DIAMETER AND SHAPE – ADVANCED PREDICTION OF APPEARANCE

THE YARN INSPECTION SYSTEM

MORE BRILLIANCE – HIGHER MARKET VALUE

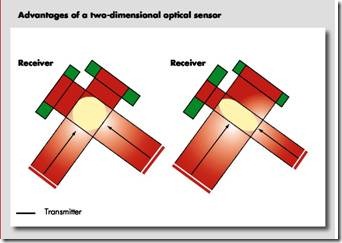

12% of problems in dyeing are caused by shape and density variation. Spinning methods, machine components and raw material directly impact those quality characteristics. The two-dimensional diameter measurement of the USTER® OM SENSOR enables the determination of yarn roundness (shape) and consequently the controlling of the brilliance and lustre in a fabric. Exactly those characteristics can often be the reason for complaints about garments.

EXTENDED QUALITY CONTROL MAKES THE DIFFERENCES VISIBLE

A length of yarn is practically never completely round. A fact which has a decisive influence on the look of fabric. Optoelectronic measuring provides new possibilities for predicting the quality of yarns – to your advantage!

With a revolutionary two-dimensional measuring method, the USTER® OM SENSOR for the USTER® TESTER 5 defines the diameter and at the same time evaluates the surface structure, shape and density of yarn. These quality parameters are especially important for testing yarns which will be finished using state-of-the-art spinning processes, which are conditioned, or contain conducting fibers.

ACCEPTED – USTER® STATISTICS

Differing dye behavior makes fabric and knitted fabric unuseable. The expected appearance of further produced goods will be predictable with the help of the new quality parameters.

Parameters which are recognized all over the world guarantee an optimal yarn trading process. An automatic assessment of the yarn quality can be done either by means of the USTER® STATISTICS or own choice of limits.

TWIST MEASUREMENT IS REPLACEABLE

In the final dyeing process, any variation in the diameter of the processed yarn will make the produced fabric unuseable. Differences of more than 10% in the absolute yarn diameter (2DØ) will result in visible dyeing faults. The USTER® TESTER 5 OM SENSOR and knowledge of the effective or relative mass allows controlling of the twist variations of the spinning machines.

OPTIMIZED QUALITY – INCREASED PROFITS

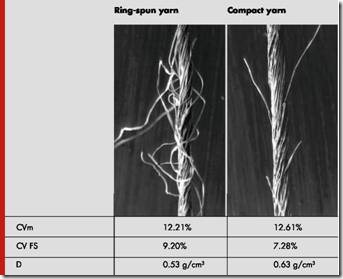

Loose fibers or loose fiber accumulations in the yarn strongly disturb the appearance of knitted goods. These faults are not detectable with a capacitive measurement. Only the unique USTER® OM SENSOR can identify disturbing diameter variations (CV FS). Controlling of CV FS helps to prevent production of cloudy knitwear. A significant reduction of second quality.

USTER® OM SENSOR – A MUST FOR COMPACT SPINNING

Compact yarns have a greater density (D) and a better variation in the fine structure (CV FS). The better fiber compactness makes compact yarn appear more even which is reflected in the diameter variation, an important quality parameter in yarn trading. With such a high visual evenness, the smallest increases or decreases in the mass of compact yarn are disturbing even though they seldom appear.

The variation of the number of fibers in the cross-section is similar for both, ring and compact yarns – the variation coefficients of the mass (CVm) stay at the same level.

USTER® OM SENSOR WITH THE USTER® TESTER 5

The simultaneous measurement of diameter variation, shape and density completes the controlling of yarn quality. This information is gained by optoelectronic measuring of the two-dimensional yarn diameter.

The Standard from Fiber to Fabric

USTER® is the world’s leading supplier of total quality solutions from fiber to fabric. USTER® standards and precise measurement provide unparalleled advantages for producing best quality at minimum cost.

USTER® – Think Quality

Our commitment to state-of-the-art technology ensures the comfort and feel of the finished product – satisfying the demands of a sophisticated market. We help our customers to benefit from our applied knowledge and experience – to think quality, think USTER®.

Broad Range of Products

USTER® occupies a unique position in the textile industry. With our broad range of products, we have a wide reach across the textile chain that is unmatched by any other supplier in the market.

Optimal Service – Complete Satisfaction

Know-how transfer and instant help – we are where our customers are. A total of 200

certified service engineers worldwide grants fast and reliable technical support. Benefit

from local know-how transfer in your specific markets and enjoy our service à la carte.

USTER® STATISTICS – The Textile Industry Standards

We set the standards for quality control in the global textile industry. With USTER® 34!4)34)#3 we provide the benchmarks that are the basis for the trading of textile products at assured levels of quality across global markets.

USTERIZED® – Brand Your Products with Quality

USTERIZED® stands for “defined quality assured” within the textile chain. We invite selected customers to join the USTERIZED® Member Program. More information at www.usterized.com.

USTER® Worldwide

With three technology centers, six regional service centers and 50 representative offices around the world, USTER® is always sure of delivering only the best to its customers. USTER® – committed to excellence, committed to quality. And that will never change.