The decentralised sector of powerlooms in Tamilnadu contributes significantly to the fabric demand for domestic consumption as well as exports and therefore, it is most important and crucial to the economy of the country in general and to Tamilnadu in particular. Improved looms with better technology will ensure the quality fabrics production either in grey or yarn dyed form.

Considering the above, modernising/upgrading technology levels in the powerloom sector has become imperative and the central / state government has initiated urgent measures in this direction. Since the year 2001-2002, the implementation of the National Textile Policy took off with the announcement of a special textile package as part of the annual budget for 2001-2002 including duty relief, concessions and special programmes aimed at accelerating modernisation and growth of the textile industry.

It has specifically emphasized on modernisation of the weaving sector by launching a programme for induction of 50,000 shuttleless looms and conversion of 2,50,000 plain looms into semi automatic and automatic looms in the decentralised powerloom sector. In the light of the above targets and the urgency to meet the deadline of WTO regime beginning from January 2005, the induction of shuttleless looms and upgradation of the plain looms into automatic and semi automatic looms in the state is urgently called for. In order to achieve the targets in the above direction, the present status of the technology levels and loom conditions as well as the investment capabilities of the powerloom owners are assessed through the study which are presented below.

4.1 Type of looms

The powerloom industry in the state produces grey fabrics for further processing including surgical/bandage cloth as well as yarn dyed textile items like saree, lungi, made ups like bedsheets, furnishings, napkins etc. All the yarn dyed fabrics are being produced by the handlooms also that have been taken over slowly and gradually by the powerloom sector. Based on the above production pattern, the technology level of looms used in the

state has remained low and these are treated in the perception of the weavers as improved handlooms and not really power operated higher technology weaving machines. It is very common in this area to substitute manual pirn changes in the powerlooms in order to save on the installation of drop box attachments. Thus, the check varieties including lungi materials have been produced on plain looms without drop box attachment by resorting to manual pirn changes as required for checks. With this background one should view the technology level of looms in the state in order to understand them better.

4.1.1 Definition of different types of looms

Plain loom: Plain loom denotes the loom without any warp or weft stop automatic control mechanisms. Also, the take off motions may not be present in the loom. However, in such looms dobby, jacquard or drop box attachment may be present as additional attachments according to the requirement of the weaver.

Semi automatic loom : This type of loom is basically the plain loom with additional attachments of automatic electronic/mechanical warp stop as well as weft stop motions along with positive let off motions. In the case of some clusters of Tamilnadu powerloom sector, the looms without positive let off motions but incorporating automatic warp and weft stop motions have been classified as semi automatic looms. As in the case of plain looms, the semi automatic loom may have additional attachment of dobby or jacquard or drop box as the case may be.

Automatic loom: An automatic loom is basically one that has auto pirn changing mechanism along with all the automatic warp and weft stop motions as well as positive let off motions.

Shuttleless loom : Shuttleless loom may be of the type of air jet, water jet, projectile, rapier etc. In the case of Tamilnadu powerloom sector, there are only projectile or rapier looms with attachments of cam-dobby etc. and procured normally as second hand machinery.

4.2 Penetration of higher technology in the looms used

It is observed that the looms used presently are mostly plain looms and the number of automatic and semi automatic looms is very limited or almost insignificant. Only in the recent times, some leading manufacturers have procured few shuttleless looms of second hand nature in the state. It is estimated that about 6,000 shuttleless/automatic looms that are mostly second hand ones are installed in the powerloom sector. Considering the product types of the decentralised sector which comprises of significant quantities of grey as well as yarn dyed fabrics, the type of upgradation in the loom technology is to be understood in minute details and suitable measures are to be taken accordingly. If the measures taken are not designed to meet the sectoral variations, the modernisation goal will not be achieved. Most of the entrepreneurs are of the opinion that only conventional shuttle looms or at best semi automatic/automatic shuttle/pirn change looms are economically viable for most of the qualities woven despite all the limitations posed by them.

To cite a few examples of technological changes that are taking place in the powerloom sector of the state, shuttleless looms of Sulzer make have been imported and installed by units in Somanur, Palladam areas of Coimbatore cluster, Komarapalayam in Erode cluster, Salem, Chennai and nearby areas of Chennai cluster and in Rajapalayam area of Madurai cluster (where the exportable gauze cloth weaving is predominant). Computer aided designing has been started in Karur. In the Kappalur industrial estate outside Madurai, there are about 50 units each with 4-8 new automatic shuttleless or second hand imported looms. There are few units near Salem with shuttleless looms imported as second hand machinery.

A few enterprising entrepreneurs have already put up shuttleless looms as stated above but they are very insignificant in number. So far a majority of the powerloom weavers have been unable to avail funds under the TUF Scheme and only a few well to do units have gone ahead with modernisation albeit without TUFS.

4.3 Estimated number of looms and their types

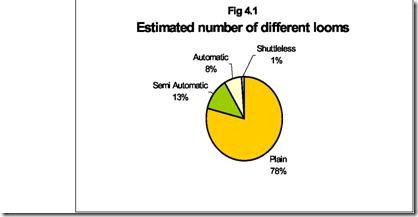

It is observed that around 91% of the looms in the state’s powerloom sector are plain looms of low technology without any electronic/mechanical warp/weft stop motions or the positive let off motion. Only less than 7.5% of the looms are of improved type and identified as semi automatic looms having warp/weft stop motions as well as positive let off motion. There are a small number of automatic and shuttleless looms in few pockets, which is gradually expanding. The survey data reveals that 1% of the looms are automatic and 0.3% of the looms are of shuttleless. From the field observations also, these estimates of automatic and shuttleless looms are found to be consistent.

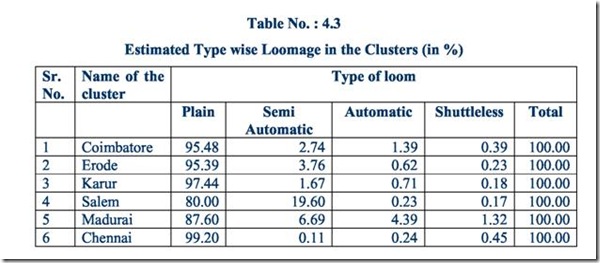

4.3.1 Type wise loomage in the clusters

Among the clusters, the predominant presence of plain looms in proportion to the total number of looms is observed. In the case of Salem cluster, there is a predominance of semi automatic looms. Out of the total semi automatic looms in the sector, two-thirds of the semi automatic looms are in this cluster. The looms with two additional mechanisms only have been considered as semi automatic here whereas in other clusters in addition to warp and weft stop motions, positive let off motion has also been considered as an integral

part of the semi automatic loom. In the case of automatic looms, Coimbatore cluster has the largest concentration accounting for 47% of the total automatic looms. Regarding shuttleless looms, significant presence is observed in Coimbatore, Madurai and Erode clusters.

Within the clusters, the composition of different types of looms also reflects the same trend. In all the clusters, the plain looms are seen to hover around 80% or more in the total looms. The rest constitutes of the semi automatic, automatic and shuttleless looms in each cluster. In the case of semi automatic looms, it is the largest in Salem accounting for 20% of the cluster’s total looms. It is the lowest in Chennai cluster forming less than 1% which may be due to the non-preference of weavers for installing auto warp and weft stop motions. One more factor for the avoidance of semi auto mechanisms is that one weaver tends only one loom and most of the looms are having dobby/jacquard attachments for producing home textiles with woven designs. Automatic looms form a significant proportion in Madurai cluster as many of them are engaged in the production of medical textiles in grey form and, therefore, there is a preference for automatic looms in this cluster. In Coimbatore and Karur also, these automatic looms are more compared to other clusters. Regarding shuttleless looms, larger number of looms are found in Coimbatore cluster which is a more advanced region compared to others and in the total 1.39 lakh looms, it forms around 0.4%. In Madurai cluster also, the proportion of shuttleless looms is very significant and the reason for this may be the higher investment capacities of the weaving units that are concentrating on export business.

4.4 Pattern of new and second hand looms installation

“Technologically, the small and large firms tend to be different. The earliest powerlooms in India were set up with rejected looms from mills. But in the more recent clusters such as Tamilnadu, the main source of looms has been the Indian brands. At first, large Indian factories made these, but by the 1970s there was a tendency to fabricate them in the powerloom towns. One reason given in the fieldwork for the rarity of second hand looms is that the remote and semi rural location of powerloom operators made servicing and availability of spares difficult. This problem led to a bias for simple and known machines produced on the spot. While local looms define the average technological standard, there is a wide dispersion in the quality of operation of local looms. These machines are slow and tend to be badly maintained and operated in a small firm. On the other hand, in the larger firms, machines of similar vintage tend to be better maintained and almost invariably have dobby attachments. In the larger segment, automatic and shuttleless looms are now far more common than a decade ago.

When export of cotton cloth surged in the early 1990s, there were two types of effects on Tamilnadu. In the case of indirect exports, which consisted mainly of greys processed out of state, the effect was an expansion of loomage without much qualitative change in organisation or technology. But, in the case direct exports, which consist of both grey and coloured cloth of non-traditional types, there have been technological and organisational changes” (Tirthankar Roy).

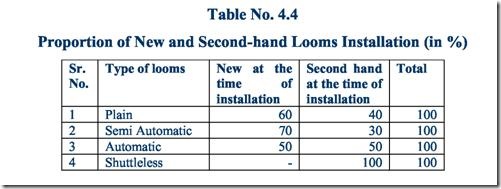

4.4.1 Proportion of new and second hand looms installation

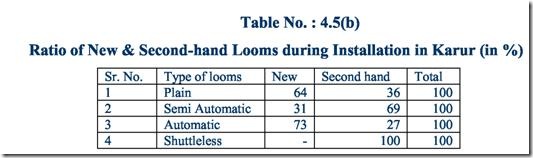

It is observed that a majority of the powerlooms in the state is new at the time of installation. Among the plain looms, 60% are stated to be new and only 40% were second hand machines at the time of installation. As indicated above, the weavers have preferred new looms locally manufactured due to the lower cost, simple operational mechanism and easy maintenance. In comparison, a majority of the semi automatic looms also are seen to be new which constitute about as high as 70% of such looms. This trend is reversed as the price of the looms goes up. In automatic looms, only 50% are stated to be new at installation. An interesting finding is regarding shuttleless looms that show that all 100% are second hand looms at the time of installation. The reason for this may be financial as well as the availability of sophisticated second hand looms from abroad. There are also other favourable features regarding the second hand looms that have influenced the Tamilnadu powerloom weavers to opt for the same.

4.4.2 Cluster wise proportion of new and second hand looms installation

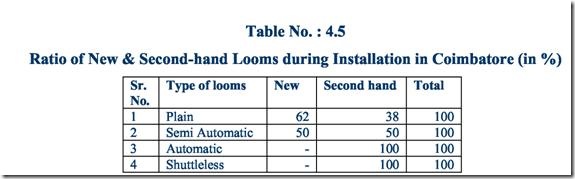

Coimbatore: In this cluster, a majority of the powerlooms is new at the time of installation. Among the plain looms, 62% are stated to be new and only 38% were second hand machines at the time of installation. In semi automatic looms, 50% of the looms are observed to be new and the balance 50% of the looms are of second hand machines. Similar to the overall sectoral pattern, in Coimbatore cluster also, the automatic and shuttleless looms are almost second hand machines at the time of installation. Due to the nearness of Coimbatore, the weavers are able to access information on import of second hand machinery more easily than other areas.

Erode: In this cluster, 46% of the plain looms are stated to be new at the time of installation and the remaining 54% of the looms are second hand machines. Compared to this, in semi automatic looms, 67% of the looms are stated to be new and only 33% are second hand machines. In this cluster, automatic and shuttleless looms are significant as compared to other clusters. Due to the predominance of handloom weaving in Erode and nearby areas, the higher technology shuttleless looms are also found to be popular in this cluster.

Karur: Karur is seen to reflect a different picture from other clusters. In plain looms, more than two-third of the looms are new and one-third is only second hand at the time of installation. As regards the semi automatic looms, one-third of the looms are stated to be new and two-third of them are second hand. The reason for this may be that the weavers have gone for the installation of warp and weft stop motions subsequently in a larger way. About three-fourth of the automatic looms are new at the time of installation and the balance one-fourth is second hand machines. This may be due to exit of weaving units uncommon comparatively than in other clusters. As in the case of the overall pattern, all shuttleless looms are stated to be of second hand machines. This is naturally due to the cost considerations and other aspects.

Salem: Only 64% of the plain looms have been reported to be new machines at installation whereas all the semi automatic looms are new purchases. In the case of automatic looms, all are found to be second hand machines. Even in the case of shuttleless looms, it is learnt that they are of second hand imported machines.

Madurai : In Madurai cluster, the plain, semi automatic, automatic and shuttleless looms are present and out of these types of looms, two-thirds of the plain looms are reportedly installed as new looms and only one-third are second hand. In the case of semi automatic looms, all the looms are seen to be new machines. In the case of automatic looms also, more than half of them are new and the balance second hand. The shuttleless looms are observed to be second hand machines.

Chennai : In Chennai, almost all the plain and semi automatic looms are new at the

time of installation. The reason may be that the units are financially sound and the products are export oriented. Another major factor may be the non-availability of second hand machines locally. Due to the high prices of shuttleless looms and also due to the ready availability abroad, all the shuttleless looms are second hand machines at the time of installation.

4.5 Vintage of existing looms

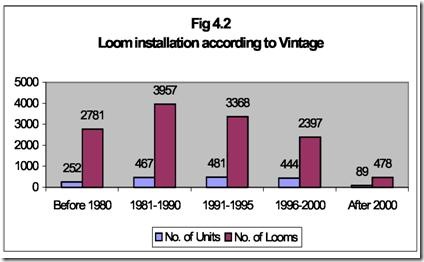

In the powerloom sector of Tamilnadu, majority of the looms are of low technology. A rough idea on the use of machines and their technology level is derived on the basis of their vintage. Accordingly, all the looms have been grouped under different periods of installation - (i) upto 1980 (ii) during 1981-1990 (iii) 1991-1995 (iv) 1996-2000 and (v) after 2000 and details are as given below.

Three-fourths of the looms have come into existence in the last two decades, i.e., in 1980s and 1990s. The period wise addition of the looms shows that about 21% of the looms were installed in pre 1980 period and continue to function till date. The second period of 1981-1990 has witnessed an addition of 30% whereas the third period of 1991-

1995 has registered an addition of around 26%. Apparently, the growth of the looms in the powerloom industry has been more appreciable during post 1990 period. During 1996-2000, the growth has been around 19%.

Regarding the growth of the powerlooms in different clusters, it is observed that Karur has registered larger growth of 63% during 1991-2000 as compared to the general trend of 45% growth in Tamilnadu. All other clusters are closer to the general trend of 45% growth during 1991-2000.

4.6 Loom width

The looms used in the sector are mostly locally manufactured ones and, therefore, the width has been either narrow or medium depending upon the product type being manufactured. In the area-wise segmentation of products, the looms also have got segmented in narrow and medium widths. In the case of looms devoted for the production of towels, napkins etc. the narrow width looms have been preferred. For products such as yarn dyed fabrics of shirting, dress material, saree, dhoti etc. the medium width looms have been preferred. As the exports have been prominent and attained significance only in the 90s and due to the availability/non-availability of wider width looms, most of the new looms have been in the normal width category. Only in very few cases, wider width looms have been procured and installed in some pockets of the sector.

More than 90% of the powerlooms in the state are plain looms and, therefore, the distribution of the looms in different width sizes for these plain looms have been as indicated below. The width of the loom ranges from 34 inches to 130 inches depending upon the areas and the products. The narrow width looms have been observed to be in operation mainly in Erode, Salem and Madurai clusters because of larger volume of

towels/napkins production. The presence of such narrow width looms is very insignificant in Coimbatore and Karur clusters. Such narrow looms are completely absent in Chennai cluster.

4.6.1 Declining trend in narrow width looms

It is observed that there is a declining trend in the growth of looms with the width of less than 54 inches. Before 1990, more number of units has come up with this type of looms, which has started declining from the year 1991. This width category constitutes 7.97% in the total loomage. In the case of looms with the width range of 55-90 inches also, the growth pattern shown is a fluctuating one and it is bound to decline in the coming years. It is worth noting that the looms with 90 and above inches in width are showing marked increasing growth over other loom sizes. The powerloom owners are seen to prefer the wider width looms with width ranging from 90-120+ inches over the earlier lesser width looms. This may be due to the market demand, which is in favour of fabrics above 90 inches width in the grey varieties. The versatility of these wider width looms permits the weaving of more than one fabric at the same time thus reducing the cost of weaving substantially for narrow width items like towels, napkins as well as normal width fabrics. In yarn dyed also, wider width looms are becoming popular in clusters like Karur where bed linen etc. are demanded in wider widths only.

4.6.2 Shift towards wider width looms

In the sector as a whole, around 10% of the looms are in the wider width range of 90 inches and above. Further such looms are in very large numbers in the clusters of Coimbatore as well as Chennai. In the case of Chennai cluster, over 60% of the looms are having the wider width of 90 inches and above which is followed by Coimbatore cluster with around 40% of wider width looms. In Salem cluster also, the wider width looms are very significant which are forming 19% in the total looms. Contrary to the above, there is complete absence of wider width looms in Madurai cluster.

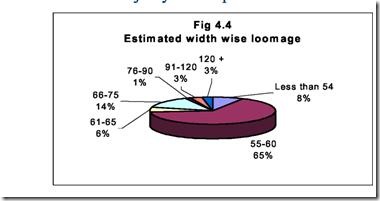

4.7 Estimated width wise loomage

A majority of the powerlooms in the state is having the width ranging from 55

inches to 60 inches, which form about

65% in the total looms. These looms

are estimated at around 2.86 lakh

looms in the sector. Another 21% of

the looms are having widths ranging

from 61 inches to 90 inches and form

about 0.91 lakh in the total. Even

within this range, the looms with width of 66 inches to 75 inches form about 14% in the

overall total out of the 21%. The wider width looms falling under the range group of 91

inches to above 120 inches are to the extent 6% of the total looms in the state. Except

Karur cluster, in all other five clusters, the looms in the range of 55-60 inches are found to

be more than 60% to 85% in their respective total looms. In Karur, surprisingly the looms are generally above 60 inches.

4.7.1 Estimated width wise loomage in different clusters

Coimbatore cluster: In Coimbatore cluster, less than 54-inch looms constitute only 2% whereas the majority of looms are seen to be in the width range of 55-60 inches that constitute 65 percent of the total looms in the cluster. The looms in the width range of 61 - 90 inches are to the extent of 24%. The wider width looms of 91-120 and above constitute another 10% in Coimbatore cluster. It is also observed that the wider width looms of above 75 inches have come into existence mostly after 1995 in this cluster. Not many people are seen to go for this type of looms from the beginning. There is marked preference for putting up wider width looms of above 120 inches in this cluster as it is seen that some units with such looms have come up from 1995 onwards. As compared to the average size of 14 looms per unit, the average loom size is 29.50 looms per unit with width of 120 inches indicating the fact that such wider width looms are being put up in large sized units only.

Erode Cluster : In Erode cluster, less than 54 inch looms constitute 10% of the looms. The majority of looms are seen to be in the width range of 55-60 inches, which constitute 75% of the total looms in this cluster. The looms with the width range of 61-90 inches are forming around 8 percent only. The wider width looms of 91-120 inches and above constitute another 7% in this cluster. It is also observed that the wider width loom of above 120 inches is growing gradually over the years in this cluster. There is marked preference for putting up wider width looms of above 120 inches in this cluster as it is seen that many units are coming up with such looms since 1980 onwards. As compared to the

average size of 15 looms per unit, the average loom size is 4.53 looms per unit with width of 120 inches indicating the fact that such wider width looms are being put up in smaller sized units.

Karur Cluster : Unlike other clusters, this cluster presents a different picture as regards the width of the looms operating in the powerloom sector. It is observed that the looms with less than 54 inches are almost absent and even in the next range of 55-60 inches looms, it is only 3% in the total. A large number of looms are in the width category of 60-90 inches accounting for 74% share that is very encouraging to note. Further, this cluster has got significant number of wider width looms falling in the category of 90-120+ inches width with a share of 23% that is comparatively higher. It is also observed that the wider width looms of above 120 inches is growing gradually at a faster rate over the years in this cluster. As compared to the average size of 5 looms per unit, the average loom size is 3.67 looms per unit with width of 120 inches indicating the fact that such wider width looms are being put up in smaller sized units.

Salem Cluster : In this cluster, less than 54 inch looms constitute 15% of the looms which is the highest among all the clusters. It is also important to note that in this cluster the next 84% of the looms are having the width of 55-60 inches. The share of looms with above 60 inches is very negligible. Therefore greater attention has to be paid to modernise the looms with wider width looms in this cluster. The growth of looms is also not in conformity with other clusters as it is seen that the looms are declining in numbers instead of increasing. In conformity with the average size of 8 looms per unit, the average loom size is 8 looms per unit with the width of 120 inches registering the fact that the wider width looms are being put up in the medium sized units.

Madurai Cluster: It may be noted that less than 54 inch looms form only 6% in the total looms. The majority of looms are seen to be in the width range of 55-60 inches that constitute 61 percent of the total looms. The looms with the width range of 61-90 inches are accounting for 33%. It is worth noting that in this cluster the wider width looms of 90 inches and above are almost nil. As compared to average size of 24.28 looms per unit, the average size of 37.05 looms is seen to be in the range of 66-75 inch category.

Chennai Cluster : In this cluster, less than 54 inch looms are seen to be completely absent. The major portion of looms are seen to be in the width range of 55-60 inches which form about 83% of the total looms in this cluster. The looms with the width range of 61-90 inches are forming about another 17%. It is also observed that the looms with 120+ inches width are completely absent. As compared to the average size of 12.33 looms per unit, 64 looms are the average loom size for the width category of 91-120 inches.

4.8 Plain looms with dobby, jacquard and drop box attachments

It is seen that 57% of the looms are having some kind of attachment in order to create designs in the fabrics being produced. The remaining 43% of the looms are not having any design creating attachments. This is so because in the case of the grey fabric manufacturing looms in Coimbatore cluster and nearby areas, there is less need for dobby or jacquard. Therefore, almost half of the looms in Tamilnadu are not having any dobby or jacquard type of attachments. Among the clusters, in Karur cluster 96% of the looms have either dobby or jacquard attachments whereas in Coimbatore cluster only less than 2% of the looms have such type of additional design attachments. Even in Chennai cluster, all the looms are having drop box attachments, as the major production happens to be lungi/shirting. In Salem cluster also, a major chunk of the looms have attachments of dobby, jacquard etc. But in the case of Madurai cluster, only 30% of the looms do have such type of attachments. In Erode cluster where the product categories are of both grey and yarn dyed types, the looms with design creating attachments are 61 %. From the above, it may be seen that depending upon the products requiring jacquard or dobby designs, the looms are seen to have such additional attachments. Further, due to the small size of the orders, there are frequent changes in the designs that are to be catered to by the smaller

units. Depending upon the market demand, the owners of the looms are installing the additional attachments for design purpose. In many cases, the small weavers have complained about the cost increase due to the installation of dobby or jacquard as per the master weaver’s requirements.

It may be noted that among the looms with attachments, around 85% of them are having either dobby or drop box separately or in combination of both. The balance 15% is accounted for jacquard alone or jacquard with drop box or terry looms.

Dobby attached looms : It is seen that 22% of the looms are having only dobby attachment. Such kind of looms are comparatively more in Madurai and Salem clusters due to the production of saree varieties which requires the above for border designs. In the case of Coimbatore also,

this accounts for 1/3rd of the looms with attachments. In Karur and Erode clusters, the percentage of such looms with only dobby attachment is very less.

Jacquard attached looms : Coming to the looms with jacquard attachment in the overall powerloom sector with plain looms, 10% is seen to be with jacquard attachment. More such looms are found in Karur cluster because of the reason that fabrics with jacquard designs are being produced for export purpose in the form of furnishing material, napkins, towels etc. Jacquard looms are completely absent in the two clusters of Coimbatore and Chennai because of the varieties produced that do not require the designs.

Drop Box attached looms : Within the 57% looms with attachments in the sector, the looms with drop box form about 30%. The drop box looms are more in use in the clusters of Chennai, Erode and Madurai where lungi, shirting etc. are being produced in larger quantities. In Chennai cluster, all the sampled looms are found to have drop box attachment only and there are no other jacquard or dobby attachments. Next to Chennai cluster, the greater usage of drop box is found in Erode cluster where such looms are seen to be upto 53%. In the case of Madurai cluster, it is as much as 37%. In Coimbatore cluster also, drop box is being used to a significant extent.

Dobby and Drop Box attached looms : It is worth noting that the largest number of looms (3 1 % in the looms with attachments category) are having a combination of dobby and drop box attachments. Such type of looms are greater in number in the case of Salem cluster where it is found that around 55% of the looms with attachment are having the above. In the case of Erode cluster, such type of looms form 26% followed by Karur cluster with 24%. Even in the case of Madurai cluster, a significant number of looms are with the above combination of attachments. Such type of looms are completely absent in the case of Coimbatore and Chennai clusters.

Jacquard with Drop Box attached looms : Among the category of looms with attachment, about 6% looms are having a combination of jacquard with drop box which can produce higher unit value fabrics of different types. As the export market requires such designs using jacquard and drop box, Karur cluster is seen to have larger number of such looms with 27%. A small percentage of such looms are also seen in Erode and Salem clusters. In all the other three clusters, such looms are completely absent.

Terry looms : The production of terry towels and other related fabrics are also being manufactured in certain areas of the state. Madurai is one such cluster where the production of towels requires terry looms. In Coimbatore cluster also, there is an occurrence of such terry looms in the sample survey. In all the other four clusters, such looms are reported to be absent.

Terry with Drop Box : Again in Madurai cluster a small percentage of looms are reported to be having drop box with terry looms.

No attachments : Regarding the looms without any attachment, it is in Coimbatore cluster where 98% of the looms are without any attachment. This is followed by Madurai cluster where 70% of the looms are not having any type of attachments. In the case of Erode cluster also, more than 1/3rd of the looms are not having any attachments. In case of Karur and Chennai clusters, such looms are very few.

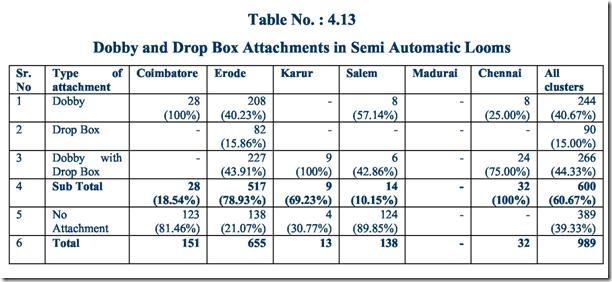

4.9 Semi automatic looms with dobby and drop box attachments

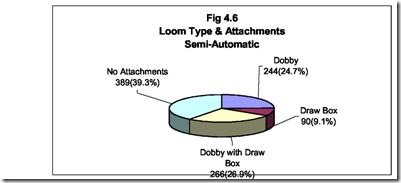

It is observed from the survey results that around 61% of semi automatic looms are reported to have some attachments for creating design fabrics whereas the balance 39% are not having any attachments. In the case of larger sized units with 49 or more, the share of looms with dobby/jacquard attachment is 74%.

Among the looms with attachments, around 85% of the looms are having either dobby or dobby with drop box. The balance 15% is accounted by drop box looms thus indicating the overall

level of 61 % looms with attachments.

In Coimbatore cluster, the looms are having dobby attachments whereas in Erode cluster dobby, drop box and dobby with drop box looms are accounting for 40%, 16% and 44% respectively. The semi automatic looms in Karur cluster are stated to be having dobby with drop box attachment. In Salem cluster, the semi automatic looms are having either dobby or dobby with drop box. Likewise in Chennai cluster also, the looms are either with dobby or drop box.

4.10 Automatic looms with dobby and drop box attachments

In the case of automatic looms, only 25% of the looms are reported to have some attachments for creating design fabrics and the balance 75% are not having any attachment. Within the above 25% looms, dobby attachment is seen in 30% of the looms and another 54% of the looms are having dobby with drop box attachments. The looms with jacquard and drop box attachments are also present which forms about 16% in the looms with attachment category.

The dobby looms are found in Karur cluster only. Like wise, the looms with dobby and drop box attachments are found to be mostly in Madurai cluster. In Salem cluster, the automatic looms are reported to have jacquard and drop box attachments.

4.11 Shuttleless looms with dobby and drop box attachments

In the case of shuttleless looms, around 36% are reportedly having dobby attachments. Such looms are in existence in Karur as well as Chennai clusters. As the production dictates to have such attachments, the powerloom operators are accordingly providing

the attachments. In this category also, some looms are found to be having jacquard with

drop box facilities. Such looms are in existence in Salem cluster where the products

manufactured include ladies dress material and sarees. This forms about 3% in the total

shuttleless looms.

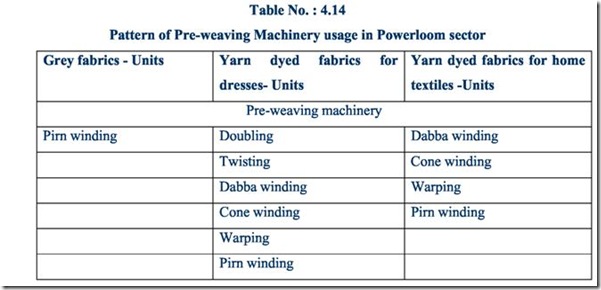

4.12 Preparatory machines installed and used in the powerloom sector

The production of cloth in the composite mill is carried out under one roof. The processes involved right from procuring raw material, that is fibres to the final products are carried out under overall supervision and control of single management. However, in the powerloom sector the production process starts only after the procurement of yarn; and only warping and weaving processes are being carried out. In some units, sizing activities are also being carried out besides doubling and twisting of yarns. The types of pre-weaving machinery available with the powerloom units vary according to the product being manufactured.

In the case of units producing grey fabrics, the major concentration of warping and sizing units are located in and around Somanur, Avinashi, Palladam, Erode, Tiruchengode etc. There are more than 200 sizing units operating in these areas. The weaving units

producing independently as also for the master weavers mostly procure the sized beams. In this grey cloth production, pirn winding machines are used which are power operated/power driven. Such simple winding machines could be found in almost all the units.

In the case of units producing yarn dyed fabrics, pre-weaving processes are being carried out on power operated machines. The units producing yarn dyed fabrics procure yarn in the first instance in the hank/cone form. After dyeing of yarn, warping beams are prepared by the units. In some cases, only machine dyeing i.e., cone, cheese dyeing is resorted to whereas in a majority of cases, the yarn dyeing is manual. The master weavers make the supply of dyed yarn. The units producing the textiles do only warping and, therefore, these units have pre-weaving machines basically for warping and pirn winding. These machines are mostly power operated. Cone, Dabba as well as Bobbin winding machines for converting dyed hank yarn into bobbins that are required for warping purpose, are also used by the powerloom units. These units do not require sizing of the yarn as mostly the doubled yarn is being used in the warp.

4.12.1 Overall sectoral pattern

Generally, the following pattern of usage of pre weaving machinery in the powerloom sector is observed:

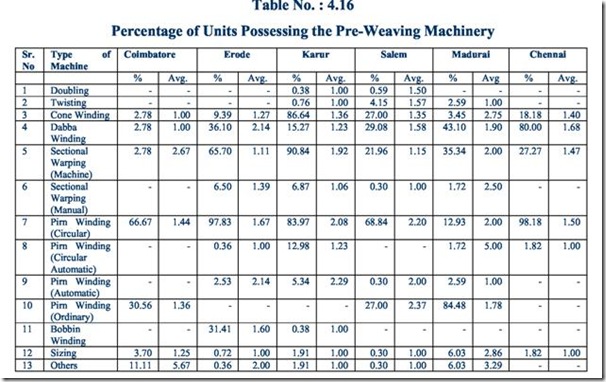

As explained above, all the powerloom units invariably do possess either ordinary or automatic pirn winding machines. It is seen that 75% of the powerloom units possess only circular pirn winding machines. This is the major item of machinery required by the units. In addition to the above, 2-3% of the units are reported to possess either automatic circular pirn winding machines or horizontal machines. Further, around 19% of the units are reportedly in possession of non-circular type pirn winding machines. This shows the backwardness in the level of technology used for pirn winding purpose. The powerloom owners are minimizing their investment in the looms as well as the preparatory machinery and, therefore, the low level technology machines are used for pirn winding. The quality improvement and reduction of wastage is possible by adopting higher technology in the above process. The average number of pirn winding machines per unit is seen to be 2 for circular machines as well as automatic/ordinary machines. Only in the case of automatic circular pirn winding machines the average is less than 2 (at 1.42). The average number of sectional warping machine (power driven mechanical) per unit is more than 1 (at 1.55 machines per unit). In the case of sectional warping also, the average is more than 1 per unit. In order to produce quality fabrics, there is an urgent need to modernise and upgrade the technology level in warping process also. There is need for the units using manual warping to switch over to machine warping in order to increase the productivity and efficiency in addition to quality improvement.

The next important machinery in the pre-weaving process for the units producing yarn dyed fabrics is the warping machine unlike the grey fabric weaving units. This warping machines used are seen to be of two types - manual or mechanical for yarn dyed fabric manufacture. In the case of the powerloom units, it is mostly mechanical and sectional warping is done. As nearly 50% of the powerloom units are using sized beams for grey fabric production and another 50% percent of the units are found to possess warping machines. It may be noted further that these warping machines are not full-fledged independent machines but locally made simpler type without any individual motors. Therefore, the cost of such warping machines is very low and affordable for the capital starved tiny units. Instead of terming such instruments as warping machines, we may term them as warping tools. In places like Karur and nearby areas, the warping is carried out in a most rudimentary manner such as using a fishnet in place of creel etc.

The third important machinery required in pre weaving process for the units engaged in yarn dyed fabrics are the winding, doubling and twisting machines. As much as 31% of the units are having cone winding machines and another 29% of the units are managing with dabba winding machines. It is also possible that within the same unit both the types of winding machines are being used for the preparation of warping beams. The average number of cone winding and dabba winding machines are seen to be 1.36 and 1.76 respectively, thus indicating that according to the requirements the powerlooms are using more than 1 such winding machines. The dabba winding machines are all of low technology and therefore wastage and quality problems are bound to occur in the production process. Bobbin winding machines are also reported in about 8 percent of the units with the possession of more than 1 such machine.

Some of the powerloom units have reported to possess doubling and twisting machines in areas mainly like Salem. The machines are being used for processing the yarn by doubling and twisting that are required for the production of high unit value products such as sarees, dress material etc. using synthetic/man-made filament yarns. The doubling machines are seen only in less than 1 percent of the units whereas twisting machines are seen in around 2 percent of the units. The number of machines per unit is also more than 1 per unit in both the types of machines.

Pirn winding machines: All the units are having one or other types of pirn winding machines in order to convert the hank or cone yarn into pirn-bobbins. Yet in a few exceptions, the job-work units have reportedly been provided with weft-yarn in bobbins for pirns. There are four types of pirn winding machines in the sector that are: (1) circular, (2) circular automatic, (3) automatic and (4) ordinary.

In the case of the powerloom sector in Tamilnadu, the weaver being a subsistence unit, all cost saving measures are resorted to in every possible way. Therefore, instead of individual motor for each loom, by shaft and belt system, all looms are driven by single motor. By making use of the automotive power from the same source, all pre-weaving activities are also carried out be it the warping, pirn winding, twisting or any other related activities. The cost of such pre-weaving machine is very less due to the absence of any individual motor drive and it is generally seen that the pirn winding machine of local make is procured at the rate of Rs.2000-3000 with four spindles.

Most of these machines are driven by shaft driven belt system and, therefore, do not have any individual motors. Among the pirn winding machines, 75 percent are reported to be circular pirn winding machines; 5 percent are automatic winding machines and the balance are of ordinary winding machines. Except in Madurai cluster, the circular pirn winding is seen to be dominant in all the other clusters.

Warping machines: As stated above, only those powerlooms that produce yarn dyed fabrics generally use warping machines. Therefore, 48% of the units have reported to possess sectional warping machines and each unit is having one or two machines according to their requirements. Additionally, 3% of the units are reported to have sectional warping being carried out manually. The sectional warping machines are comparatively more in the clusters like Karur and Erode where the production of yarn dyed fabrics of home textiles as well as dresses is predominant.

Even though we have termed it as warping machine, in reality the warping is done in a crude manner having some kind of rudimentary contraption. In places like Karur and Salem, the warping machine denotes only a mounted beam, which can rotate without any individual motor but from the common shaft belt system. There is no creel used for the mounting of cones or bobbins but the cones/bobbins are kept on the floor and each thread drawn through the holes in the fishnet spread and stretched above the cones. The threads drawn like this are taken to the rolling beam in sectional warping way and transferred to the warpers’ beam. For warping, the cost of the machine is only the beam roller without any motor or any other mechanism. Even the space requirement for warping is very less as these activities are carried out within a small space of 4 feet x 10 feet adjacent to the powerlooms.

Doubling and twisting machines: Less than 2 percent of the units are found to possess twisting/doubling machines. Salem cluster is seen to possess more number of Twisting as well as doubling machines. The units who produce sarees and ladies dress materials mostly use the twisting/doubling machines by using polyester filament, viscose filament and acrylic yarns. The machines are generally old and of local make. These are simple mechanisms without having any individual motors but depending on the common shaft

systems that are used for looms and pirn winding purpose. The cost of each machine ranges from Rs. 5,000 to Rs. 15,000.

Cone/Dabba winding: For the conversion of dyed yarn in hank form, cone and dabba winding machines are being used. About 31% of the units are reported to have cone-winding machines whereas dabba winding machines are also used in 29% of the units. About 8% of the units have reported to possess bobbin-winding machines.

Table No. : 4.15

Pre-Weaving Machines in Powerloom Units

4.12.2 Cluster wise variations in usage of pre-weaving machinery

Coimbatore cluster: In this cluster, the pirn winding machines are the additional preparatory machines though a small number of units having yarn dyed fabrics production may possess pirn winding, dabba winding, sectional warping machines etc. A few of the powerloom units are also having sizing units.

Erode cluster : In Erode cluster, 98% of the units are having circular pirn winding machines and the balance units are having automatic pirn winding machines. In the case of warping, 66% of the units have reported to possess sectional warping machines in addition

to 6% of the units having manual sectional warping. Additionally 10% of the units have cone-winding machines and 36 percent of the units are having dabba winding machines. About 31 percent of the units are also having bobbin-winding machines.

Karur cluster: In Karur cluster, 84 percent of the units are having circular pirn winding machines and another 13 percent of the units are reported to have circular automatic pirn winding machines. Automatic pirn winding machines are being used by 5 percent of the units. In the case of warping, almost 91 percent of the units have reported to possess sectional warping machines besides 7 percent of the units having manual sectional warping. Further, the cone winding machines are being used in as much as 87 percent of the units whereas 15 percent of the units are having dabba winding machines. The bobbin winding machines are reported to be absent in this cluster.

Salem cluster: In this cluster, the circular pirn winding machines are used to the extent of 69 percent. Circular automatic pirn winding as well as automatic pirn winding machines are reported to be nil in this cluster. As much as 27 percent of the units are reported to have ordinary pirn winding machines. In the case of warping, 22 percent of the units have reported to possess sectional warping machines. Cone winding and dabba winding machines are being used in as much as 27 and 29 percent respectively.

Madurai cluster: In Madurai cluster, ordinary pirn winding machines are being mostly used to the extent of 84 percent. Another 13 percent of the units are having circular pirn winding machines. Only 5 percent of the units are reported to have automatic circular and other types of machines. A total of 35 units are reported to have sectional warping machines in addition to 2 percent manual sectional warping. Around 43 percent of the units in this cluster are reported to have dabba winding machines with average possession of 1 or 2 machines per unit. Twisting and cone winding machines are also possessed by about 3 percent of the units.

Chennai cluster: Almost all the units are having circular pirn winding machines out of which one or two units have automatic machines. As dyed yarn fabrics are produced in this cluster, 80 percent of the units use dabba winding machines and another 18 percent use cone winding machines. As regards to warping, 27 percent of the units use sectional warping machines and one unit is reported to have sizing facility also.

The details on the percentage of units possessing the pre-weaving machinery are presented below: