FlexiRotorS 3000 / Duo-Spinner

Why?

The need to supply smaller lots of yarn is increasingly felt also in the rotor spinning field where quick and reliable delivery times are a must.

While the technologically advanced components of the spinning boxes and the ease and rapidity, with which they are changed, have made rotor spinning so highly flexible in terms of processing possibilities and ranges, it also holds true that the machines available on the market today do not have the same industrial flexibility.

Because of this, it was essential to offer a “totally flexible” rotor spinning process besides guaranteeing the technological performances of quality and speed, which have already been reached by using a new high quality spinning box.

Consequently FlexiRotorS 3000, besides guaranteeing the highest speed and take-up performances, ensures:

· best production planning

· minimised “unproductive time”

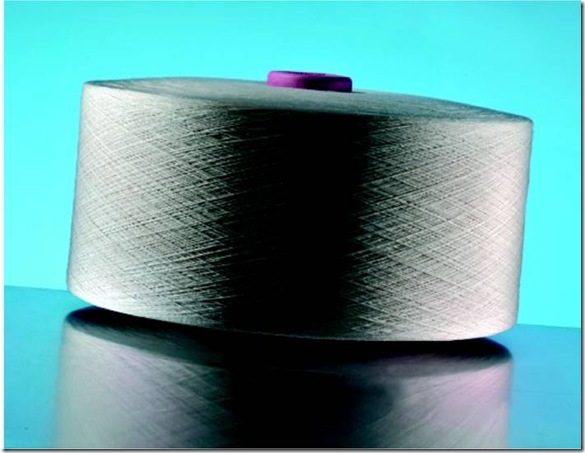

· high quality yarn and packages

thanks to:

· indipendent sides

· intelligent piecing and doffing trolleys

· “electronic” take-up of the certified package.

Flexability is what we are offering with our new rotor spinning frame

Electronic package take-up

All the parameters listed above can be set on the PC that controls the electronic control device (Electronic Threadguide Drive) on the control headstock. Via the PC in fact, it is possible to make packages of different sizes, densities and crosswinding angles according to market requirements and the downstream processes. Packages can also be made with a different traverse and centring in relation to the centre line of the tube.

Certified electronic package take-up

From a cylindrical to a tapered package

A simple “tapered take-up kit” can be fitted to each winding unit to change the package from cylindrical to conical type.

Quick change of the cradle centres

Thanks to the particular configuration of the cradle, the cone holders can be changed easily using a simple tool.

Packages with a maximum diameter of 320 mm in cylindrical packages weighing 6 kilograms, thanks to the characteristics and E.P.B. (Electronic Package Building).

Higher warping creel allocation and fewer tubes in circulation. This saving can be quantified as about 30% if it refers to the maximum weights obtainable with other machines with the same diameter.

Packages certified for length and density

Once the package length is reached – set on the PC – the diameter is also checked

during doffing. Any packages with diameters smaller or larger than the tolerance range set on the PC are not discharged and the unit goes into the alarm status.

Flexible piecing and doffing cycle

Control logic

The doffing and piecing trolley is able to control both sides of the machine as follows:

· each trolley is strictly bound to its own side;

· both trolleys control the

two sides separately

(automatic sharing of the work load);

· if one trolley is being serviced, the other one controls both sides.

When going from one front to the other, the trolleys are automatically set with the adjustments required by the front on which they are going to work.

Totally flexible piecing and doffing cycle

Should one of the operations, necessary to complete the cycle fail, same is repeated. This is thanks to the total independency of all the devices which are powered individually by stepping motors.

Monitoring the cycle

A set of sensors, mounted on the units, monitor not only the various mechanical phases of their movements or rotation, but also the presence and correct position of the yarn in each phase.

As a result, mechanical and technological splicing repetitiveness is guaranteed.

Piecing dynamics / Doffing dynamics

Doffing dynamics

While the package is being removed from the cradle, a new tube is sent automatically from the centralised magazine and loaded on the trolley. The auxiliary package, always on the trolley, supplies the yarn for piecing. The splice is eliminated and the yarn is simultaneously placed on the tube for the reserve before being sent to the threadguide. A simple display on the trolley shows the coded piecing and doffing sequence as well as any alarms.

Piecing dynamics – High efficiency and piecing constancy

Yarn piecing is done at the constant speed of the rotors. Piecing speed can be adjusted via the PC and can vary from 60-100% of the normal working speed.

After piecing, the trolley wind the yarn into the package until the package reach the winding speed.

Throughout the piecing process, the yarn, including the splice, is constantly monitored by the electronic clearer.

The two separate sides ensure maximum flexibility because it is possible to work with two different materials, counts, twists, drafts, rotor speeds, combing roller speeds, densities, diameters, etc.

Optimum planning of system production

The different ongoing productions can be divided for a single front instead of for a

single machine and, as a result, responding quickly to requirements of yarn lots with short delivery terms.

The fact that the two fronts are independent together with the ability of the two trolleys to simultaneously control one machine front, leads to a more efficient:

· lot change,

· machine front maintenace.

Packages of different colours can be processed on the same front without any possibility of contamination thanks to the large waste collecting channel, strategically positioned under the spinning box. A set of mobile brushes with reciprocating motion discharge the waste into a suction unit.

In addition, thanks to the way in which the two trolleys control the sides, one of the trolleys can be assigned a number of units from the other front to increase capacity.

Independent sides

Control headstock

PalmComputer

All spinning process parameters are set via the PC for each machine front:

· Rotor speed

· Combing roller speed

· Draft

· Twist

· Winding tension

· Crosswinding angle

· Antiribboning

· Axial displacement

· E.P.B. (electronic package take-up)

· Suction

· D.P.T. Piecing/doffing trolleys

Setting is also possible when the machine is working.

A “safety” software guarantees monitoring and constancy of the work parameters as well as the ratios between them.

As a result all machine settings are maintained even in case of a temporary power cut and/or if the machine is switched off.

The package cradle counterweight and damping are pneumatically adjustable with separate systems, but centralised in the headstock of each machine side.

Hence minimal operator intervention is required.

Radio-communication and machine parameter setting system.

A portable palmtop PC interacts via radio with the whole electronic system of the machine so the person in charge can remotely monitor machine performance and set all data as if he were in front of the main PC.

This palmtop PC can work on all machines in the room.

Spinning unit

The consistancy of yarn quality is, first of all, the result of the spinning unit’s drive mechanism box is configurated and its position in relation to the machine body’s control devices; in fact, the spinning frame body has been built with:

· a compact and all-in-one body;

· interface constancy with

the sliver feed shaft;

· all-in-one fibre conveyor channel.

The fibre support, incorporated inside the combing roller seat, guarantees a continuous and effective paralleling action which provides constant yarn quality.

The sliver feed shaft is always meshed with the main shaft even when the unit is opened at piecing time and during maintenance. This means there are no jerky movements which would cause yarn defects.

Spinning box

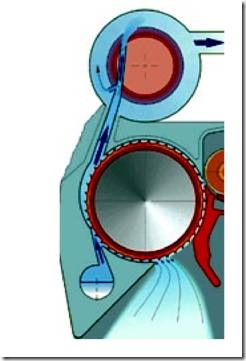

The SC-S spinning box features all the latest developments in the high speed rotor spinning field.

Thanks to the wide choice of components it is possible to reach maximum results with all fibres.

No tools are needed to work on the spinning box and each component can be changed easily by hand.

SC-S: a consolidated rotor spinning technology

Special spinning box for Man Made Fibres with

SPEED-PASS

As synthetic and man made fibres are bulkier than cotton, it was necessary to modify the combing roller compartment to allow for a better separation of the fibres going from the combing roller to the conveyor channel.

SPEED-PASS helps increase the volume of air needed at the entrance to the conveyor channel in order to remove all the fibres from the combing roller and straighten them completely during their acceleration in the rotor.

This is why by using SPEED-PASS you will also benefit in processing cotton and cotton blends with coarse counts.

The all-in-one fibre conveyor channel ensures there is no undesired air turbulence and hence a perfect control of the fibres that are accelerated in the rotor groove.

Sliver cleaning and By-Pass According to the impurities of the sliver, the by-pass makes it possible to optimise the

balance of the technological air required for spinning as well as the air needed to separate the scraps in counter stream.

The latest Twin disc generation

New Twin disc

The new Twin disc has been optimised to reduce energy consumption

· Discs with a bigger diameter

· Tangential belt with a reduced section

· Shorter rotor shaft

A new “lubricating cartridge” ensures:

· precise axial positioning of the rotor

· no lubricating dirt

· a cartridge that is easy to service and replace

Yarn path

Electronic Yarn Feeler Maximum functionality even with the finest counts or when soft packages are made. High sensitivity and rapid intervention.

Waxing unit (optional) Characterised by a single drive control, rotation stops if the yarn breaks, no dispersion or dropping of wax. Even consumption, easy to replace, wide range of settings for the quantity of wax.

Clearers (optional) Capacitive and/or optical clearer systems can be applied

to eliminate defects on yarns, including foreign fibres.

Individual PC monitoring Each spinning unit is equipped with an alarm monitoring system. The operator is informed in real time of any alarm that has been detected.

Suction system

Dimensions and installation layout

The main inverter controlled suction unit creates the vacuum and volume of technological air for the spinning boxes and piecing and doffing trolleys.

A second smaller suction unit increases the vacuum for the piecing and doffing trolleys.

The technological air channels of the boxes and trolleys are separate and independent so that waste is collected in the relative filters.

Timed filter cleaning is adjustable on the PC and can be done while the machine is working thanks to a by-pass system started by its own pushbutton.

The PC also modifies the pneumatic working parameters of the main suction unit, on a timed basis, according to the waste from the boxes, to guarantee suction constancy during spinning.

Technical summary

Rotor spinning frame with two independent sides featuring automatic distribution of the empty tubes and an automatic system for piecing, package doffing and rotor cleaning. 24-unit modules on 2 fronts. Maximum number of units per machine: 360 Gauge: 230 mm Technological data Processable materials: cotton, man-made and synthetic fibres, blends, technical fibres (Kevlar, Nomex). Maximum fibre length: 60 mm. Sliver count: Ne 0.08 – 0.27 (6000–2200 Tex) Yarn count: Ne 4 – Ne 60 Feeding pots: max. height: 42” (1066 mm) with possibility of raised machine to reach a clearance of up to 1270 mm for 46” high pots 16” and 17.5” diameters (on two rows) 18” and 20” diameters on three rows Draft range: 16 ÷ 400 Twist rate: 115 ÷ 1500 T/m Winding tension ratio: 0.9 ÷ 1.1 Spinning unit Rotors: diameter: 28; 30; 31; 33; 36; 40; 46; 56 mm

speed: 35.000 ÷ 150.000 r.p.m. Combing rollers: sawtooth; diameter: 75 mm;

speed from 7.000 to 10.000 r.p.m.

Navels: in ceramic, with and without notches

Twist-trap: smooth surface or insert with 3 twist-retaining bars

Sliver cleaning: highly efficient thanks to the centrifugal and gravity effect Transporting impurities: with Sweep Cat or conveyor belt with suction in the headstock and tail end Winding unit Dimensions of standard take-up tubes: cylindrical: Ø 54 x 170 mm

Ø 54/43 x 170 mm with inverted tip tapered: 3°51’ also with inverted tip

4°20’ also with inverted tip Dimensions of special take-up tubes: on tapered machine: Ø 79/69x170 mm

Ø 68/55x170 mm cylindrical type: Ø 41.28x170 mm

Ø 54x170 mm

Ø 69x170 mm

Ø 75 / 69x170 mm

on cylindrical machine: tapered 1°51’ also with inverted tip

Package dimensions: cylindrical Ø 320 mm

tapered Ø 280 mm Grooved roll traverse: 100÷158 mm settable on the PC

Package densities: cylindrical: 0.5 – 0.32 kg/dm3

tapered: 0.45 – 0.36 kg/dm3 Crosswinding angles: variable from14°÷20° settable on the PC Take-up speed up to 250 m/min. Electronically controlled anti-patterning system Axial displacement command up to 6 mm settable on the PC for an even package edge density Pneumatic counterweight system and package damping with mechanical vibration damper. Centralised control. Mechanical tapered package compensator Electronic yarn length measuring device Electronic yarn feeler:

it stops feeding of the sliver in case of yarn breakage Automated system Possibility of using 2 trolleys on the same front Trolley translation speed: 25 m/min. Rotor cleaning Programmable preventive rotor cleaning Doffing cycle time: about 32 seconds Programmable doffing at set lengths Automatic tube feed device with a capacity of 150 tubes per front Tubes without prewound yarn Elimination of yarn splice before the beginning of the new package Package unloading on two completely independent belts Feed sliver detection system Anti-marriage sliver safety device Diagnostics during trolley cycle phases Adjustment of piecing parameters when going from one front to the

other Selection of the number of piecing attempts for start up and normal operation Headstok Computerised system for setting, checking and viewing all spinning and winding parameters. Programmer for the number of packages unloaded Machine generated air and sliver cleaning air can be discharged through underground or overhead ducts Motors cooled by air taken from outside the headstock Fire warning system with automatic isolation of the vacuum ducts Automatic powering system of the electrical axes in the case of power cuts (up to 3 seconds) Optional devices Individually controlled waxing unit Clearers: USTER QUANTUM (either optical or capacity with FF) BARCO PROFILE (optical) with FF Auxiliary trolley Installation of 3 or 4 trolleys

SAvIO MACCHINE TESSILI S.P.A.

33170 PORDENONE (Italy)

Via Udine, 105

Tel. 0434 397422 Fax (0434) 397599 www.saviospa.it order@saviospa.it