Loyal textiles was established in the late 1800's by Sir EDSasson, with imported second hand machines from England as a spinning and weaving mill. In the year 1953, the company was bought over by Karumuttu Thiagarajar Chettiar, a visionary and doyen of the South Indian textile industry. Loyal textiles were reborn as a modern textile mill under his management.

Loyal has several firsts to its credit in introducing technology to Indian textile industry.

In the year 1979, air jet technology was introduced. The first open width continuous dyeing plant was commissioned for knitting in the year 2006 and the first ozone based waste water treatment plant was commissioned in 2007.

In the area of safety clothing, Loyal is the only Indian company to manufacture EN EN EN certified garments for high visibility, flame resistant, explosion proof and electrically conducting garments.

Over the years after it came into Karumuttu's fold, it has grown from a spinning and weaving mill into a fully integrated textile plant with different types of spinning, weaving, knitting, wet processing of both knits and wovens including special finishes and garmenting.

In the year 1996, Loyal made its first overseas venture by buying into a marketing company involved in product design, warehousing and logistics in Italy.

Loyal believes in long term commitment, transparent relationship with all its stake holders.

Loyal is a USD 100 million textile company.

Spinning

Loyal has state-of-the-art spinning plants comprising of the latest machines from international leaders like Reuter, Trutzschler, Murata, Toyota, Schlafhorst and Lakshmi.

Starting from bale pluckers with color contamination checking to link coner with state of the art clearers to eliminate both color and PP contamination.

Unit One 21,000 spindles with 5,000 spindles compact spinning producing combed counts: above 80's upto 140's

tons:100 per month

Unit Two 26,000 spindles compact spinning producing combed

counts: 40's to 100's tons:150 per month

Unit Three 11,000 spindles with 6,000 spindles compact producing combed counts: 40's to 80's

tons: 55 per month

Unit Four 3,000 spindles producing combed mélange yarns in different colour and fibre blend tons: 40 per month

Unit Five 3,000 spindles producing mélange yarns tons: 40 per month

Unit Six 1,680 rotors producing open end yarns counts: 6's to 20's

tons: 360 per month

Unit Seven 26,000 spindles combed cotton knitting yarns counts: 24's to 50's

tons: 360 per month

Unit Eight 23,000 spindles producing combed cotton yarns counts: 20's to 40's

tons: 360 per month

Unit Nine 12,700 spindles producing polyester spun and poly cotton yarns for knitting and weaving tons: 200 per month

Unit Ten 12,000 spindles producing carded fancy and regular yarns counts: 6's to 30's

tons: 250 per month

Unit Eleven 3,400 rotors producing open end yarn from 100% cotton counts:16's to 30's

tons: 450 per month

E-manufacturing facilities comprise of state-of-the-art machines like Reuter, Trutzschler, Marzoli, Electrojet, Elite Suessen, LMW machines, KTTM auto doff spinning machines, Toyota ring spinning with multi count, multi twist and stub attachment, Link Coners, Schalfhorst / Savio with contamination clearers.

Cotton is checked through camera based contamination eliminators installed in blow room with polypropylene checking at two levels before feeding into cards.

Twisting department consists of:

Murata and Peas Metler parallel winding machines. 60 TFO machines. 160 drums RITE gassing machines and 720 drums of winding machines.

Xorella steam setting machines to condition folded yarns from 2/10's to 2/140's gassed.

Weaving

Weaving preparatory consists of Benninger warping and sizing.

4 warping machines and 3 sizing machines besides one sectional warping machine.

Loyal has wide width air jet looms, narrow width air jet looms and wide width rapier looms with dobbies, twin beam and jacquards.

Loyal produces nearly 100,000 meters of fabrics per day in width from 160 cms to 330 cms in count range from 6's to 140's including very densely woven fabrics.

Quality

Quality control at Loyal begins at the ginnery. Loyal's cotton selectors choose the gins from where Loyal buys its cotton.

100% of the cotton is tested using HVI instruments and issued for mizing using a balem management system which ensures a narrow band of average yellowness and micronaire values. Other instruments in the lab are AFIS, yarn and preparatory slivers evenness tester, UsterClassimat, Tensorapid strength tester from Premier.

Loyal uses a combination of cottons from Egypt, USA, Israel and India to produce yarns for different customer specifications.

100% of both knit and woven cloths grey, as well as dyed are inspected before packing.

Knitting

Knitting department consists of knitting machines in diameter from 26" to 36" in gauge from 18GG to 36GG from Mayer and Cie, Terrot, Panylung and Unitex machines. Most of them are equipped to produce over 100 kg per roll Single Jersey, Interlocks, Ribs, 3Thread Fleece, Piquepolo etc.

Open width knitting machines to knit cotton/lycra fabrics with all feeders lycra.

Flat knitting machines to produce collars and cuffs. The knitting capacity is 1,000 tons per month.

All yarns used in knitting are Xorella conditioned waxed yarns cleared using color and PP contamination clearers.

Garments Units

Garments division has Gerber automatic spreading and cutting machines, Juki Brother and Special purpose machines including automatic pocket setters, welt pocket makers, profile stitching machines, collar making and stitching machines, belt loop attaching machines etc.

All machines have underbed trimmers and a computer stitch control. 10,000 complex garments with multiple pockets and design features can be made per day.

Home Textiles

Loyal has an exclusive division for household textiles. Its core business is

designing and marketing bed linen, bathing items and upholstery like flat

fitted pillow cases, shams, duvets, comfort shells with and without down

proof, bed skirts, shower curtains and sofa covers.

Majority of our products are 100% cotton and have high thread counts. We

concentrate on traditional plains, twills, drills, satins, sateens, yarn dyed

stripes, self stripes, dobbies, plaids, chambrays and jacquards.

We have weaving facilities upto 140 inches and can give a maximum

finished width of 114 inches.

Salient features of our products are good fit and colour fastness for all shades and the fact that we do 100% inspection of all our shipments.

Organic Textiles

Loyal strongly believes that the organic way of cotton cultivation and eco friendly ways of converting the raw material into finished product is the only sustainable way.

Loyal strongly believes that we have taken the universe on loan from the previous generation to be handed over to the next generation and it also believes in being responsible to improve whatever it has obtained.

Loyal is certified by "Control Union World Group" (formerly known as "SKAL International) to supply organic products under GOTS.

All the plants - spinning, weaving, knitting, dyeing & finishing and garmenting are GOTS certified for processing organic cotton.

Certification Standard Awards

Certification

· Certified 3 Star Export House

· ISO:9000:2000 Certified

· IS0:14001: EMS Certified

· SCAL Organic Productions MT Certified

· SA8000 Certification underway

· Corporate office under green building (IGBC) certification

Standard

· OAK Tech standards for dyed fabrics

· Bardush standards for European industrial wash

· BS 2576/1986 & ASTM D1424/1996 standards for fabric

· ASTM D5034/ASTM D1424 standards for dyed fabric

· ISO 13934-1/ISO 4074-2 dyed fabric for purpose

Awards

· Bronze trophy for the year 1997-98 for being third largest exporter of cotton

fabrics in the country

· Silver trophy for the year 1998-99 for being the second largest exporter of

cotton fabrics in the country

· Silver trophy by AEPC for being fourth largest exporter of garments under

non-quota category for the year 1999

· Bronze trophy for outstanding export performance in yarn amongst mill

exporters from TEXPROCIL for the year 2001-02

· Bronze trophy for the year 2004-2005 for being third largest exporter of cotton

fabrics in the country

· Gold Trophy for the year 2006-07 for being the largest exporter of cotton

fabrics in the country.

Joint Venture / Overseas Office

Gruppo P&P Loyal s.p.a

Via Valdilocchi, 2-19126

La Spezia, Italy

E mail: info@peployal.it

Loyal Textiles (UK) Ltd.

48, Bessencourt, Holmes Chapel,

Cheshire CW4 7NB, England

E mail: david@loyaltextiles.co.uk

Exports

The major markets for our products are as follows:

Garments Europe, Switzerland, Middle East and USA

Finished Fabrics UK, Sri Lanka, Dubai, Europe and USA

Home Textiles USA, Europe and Japan

Grey Fabrics USA, Europe, Hong Kong, South Korea, Israel and UK

Yarn Europe, Japan, Hong Kong, Korea, Australia, Spain, Egypt,

Israel , Turkey, Thailand, Taiwan and Bangladesh

Environmental Management system

(ISO - 14001)

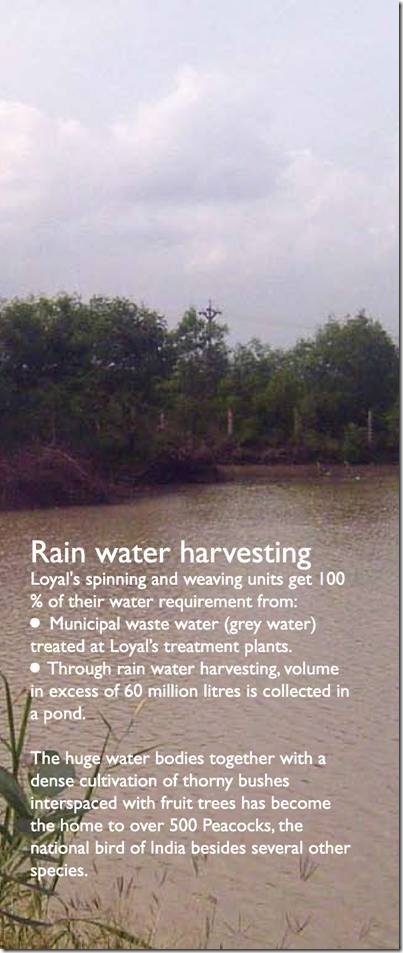

· Complying with applicable environmental legislations and regulations

· Conserving natural resources through responsible management of energy and water use

· Dyeing of fabrics using extremely water frugal technology and E- control dyeing

· Waste water C.O.D and B.O.D reduced to acceptable levels using a combination of bio tower and areation tank

· Reducing environmental impacts through reuse, recycle and minimization of waste

· Adopting cost effective measures in the prevention of pollution from our processes

· Motivating and preparing all employees to take personal accountability for protecting the environ

· Planning, implementing and reviewing environmental objectives & targets

· Regularly reviewing and improving our environmental management system

Persons to be contacted:

Mr Manikam Ramaswami

Chairman & Managing Director

Ioyal@loyaltextiles.com

Mr KL Palaniappan Senior Vice President klp@loyaltextiles.com