SPINNING – THE PRESENT SCENE

SPINNING

– THE OPTIONS

RING SPINNING

RING SPINNING

· The “standard” for judging yarn quality;

· Improvements in recent years: – higher traveler velocity,

– automatic doffing,

– longer machines

– link winding,

– splicing,

– smaller ring sizes

have interacted to yield cumulative benefits (potential spindle speed increase from 10,000 to 25,000);

THE FUTURE OF RING

SPINNING ??

· Longer machines (1488 spindles available)?

· High drafts?

· “Heavy roving” or “light weight sliver” feed?

· Higher traveller speed (or alternative)?

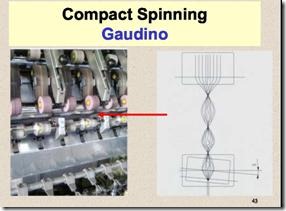

· Compact Spinning?

· Spindle ID# used with defect detection at winding?

RING SPINNING

RING AND TRAVELER

DEVELOPMENTS

A new spinning system to replace the ring system ?

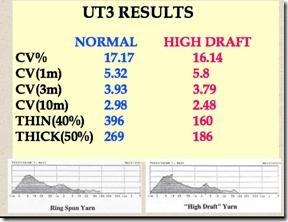

PROBLEMS WITH HIGH DRAFTS?

“Hitherto the evaluation of drafting systems has been based only on yarn quality measurements such as appearance tests, Uster % and Spectrograph.

However these tests often fail to give

high correlation with the final fabric quality.”

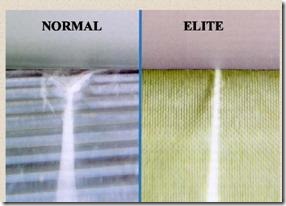

Ring Spinning

– Compact Spinning

· A lot of interest in the system

(outside USA).

· Offers selective advantages of

– Compact yarn structure; – Reduced Hairiness;

– Higher tenacity;

– Lower Twist;

– Higher productivity

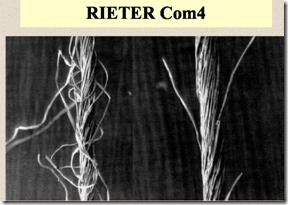

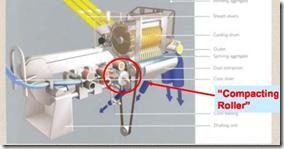

COMPACT SPINNING

Compared to conventional spinning compact yarns can be:

– Stronger

– Less hairy

– Spun with lower twist

– Softer

– Need less sizing

– Produce less fly in knitting, etc

________________________________________________________________________________________________________________________ 51

COMPACT SPINNING

· Machinery costs 50 –100% greater than conventional?

· Yarn costs 10-20% higher than conventional?

· Problems with shorter fibers, “trash”, fiber adhesion, etc.

· Reduced hairs can impact spindle speed and potentially weaving costs?

· Are compact yarns needed for all markets?

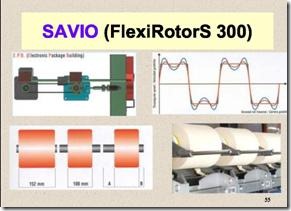

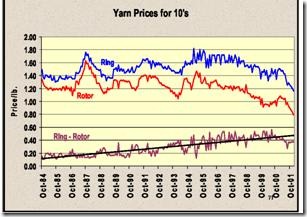

ROTOR SPINNING

ROTOR SPINNING

· Good for weaving and knitting;

· Longer frames being introduced - up to 320 positions;

· Smaller rotors used at higher speeds (150,000 revs/min);

· “Customers” prefer ring spun!

· In USA “upgrading” being carried out.

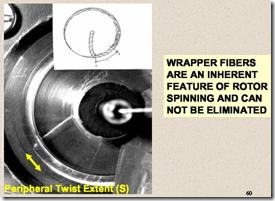

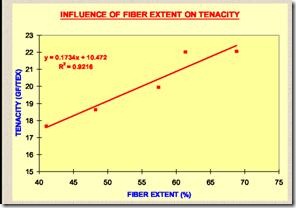

| Twist in the rotor is a combination of: · Real twist created by the rotation of the rotor; · Temporary twist – due to the interaction of the yarn and the navel – The latter is further influenced by the fiber properties (length, fineness, friction), spinning speed, opening roller, etc. Thus the twist measured inside the rotor can be more than double the twist in the final yarn ________________________________________________________________________________ 62 |

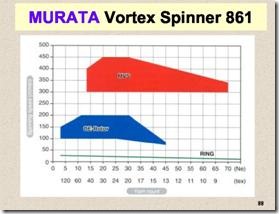

JET AND VORTEX

SPINNING

VORTEX SPINNING

· Problems of fiber waste 5-8%;

· System is still restricted to finer counts;

· Even though potentially capable of 100% cotton used mainly for blends;

· Major advantage of Jet and Vortex is low hairiness and less pilling.

· Problems of fabric appearance (use of high draft system) ?

SELF-TWIST SPINNING

Self Twist Spinning MACART S300

GILBOS Air Twist System

· Creates a yarns that looks like a multifold twisted yarn.

· Uses “detorque jets” to create S and Z alternating twist in filaments.

· These then self twist to form a coherent structure.

· No twist area reinforced by intermingling jet.

· Computer control of process

COMPOSITE YARNS

COMPOSITE SPINNING

· Staple (cotton or wool) + Filament (?)

· Filament can be:

– bonded to staple fiber (Bobtex?),

– wrapped with staple fiber (core spun),

– wrapped around staple fiber (wrap-spun {hollow-spindle})

· Good for “technical” uses - problems with aesthetics and cost.

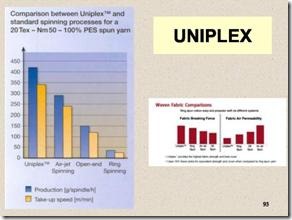

FRICTION SPINNING

“Compact Spinning”

FEHRER DREF 3000

CENTRIFUGAL SPINNING

· Old idea currently arousing interest among machinery makers.

· Technique should yield properties almost identical to ring spun yarn.

· Automation an essential feature of the system.

THE FUTURE?

SPINNING MACHINES

(USA & Canada)

FUTURE DEVELOPMENTS

· Ring will continue to dominate.

· Rotor improvements –better utilization of present potential speeds.

· Vortex will increase – particularly with ongoing developments – and possible speed increases.

· Other systems – difficult to see justification for development costs.

NEW DEVELOPMENTS ?

· Who pays for development?

· High quality yarn is a given requirement!

· “New” supply chain is dominated by a few retailers and thus higher spinning costs (associated with new machinery and/or more expensive fiber) must be borne by spinner?

NEW MARKETS ?

· Technical yarns

· Medical applications

· Smart materials

· Niche markets

THANKYOU FOR YOUR ATTENTION