Today many manufacturers are certified with ISO 5235. This standard accepts the thickness variation as +/- 0,05 mm. The new production concept of ASTEKS allows to have a toler NT-86/S ance of not more than 0,02 mm.

What brings this improvement to the apron users? Would they really benefit from this? Up today many researches have been made about lowering the Shore hardness degrees, but the direct effect of the apron thickness to the yarn quality has never been investigated, as far as we know.

In many spinning mills and at the Ege University Textile Engineering Branch some

sample yarns have been spun with different fiber material, using ASTEKS NT -86/S aprons and eccentric aprons (0,05 mm). These yarns have been Uster tested and the influence of the "X" space to the yarn irregularity of both samples investigated. These trials were carried out on the same spindles with same roving, only top aprons were different. Many trials in different spinning mills have proved that the Uster values of yarns spun with NT-86/S are much lower especially in thick and thin places of the apron.

Following two figures show the results of these tests. One of them was carried out at the EgeUniversity, yarn count Ne 30/1 carded and the other one was spun at Dinarsu, yarn

count 35/1 acrylics (long fiber). The results show that the reason of the quality improvement, (especially the Uster values and the thick and thin places) originate from the regularity of the top apron. The test results show further, how important the thickness variation of an apron is.

1.5. open aprons and reasons which

Open aprons are a rapid and economical solution to replace the broken endless aprons for different reasons. It is advisable that, the number of open aprons should not exceed 20 % of the total number of spindles on one machine. Otherwise, the number of breakages and the Uster Values can increase. For that reason using open aprons must be taken as a temporary solution, and should be replaced with endless aprons by every general oved haul of the machine.

You can achieve good results with ASTEKS bottom aprons if you take care of the following points:

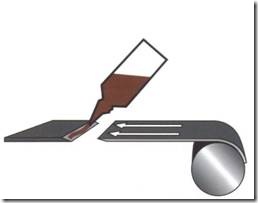

1- The skived part of the apron should easily pass the cylinder during rotating. To achieve this, the apron must be attached in rotating direction. If not, the apron will be hindered during passing over the cylinder. Due to this reason, the glueing part will be forced to be broken..

2- The skived part should never be thicker than the apron itself. Never use too much adhesive during glueing. Excessive adhesive will cause to thickness and hardness of

the glued part

which prolongs the drying time.

3- One of the main reasons for rupture of the open aprons is unsufficient pressure during glueing. Therefore, pressing process should last until complete drying of the glued place has been achieved.

4- By using the special gloves, which are delivered with ASTEKS open apron adhesives, a reliable, clean and rapid gluenig can be achieved. We recommend to use these gloves during glueing.

5- The glueing force of an adhesive is very important. The "Cyona Acrylat" type adhesives have an application life of appr. 6 months, and must be kept in cool environment during the transport to the user. Otherwise, apron will not stick properly or will rupture soon.

6- Asteks apron adhesive, a product of Asteks - Loctite cooperation, is designed for minimizing the hardness on the joint part and providing enough time to the user for using the adhesive during adhesion.