Investigation was carried out on how the tensile and related properties of Siro yarns, spun from two separated rovings of different types of materials, were affected by the twist factor and draft. Comparison on Siro yarns and two-fold yarns of the same linear density and twist factor revealed that the former was better in tensile strength and related properties. The Siro yarns are believed to be able to bear extra tension during manufacturing processes such as weaving and knitting.

Keywords : yarn strength, evenness, imperfections, hairiness.

1. INTRODUCTION

In Siro spinning, two parallel fibre strands, separated at a distance, are drafted simultaneously in the drafting zone. After they emerge from the front roller nip, they converge to form a yarn by twisting. Previous researches") mostly focused on studying spinning geometry and yarn parameters for producing yarn from rovings of the same fibre type. There has been very limited information available regarding the use of rovings of two different kinds of materials on the Siro system. Thus, the present work was designed to carry out some spinning trials on attenuating two rovings of different fibre materials in the drafting zone and to investigate the capability of the resulting Siro yarn.

In staple yarns, twist is essential to hold the fibres together and to impart some degree of cohesiveness to the structure. Twist is a means by which a bundle of fibres is held together so that the ultimate structure is made capable of withstanding the stresses and strains generated in the next manufacturing steps. The role of twist in yarn is essential to manipulate the yarn properties. Thus, the influence of twist on the Siro spun yarn tensile strength was also included in the present work.

2. EXPERIMENTATION 2.1. Selection of materials

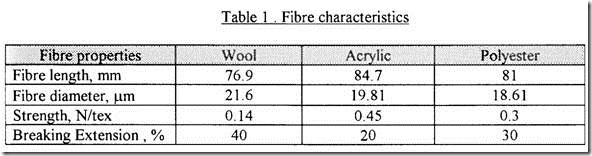

Wool, polyester and acrylic fibres were selected for the study. The characteristics of the fibres are shown in Table 1. All samples prepared for the present work were conditioned and tested under standard atmospheric conditions ( 20 + 2°C and 65 ±2 % relative humidity).

The Instruments for testing the fibre properties are listed in Table 2. The processing parameter used in drawing and roving are shown in Table 3. Table 4 gives the sequence of machinery used to produce the yarns.

2.2. Production of two-fold yarn

Comparison was made between Siro and two-fold yarns of the same linear density. A worsted twist factor of 2.2 [2600 (tpm x -qtex)] was adopted. This enabled the advantages of Siro yarn to be compared with those of two-fold yarn. Comparison was also made between the yarns of different linear density, to identify the effect of changes in draft on the properties of the two series of yarns.

Since the folded twist of the two-ply yarn should be equal to that of its corresponding Siro yarn, and the folded twist of a two-ply yarn is usually set at 70% of that of the single yarn, it is necessary to calculate the required twist that should be inserted into the single yarn by dividing the folded twist by 70%. Table 5 shows the required amount of twist inserted into the yarns.

3. RESULTS

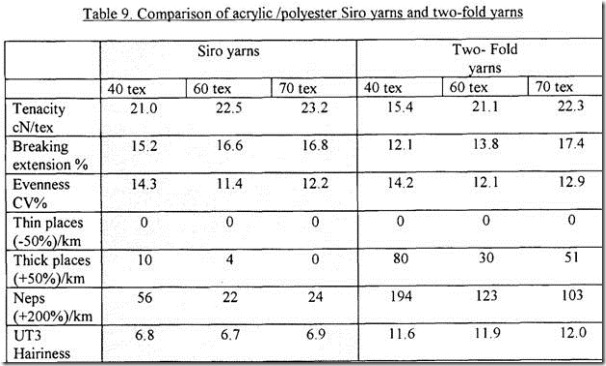

The properties of the Siro and two-fold yarns are compared in Tables 6-9. 3.1. Comparison and•evaluation amongst Siro and two-fold yarns

Referring to Table 6, for pure wool worsted yarns, when the yarn linear density increased from 40 tex to 70 tex, the tenacity of the two-fold yarns increased from 7.8 to 8.3 cN/tex while that of the Siro yarns increased from 6.7 cN/tex at 40 tex, 8.5 at 60 tex to 8.7 at 70 tex. The Siro yarns, except for the 40 tex, were significantly stronger than the two-fold yarns, by 4.7% to 14.9% at twist factor 2.2. The breaking extension of Siro yarns was also significantly better than that of the two-fold yarns, by 60% to 73%. The evenness of the two-fold yarns was better than that of Siro yarns. At the twist factor of 2.2, Siro yarns were significantly less hairy than the two-fold yarns, by 10% to 18%.

For the wool/acrylic blended yarns, in referring to Table 7, the tenacity of two-fold yarns increased from 9.7 cN/tex at 40 tex, to 11.0 at 60 tex and 11.6 at 70 tex. Tenacity of the Siro yarns increased from 13.3 to 15.4 cN/tex. The Siro yarns were significantly stronger than the two-fold yarns, by 32% to 37%. The breaking extension of the Siro yarns was higher than that of two-fold yarns, by 56% to 125%. The evenness of the Siro yarns was better than that of two-fold yarns. The yarn evenness CV% of the two-fold yarn ranged from 15.8 at 40 tex to 13.1 at 70 tex while the evenness CV% of the Siro yarns decreased from 15.5 to 11.9 as the yarn linear density increased. The hairiness of the Siro yarn was lower than that of the twofold yarn, by 44% to 50%.

From Table 8, it can be seen that the tenacity of wool/polyester Siro yarn was higher than that of the two-fold yarn, by 6% to 23%. The tenacity of the two-fold yarns increased from 13.9 cN/tex at 40 tex, 14.9 at 60 tex to 15.8 at 70 tex. The tenacity of Siro yarns increased sharply from 14.8 to 19.5 cN/tex. The breaking extension of the Siro yarns was higher than that of the two-fold yarns, by 3% to 20%. The evenness of the Siro yarns was also better than that of the two-fold yarns. The evenness of the Siro yarns and two-fold yarns ranged from 17.6 at 40 tex to 12.6 at 70 tex and from 18.6 at 40 tex to 13.9 at 70 tex, respectively. The Siro yarns were significantly less hairy than the two-fold yarns, by from 30% to 41%.

For the synthetic (acrylic/polyester) fibre blended yarns (Table 9), the tenacity of the two-fold yarns increased sharply from 15.4 to 22.3 cN/tex as the linear density increased from 40 tex to 70 tex. The Siro yarn again exhibited better tensile strength, by 4% to 27%, compared to the two-fold yarns; it increased from 21.0 cN/tex at 40 tex, 22.5 at 60 tex to 23.2 at 70 tex. The breaking extension was generally higher for the Siro yarns. The evenness CV% of the Siro yarns decreased from 14.3 to 12.2, and that of the two-fold yarns decreased from 14.2 to 12.9, as the yarn linear density increased. The two-fold yarns were more hairy than the Siro yarns. The hairiness of the two-fold yarns increased from 11.6 to 12.0 and the hairiness of the Siro yarns increased from 6.8 to 6.9 as the linear density increased from 40 tex to 70 tex.

4. DISCUSSION

The present work focused on a comparison of the yarn properties of Siro yarns and two-fold yarns of equivalent yarn linear density. It was found that the Siro yarns were generally superior to the two-fold yarns in terms of yarn strength.

The breaking strength of the Siro yarn is higher than that of the two-fold yarns of equivalent linear density due to the particular Siro yarn structure - due to the fibres being more firmly bound within the yarn structure. The two twisted strands of the drafted fibres caused some surfaces fibres to be trapped into the Siro yarn so as to increase the inter-fibre cohesion in the yarn which can withstand higher breaking forces. In Siro spinning, the sense of twist is the same for both the single ends and the composite product. This gives a yarn that is somewhat more compact , with a firmer core, than the usual two-fold yarn with opposing singles and folding.

The better tenacity of Siro yarn could also be ascribed to the fact that the single strands have comparatively low twist which results in better and more even load sharing by the constituent fibres. In the process of yarn formation, fibres distribution is subjected to the twisting operation. The combination of varying numbers of fibres per cross section with varying forces binding these fibres together because of twist variation leads to varying tensile properties.

Another relevant factor with respect to the inferior yarn strength of two-fold yarns is the additional freedom of lateral movement permitted to the fibres. During extension of the yarn, the plies become grossly deformed r.nd the lateral displacement of fibres at different initial positions appear to follow a complex pattern. Fibres initially in the centre of the plies begin to move towards the central yarn axis. Fibres at greater initial radial positions in the plies simultaneously begin to gather around their own ply axis which is already moving independently towards the yarn axis.

The Siro yarns generally also performed better than the two-fold yarns in terms of evenness and degrees of imperfections. This is because the Siro yarn is produced by two strands of roving ; there would be a better parallel and straightening effect between the separated fibre strands during drafting. Since peripheral distribution of fibres during spinning is a combined effect governed to a large extent by the staple length, fibre cross-sectional resistance to twisting and other process parameters, it would not be possible to deduce the exact relationship of the combined fibre parameters and yarn unevenness. The poorer uniformity of the two-fold yarns may also be due to the greater number of production processes involved in producing two-fold yarns as compared to Siro yarns.

K.P.S. Cheng & C.H. Yuen

Institute of Textiles and Clothing, The Hong Kong Polytechnic University