The friction between yarn to metal should be as low as possible for those entire textile processing. Lower the yarn to metal friction, lower will be the yarn breakage rate in next processing; higher will be the product quality. Yarn frictional behaviour (yarn surface characteristics) can be controlled in the spinning stages for DREF-3 yarn. The main object of this paper is to optimize the spinning parameters which give the minimum yarn to metal friction and the same time influence of yarn to metal coefficient of friction on the yarn properties.

Keywords: DREF-3; Friction; Hairiness; Diameter; Sp-volume

INTRODUCTION

Friction spinning technology has shown immense potential as the alter native to conventional Ring Spinning System, especially in the coarse range. However, the yarns spun in this system are not readily acceptable due to their poor tenacity and extension. The utilization of fibre tenacity depends upon the interaction between the fibre characteristics and the mechanism of yarn formation. The consequent utilization of the core/sheath structure forms the main advantages of the DREF-3 friction spinning process for the produced yarn and as a consequence for the end product. DREF yarns not only answer the requirement of abrasion resistance, dimensional stability, optimum wear comfort, durability but also incorporate a variety of qualitative and economic advantages. Apart from, yarn surface characteristics are also an important factor. During textile processing, yarn passes through different metallic surface like head eye. The friction between yarn to metal should be as low as possible for those entire textile processing. Lower the yarn to metal friction, lower will be the yarn breakage rate in next processing; higher will be the product quality. Yarn frictional behaviour (yarn surface characteristics) can be controlled in the spinning stages for DREF-3 yarn.

The main object of this paper is to optimize the spinning parameters which give the minimum yarn to metal friction and the same time influence of yarn to metal coefficient of friction on the yarn properties. A series of Multiple Regression Analysis has been carried out with the help of STATISTICA in computer.

The frictional properties of friction spun yarns, ring spun yarns and other yarns spun on modern spinning systems have been compared by several authors and the findings have been at times divergent because of the differences in raw material and processing conditions.1-12

MATERIALS AND METHODS Material

Gray cotton finisher drawing sliver of 3.4K tex is used. Slivers are the mixture of S6 and J34 RG types of cotton fibres. It is used for both the core and sheath.

Sample Preparation

For both the core and sheath, 100% cotton finisher drawing slivers are used, having the hank of 3.4K tex. Friction spun yarns of nominal count 10Ne (16.93Nm) have been produced on DREF-3 friction spinning machine of different core/sheath ratios —50/50, 60/40, 70/30 and 80/20 at a constant delivery speed of 100 m/min. Yarns were produced at the three different suction pressure levels of –25m bar, –20m bar, and –16m bar. Three different friction ratio (D/R) were being selected and accordingly yarns were produced. The level of friction ratios are 4.08, 4.76 and 5.44. Friction ratios were varied by changing the friction drum rpm (R), while the delivery speed of 100 m/min (D) is kept constant for each case. Three different friction drum speeds are 3000 rpm, 3500 rpm, 4000 rpm, respectively.

So the three parameters, namely, level of suction pressure, friction ratio and core/sheath ratios of the yarn were changed and shown in Table 1. As a result 36 samples were prepared for testing.

The following processed parameters were used for preparing the samples of yarn on DREF-3 friction spinning machine.

Carding drum speed =12000 rpm

Delivery speed =100 m/min

Count of yarn produced =16.93Nm=10Ne=59.05tex Distance between spinning drum= 0.1 mm.

TEST METHODS

Determination of Yarn to Metal Coefficient of Friction

The yarn to metal coefficient of friction, were measured by ‘Static Yarn Friction Metre (inclined plane model)’. Values obtained from the instrument are in degree. The corresponding g values have been obtained by using the

formula g =tan 0. Twenty observation of each sample are taken. This was averaged out.

Determination of Yarn Hairiness

The yarn hairiness has been measured by 'JTRL' yarn hairiness tester. Fifteen observations were made for each sample. The instrument measure the number of hairs present in 225 cm of yarn length in 5s intervals. It also measured the number of hairs present above 1 mm of the yarn surface.

Determination of Yarn Diameter

The yarn diameters were measured by ‘WES WOX OPTIK’ travelling microscope. Twenty observations were taken from each sample. The values were then averaged out and corresponding yarn specific volume and packing coefficient of the yarn was then calculated.

RESULTS AND DISCUSSION

Effect of Negative Suction Pressure and Friction Ratio on Yarn Specific Volume

It has been found from Tables 2, 6 and 7 and Figure 1 and also from multiple regression analysis that the specific volume has been strongly correlated with negative suction pressure. As the negative suction pressure increases, the fibres are tightly pressed over the spinning drum receiving more amount of twist and less slippage. Therefore, yarn diameter decreases due to more transverse force on the surface fibres, generated by the spinning drum. Therefore, more compact structure of the yarn has been formed with less yarn diameter. At higher negative suction pressure and higher level of twist better consolidation of fibres, resulting lower yarn diameter and specific volume, but at higher negative suction pressure and low twist level, the slippage between fibres and spinning drum has been taken place resulting high specific volume.

Effect of Yarn Friction Ratio and Negative Suction Pressure on Yarn Diameter

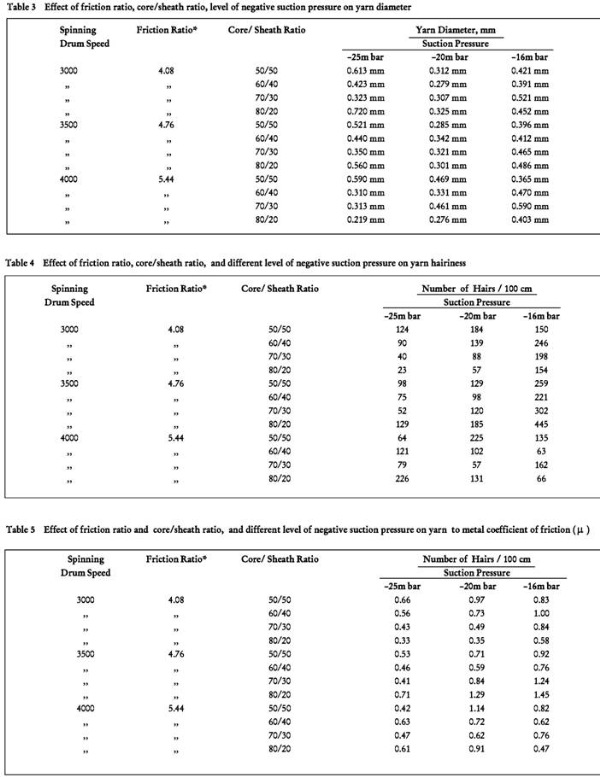

It has been found from Tables 3, 6 and 7 and Figure 2 and also from multiple regression analysis that as the negative suction pressure increases, the yarn diameter decreases to a minimum value and after that the diameter of yarn increases with the rise of negative suction pressure. It may be due the fact that with the increase in negative suction pressure, the fibres of core/ sheath go to better consolidation, resulting in lower diameter. But at higher negative suction pressure due to slippage between fibres and spinning drum, lower consolidation and compactness of fibres have taken place. This trend is true for all twist levels. On the other hand, as the friction ratio (twist) increases, torque on the fibres at the spinning zone increases. So the fibres get better binding, resulting in lower diameter of the yarn even at higher negative suction pressure. But at lower negative suction pressure with the rise of yarn twist, yarn diameter increases slowly. The reason may be due to lack of holding of fibres over the spinning drum. Fibres are less effectively held by the spinning drum and maximum slippage occurs between yarn and spinning drum.

Effect of Friction Ratio and Suction Pressure on Yarn Hairiness

It has been found from Tables 4, 6 and 7 and Figure 3 and also from multiple regression analysis that as the negative suction pressure rises, the yarn hairiness gradually decreases and this trend is true for all twist levels. Higher negative suction

pressure helps to hold the surface fibres over the yarn surface effectively. Better wrapping of surface fibres have been taken place with less helix angle. At lower negative suction pressure, the surface fibres are less effectively wrapped over the core fibres and not hold by the spinning drum properly, resulting higher hairiness of yarn. With the increase of friction ratio, the yarn hairiness decreases at core/sheath ratio of 50/50. But with a core/sheath ratio more than 50/50, ie, with a gradual decrease of surface fibres percentage, the yarn hairiness increases. As the twist increases, the surface fibres are less compactly wrapped over the core structure due to less number of surface fibres, resulting higher yarn hairiness. May be too much short fibres of cotton are responsible for this high yarn hairiness.

Effect of Negative Suction Pressure and Friction Ratio on Yarn to Metal Coefficient of Friction

It has been found from Tables 5, 6 and 7 and Figure 4 and also from multiple regression analysis As the negative suction pressure decreases the value of g increase. It signifies that at lower suction pressure uneven yarns are created. Higher the unevenness of yarn, ie, waviness of yarn, higher will be the value of µ . On the other hand at the lower negative suction pressure, the yarn hairiness is much higher which can give higher value of µ . It is observed that the value of µ is higher at lower twist. It may be due to the low unevenness of yarn at higher twist level. The opposite trend is observed at higher

negative suction pressure level. It may be due to the slippage between fibres and spinning drum. The surface fibres are less effectively wrapped over the core fibres which show higher yarn hairiness and higher value of µ .

MULTIPLE REGRESSION ANALYSIS Yarn Specific Volume

It has been observed from Tables 2, 6 and 7 that yarn specific volume is strongly correlated with friction ratio (X1) and negative suction pressure (X3) with a equation of Y= 0.114456X3 + 0.231X1 and with a correlation coefficient of 0.871 but not dependable on core/sheath ratio (X2).

Yarn Diameter

It has been observed from Tables 3, 6 and 7 that yarn diameter is strongly correlated with friction ratio(X1) and negative suction pressure(X3) with an equation of Y= 0.0519677X 1+ 0.007783X3 and with correlation coefficient of 0.959 but not dependable on core/sheath ratio(X2).

Yarn Hairiness

It has been observed from Tables 4, 6 and 7 that yarn hairiness is strongly correlated with friction ratio(X1) and negative suction pressure(X3) with a equation of Y=54.2055 X1 –0.5995 X3X1 and with correlation coefficient of 0.8674 but not dependable on core/ sheath ratio(X2).

Yarn to Metal Coefficient of Friction

It has been observed from Tables 5,7and 6 that yarn to metal friction coefficient (Y) is strongly correlated with friction ratio(X1) and negative suction pressure(X3) with a equation of Y=1.1098 X3–0.4.0373 X1 and with correlation coefficient of 0.3546 but not dependable on core/sheath ratio(X2).

CONCLUSIONS

Specific volume of DREF-3 cotton yarn is highly correlated with friction ratio (twist) and negative suction pressure level. Lower specific volume of yarn has been observed at higher negative suction pressure and at higher twist level.

Yarn diameter of DREF-3 cotton yarn is significantly correlated with friction ratio and negative suction pressure. Lower yarn diameter has been observed at higher negative suction pressure and at higher twist level.

Lower hairiness of DREF-3 cotton yarn has been observed at higher suction pressure.

Yarn to metal coefficient of friction depends on friction ratio (twist) and negative suction pressure.

Dr S Bhattacharyya, Member

Dr S M Chatterjee, Fellow