COSMOS - Two-for-one twister

Cosmos represents another Savio proposal in in the field of twisting to ensure maximum cost-effectiveness of the technological process through constructional solutions that allow a reduction in investment with a minimum of energy consumption. The aim of all this is to maximize the productivity of the machine, the quality of the package and the twisted yarn, along with the technological flexibility, that is today an indispensable requirement for any textile market.

Machine productivity

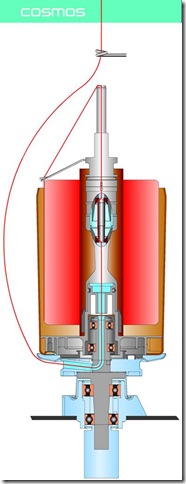

The spindle

Savio’s many years of experience in the creation of various models of twisters, and especially spindles, has allowed the development:

· range of rotors, with shapes and manufacturing techniques aimed at maximizing the weights of packages being fed, with different materials and counts, always giving priority to energy absorption.

· System of rotor rotation by means of two pairs of bearings:

the upper bearings, high-performance, with upper protections and maintenance free lubrication;

the lower bearings, lubricated with grease with separate external nipples.

· adjustment of twisting tension through a 6-position adjustable system.

Quality of yarn and package

Special attention has been given to:

· reduction of twisting tension through optimization of the shape of the balloon, obtained though a different layout of the elements that control it.

· Accurate finishing and surface treatment of all parts that come into contact with the yarn.

· Consolidated mechanical system of anti-ribboning, variable for types of different yarn and materials.

· Mechanical counterweight of package arms.

· System of modulation and distribution of the yarn on package, mechanical type.

· Self-cleaning of lower part of spindle by means of air ventilation.

· Separation panels along the machine to prevent accumulation and contamination of dust.

Technological flexibility

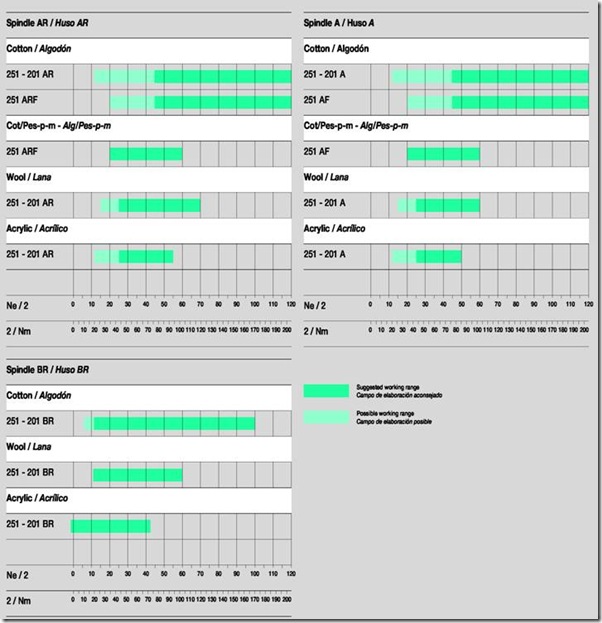

· The availability of different types of spindles makes it possible to optimize the production for the materials and different range of counts.

· Gauges between spindles: 250 mm. to offer the greatest possibility of twisting from the coarse to fine counts;

200 mm to optimize the ratio between number of spindles and space occupied.

· Balloon limiter (optional), which can also be installed subsequently, to maximize cost-efficiency of the

process for different counts and weights of the packages being fed.

· Waxing unit (optional) to prepare packages to be used for knitting.

· Special flyer (optional) for twisting elasticized yarns.

Highly consolidated take-up system

The mechanical cam system, for the distribution of the yarn on the spindle, for the modulation and cross angle, is housed in a centralized box, with oil lubrication activated by a special pump.

The pulleys for twist and

overfeed are easily accessible from outside and controlled by high-performance, low-noise toothed belts.

Possible working range

Overall dimensions and installation layout

SAvIO MACCHINE TESSILI S.P.A.

33170 PORDENONE (Italy)

Via Udine, 105

Tel. 0434 397422 Fax (0434) 397599

www.saviospa.it

order@saviospa.it