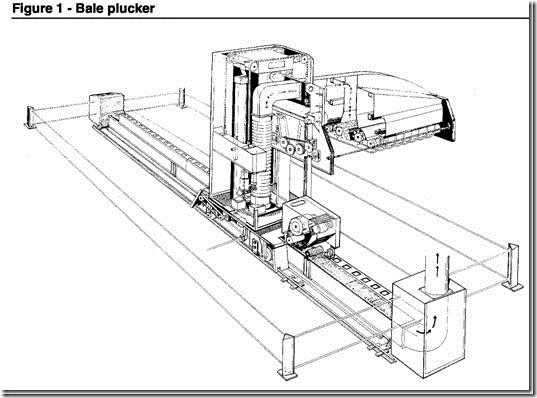

Spinning preparation begins with the bale plucker (Fig. 1).

This machine has been fundamental in improving quality, as it enables to remove from the feeding bales, which number can be up to 100, very small tufts of material.

This fact is the ideal prerequisite for a good blending in the subsequent passages.

The plucking carriage can handle cotton and man-made fibres with up to 60 mm staple length.

The subsequent opening and blending line must be studied and adjusted according to the kind of cotton, to its degree of impurity and to the quality to be obtained.

The search after blends of different qualities of cotton is of utmost importance to optimize the quality/cost ratio.

The mixer (Fig. 2) plays therefore a fundamental role to produce a homogeneous fibre mixture which can lead to an optimal regularity in terms of tenacity and of count of the end-product and consequently to reduce yarn breakages on the following machines.

The automatic mixer can have up to eight cells , with standard delivery or with joint cleaning unit.

The material, reduced to small tufts, is delivered to the horizontal opener and to the dust separator.

In case of blending of two different fibres, two weighing hopper feeders can enter into the line, in order to achieve an intimate blend of the two fibres (Fig. 3).

The fibres are conveyed by a power-driven fan into the feeding channel of the feed chute positioned above the cards.

Each card is equipped with its own feed chute. In some cases a horizontal opener is used, equipped with dust suction hood before the feed chutes.

A regular feeding of the material to the upper rooms of the feed chutes and a constant weight of the delivery material guarantee the excellent count regularity of the card sliver. In the opening line, machines have been included which detect foreign substances among the cotton fibres, as heavy matters, synthetic material, etc. and eliminate them through local suction systems.

The spinning preparation phases are summarized in Chart 2.

(*) Number and type of opening and picking machines depend greatly on the quality degree and on the impurity contents of cotton