Introduction

The new compact spinning systems EliTe and ComforSpin® result in yarns being produced which place new demands on the ring and ring traveller system. Compact yarns are distinguished by a particularly smooth surface with hardly any disturbing elements. Since all the fibres are firmly embedded in the body of the yarn they are subject to much less abrasion at the deflection points so that virtually no processing errors occur. The space required by the yarn in the yarn thread passage is kept to a minimum.

However, this extremely low degree of hairiness results in under-lubrication of the open friction system and that, in turn, places special demands on the rings and travellers.

Obviously the performance of rings and ring traveller systems is influenced by other factors. This article primarily analyses the lack of lubrication and its repercussions on the rings and travellers.

Function of the ring and traveller

To complete the picture, here, once again, the relevant features of the ring and traveller:

· The ring traveller system is a braking system (creates the yarn tension)

· The ring and ring traveller system is lubricated

by fibre elements, wax and other particles (fibre film). This coating must regenerate itself continuously. If the fibre film is stripped away, metal contact between the ring and traveller results

· The friction (friction coefficient) depends on a

variety of parameters such as fibre type, lubricating content of the fibres, ring and traveller surface, shape and profile of the traveller etc.

Requirements of the ring surface

The lack of lubrication produced by compact yarns results in the traveller running surface on the ring being subject to considerable friction. If no lubricating film exists, temperatures of over 800o C occur in the contact area of the traveller/ring. With conventional ring surfaces, small particles of traveller material are welded onto the ring in what is referred to as a micro welding process. This leads to premature wear and tear of the ring and results in erratic traveller operation, differences in the yarn tension and a reduction in the yarn quality. For compact yarns, therefore, it is very important that rings with an excellent resistance to wear and tear are used.

Flange shapes

Compact yarns are mostly produced in finer yarn counts. The flange 1 profile and the inclined flange profile Orbit are preferred as used successfully for conventional ring yarns.

Bräcker rings and travellers for the successful processing of compact yarns

Rings

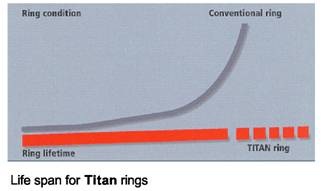

Bräcker Titan rings satisfy the requirements in terms of resistance to wear and tear and ensure that traveller material is not welded onto the ring. This, therefore, ensures that constant yarn quality can be produced from spindle to spindle and machine to machine.

The life span of a Titan ring is extremely long so that an optimal yarn quality is guaranteed over a considerable time span.

The flange shape Fl 1 A98 is installed in Suessen EliTe machines as the standard fitting and can be used universally for the entire yarn count range both for normal and high performance use.

Orbit rings are suitable for the high performance domain and are used exclusively on Rieter K40 and K44 machines. Yarns coarser than Ne 30 and finer

than Ne 80 are also spun on Rieter K-machines preferably on flange rings.

Travellers

In order to make best use of the reduced fibre lubrication, travellers offering a deeper yarn passage must be used. Due to the compactness of the yarns, however, no negative repercussions such as production neps occur. Moreover, for cotton yarns, a broad half-round profile (udr) is preferred whilst for blends and special yarns a normal half-round profile (dr) is desirable.

C 1 EL udr and SFB 2.8 RL dr are the travellers used most for spinning compact yarns. Nevertheless, the performance parameters and any specific customer wishes are to be taken into account.

The following list (table 1) illustrates the recommended ring travellers for the compact spinning process. The details are based on data from more than 30 spinning mills and represent the majority of the installed spindles for compact yarns.

Summary

The processing of compact yarns places special demands on rings and travellers. Thanks to intensive co-operation with the machine manufacturers and users since the introduction of compact yarns, Bräcker has become the leading

Table 1

player in the production of rings and travellers. Why don't you take advantage of Bräcker's broad-based experience, too.

Franz Oberholzer, Head Research Rings and Travellers, Bräcker AG, Pfäffikon-Zürich, Switzerland

Contacts

Bräcker AG

Obermattstrasse 65

CH-8330 Pfäffikon-Zürich Switzerland

E-mail: sales(a)bracker.ch

Bräcker S. A.

132, rue Clemenceau F-68920 Wintzenheim France

E-mail: sales(a)bracker.fr

Italy: Bräcker S:R:L

E-mail: morera.bracker(a)mail.inet.it

Mexico: Bräcker de Mexico S.A. de C.V. E-mail: brackerm(a)avantel.net

Agencies: see Web

Web www.bracker.ch