Determining Fibre Properties and Linear Density Effect on Cotton Yarn Hairiness in Ring Spinning

Abstract

The hairiness of a yarn can be defined as the total number or total length of the fibres which leave from the unit yarn’s surface. Yarn hairiness is formed by surface fibre edges which leave the yarn center and spoil its appearance. Except for a few special cases, yarn hairiness is an undesirable property in a yarn; an excessive degree of hairiness can cause serious problems in both yarn production and in subsequent textile processes.

The aim of this study is to examine the effect of cotton fibre properties and linear density on yarn hairiness. For this purpose, two different yarn counts were produced from 15 different characterised cottons with the same process and machine parameters. Yarn hairiness was tested with a Zweigle yarn hairiness meter. The fibre parameters were tested with HVI test equipment. The fibre parameters and yarn hairiness results were analysed with the help of the SPSS and MINITAB statistical pocket programs. We basically used multiple regression analysis method for our test results. Among all the parameters examined in this study, yarn linear density is the most important parameter affecting yarn hairiness. An increase in yarn linear density increases the hairiness. Secondly, fibre length is also another important parameter which influences hairiness. The increase in fibre length decreases hairiness.

Key words: cotton yarn hairiness, regression analysis, Zweigle yarn hairiness tester, HVI test machine.

Introduction

Yarn hairiness is a quite complex parameter of yarn quality that is affected by various parameters. Many researchers have devoted their attention to the influence of fibre parameters on yarn hairiness. These results sometimes differ because of the nature of different measuring principles. It is generally ac-

cepted that a certain level of hairiness in yarn is unavoidable, owing to the practical limitations of mechanical processing machines [1].

Spinners are therefore interested in knowing the effect of fibre properties on yarn hairiness for the selection of a suitable raw material. According to previous research, fineness has the maximum effect on yarn hairiness among the fibre properties, followed by fibre length, whereas maturity contributes very little towards hairiness. Fineness, length and long-fibre percentage jointly influence the formation of yarn hairiness to a considerable extent. An interesting finding is that the independent relationship of long-fibre percentage with yarn hairiness is significant, whereas short- and medium-fibre percentages are not significant [2].

Barella was one of the first researchers into yarn hairiness who introduced a new technique in hairiness measurement, based on counting the number of the fibres and their diameters as well as yarn. Barella classified hairiness as ‘protruding fibre ends’, ‘the looped fibres’ and ‘wild fibres’ on the basis of the research done by Morton &Yen into fibre migration in cotton worsted and spun rayon yarn. He also studied the various causes of yarn hairiness by only changing the yarn twist value. He found that the number of the fibre ends on the yarn surface remained constant when yarn twist was increased in cotton yarns [3].

Barella and Manich manufactured cotton spun yarns from 34 staple stocks by means of the ring spinning (34 yarns) and rotor spinning (29 yarns) processes, and tested the hairiness of these yarns with a Shirley hairiness meter. For each spinning system, yarns were produced at two values of yarn linear density, but the twist multiplier was kept constant within the series for each spinning process. The results showed that the hairiness of ring spun yarns was higher than that of rotor yarns. They also found that fibre length and its uniformity have the greatest influence on hairiness for both ring- and rotor-spun yarns, and fibre fineness has only a slight influence on the yarn hairiness of ring-spun yarns [4].

Pillay et al. carried out a comparative study into the structure of rotor- and ring-spun yarns from cotton and man-made fibres. They showed that the effective length of the fibres in yarn, as represented by the fibre spinning coefficient, is significantly lower in OE yarns than in ring yarns. They found that in OE yarns, fibres migrate in a different way, and the mean fibre position and amplitude of migration are lower than those in conventional ring yarns [5].

Viswanathan et al. examined the influence of fibre characteristics on the hairiness of cotton yarns. They found that fineness has the maximum effect on yarn hairiness, followed by fibre length. There is an independent relationship between

long fibre percentage and yarn hairiness, whereas those of short- and medium-fibre percentages are not significant. [6].

Hequet and Ethridge determined the effect of cotton fibre length distribution on yarn quality. For the carded ring-spun yarns, their results showed that the shortest and the longest fibres exhibited the highest correlation with the yarn evenness (CV%), the number of thin places, and the number of thick places. For the combed ring-spun yarns and rotor yarns, the longest fibres exhibited the highest correlation with the yarn evenness (CV%), thin places and thick places. The shortest and the longest fibres are highly correlated with the hairiness for all types of yarns. The shortest fibres increase hairiness, while the longest fibres decrease it [7].

Materials and methods

This study is focused on the effect of fibre parameters on cotton yarn hairiness.

For this purpose, two different carded yarn counts were spun from 15 different raw materials which were supplied from different textile mills in sliver form. In the roving machine, 0.5 ktex count and 42 T/m rovings were obtained from all the draw frame bands. These rovings were then spun with conventional ring machines. We used identical machine conditions for both the roving and yarn production processes in order to eliminate the effect of these parameters on hairiness. The experimental part of the work described in this article was carried out in Ege University’s Textile & Apparel Research and Application Centre. Table 1 shows the experimental plan of the study.

The fibre length, micronaire, uniformity ratio, strength, short fibre index, elongation, trash count, brightness and yellowness parameters of each cotton samples were tested with an HVI test machine.

For a comprehensive examination of yarn hairiness, the following hairiness parameters should be available; (i.) total number of hairs per unit yarn length, (ii.) total length of hairs per unit, (iii.) the length and number of hairs longer than or equal to 3 mm per unit length. The Zweigle yarn hairiness meter serves this purpose well. We tested the yarns with this machine and determined the number of hairs for different length classes including 1, 2, 3, 4, 6, 8, 10, 12, 15, 18, 21, 25 mm, as well as the S3 code, which defines the total number of hairs 3 mm and above hair lengths.

The results obtained from the laboratory testing of fibre and yarn samples were evaluated by using the SPSS statistical program. We basically used the multiple regressing analysis method with the significance level of α=0.05 for our test significance level of α=0.05 for our test results. All multiple regression analyses were carried out for both yarn counts together and separately.

To select the best model for regression analysis, we used MINITAB and chose the best model according to their corrected R2 values. Mostly, the best model which was selected for analysis had the highest corrected R2 value [8].

Results and discussion

The measurement results of the fibre properties used in our statistical analysis

- fibre fineness, fibre strength, 2.5% span length, uniformity, short fibre percentage, breaking elongation and trash count - are given in Table 2.

Generally, the correlation between yarn parameters and hairiness factors are not calculated for every single millimetre of the fibre length (from 1 mm up to 10 mm), as these cause very divergent results. According to the previous researches on yarn hairiness, there are two different approaches for the length of hairs which cause problems in yarn and fabric production. The first approach claims that hair lengths of 3 mm and shorter are important [4, 5, 7]; while the other states that the total number of 3 mm and longer lengths (S3 code) of fibres caused hairiness [9, 10, 11]. In this study, we evaluated the hairiness results according to 1, 2, 3 mm hair lengths and S3 codes together. The number of 1, 2 and 3 mm hair lengths and the value of S3 codes are given in Table 3.

Each parameter experimented in this study is explained below;

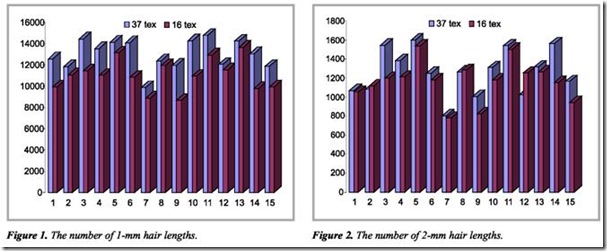

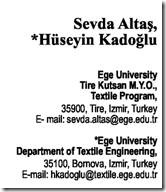

Linear density effect: Yarn linear density is statistically significant when evaluating both yarn counts together with SPSS. We found a direct relationship between yarn linear density and hairiness; the hairiness increases when the yarn linear density increases. In other words, coarse yarns have more hairs than fine yarns for all the observed hair lengths. This can be explained by the increase of fibres in the cross-section of yarn. The numbers of 1, 2 and 3 mm hairs and the values of S3 codes for all yarn samples are given in Figures 1 - 4.

Length effect: When 37 tex and 16 tex yarns were evaluated together, except for 2 mm hair length, fibre length was found to be statistically significant. When we examine the effect of fibre length on hairiness for two yarn counts separately, the results are different. While in 37 tex

yarns fibre length is found to be statistically significant for S3 codes only, in 16 tex yarns it is found to be statistically significant for 1, 2, 3 hair lengths and S3 codes. According to these results, we can say that fibre length property is more important in fine yarns than in coarser yarns. Yarn hairiness decreases as the fibre length increases.

Fineness effect: Fibre fineness property is found statistically significant for 2 and 3 mm hair lengths when evaluating two yarn counts together. Evaluating the effect of fineness for 37 tex and 16 tex separately, as for fibre length, we found that the results differed. While in 37 tex yarns fineness is statistically significant for 1 mm hair length only, in 16 tex yarns, it is found to be statistically significant for 2, 3 mm hair lengths and S3 codes. According to these results, we can say that fibre fineness is a much more important parameter in fine yarns than in coarse yarns. Yarn hairiness increases as

the fibre fineness value (micronaire) increases due to high flexural and torsional rigidities.

Strength effect: Fibre strength is statistically significant for 2 mm hair length only when evaluating two yarn counts together. Evaluating the effect of fineness for 37 tex and 16 tex separately, the results are nearly the same. In 37 tex, fibre strength is found statistically significant for 2 and 3 mm hair lengths. In 16 tex, fibre strength is statistically significant for 1 and 3 mm hair lengths. The increase in fibre strength decreases yarn hairiness. In addition to this, we found that fibre strength is more important on shorter hairs below 3 mm in length.

Uniformity effect: Uniformity is found to be statistically significant for S3 codes only when evaluating two yarn counts together. In 37 tex yarns, uniformity is also statistically significant for S3 codes only. However in 16 tex yarns, the uniformity is statistically significant for 1 mm hair length only. According to these results, we can say that uniformity is mostly effective for hairs above 3 mm in length. The increase in uniformity index value increases hairiness. This relationship is unexpected, according to the uniformity measuring principle.

Short-fibre percentage: Short-fibre percentage is statistically significant for 1 mm hair length and S3 code when evaluating both 37 tex and 16 tex yarns together. Evaluating the effect of short-fibre percentages in 37 tex and 16 tex

separately, the results are very different. While in 37 tex yarns the short-fibre percentage is statistically significant for 1, 2, 3 mm hair lengths and S3 codes, in 16 tex yarn it is statistically significant only for 2 mm hair length. The increase in the short-fibre percentage increase hairiness. Examining these results it can be concluded that the short-fibre percentage plays a more vital role in coarse yarns than fine yarns.

Breaking elongation: Breaking elongation is statistically significant only in 37 tex when evaluating these yarns separately. The increase in breaking elongation decreases hairiness. According to these results, breaking elongation is more important for hairs above 3 mm in length, especially in coarse yarns.

Trash quantity: Trash quantity is statistically significant for 1 mm hair length in 37 tex yarns and 2 mm hair length in 16 tex yarns when evaluating yarns separately. Analysing these results, we can say that trash quantity has no important effect on yarn hairiness.

Summary and conclusions

The aim of this study was to examine the effect of cotton fibre properties and linear density on yarn hairiness. For this purpose, two different yarn counts were produced from 15 different characterised cottons with the same process and machine parameters. Yarn hairiness was tested with a Zweigle yarn hairiness meter. The fibre parameters and yarn

hairiness results were analysed with the help of the SPSS and MINITAB statistical pocket programs. We basically used a multiple regression analysis method for our test results with a significance level of α=0.05. Considering our experimental of α=0.05. Considering our experimental measurements and statistical analysis, we can summarise the results of this study as follows (Table 4);

Among all the parameters considered

in this study, yarn linear density is the most important parameter that affects the hairiness. Hairiness increases when the yarn linear density increases.

Among all raw material parameters,

fibre length is the most important fibre property that affects the hairiness. The increase in fibre length decreases hairiness.

Fibre fineness property is more important for 16 tex yarns; on the other hand, the short-fibre percentage plays a vital role for 37 tex yarns’ hairiness.

In addition to these results, we did

not observe any direct relationship between trash count parameters and yarn hairiness.