarn that is unparalleled to date. This also has a positive impact on cleaning eff ort and running properties on the drawframe and in the subsequent process.

ENHANCED YARN CLEANLINESS DUE TO SUCTION AND CLEANING LIPS ON THE TOP ROLLERS

Cleaning lips resting on the top rollers direct the suction fl ow accurately into the drafting zones where extraction is required. The cleaning lips strip attendant fi brous material off the top rollers. Accumulations of dirt on the cleaning lips pass directly into the suction system as the lips are raised intermittently. Mill trials have documented less congestion in the sliver funnel due to accumulated dust on the pressure bar. Enhanced yarn cleanliness is refl ected in reduced IPI and Classimat defects as well as yarn clearer cuts. By comparison, conventional suction systems with cleaning bars are considerably less effi cient.

IMPROVED PRODUCTIVITY AND OPERATION

The cleaning lips (patent pending) and their confi guration reduce the formation of deposits on the top rollers of the drafting system and thus the cleaning eff ort required. The cleaning lips also have a positive impact during the processing of cotton containing honeydew. Fewer stoppages for cleaning and fewer laps in the drafting system increase the productivity of the machine.

CLEANLINESS AT THE SLIVER INFEED

Suction points at the sliver infeed, i.e. under the jockey rollers and prior to autoleveler scanning (see illustration on page 12), ensure optimum sliver cleanliness and low cleaning eff ort. A supplementary suction unit in front of the drafting system on the SB-D 40 also helps to improve dust removal further on the machine without autoleveling (see illustration above).

CONSTANT SUCTION PERFORMANCE WITH AUTOMATIC FILTER CLEANING

Automatic fi lter cleaning by means of a stripper maintains the vacuum and thus the cleaning effi ciency of the suction system at an almost constant, high level. This results in consistent sliver and yarn quality as well as running properties in the subsequent process. On other machines with manual fi lter cleaning, suction performance declines progressively due to the formation of a layer of dirt on the fi lter screen. This inevitably has an impact on quality and productivity in subsequent processes.

| QUALITY AND ECONOMY THROUGH PRECISE FIBER GUIDANCE The Rieter 4-over-3 drafting system is the heart of the draw-frame. The bottom rollers with high-precision fl uting and a pressure bar with a special profi le in the main drafting zone ensure accurate fi ber guidance. Advantages in terms of geometry and the bottom roller bearing permit smaller roller gaps than on other drawframes. The standard drafting system for delivery speeds of up to 1 100 m/min permits smaller roller gaps than on other drafting systems. This insures good processing of cotton types with short fi ber lengths or noil, and creates potential for economies in raw material use. The fourth top roller gently diverts the fi bers and also ensures perfect running properties. A redesigned web guide nozzle brings the web together especially gently after it leaves the drafting system and prevents unwelcome fi ber entanglement. VARIABLE LOADING WITH LARGE TOP ROLLERS Loading of the top rollers is variably adjustable by spring elements or pneumatically (option). Automatic load relief on the top rollers prevents deformation of the covers during machine stoppages which assures the quality of the sliver produced. The large diameter of the top rollers (38 mm) compared to competing products guarantees superior running properties with low roller temperature and long service life. RAPID LOAD RELIEF ON THE TOP ROLLERS IN THE EVENT OF LAP FORMATION In the event of lap formation, immediate load relief on the top rollers while the machine is still being braked prevents the formation of large, compressed sliver laps. This enables laps to be removed easily and quickly without using knives, and preserves the roller cover. Quality and machine productivity are assured. |

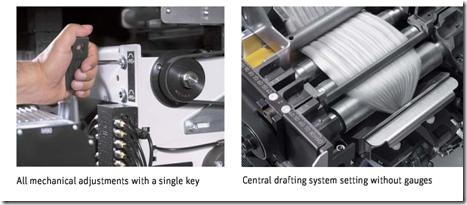

Central setting of roller gaps permits rapid blend changes. Break draft and main draft distances can be set independently of each other for the fi rst time. The roller gaps can be read off a scale, which makes setting gauges unnecessary. The belts can remain tensioned during setting. All mechanical settings can be performed with a single key.

The top rollers are swivel-mounted on the loading arm. This permits optimum accessibility. The sliver is threaded-in with the help of compressed air. The mounting bracket of the web guide nozzle is pivoted, which makes access to the take-off discs considerably easier. All technology components are designed so that they can only be used in the correct position. This prevents damage due to incorrect operation.

SHORT FIBER DRAFTING SYSTEM FOR UNIFORM DRAFTING OF SLIVERS CONTAINING VERY SHORT FIBERS

A short fi ber drafting system is also available as an option for processing fi bers less than 1 inch (< 25 mm) long. The even shorter drafting distances – compared with the standard drafting system – improve fi ber control and reduce floating fi bers. This has a positive impact on sliver and yarn quality. The use of smaller top rollers with a diameter of 36 mm enables a maximum delivery speed of 550 m/min to be achieved.

CLEANcoil – Innovation in coiling

CLEANCOIL FOR SLIVER COILING WITHOUT DEPOSITS OF FINISHING AGENT

Deposits of fi nishing agent sometimes occur on the underside of the coiler when manmade fi bers and blends are being processed. This has an adverse eff ect on quality values, causes displaced sliver layers or necessitates frequent cleaning. The CLEANcoil coiler resolves the problem with a honeycomb structure on its underside (patent pending), which is being used

for the fi rst time in the textile industry. When polyester is being processed, the cleaning cycle can vary from 2-3 hours to

1-7 days, depending on the type and amount of fi ber fi nish. Even with critical types of manmade fi ber, CLEANcoil guarantees high can capacity, neat sliver coiling and ensures trouble-free sliver running in the subsequent process. CLEANcoil is the new standard coiler for all materials, i.e. also for carded and combed cotton, and off ers maximum fl exibility.

RELIABLE SLIVER SEPARATION WITHOUT ADDITIONAL MECHANICAL DEVICES

Active sliver separation is necessary for trouble-free can changing when processing fi bers with high fi ber/fi ber friction, such as manmade fi bers. The new generation of drawframes makes its mark here with an ingenious solution. A thin place created between the drafting system and the take-off calender roller is transported until it is below the coiler, where it breaks when can change takes place. This solution (patent pending) requires neither additional mechanical devices nor drives as on conventional sliver separators. It is included in the machine‘s standard equipment.

Reliability with the Rieter Quality Monitor

CONTINUOUS QUALITY MONITORING

The Rieter Quality Monitor (RQM) reliably prevents the production of defective slivers. It operates independently of the auto-leveling unit. RQM continuously monitors the thickness of the sliver being delivered via the movable calender disc and stops the drawframe automatically when preset limit values are exceeded.

The calender discs are made from special steel with a low-wear surface coating. The higher precision of the sensor enables the number of sliver tests in the laboratory to be reduced further. RQM shows eight diff erent CV% readings, the A% value, the spectrogram and thick places on the machine display. Connection to Rieter‘s SPIDERweb data collection system is optional for more extensive analyses.

QUALITY DATA COLLECTED BY RQM

· Sliver count (A%)

· Sliver regularity (CV%) and length variation values for 5 cm, 10 cm, 25 cm, 50 cm, 1 m, 3 m and 5 m

· Current spectrogram

· Presentation of quality diagrams for up to 11 days

· Thick places > 2 cm

ADVANTAGES OF THICK PLACE DETECTION

· Monitoring of cleaning and maintenance services on the card, comber and drawframe

· Monitoring of the sliver piecing

· Assistance with technological optimization

· Improving sliver and yarn quality

· Ensuring higher productivity on the roving frame, fi nal spinning machine and winder

RAPID FAULT DIAGNOSIS WITH AUTOHELP

AUTOhelp fault diagnosis results in faster trouble-shooting and ensures high machine availability. When a spectrogram peak occurs, RQM stops the drawframe. Possible causes of faults ar indicated in the gearing layout on the machine display.

FEED SLIVER QUALITY DISPLAY

The A% and CV% readings of the feed slivers can now be displayed on the RSB-D 40. These values are ascertained by the scanning discs of the autoleveling unit. This helps personnel to detect and analyze defects in the upstream processes.

Control panel

RAPID INFORMATION AND SETTING

The keys on the control panel are labeled with simple, self-explanatory symbols. The display also shows all machine states in pictorial form. This simplifi es the operator‘s work considerably.

OVERVIEW OF CONTROL PANEL FUNCTIONS

· User-oriented operation:

1. Basic mode with reduced range of menu and data images

2. Expert mode with all setting options

· Direct selector keys for rapid access to frequently used functions

· MEMOset article management:

1. Rapid batch change via preset parameters

2. Up to 20 diff erent articles can be stored and retrieved

· Detailed display of machine stoppages, their reasons and duration

· Logbook for complete documentation of machine settings (change history)

· Languages: Chinese, English, French, German , Greek, Indonesian, Italian, Portuguese, Russian, Spanish, Thai, Turkish, Urdu

Low maintenance costs

ERGONOMIC, SAFE MACHINE DESIGN

The structure of the drawframe is asymmetrical, i.e. the main components such as scanning, drafting system and coiling are not in the center of the machine, but are off set in the direction of operating personnel. This also simplifi es operating procedures for personnel who are not so tall.

Three hoods open wide to provide optimum access to the main machine components, both from the side and from above. The wide work platform with handrails also improves working convenience and safety.

RAPID, EASY AND RELIABLE MAINTENANCE

In order to ensure maximum reliability, the drawframe‘s standard equipment includes a central lubricating strip, which supplies all the relevant points with lubricant. The lubricating strip is ideally accessible and reduces the risk of important lubrication points being forgotten.

A central, externally accessible lubrication system comprising only one lubricating nipple is also available as an option. In this case the machine signals its lubricating requirements and indicates to maintenance personnel on the control panel the amount of lubricant to be applied. Lubrication can actually be performed while the machine is running.

A further option is fully automated lubrication by means of a built-in pump with a large grease tank, which operates without any intervention by personnel. All central lubrication systems reduce maintenance eff ort and increase operating reliability.

LONG SERVICE LIFE OF COMPONENTS

The movement of air resulting from the pressure prevailing in the interior forces machine heat outward. The reduction in interior temperature and the vibration-optimized machine frame result in long service lives for electronic and mechanical components. All major components involved in fi ber guidance feature an especially resistant Rieter surface coating which ensures a long service life.

ROBUST, SIMPLE DRIVES

With the integrated extraction system the RSB-D 40 requires only four motors, i.e. three robust asynchronous motors and one AC servomotor with inverter. The SB-D 40 has only three asynchronous motors. Compared with other machine concepts, Rieter drawframes therefore need only a fraction of the motors and inverters and thus display higher reliability.

A voltage stabilizer is available as an option in order to ensure that the drawframes remain fully operational, even in the event of short-term fluctuations in mains power.

ENERGY SAVING

Mill trials indicate energy savings of up to 10% compared with the previous model, depending on the quality of the feed sliver. Belt drives instead of complex gear assemblies and the small number of motors and inverters keep energy consumption low. Furthermore, the lower masses being moved in comparison

to the RSB-D 35 and the shorter drive chain reduce energy consumption.

ELECTRONIC DOCUMENTATION

Operating instructions, spare parts catalog and electrical documentation are supplied both as hard copy and in electronic form on CD. User-friendly navigation and 3D illustrations in the electronic documents facilitate rapid location of the required topic. Video fi lms of all major setting operations ensure understanding and can be used for training personnel. A high level of personnel expertise ensures the quality and productivity of the drawframe.

SLIVERPROFESSIONAL EXPERT SYSTEM

SLIVERprofessional, the proven, machine-independent expert system on CD, is available as an option and provides valuable technological support.

Its main functions are:

· Recommended settings depending on the raw material for the machine as a whole

· Analysis of spectrogram defects: periods and drafting waves

· Managing batch data

· Analytical software in 11 languages: Chinese, Czech, English, French, German, Italian, Portuguese, Russian, Spanish, Turkish and Urdu

· Sphere of application: RSB-D 30/35/40 and SB-D 10/15/40

Sliver feed and can logistics at the delivery end

SLIVER FEED VERSIONS

Drawframe infeed can take the form of positively driven roller feed or a fi xed creel. The supports can be adjusted in height and adapted to the relevant can height. The following sliver feed versions are available depending on the space available in the spinning mill:

· Single or double-row can arrangement for 4 to 8-fold doubling (driven feed)

· Double-row, T-form can arrangement for 8-fold doubling in especially limited space (length) (driven feed); not for combed cotton

· Double-row can arrangement for 6 to 8-fold doubling (creel)

AUTOMATIC CAN CHANGER

All SB-D 40 and RSB-D 40 drawframes are equipped with an automatic rotary can changer. The complete range of cans with diameters from 210 mm to 1 000 mm can be handled. The empty cans are fed reliably on a roller conveyor. An additional motor is unnecessary. The empty can magazine accommodates up to 8 cans, depending on can diameter, which results in long running periods without personnel intervention. When space is limited in terms of machine length, shorter empty can magazines can also be chosen. The full cans are ejected onto the

fl oor or onto a can trolley (optional).

| CANlink is an economically attractive solution for automatic can transport between two drawframe passages. The operating principle of CANlink is remarkably simple: 1. The cans are fi lled at the fi rst passage 2. The full cans are automatically ejected into a reserve row 3. After the feed cans in the 2nd passage have been emptied, the reserve cans are pushed manually into the feed position and the empty cans are thus simultaneously ejected into the empty can position. The empty cans are transported automatically back to the 1st passage. |

· No cans are transported manually

· The top layers of sliver are not damaged by operating personnel

· Confusion between material is prevented

· Effi ciency of the drawframe pair is increased

· Changing time of feed cans is reduced

· Number of cans in circulation is reduced

· Clearly laid-out production lines

The drawframe in the spinning process

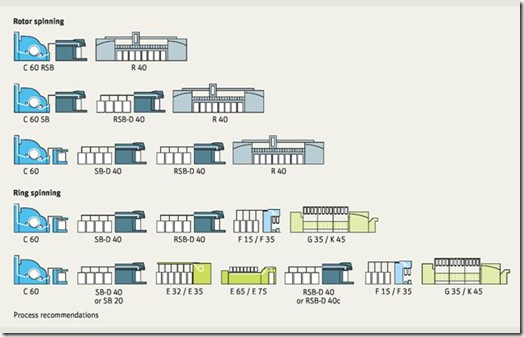

C 60 SB / RSB – BASIS FOR SHORTER PROCESSES

The C 60 card with integrated SB or RSB drawframe module e ables processes to be shortened, especially in rotor spinning. Rieter therefore always off ers the most economical process fo diff erent quality requirements.

RSB-D 40 – FOR SUPERIOR QUALITY, PRODUCTIVITY AND FLEXIBILITY

The RSB-D 40 is the ideal fi nal passage in any spinning preparation operation. Rieter autoleveling technology ensures outstanding running properties in subsequent manufacturing processes and the highest quality standards in the yarn and the end product.

SB-D 40 – THE PERFECT COMPLEMENT TO THE RSB-D 40

The SB-D 40 without autoleveling is the perfect partner for the RSB-D 40 for highly flexible lines operating with maximum effi - ciency. Delivery speed and output are ideally coordinated. The largely identical structure of the two models is an advantage

for operation and maintenance.

RSB-D 40C – AN ALTERNATIVE IN THE RIETER COMBING SET With a maximum delivery speed of 550 m/min, the RSB-D 40c autoleveler drawframe is especially suitable for use after the combing process.

Rieter Machine Works Ltd.

Klosterstrasse 20

CH-8406 Winterthur T +41 52 208 71 71 F +41 52 208 83 20 sales.sys@rieter.com